Innovative Cooling Techniques For Turbine Engines

SEP 23, 20255 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Cooling Technology Background and Goals

The primary objective of researching innovative cooling techniques for turbine engines is to enhance their efficiency, reliability, and lifespan. Turbine engines, widely used in aviation and power generation, operate under extreme temperatures, necessitating advanced cooling methods to prevent overheating and material degradation. This report aims to provide a comprehensive overview of the current state of cooling technologies, identify key challenges, and explore potential advancements in this field.

Understanding the market demand for innovative cooling techniques in turbine engines involves analyzing the growing need for more efficient and durable engines in various industries. The aviation sector, in particular, is experiencing increased demand for fuel-efficient and environmentally friendly engines, driving the need for advanced cooling solutions. Additionally, the power generation industry seeks to improve the performance and longevity of gas turbines, further emphasizing the importance of innovative cooling methods. Evaluating market trends and potential growth areas will help in identifying opportunities for technological advancements and strategic investments.

Turbine Engine Cooling Market Demand Analysis

- Market Demand Overview: The demand for innovative cooling techniques in turbine engines is driven by the need for higher efficiency, reduced emissions, and improved performance. As environmental regulations become stricter, the market seeks solutions that can enhance thermal management.

- Industry Growth: The turbine engine market is experiencing significant growth, particularly in the aerospace and energy sectors. This growth is fueled by the increasing demand for air travel and the expansion of renewable energy sources, which require efficient and reliable turbine engines.

- Technological Advancements: Advances in materials science, such as the development of high-temperature alloys and ceramic matrix composites, are enabling more effective cooling solutions. These materials can withstand higher temperatures, allowing for more efficient engine operation.

- Competitive Landscape: Major players in the turbine engine market are investing heavily in R&D to develop innovative cooling technologies. Companies like General Electric, Rolls-Royce, and Pratt & Whitney are leading the way with cutting-edge solutions.

- Regional Demand: The demand for turbine engine cooling technologies varies by region. North America and Europe are leading markets due to their advanced aerospace industries, while Asia-Pacific is emerging as a significant market due to rapid industrialization and infrastructure development.

- Future Trends: The future of turbine engine cooling will likely involve the integration of smart technologies, such as sensors and AI, to optimize cooling processes in real-time. Additionally, the push towards sustainable and green technologies will drive further innovation in this field.

Turbine Engine Cooling Technology Status and Challenges

## Run:

Based on the provided directory "Turbine Engine Cooling Technology Status and Challenges," generate the corresponding content for the technical research report on "Innovative Cooling Techniques for Turbine Engines."

## Output:

- Current State: Turbine engine cooling technologies have advanced significantly, focusing on enhancing thermal efficiency and durability. Techniques such as film cooling, internal cooling passages, and advanced thermal barrier coatings are widely used.

- Challenges: Key challenges include managing higher thermal loads due to increased engine performance, material limitations under extreme temperatures, and the need for more efficient cooling methods to reduce fuel consumption and emissions.

- Geographical Distribution: Research and development are concentrated in regions with strong aerospace industries, such as the United States, Europe, and Asia, with significant contributions from leading aerospace companies and research institutions.

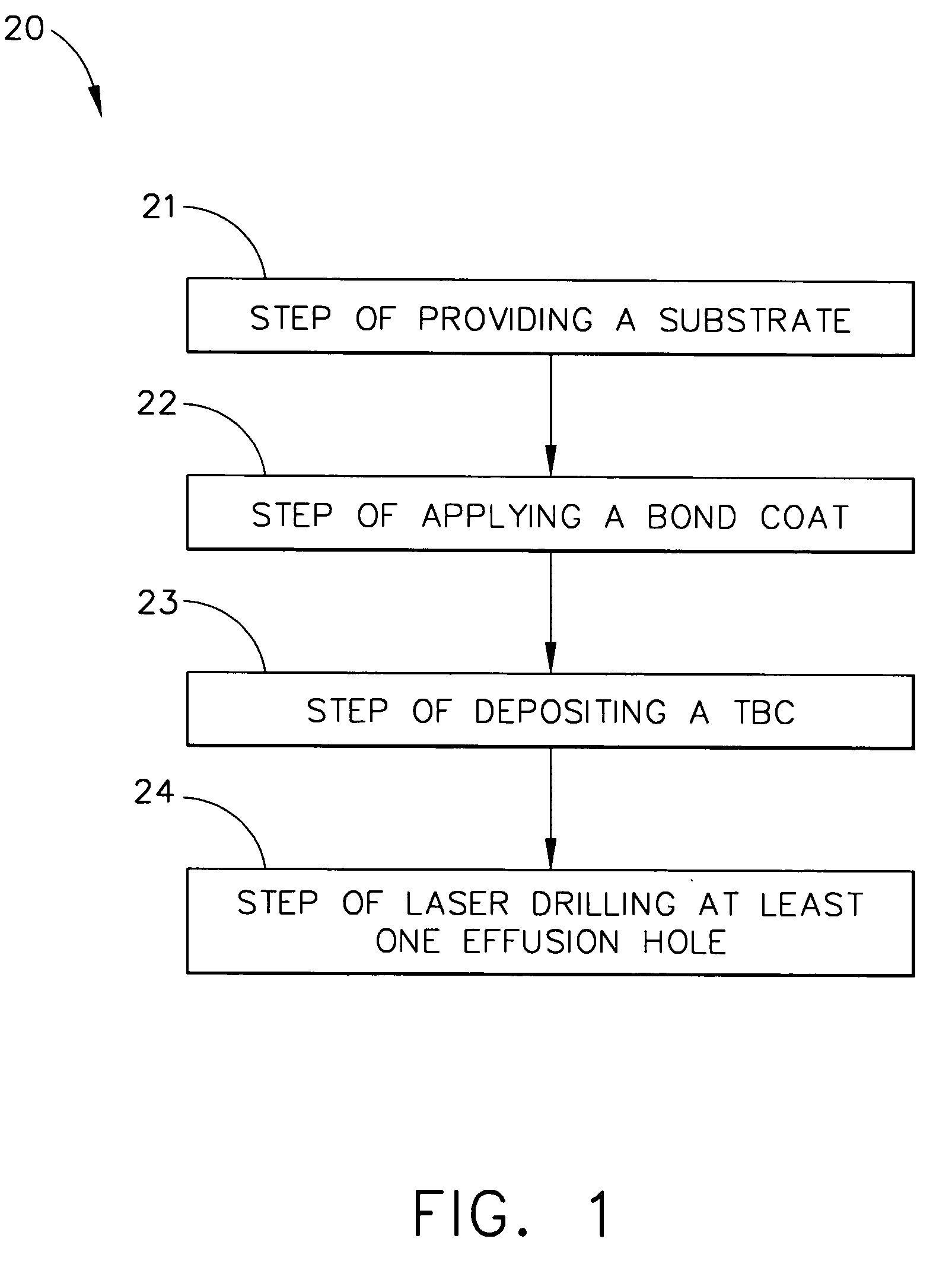

Turbine Engine Cooling Current Technical Solutions

01 Advanced Cooling Techniques

Advanced cooling techniques, such as film and impingement cooling, significantly enhance turbine engine cooling efficiency by directing cooling air onto hot components.- Advanced Cooling Techniques: Innovative cooling techniques, such as film and impingement cooling, enhance turbine engine cooling efficiency by directing cooling air onto hot components.

- Thermal Barrier Coatings: Thermal barrier coatings (TBCs) protect turbine components from high temperatures by acting as an insulating layer, reducing heat transfer and improving cooling efficiency.

- Optimized Cooling Air Flow: Optimizing cooling air flow within turbine engines involves designing air passages to ensure effective distribution to critical areas, maintaining optimal temperatures.

- Heat Exchangers: Heat exchangers transfer heat from hot components to cooler areas, managing thermal load and maintaining engine performance.

- Advanced Materials: Advanced materials like ceramic matrix composites and superalloys enhance cooling efficiency by withstanding higher temperatures, reducing the need for extensive cooling.

02 Thermal Barrier Coatings

Thermal barrier coatings (TBCs) protect turbine components from high temperatures by acting as an insulating layer, reducing heat transfer and extending component lifespan.Expand Specific Solutions03 Optimized Cooling Air Flow

Optimizing cooling air flow within turbine engines involves designing internal passages to ensure effective distribution to critical areas.Expand Specific Solutions04 Innovative Blade Designs

Innovative turbine blade designs, such as internal cooling channels or advanced aerodynamic shapes, improve cooling efficiency by facilitating better heat dissipation.Expand Specific Solutions05 High-Performance Materials

High-performance materials like advanced alloys and ceramics enhance cooling efficiency by withstanding higher temperatures, reducing the need for extensive cooling.Expand Specific Solutions

Turbine Engine Cooling Main Player Analysis

The competitive landscape for innovative cooling techniques for turbine engines includes established leaders and emerging players. Major companies like United Technologies Corp., General Electric Company, Honeywell International Technologies Ltd., and Rolls-Royce Plc lead in technological advancements. Emerging entities like Beihang University and Northwestern Polytechnical University also contribute to innovation.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced cooling techniques using ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs) to improve engine efficiency and durability.

Strength: High-temperature resistance and improved efficiency. Weakness: High cost and manufacturing complexity.

General Electric Company

Technical Solution: General Electric Company focuses on advanced air cooling systems and CMCs to enhance thermal efficiency and engine longevity.

Strength: Proven technology with efficiency gains. Weakness: Costly and complex implementation.

Turbine Engine Cooling Key Technology Interpretation

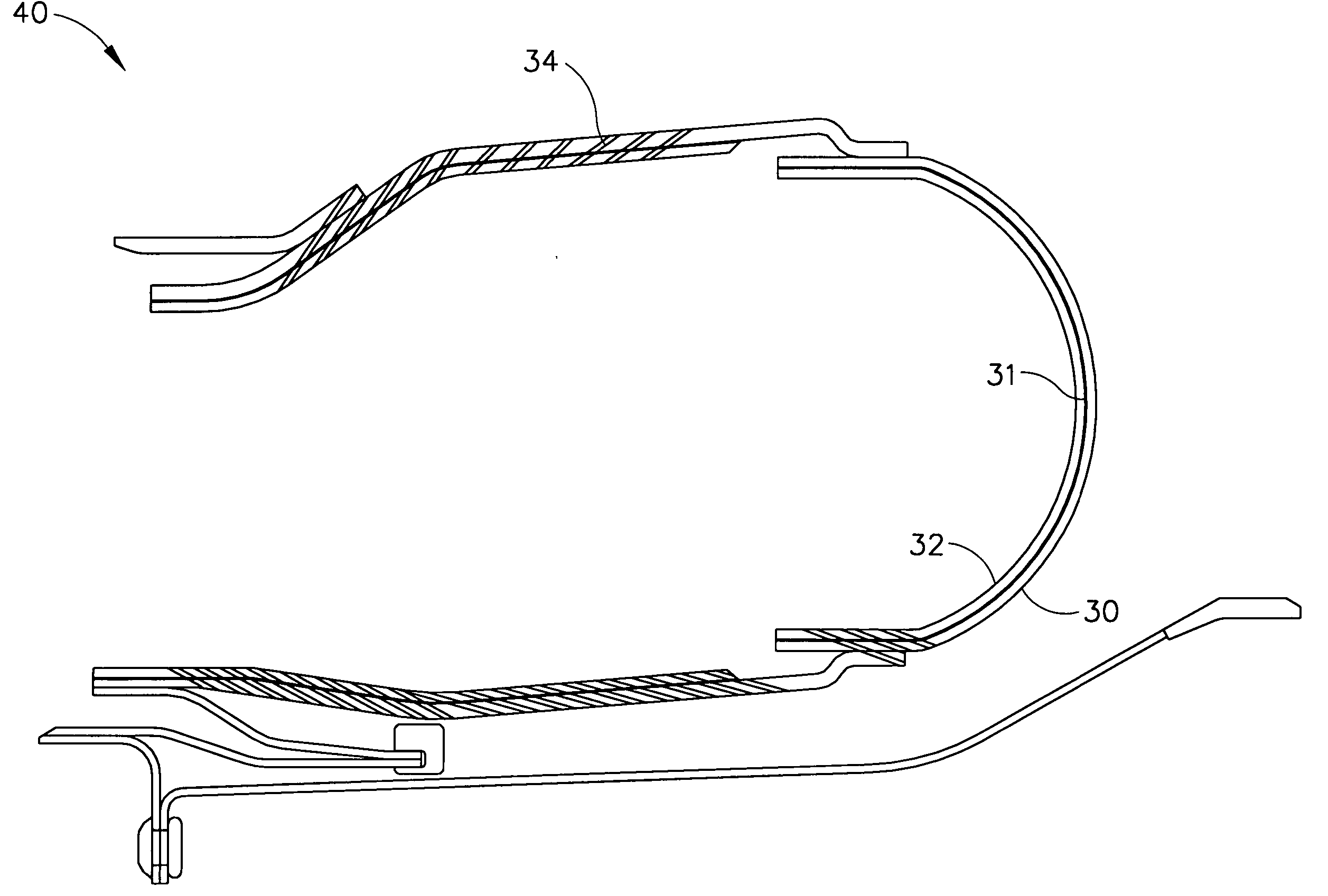

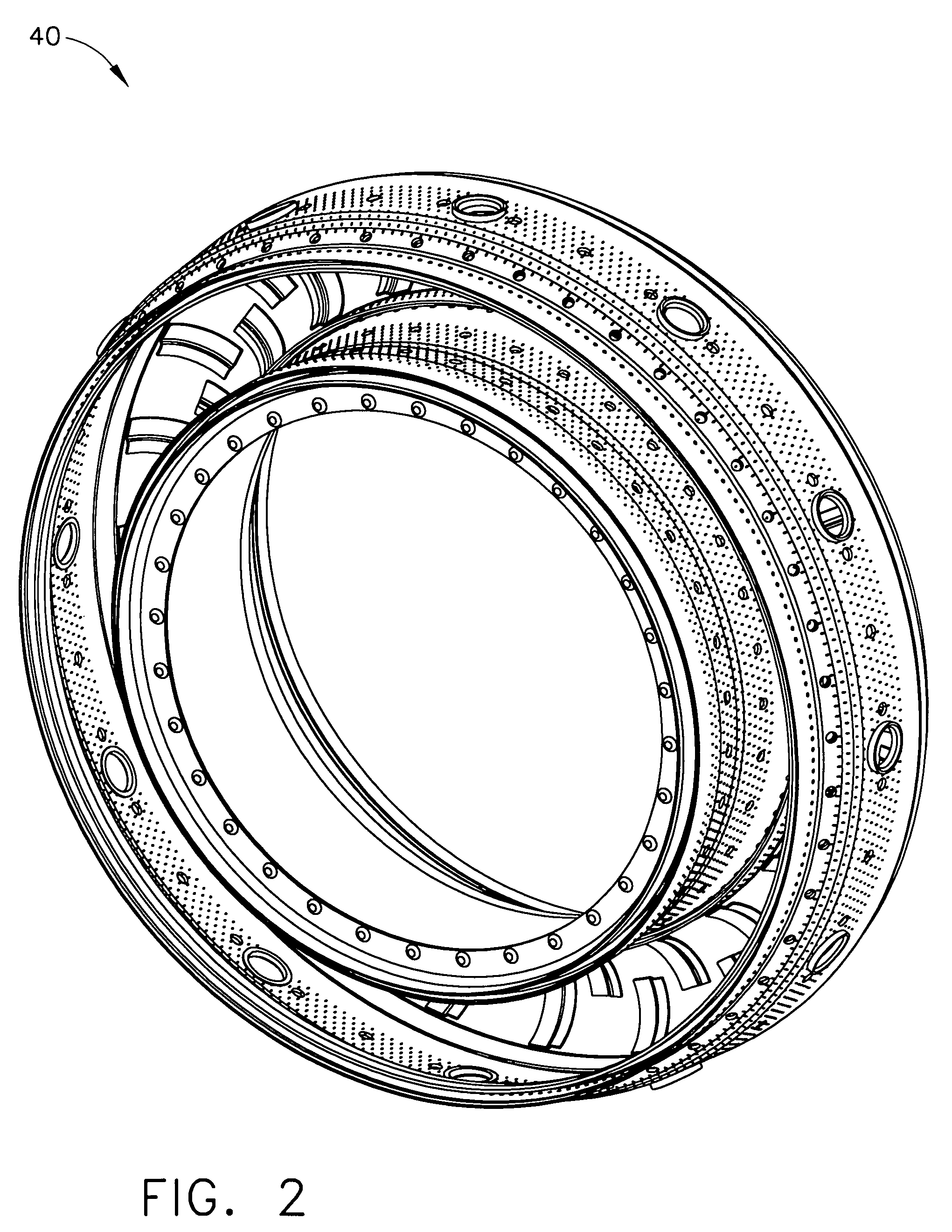

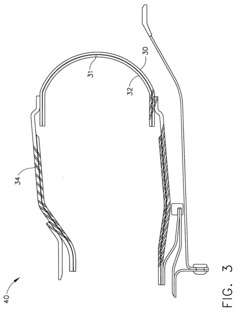

Combined effusion and thick TBC cooling method

PatentInactiveUS20060016191A1

Innovation

- Combination of thermal barrier coatings (TBC) with effusion holes for enhanced cooling efficiency.

- Application of columnar crack structure or segmentation microcracked structure in TBC to improve coating durability.

- Drilling effusion holes through the coated material to reduce cooling film thickness and enhance cooling performance.

Turbine Engine Cooling Environmental Impact Analysis

The environmental impact of innovative cooling techniques for turbine engines is a multifaceted issue that encompasses several key areas. Firstly, the implementation of advanced cooling methods can significantly reduce the thermal footprint of turbine engines, leading to lower emissions of greenhouse gases and other pollutants. This reduction is crucial in mitigating the environmental impact of aviation and power generation industries, which are major contributors to global emissions. Additionally, improved cooling efficiency can enhance the overall performance and lifespan of turbine engines, leading to less frequent replacements and, consequently, a reduction in the environmental burden associated with manufacturing and disposal processes.

Moreover, innovative cooling techniques often involve the use of advanced materials and technologies that can have their own environmental implications. For instance, the production and disposal of high-performance cooling materials may introduce new environmental challenges, such as resource depletion and waste management issues. It is essential to conduct a comprehensive life cycle assessment of these materials to fully understand their environmental impact and to develop strategies for sustainable use and disposal.

Finally, the adoption of these cooling techniques can influence the regulatory landscape, as governments and international bodies may need to update standards and guidelines to reflect the new technologies. This can drive further innovation and adoption of environmentally friendly practices across the industry. Overall, while innovative cooling techniques for turbine engines offer significant potential for reducing environmental impact, it is crucial to consider the entire lifecycle and regulatory implications to ensure a holistic approach to sustainability.

Turbine Engine Cooling Policy and Regulatory Impact

The implementation of innovative cooling techniques for turbine engines is significantly influenced by existing policies and regulatory frameworks. These regulations are designed to ensure the safety, efficiency, and environmental compliance of turbine engines. Regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) set stringent standards that cooling technologies must meet. These standards cover aspects such as thermal efficiency, emissions, and material durability under high-temperature conditions. Compliance with these regulations is mandatory for the certification and commercial deployment of new cooling technologies.

Moreover, environmental regulations aimed at reducing greenhouse gas emissions and improving fuel efficiency are driving the development of advanced cooling techniques. Policies promoting sustainability and energy efficiency incentivize the adoption of innovative cooling solutions that can enhance engine performance while minimizing environmental impact. These regulations often include specific targets for emission reductions and fuel consumption, which directly impact the design and implementation of cooling systems.

The regulatory landscape also affects the pace of innovation and market entry for new cooling technologies. Companies must navigate a complex approval process, which can be time-consuming and costly. However, successful compliance can lead to significant competitive advantages, including market access and enhanced reputation. Therefore, understanding and aligning with regulatory requirements is crucial for the successful development and deployment of innovative cooling techniques in turbine engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!