Improving Cooling Efficiency Of Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

The primary goal of this research is to explore methods to enhance the cooling efficiency of turbine engines. This involves a comprehensive examination of the historical development and evolution of turbine engine cooling technologies. Understanding the progression of these technologies is crucial for identifying key trends and milestones that have shaped the current state of the art. By analyzing past advancements, we can better predict future developments and set clear technical objectives for improving cooling efficiency. This background knowledge will serve as a foundation for identifying innovative solutions and guiding strategic planning in the field of turbine engine cooling.

Turbine Engine Market Demand Analysis

- Market Demand: The demand for turbine engines is driven by the aviation, power generation, and industrial sectors. Increasing air travel and the need for efficient power generation are key factors.

- Growth Drivers: Technological advancements, environmental regulations, and the push for higher fuel efficiency are propelling the market forward.

- Market Size: The global turbine engine market is substantial, with significant investments in R&D and infrastructure. The market is expected to grow steadily over the next decade.

- Regional Analysis: North America and Europe are leading markets due to established aerospace industries. Asia-Pacific is emerging rapidly, driven by industrialization and increasing air travel.

- Industry Trends: There is a trend towards lightweight materials, advanced cooling technologies, and hybrid engines to improve efficiency and reduce emissions.

- Challenges: High development costs, stringent regulatory requirements, and the need for continuous innovation are major challenges in the market.

- Future Outlook: The market is poised for growth with ongoing advancements in materials science, aerodynamics, and cooling technologies, aiming to enhance performance and sustainability.

Turbine Engine Technology Status and Challenges

- Current Development Status: Turbine engine cooling technologies have advanced significantly, focusing on enhancing thermal efficiency and durability. Key methods include advanced cooling channels, thermal barrier coatings, and optimized airflow designs.

- Challenges: Major challenges include managing high thermal loads, material degradation at elevated temperatures, and maintaining structural integrity. Innovations are needed to improve heat dissipation and material resilience.

- Geographical Distribution: Leading research and development are concentrated in regions with strong aerospace industries, such as the United States, Europe, and Asia. These areas host major players and research institutions driving technological advancements.

Turbine Engine Current Technical Solutions

01 Advanced cooling techniques for turbine blades

Various advanced cooling techniques can be applied to turbine blades to enhance cooling efficiency. These techniques include the use of film cooling, internal cooling channels, and thermal barrier coatings. These methods help to reduce the temperature of the turbine blades, thereby improving their performance and lifespan.- Advanced cooling techniques for turbine blades: Various advanced cooling techniques can be applied to turbine blades to enhance cooling efficiency. These techniques include the use of film cooling, internal cooling channels, and transpiration cooling. These methods help to maintain the structural integrity of the blades under high-temperature conditions.

- Use of thermal barrier coatings: Thermal barrier coatings (TBCs) are applied to turbine components to protect them from high temperatures and improve cooling efficiency. TBCs act as an insulating layer, reducing the heat load on the underlying material and allowing for higher operating temperatures.

- Optimized cooling air flow management: Effective management of cooling air flow within turbine engines is crucial for enhancing cooling efficiency. Techniques such as optimizing the distribution of cooling air and using advanced cooling air delivery systems can significantly improve the cooling performance of turbine engines.

- Innovative materials for turbine components: The use of innovative materials, such as advanced alloys and ceramics, in turbine components can improve cooling efficiency. These materials have superior thermal properties and can withstand higher temperatures, reducing the need for extensive cooling.

- Enhanced heat exchangers: The development of enhanced heat exchangers for turbine engines can improve cooling efficiency. These heat exchangers are designed to maximize heat transfer and minimize pressure losses, ensuring effective cooling of turbine components.

02 Innovative materials for improved heat resistance

The use of innovative materials with high heat resistance can significantly improve the cooling efficiency of turbine engines. Materials such as ceramic matrix composites and superalloys are commonly used due to their ability to withstand high temperatures and reduce thermal stress on engine components.Expand Specific Solutions03 Optimized cooling air flow management

Optimizing the management of cooling air flow within turbine engines can enhance cooling efficiency. Techniques such as variable geometry components and optimized cooling air distribution help to ensure that cooling air is effectively directed to critical areas, reducing overall engine temperature.Expand Specific Solutions04 Enhanced heat exchangers for turbine engines

The development of enhanced heat exchangers can improve the cooling efficiency of turbine engines. These heat exchangers are designed to maximize heat transfer and minimize pressure loss, thereby improving the overall thermal management of the engine.Expand Specific Solutions05 Advanced cooling system designs

Advanced cooling system designs, including the use of closed-loop cooling systems and integrated cooling circuits, can significantly enhance the cooling efficiency of turbine engines. These systems are designed to provide efficient heat removal and maintain optimal operating temperatures.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for improving the cooling efficiency of turbine engines includes established leaders and innovative newcomers. The market is driven by demand in aviation and power generation. Companies like United Technologies Corp., Rolls-Royce Plc, General Electric Company, Pratt & Whitney Canada Corp., and Honeywell International Technologies Ltd. lead with advanced materials and cooling technologies.

United Technologies Corp.

Technical Solution: United Technologies Corp. uses ceramic matrix composites (CMCs) and advanced thermal barrier coatings (TBCs) to improve turbine engine efficiency and lifespan.

Strength: High-temperature resistance and durability. Weakness: High cost.

Rolls-Royce Plc

Technical Solution: Rolls-Royce Plc enhances cooling efficiency with innovative blade cooling techniques and advanced materials.

Strength: Enhanced cooling efficiency. Weakness: Design complexity.

Turbine Engine Key Technology Interpretation

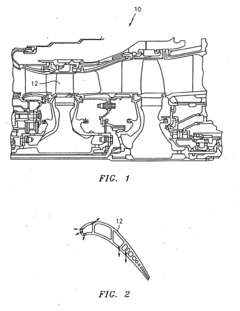

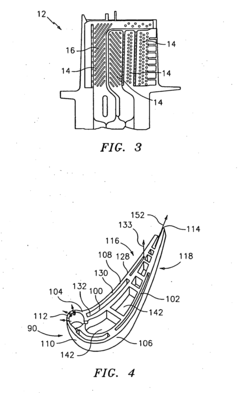

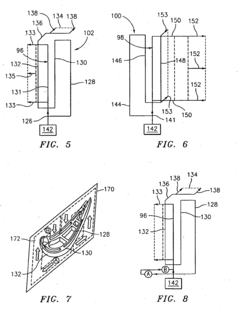

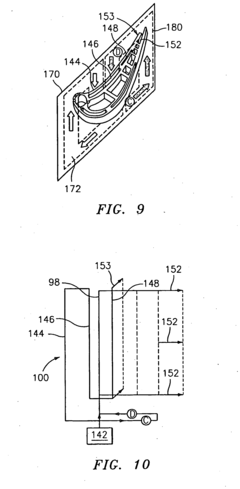

Integrated platform, tip, and main body microcircuits for turbine blades

PatentActiveEP1882819B1

Innovation

- Coating the airfoil with a thermal barrier coating to enhance thermal protection.

- Improving film cooling through slots to enhance cooling effectiveness.

- Enhancing heat pick-up and transfer coefficients in the blade cooling passages.

Turbine Engine Cooling Efficiency Improvement Economic Analysis

The economic analysis of improving cooling efficiency in turbine engines involves evaluating the cost-benefit ratio of implementing advanced cooling technologies. This includes assessing the initial investment required for research, development, and deployment of new cooling systems against the potential savings in operational costs and maintenance. Enhanced cooling efficiency can lead to significant fuel savings, reduced wear and tear on engine components, and extended engine life, which collectively contribute to lower overall operating costs. Additionally, improved cooling can enhance engine performance and reliability, potentially leading to increased revenue through higher efficiency and reduced downtime.

Market demand for more efficient turbine engines is driven by the aviation and energy sectors' need to reduce fuel consumption and emissions. As regulatory pressures increase and fuel prices fluctuate, the economic incentive to adopt advanced cooling technologies becomes more compelling. The analysis should also consider the competitive landscape, where companies that invest in innovative cooling solutions may gain a market advantage by offering more efficient and environmentally friendly engines.

Furthermore, the economic analysis should factor in potential government incentives or subsidies for adopting greener technologies, which can offset some of the initial costs. By quantifying these economic impacts, stakeholders can make informed decisions about investing in cooling efficiency improvements, balancing short-term expenditures with long-term gains in performance, cost savings, and market positioning.

Turbine Engine Cooling Efficiency Improvement Policy and Regulatory Impact

The improvement of cooling efficiency in turbine engines is significantly influenced by policy and regulatory frameworks. These frameworks are designed to ensure that advancements in turbine technology align with environmental standards and safety regulations. Policies often mandate reductions in emissions and improvements in fuel efficiency, which directly impact the design and operation of turbine cooling systems. Regulatory bodies such as the Environmental Protection Agency (EPA) and the International Civil Aviation Organization (ICAO) set stringent guidelines that drive innovation in cooling technologies to meet these standards.

Compliance with these regulations necessitates continuous research and development in advanced materials and cooling techniques. For instance, the use of ceramic matrix composites (CMCs) and advanced thermal barrier coatings (TBCs) are being explored to enhance cooling efficiency while maintaining structural integrity at high temperatures. These materials not only improve thermal management but also contribute to overall engine efficiency and longevity.

Moreover, government incentives and funding for research in green technologies play a crucial role in accelerating the development of more efficient cooling systems. Policies promoting sustainable aviation and energy efficiency encourage manufacturers to invest in cutting-edge cooling technologies. As a result, the regulatory landscape not only ensures adherence to safety and environmental standards but also fosters innovation and technological advancement in turbine engine cooling efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!