Improving The Cooling Efficiency Of Check Valves

Check Valve Technology Background And Goals

The primary objective of this report is to enhance the cooling efficiency of check valves, which play a crucial role in various industrial applications. Improving their thermal performance can lead to increased operational reliability, extended service life, and reduced maintenance costs. This research aims to explore innovative solutions that can effectively dissipate heat generated during valve operation, thereby mitigating the risk of overheating and potential failures.

Key areas of focus include optimizing valve design, incorporating advanced materials with superior thermal conductivity, and investigating novel cooling mechanisms. Computational fluid dynamics simulations and experimental testing will be employed to evaluate the effectiveness of proposed solutions and validate their practical implementation. The ultimate goal is to develop cost-effective and scalable cooling strategies that can be seamlessly integrated into existing valve systems, enabling improved overall system efficiency and performance.

Technology Market Demand Analysis

The demand for efficient cooling solutions has been steadily rising across various industries and sectors. With increasing concerns over energy consumption, environmental impact, and operational costs, businesses and consumers alike are seeking innovative cooling technologies that offer superior performance while minimizing energy usage and carbon footprint.

In the industrial sector, the need for efficient cooling is driven by the growing demand for data centers, manufacturing facilities, and power generation plants. These operations generate significant amounts of heat, necessitating robust cooling systems to maintain optimal temperatures and prevent equipment failure. Efficient cooling solutions can lead to substantial energy savings, reduced operational costs, and improved overall efficiency.

The residential and commercial building sectors also present a significant market for efficient cooling solutions. As urbanization continues to rise and global temperatures increase, the demand for air conditioning and refrigeration systems is expected to surge. Energy-efficient cooling technologies can help mitigate the environmental impact of these systems while providing comfortable living and working environments.

Furthermore, the transportation industry, including automotive, aerospace, and maritime sectors, requires efficient cooling solutions to maintain optimal performance and ensure passenger comfort. As vehicles become more technologically advanced and energy-efficient, the demand for innovative cooling systems that can dissipate heat effectively while minimizing energy consumption is increasing.

Market analysts predict that the global market for efficient cooling solutions will continue to grow at a significant rate, driven by factors such as stricter energy efficiency regulations, rising energy costs, and increasing awareness of environmental sustainability. Companies that can develop and commercialize cutting-edge cooling technologies that meet these market demands are likely to gain a competitive advantage and capture a substantial share of this rapidly expanding market.

Technology Status And Challenges

- Valve Cooling Challenges

Check valves experience high temperatures due to friction and turbulence, leading to material degradation and reduced service life. - Thermal Management Limitations

Existing cooling methods like water jackets and heat sinks have limited effectiveness, especially for high-pressure and high-temperature applications. - Material Constraints

Conventional valve materials have limited thermal conductivity, hindering effective heat dissipation from critical components. - Design Complexities

Integrating advanced cooling systems into compact valve designs poses significant engineering challenges. - Operational Environments

Harsh operating conditions, such as corrosive fluids or extreme temperatures, further complicate cooling solutions.

Current Technical Solutions

01 Cooling Efficiency Enhancement

Various check valve designs and configurations can enhance cooling efficiency through features like reduced pressure drop, optimized flow paths, and minimized leakage, regulating coolant or refrigerant flow and preventing backflow.- Improved Heat Dissipation: These inventions relate to check valves designed with features like enhanced heat dissipation mechanisms, optimized flow paths, or specialized materials to facilitate better heat transfer and cooling performance.

- Integrated Cooling Systems: These inventions involve check valves with integrated cooling systems or mechanisms, such as channels, fins, or other structures, to facilitate heat transfer and improve overall cooling efficiency.

- Optimized Flow Paths: These inventions focus on optimizing the flow paths within check valves to enhance cooling efficiency, through streamlined flow channels, strategic placement of inlets and outlets, or other modifications to improve fluid flow and heat transfer.

- Specialized Materials: These inventions involve the use of specialized materials with enhanced thermal conductivity, low thermal expansion, or other properties that facilitate better heat dissipation and cooling performance in check valves.

- Active Cooling Mechanisms: These inventions incorporate active cooling mechanisms into check valves, such as integrated fans, liquid cooling systems, or other active cooling components, to actively remove heat and improve overall cooling efficiency.

02 Integrated Cooling Channels

Some check valve designs incorporate integrated cooling channels or passages within the valve body or housing, allowing efficient heat dissipation and improving overall cooling performance, optimized for specific applications or operating conditions.Expand Specific Solutions03 Heat-Resistant Materials

The use of heat-resistant materials in check valve construction can contribute to improved cooling efficiency by withstanding high temperatures, maintaining structural integrity, and reducing the risk of deformation or failure under extreme thermal conditions.Expand Specific Solutions04 Optimized Flow Geometry

The geometry and design of flow paths within check valves can significantly impact cooling efficiency, with optimized flow geometries minimizing turbulence, reducing pressure drop, and improving heat transfer through features like streamlined flow paths and optimized valve seat angles.Expand Specific Solutions05 Advanced Sealing Mechanisms

Effective sealing mechanisms in check valves, such as specialized gaskets, sealing rings, or valve seat coatings, can contribute to improved cooling efficiency by preventing leakage, ensuring proper flow control, and maintaining system integrity for more efficient cooling performance.Expand Specific Solutions

Technology Main Player Analysis

DENSO Corp.

Fujikoki Corp.

Key Technology Interpretation

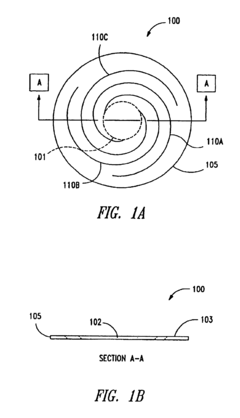

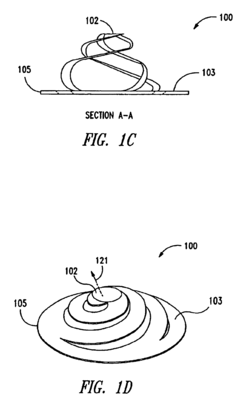

- The check valve includes an outer region and a central region with one or more cuts winding from the outer region towards the central region, allowing it to open or close by extending or retracting the central region relative to the outer region.

- The check valve design allows it to be used with both axial fans and blowers, providing more versatility compared to traditional check valves.

- The check valve is designed to minimize the negative impact of a failed fan in a plenum arrangement with multiple fans, helping to maintain the cooling efficiency of the system.

Check Valve Cooling Efficiency Improvement Economic Impact

The focus on improving the cooling efficiency of check valves holds the potential for significant economic impact across various industries, particularly those reliant on heavy machinery and fluid dynamics systems. Enhanced cooling solutions could lead to extended equipment lifespan and reduced maintenance costs, resulting in operational savings for industries such as oil and gas, manufacturing, and chemical processing. Additionally, the energy efficiency gained from optimized cooling processes can contribute to decreased operational expenses and align with sustainability goals by reducing overall energy consumption.

From a market perspective, the demand for advanced cooling solutions in check valves is likely to grow alongside increased industrialization and the push for more efficient machinery. Companies that can innovate in this space may capitalize on emerging market opportunities by providing competitive solutions that offer both economic and environmental benefits. Furthermore, as industries continue to expand their focus on reducing carbon footprints, innovations that enhance energy efficiency will not only boost economic performance but also enhance corporate social responsibility standings.

Investments in R&D for cooling technologies in check valves will drive competitiveness and open avenues for partnerships and collaborations, thereby impacting the economic landscape by fostering innovation ecosystems. The economic benefits, including reduced energy costs and enhanced operational efficiency, highlight the significant value proposition of advancing check valve cooling efficiency, underscoring its critical role in future-proofing industrial processes.

Check Valve Cooling Efficiency Improvement Policy And Regulatory Impact

Regulatory policies and government guidelines significantly influence the development and application of cooling efficiency improvements in check valves. Current regulations often focus on energy efficiency standards and emissions reduction, pushing industries to adopt more efficient technologies. These regulations encourage innovation and investments in research to develop check valves with better cooling efficiency. Compliance with international standards, such as those established by the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), ensures that products meet global efficiency and safety benchmarks.

Government incentives and subsidies can also play a crucial role, as they lower the financial burden on companies investing in cutting-edge cooling technologies. However, navigating the complex landscape of policies across different regions presents challenges, as variations in regulations can affect the uniformity and scalability of technology implementations. Moreover, future policy shifts towards more stringent environmental standards are likely, necessitating ongoing adaptability in technological designs.

Overall, understanding and aligning with these regulatory frameworks is essential for companies aiming to enhance the cooling efficiency of check valves, ensuring both compliance and competitive advantage in the global market.