How to Simplify Polycarbonate Recycling Processes?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Recycling Evolution and Objectives

Polycarbonate recycling has undergone significant evolution since its inception in the 1970s. Initially, the process was rudimentary, focusing primarily on mechanical recycling methods that involved grinding and melting the material. However, these early techniques often resulted in degraded polymer properties, limiting the applications of recycled polycarbonate.

As environmental concerns grew in the 1990s, there was a renewed focus on developing more efficient and effective recycling processes for polycarbonate. This period saw the introduction of chemical recycling methods, which aimed to break down polycarbonate into its constituent monomers. These advancements allowed for higher quality recycled materials, expanding the potential uses of recycled polycarbonate in various industries.

The turn of the millennium brought about significant technological improvements in polycarbonate recycling. Advanced sorting technologies, such as near-infrared spectroscopy and X-ray fluorescence, enabled more precise separation of polycarbonate from mixed plastic waste streams. This development greatly enhanced the purity of recycled polycarbonate, addressing one of the major challenges in the recycling process.

In recent years, the focus has shifted towards developing more energy-efficient and environmentally friendly recycling processes. Researchers have been exploring novel catalytic depolymerization techniques that can break down polycarbonate under milder conditions, reducing energy consumption and potentially harmful byproducts. Additionally, there has been growing interest in biological recycling methods, utilizing engineered enzymes to degrade polycarbonate in a more sustainable manner.

The primary objective in simplifying polycarbonate recycling processes is to develop cost-effective, scalable, and environmentally sustainable methods that can be widely adopted by the industry. This includes improving the efficiency of collection and sorting systems, enhancing the quality of recycled polycarbonate to match virgin material properties, and reducing the overall environmental impact of the recycling process.

Another crucial goal is to increase the recycling rate of polycarbonate products. Despite its recyclability, a significant portion of polycarbonate still ends up in landfills or incinerators. Simplifying the recycling process could encourage more widespread adoption of polycarbonate recycling, contributing to a circular economy and reducing plastic waste.

Looking ahead, the objectives for polycarbonate recycling include developing closed-loop recycling systems, where polycarbonate products can be continuously recycled without significant loss of quality. This ambitious goal requires further advancements in recycling technologies and a holistic approach to product design that considers end-of-life recyclability from the outset.

As environmental concerns grew in the 1990s, there was a renewed focus on developing more efficient and effective recycling processes for polycarbonate. This period saw the introduction of chemical recycling methods, which aimed to break down polycarbonate into its constituent monomers. These advancements allowed for higher quality recycled materials, expanding the potential uses of recycled polycarbonate in various industries.

The turn of the millennium brought about significant technological improvements in polycarbonate recycling. Advanced sorting technologies, such as near-infrared spectroscopy and X-ray fluorescence, enabled more precise separation of polycarbonate from mixed plastic waste streams. This development greatly enhanced the purity of recycled polycarbonate, addressing one of the major challenges in the recycling process.

In recent years, the focus has shifted towards developing more energy-efficient and environmentally friendly recycling processes. Researchers have been exploring novel catalytic depolymerization techniques that can break down polycarbonate under milder conditions, reducing energy consumption and potentially harmful byproducts. Additionally, there has been growing interest in biological recycling methods, utilizing engineered enzymes to degrade polycarbonate in a more sustainable manner.

The primary objective in simplifying polycarbonate recycling processes is to develop cost-effective, scalable, and environmentally sustainable methods that can be widely adopted by the industry. This includes improving the efficiency of collection and sorting systems, enhancing the quality of recycled polycarbonate to match virgin material properties, and reducing the overall environmental impact of the recycling process.

Another crucial goal is to increase the recycling rate of polycarbonate products. Despite its recyclability, a significant portion of polycarbonate still ends up in landfills or incinerators. Simplifying the recycling process could encourage more widespread adoption of polycarbonate recycling, contributing to a circular economy and reducing plastic waste.

Looking ahead, the objectives for polycarbonate recycling include developing closed-loop recycling systems, where polycarbonate products can be continuously recycled without significant loss of quality. This ambitious goal requires further advancements in recycling technologies and a holistic approach to product design that considers end-of-life recyclability from the outset.

Market Analysis for Simplified PC Recycling

The global market for polycarbonate (PC) recycling is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures. The demand for simplified PC recycling processes is on the rise, as industries seek more efficient and cost-effective methods to manage plastic waste. Currently, the PC recycling market is valued at several billion dollars, with projections indicating substantial expansion in the coming years.

The automotive and electronics sectors are the primary contributors to the PC recycling market. As these industries continue to grow and incorporate more plastic components in their products, the volume of PC waste is expected to increase correspondingly. This trend is creating a pressing need for innovative recycling solutions that can handle larger quantities of PC waste more efficiently.

Geographically, Asia-Pacific leads the market for PC recycling, with China and Japan being the major players. Europe follows closely, driven by stringent environmental regulations and a strong focus on circular economy principles. North America is also showing significant growth potential, particularly in the United States, where there is increasing awareness and adoption of recycling practices.

The market for simplified PC recycling processes is characterized by a growing demand for technologies that can reduce energy consumption, minimize chemical usage, and improve the quality of recycled PC. Mechanical recycling methods currently dominate the market, but there is a rising interest in chemical recycling techniques that promise higher purity recycled materials.

Key market drivers include the growing emphasis on sustainable manufacturing practices, government initiatives promoting plastic recycling, and the increasing cost of virgin polycarbonate. Additionally, consumer awareness and preference for products made from recycled materials are pushing manufacturers to incorporate more recycled PC in their production processes.

However, the market faces challenges such as the high cost of recycling equipment, contamination issues in collected PC waste, and the need for more efficient sorting technologies. These factors are creating opportunities for innovation in simplified recycling processes that can address these pain points.

The competitive landscape of the PC recycling market is diverse, with a mix of established waste management companies, specialized recycling firms, and new entrants focusing on innovative technologies. Collaborations between recycling companies and end-users are becoming more common, as industries seek to close the loop in their supply chains.

In conclusion, the market for simplified PC recycling processes shows strong growth potential, driven by environmental concerns, regulatory pressures, and industrial demand. The development of more efficient and cost-effective recycling technologies is likely to shape the future of this market, presenting significant opportunities for innovation and investment in the coming years.

The automotive and electronics sectors are the primary contributors to the PC recycling market. As these industries continue to grow and incorporate more plastic components in their products, the volume of PC waste is expected to increase correspondingly. This trend is creating a pressing need for innovative recycling solutions that can handle larger quantities of PC waste more efficiently.

Geographically, Asia-Pacific leads the market for PC recycling, with China and Japan being the major players. Europe follows closely, driven by stringent environmental regulations and a strong focus on circular economy principles. North America is also showing significant growth potential, particularly in the United States, where there is increasing awareness and adoption of recycling practices.

The market for simplified PC recycling processes is characterized by a growing demand for technologies that can reduce energy consumption, minimize chemical usage, and improve the quality of recycled PC. Mechanical recycling methods currently dominate the market, but there is a rising interest in chemical recycling techniques that promise higher purity recycled materials.

Key market drivers include the growing emphasis on sustainable manufacturing practices, government initiatives promoting plastic recycling, and the increasing cost of virgin polycarbonate. Additionally, consumer awareness and preference for products made from recycled materials are pushing manufacturers to incorporate more recycled PC in their production processes.

However, the market faces challenges such as the high cost of recycling equipment, contamination issues in collected PC waste, and the need for more efficient sorting technologies. These factors are creating opportunities for innovation in simplified recycling processes that can address these pain points.

The competitive landscape of the PC recycling market is diverse, with a mix of established waste management companies, specialized recycling firms, and new entrants focusing on innovative technologies. Collaborations between recycling companies and end-users are becoming more common, as industries seek to close the loop in their supply chains.

In conclusion, the market for simplified PC recycling processes shows strong growth potential, driven by environmental concerns, regulatory pressures, and industrial demand. The development of more efficient and cost-effective recycling technologies is likely to shape the future of this market, presenting significant opportunities for innovation and investment in the coming years.

Current Challenges in PC Recycling Processes

Polycarbonate (PC) recycling processes face several significant challenges that hinder widespread adoption and efficiency. One of the primary obstacles is the contamination of PC waste streams. Unlike some other plastics, PC is often used in complex products with multiple materials, making separation and purification difficult. This contamination can include metals, other plastics, and additives that affect the quality of recycled PC.

The presence of additives and flame retardants in PC products poses another major challenge. These substances, while essential for certain applications, can complicate the recycling process and potentially compromise the properties of recycled PC. Removing or neutralizing these additives without degrading the polymer structure remains a technical hurdle.

Energy consumption is a significant concern in PC recycling. The high melting point of PC (around 260°C) necessitates substantial energy input during the recycling process, impacting both the economic viability and environmental footprint of recycling operations. This high energy requirement also contributes to the degradation of the polymer during recycling, potentially reducing the quality of the recycled material.

The degradation of PC during recycling cycles is another critical challenge. Each time PC is reprocessed, it undergoes some level of thermal and mechanical stress, which can lead to chain scission and a reduction in molecular weight. This degradation affects the mechanical properties and overall quality of the recycled material, limiting its potential applications.

Color sorting presents an additional complexity in PC recycling. Many PC products are colored, and effectively separating these colors or producing a consistent color in recycled PC is challenging. This color variation can limit the marketability and value of recycled PC, particularly for applications requiring specific aesthetic qualities.

The economic viability of PC recycling is further challenged by the fluctuating prices of virgin PC and the often lower cost of new material compared to recycled PC. This price disparity can discourage investment in recycling infrastructure and technology development.

Lastly, the lack of standardized recycling processes and infrastructure for PC contributes to inefficiencies in the recycling chain. Unlike more commonly recycled plastics such as PET or HDPE, PC recycling often lacks dedicated collection and processing streams, leading to lower recovery rates and increased contamination of recycled material.

The presence of additives and flame retardants in PC products poses another major challenge. These substances, while essential for certain applications, can complicate the recycling process and potentially compromise the properties of recycled PC. Removing or neutralizing these additives without degrading the polymer structure remains a technical hurdle.

Energy consumption is a significant concern in PC recycling. The high melting point of PC (around 260°C) necessitates substantial energy input during the recycling process, impacting both the economic viability and environmental footprint of recycling operations. This high energy requirement also contributes to the degradation of the polymer during recycling, potentially reducing the quality of the recycled material.

The degradation of PC during recycling cycles is another critical challenge. Each time PC is reprocessed, it undergoes some level of thermal and mechanical stress, which can lead to chain scission and a reduction in molecular weight. This degradation affects the mechanical properties and overall quality of the recycled material, limiting its potential applications.

Color sorting presents an additional complexity in PC recycling. Many PC products are colored, and effectively separating these colors or producing a consistent color in recycled PC is challenging. This color variation can limit the marketability and value of recycled PC, particularly for applications requiring specific aesthetic qualities.

The economic viability of PC recycling is further challenged by the fluctuating prices of virgin PC and the often lower cost of new material compared to recycled PC. This price disparity can discourage investment in recycling infrastructure and technology development.

Lastly, the lack of standardized recycling processes and infrastructure for PC contributes to inefficiencies in the recycling chain. Unlike more commonly recycled plastics such as PET or HDPE, PC recycling often lacks dedicated collection and processing streams, leading to lower recovery rates and increased contamination of recycled material.

Existing Simplified PC Recycling Methods

01 Chemical recycling methods

Chemical recycling methods are used to break down polycarbonate into its original monomers or other valuable chemicals. This process involves using solvents or catalysts to depolymerize the polycarbonate, allowing for the recovery of high-quality raw materials that can be used to produce new polycarbonate or other products. This approach simplifies the recycling process by avoiding the need for complex sorting and separation of different plastic types.- Chemical recycling methods: Chemical recycling methods are used to break down polycarbonate into its constituent monomers or other valuable chemicals. This process involves using solvents or catalysts to depolymerize the polycarbonate, allowing for the recovery of raw materials that can be used to produce new polycarbonate or other products. This approach simplifies the recycling process by converting complex polymer structures into simpler, reusable components.

- Mechanical recycling techniques: Mechanical recycling techniques involve physical processes to recycle polycarbonate without changing its chemical structure. This may include sorting, grinding, washing, and re-melting the material. The simplified process allows for direct reuse of the polymer in new applications, reducing the need for complex chemical treatments. Improvements in mechanical recycling focus on enhancing the quality of the recycled material and increasing the efficiency of the process.

- Automated sorting and identification systems: Advanced automated sorting and identification systems are developed to simplify the polycarbonate recycling process. These systems use technologies such as spectroscopy, machine vision, and artificial intelligence to quickly and accurately identify and sort different types of plastics, including polycarbonate. By improving the purity of sorted materials, these systems enhance the efficiency and quality of the recycling process.

- Additives for improved recyclability: Innovative additives are being developed to enhance the recyclability of polycarbonate. These additives can improve the material's stability during recycling, prevent degradation, or facilitate easier separation from other materials. By incorporating these additives during the initial manufacturing process, the subsequent recycling steps can be simplified, leading to higher quality recycled polycarbonate with less effort.

- Design for recyclability: Implementing design strategies that consider the entire lifecycle of polycarbonate products, including their end-of-life recycling. This approach involves designing products with easily separable components, using compatible materials, and minimizing the use of additives or coatings that complicate recycling. By considering recyclability from the design phase, the recycling process can be significantly simplified and more effective.

02 Automated sorting and separation

Advanced automated sorting and separation technologies are employed to simplify the polycarbonate recycling process. These systems use various sensors, such as near-infrared spectroscopy or X-ray fluorescence, to quickly identify and separate polycarbonate from other plastics. This automation reduces labor costs, increases efficiency, and improves the purity of the recycled polycarbonate stream.Expand Specific Solutions03 Design for recyclability

Simplifying polycarbonate recycling begins at the product design stage. By incorporating design for recyclability principles, manufacturers can create products that are easier to disassemble and recycle. This includes using single-polymer designs, avoiding problematic additives, and implementing easily separable components. Such designs reduce the complexity of the recycling process and improve the quality of the recycled material.Expand Specific Solutions04 Mechanical recycling optimization

Mechanical recycling processes for polycarbonate are being optimized to simplify operations and improve output quality. This includes developing more efficient grinding and washing techniques, as well as advanced extrusion and pelletizing methods. These improvements help to maintain the material properties of recycled polycarbonate, making it suitable for a wider range of applications and reducing the need for virgin material.Expand Specific Solutions05 Digital tracking and management

Digital technologies are being implemented to simplify the tracking and management of polycarbonate throughout its lifecycle. This includes the use of blockchain, IoT sensors, and advanced software systems to monitor the material from production to recycling. These digital solutions improve transparency, facilitate better sorting and recycling decisions, and enable more efficient collection and processing of polycarbonate waste.Expand Specific Solutions

Key Players in Polycarbonate Recycling Industry

The polycarbonate recycling industry is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for polycarbonate recycling is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with major players like Covestro Deutschland AG, LG Chem Ltd., and SABIC Global Technologies BV leading innovation efforts. These companies are developing more efficient and cost-effective recycling processes, focusing on chemical recycling methods to produce high-quality recycled polycarbonate. Emerging players such as Wanhua Chemical Group and Shuye Environmental Technology are also contributing to technological advancements, particularly in Asia. The industry is seeing a trend towards collaborative research efforts, involving both private companies and academic institutions like the Universidad Pontificia Catolica del Peru and Qingdao University of Science & Technology.

Covestro Deutschland AG

Technical Solution: Covestro has developed an innovative chemical recycling process for polycarbonate (PC) that breaks down the polymer into its molecular building blocks. This process, known as chemolysis, uses a solvent-based technique to depolymerize PC waste into its original monomers, primarily bisphenol A (BPA) and diphenyl carbonate (DPC)[1]. The recovered monomers can then be purified and repolymerized into new high-quality PC, closing the material loop. Covestro's approach also includes the use of artificial intelligence and machine learning to optimize the recycling process, improving efficiency and reducing energy consumption[2]. Additionally, they have implemented a pilot plant to demonstrate the scalability of this technology, with plans for industrial-scale implementation in the near future[3].

Strengths: High-quality output suitable for various applications, including medical devices. Closed-loop system reducing virgin material demand. Weaknesses: Energy-intensive process, potential for solvent-related environmental concerns if not properly managed.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a mechanical recycling process for polycarbonate that focuses on maintaining the material's high performance properties. Their TRUCIRCLE™ portfolio includes mechanically recycled polycarbonate grades that are derived from post-consumer and post-industrial waste[4]. The process involves careful sorting, cleaning, and reprocessing of PC waste to produce high-quality recycled resins. SABIC has also invested in advanced sorting technologies, including near-infrared (NIR) spectroscopy, to improve the purity of the recycled material[5]. Furthermore, they have implemented a certified circular process that ensures traceability of recycled content throughout the value chain, enhancing transparency and consumer confidence[6].

Strengths: Maintains high performance properties of PC, established supply chain for recycled materials. Weaknesses: Limited to mechanical recycling, which may not be suitable for all types of PC waste.

Innovative Approaches to PC Recycling

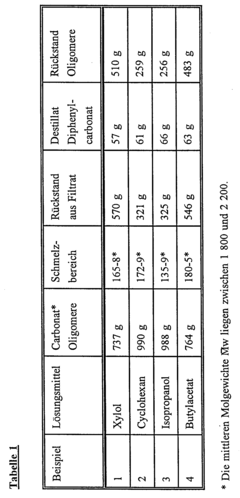

Process for chemical recycling of polycarbonates

PatentInactiveEP0688807A1

Innovation

- The process involves breaking down polycarbonates into oligocarbonates using diaryl carbonates, followed by crystallization and purification, and then polycondensing them back into thermoplastic polycarbonates, allowing for the removal of insoluble components during crystallization, which blocks phenolic OH groups and prevents oxidation or discoloration.

Method for recycling polycarbonates

PatentInactiveEP1425337A1

Innovation

- A method involving the direct condensation of polycarbonates in a vacuum melt, optionally with bisphenols or oligocarbonates having OH end groups, using specific reaction parameters and catalysts to achieve higher molecular weights, simplifying the process and avoiding initial degradation.

Environmental Impact of PC Recycling Technologies

The environmental impact of polycarbonate (PC) recycling technologies is a critical consideration in the quest to simplify and improve recycling processes. Traditional PC recycling methods often involve energy-intensive processes and the use of harmful chemicals, leading to significant environmental concerns. However, recent advancements in recycling technologies have shown promise in mitigating these impacts.

One of the primary environmental benefits of improved PC recycling is the reduction of plastic waste in landfills and oceans. By enhancing the efficiency and effectiveness of recycling processes, a larger proportion of PC products can be diverted from waste streams and reintegrated into the production cycle. This not only conserves natural resources but also reduces the carbon footprint associated with the production of virgin polycarbonate.

Energy consumption is a key factor in assessing the environmental impact of PC recycling technologies. Conventional mechanical recycling methods, while relatively simple, often require high energy inputs for grinding, melting, and re-extrusion processes. In contrast, emerging chemical recycling techniques, such as solvent-based dissolution or catalytic depolymerization, have shown potential for lower energy requirements. These methods can break down PC into its constituent monomers or oligomers, which can then be used to produce new high-quality polycarbonate with less energy than virgin production.

Water usage and pollution are also significant environmental concerns in PC recycling. Traditional recycling processes often involve washing steps that consume large volumes of water and may introduce contaminants into local water systems. Advanced recycling technologies aim to minimize water usage through closed-loop systems and more efficient cleaning methods. Additionally, some novel approaches, like supercritical fluid technology, can potentially eliminate the need for water-based cleaning altogether.

The emission of volatile organic compounds (VOCs) and other air pollutants during PC recycling is another environmental challenge. Thermal degradation of polycarbonate can release harmful substances, including bisphenol A (BPA) and phosgene precursors. Newer recycling technologies focus on lower-temperature processes and improved filtration systems to reduce air emissions. Some innovative methods, such as microwave-assisted pyrolysis, have demonstrated the potential for significantly lower emissions compared to conventional thermal recycling.

Lastly, the environmental impact of PC recycling technologies extends to the broader lifecycle of polycarbonate products. By improving the quality of recycled PC and expanding its applications, these technologies can help extend the useful life of polycarbonate materials. This, in turn, reduces the demand for virgin PC production, leading to lower overall environmental impacts across the entire lifecycle of polycarbonate products.

One of the primary environmental benefits of improved PC recycling is the reduction of plastic waste in landfills and oceans. By enhancing the efficiency and effectiveness of recycling processes, a larger proportion of PC products can be diverted from waste streams and reintegrated into the production cycle. This not only conserves natural resources but also reduces the carbon footprint associated with the production of virgin polycarbonate.

Energy consumption is a key factor in assessing the environmental impact of PC recycling technologies. Conventional mechanical recycling methods, while relatively simple, often require high energy inputs for grinding, melting, and re-extrusion processes. In contrast, emerging chemical recycling techniques, such as solvent-based dissolution or catalytic depolymerization, have shown potential for lower energy requirements. These methods can break down PC into its constituent monomers or oligomers, which can then be used to produce new high-quality polycarbonate with less energy than virgin production.

Water usage and pollution are also significant environmental concerns in PC recycling. Traditional recycling processes often involve washing steps that consume large volumes of water and may introduce contaminants into local water systems. Advanced recycling technologies aim to minimize water usage through closed-loop systems and more efficient cleaning methods. Additionally, some novel approaches, like supercritical fluid technology, can potentially eliminate the need for water-based cleaning altogether.

The emission of volatile organic compounds (VOCs) and other air pollutants during PC recycling is another environmental challenge. Thermal degradation of polycarbonate can release harmful substances, including bisphenol A (BPA) and phosgene precursors. Newer recycling technologies focus on lower-temperature processes and improved filtration systems to reduce air emissions. Some innovative methods, such as microwave-assisted pyrolysis, have demonstrated the potential for significantly lower emissions compared to conventional thermal recycling.

Lastly, the environmental impact of PC recycling technologies extends to the broader lifecycle of polycarbonate products. By improving the quality of recycled PC and expanding its applications, these technologies can help extend the useful life of polycarbonate materials. This, in turn, reduces the demand for virgin PC production, leading to lower overall environmental impacts across the entire lifecycle of polycarbonate products.

Economic Viability of Simplified PC Recycling

The economic viability of simplified polycarbonate (PC) recycling processes is a critical factor in determining the feasibility and adoption of these technologies. As the demand for sustainable practices in plastic management grows, the financial aspects of PC recycling become increasingly important.

The current PC recycling market faces several economic challenges. Traditional recycling methods often involve high energy consumption, expensive equipment, and complex separation processes, resulting in significant operational costs. These factors contribute to the relatively low recycling rates for PC compared to other plastics, despite its high value as a recyclable material.

Simplified PC recycling processes aim to address these economic barriers by reducing the complexity and cost of recycling operations. One approach involves developing more efficient sorting technologies that can accurately identify and separate PC from mixed plastic waste streams. This can significantly reduce labor costs and increase the purity of recovered PC, enhancing its market value.

Another promising avenue is the development of chemical recycling methods that can break down PC into its constituent monomers. While the initial investment in such technologies may be substantial, they offer the potential for higher-quality recycled materials and reduced processing costs in the long term. This could lead to a more favorable economic model for PC recycling.

The economic viability of simplified PC recycling also depends on external factors such as regulatory policies and market demand for recycled materials. Government incentives, such as tax breaks or subsidies for recycling operations, can significantly improve the financial attractiveness of these processes. Additionally, as more companies commit to using recycled materials in their products, the demand for high-quality recycled PC is likely to increase, potentially driving up prices and improving the economic outlook for recyclers.

Scale is another crucial factor in the economic viability of simplified PC recycling. Larger-scale operations can benefit from economies of scale, spreading fixed costs over a greater volume of processed material. This can make simplified recycling processes more cost-effective and competitive with virgin PC production.

Ultimately, the economic viability of simplified PC recycling processes will depend on their ability to reduce costs, improve efficiency, and produce high-quality recycled materials that can compete with virgin PC in terms of price and performance. As technologies continue to evolve and market conditions shift towards more sustainable practices, the economic prospects for simplified PC recycling are likely to improve, making it an increasingly attractive option for both recyclers and manufacturers.

The current PC recycling market faces several economic challenges. Traditional recycling methods often involve high energy consumption, expensive equipment, and complex separation processes, resulting in significant operational costs. These factors contribute to the relatively low recycling rates for PC compared to other plastics, despite its high value as a recyclable material.

Simplified PC recycling processes aim to address these economic barriers by reducing the complexity and cost of recycling operations. One approach involves developing more efficient sorting technologies that can accurately identify and separate PC from mixed plastic waste streams. This can significantly reduce labor costs and increase the purity of recovered PC, enhancing its market value.

Another promising avenue is the development of chemical recycling methods that can break down PC into its constituent monomers. While the initial investment in such technologies may be substantial, they offer the potential for higher-quality recycled materials and reduced processing costs in the long term. This could lead to a more favorable economic model for PC recycling.

The economic viability of simplified PC recycling also depends on external factors such as regulatory policies and market demand for recycled materials. Government incentives, such as tax breaks or subsidies for recycling operations, can significantly improve the financial attractiveness of these processes. Additionally, as more companies commit to using recycled materials in their products, the demand for high-quality recycled PC is likely to increase, potentially driving up prices and improving the economic outlook for recyclers.

Scale is another crucial factor in the economic viability of simplified PC recycling. Larger-scale operations can benefit from economies of scale, spreading fixed costs over a greater volume of processed material. This can make simplified recycling processes more cost-effective and competitive with virgin PC production.

Ultimately, the economic viability of simplified PC recycling processes will depend on their ability to reduce costs, improve efficiency, and produce high-quality recycled materials that can compete with virgin PC in terms of price and performance. As technologies continue to evolve and market conditions shift towards more sustainable practices, the economic prospects for simplified PC recycling are likely to improve, making it an increasingly attractive option for both recyclers and manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!