Investigating Throttle Body Response in Variable Geometry Turbochargers

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VGT Throttle Body Evolution

The evolution of throttle bodies in Variable Geometry Turbochargers (VGTs) represents a significant advancement in engine technology. Initially, traditional fixed geometry turbochargers relied on simple throttle bodies to control airflow. However, as VGT technology emerged, the role and design of throttle bodies underwent substantial changes.

In the early stages of VGT development, throttle bodies remained relatively basic, primarily serving to regulate air intake. As engineers recognized the potential for improved engine performance through more precise airflow control, throttle body designs began to evolve. The integration of electronic control systems marked a crucial turning point, allowing for more dynamic and responsive throttle operation.

The advent of drive-by-wire technology in the late 1990s and early 2000s further revolutionized throttle body functionality in VGTs. This innovation replaced mechanical linkages with electronic sensors and actuators, enabling more precise control over airflow and better communication with the engine management system. This integration allowed for real-time adjustments based on various engine parameters, significantly enhancing overall turbocharger performance.

As materials science progressed, throttle body construction saw improvements in durability and efficiency. The use of lightweight alloys and advanced polymers reduced overall weight while improving heat resistance and reducing friction. These advancements contributed to more responsive throttle action and better overall system reliability.

The introduction of multi-stage throttle bodies marked another milestone in VGT throttle evolution. These designs incorporated multiple butterflies or valves within a single housing, allowing for more nuanced airflow control across different engine operating conditions. This innovation proved particularly beneficial in optimizing VGT performance across a broader range of engine speeds and loads.

Recent years have seen the development of adaptive throttle bodies specifically designed for VGT applications. These advanced units incorporate sophisticated sensors and algorithms to continuously optimize airflow based on real-time turbocharger performance data. This level of integration between the throttle body and VGT system has led to significant improvements in engine responsiveness, fuel efficiency, and emissions control.

Looking forward, the evolution of VGT throttle bodies is likely to continue, with a focus on even greater precision and integration with other engine systems. Emerging technologies such as 3D-printed components and advanced materials may further enhance throttle body performance and customization capabilities for specific VGT applications.

In the early stages of VGT development, throttle bodies remained relatively basic, primarily serving to regulate air intake. As engineers recognized the potential for improved engine performance through more precise airflow control, throttle body designs began to evolve. The integration of electronic control systems marked a crucial turning point, allowing for more dynamic and responsive throttle operation.

The advent of drive-by-wire technology in the late 1990s and early 2000s further revolutionized throttle body functionality in VGTs. This innovation replaced mechanical linkages with electronic sensors and actuators, enabling more precise control over airflow and better communication with the engine management system. This integration allowed for real-time adjustments based on various engine parameters, significantly enhancing overall turbocharger performance.

As materials science progressed, throttle body construction saw improvements in durability and efficiency. The use of lightweight alloys and advanced polymers reduced overall weight while improving heat resistance and reducing friction. These advancements contributed to more responsive throttle action and better overall system reliability.

The introduction of multi-stage throttle bodies marked another milestone in VGT throttle evolution. These designs incorporated multiple butterflies or valves within a single housing, allowing for more nuanced airflow control across different engine operating conditions. This innovation proved particularly beneficial in optimizing VGT performance across a broader range of engine speeds and loads.

Recent years have seen the development of adaptive throttle bodies specifically designed for VGT applications. These advanced units incorporate sophisticated sensors and algorithms to continuously optimize airflow based on real-time turbocharger performance data. This level of integration between the throttle body and VGT system has led to significant improvements in engine responsiveness, fuel efficiency, and emissions control.

Looking forward, the evolution of VGT throttle bodies is likely to continue, with a focus on even greater precision and integration with other engine systems. Emerging technologies such as 3D-printed components and advanced materials may further enhance throttle body performance and customization capabilities for specific VGT applications.

Market Demand Analysis

The market demand for variable geometry turbochargers (VGTs) with advanced throttle body response capabilities has been steadily increasing in recent years. This growth is primarily driven by the automotive industry's push towards more efficient and environmentally friendly vehicles. As emission regulations become stricter worldwide, automakers are seeking innovative solutions to improve engine performance while reducing fuel consumption and emissions.

The global VGT market is expected to experience significant growth in the coming years. This expansion is fueled by the rising adoption of turbocharged engines in passenger cars and commercial vehicles. The demand for VGTs is particularly strong in regions with stringent emission norms, such as Europe and North America. Additionally, emerging markets like China and India are showing increased interest in VGT technology as they strive to meet more stringent environmental standards.

One of the key factors driving market demand is the ability of VGTs with improved throttle body response to enhance engine performance across a wide range of operating conditions. This technology allows for better low-end torque, reduced turbo lag, and improved overall engine efficiency. As a result, vehicle manufacturers are increasingly incorporating VGTs into their powertrains to meet both performance and efficiency targets.

The commercial vehicle sector represents a significant portion of the VGT market. Heavy-duty trucks and buses require robust turbocharging solutions to meet stringent emission standards while maintaining power output. The improved throttle body response in VGTs helps these vehicles achieve better fuel economy and reduced emissions, making them attractive to fleet operators looking to minimize operating costs and environmental impact.

In the passenger car segment, there is a growing trend towards downsized engines with turbocharging. This shift is driven by the need for improved fuel efficiency without compromising performance. VGTs with enhanced throttle body response play a crucial role in this strategy, allowing smaller engines to deliver power comparable to larger naturally aspirated units while consuming less fuel.

The aftermarket for VGTs is also experiencing growth, as vehicle owners seek to upgrade their existing turbocharged engines for better performance and efficiency. This trend is particularly evident in the performance and tuning markets, where enthusiasts are willing to invest in advanced turbocharging solutions.

As the automotive industry continues to evolve towards electrification, the demand for VGTs is expected to remain strong in the medium term. Hybrid powertrains, which combine internal combustion engines with electric motors, often utilize turbocharging technology to optimize the performance of the combustion engine. This hybrid application presents a new market opportunity for VGT manufacturers, especially as the industry transitions towards full electrification.

The global VGT market is expected to experience significant growth in the coming years. This expansion is fueled by the rising adoption of turbocharged engines in passenger cars and commercial vehicles. The demand for VGTs is particularly strong in regions with stringent emission norms, such as Europe and North America. Additionally, emerging markets like China and India are showing increased interest in VGT technology as they strive to meet more stringent environmental standards.

One of the key factors driving market demand is the ability of VGTs with improved throttle body response to enhance engine performance across a wide range of operating conditions. This technology allows for better low-end torque, reduced turbo lag, and improved overall engine efficiency. As a result, vehicle manufacturers are increasingly incorporating VGTs into their powertrains to meet both performance and efficiency targets.

The commercial vehicle sector represents a significant portion of the VGT market. Heavy-duty trucks and buses require robust turbocharging solutions to meet stringent emission standards while maintaining power output. The improved throttle body response in VGTs helps these vehicles achieve better fuel economy and reduced emissions, making them attractive to fleet operators looking to minimize operating costs and environmental impact.

In the passenger car segment, there is a growing trend towards downsized engines with turbocharging. This shift is driven by the need for improved fuel efficiency without compromising performance. VGTs with enhanced throttle body response play a crucial role in this strategy, allowing smaller engines to deliver power comparable to larger naturally aspirated units while consuming less fuel.

The aftermarket for VGTs is also experiencing growth, as vehicle owners seek to upgrade their existing turbocharged engines for better performance and efficiency. This trend is particularly evident in the performance and tuning markets, where enthusiasts are willing to invest in advanced turbocharging solutions.

As the automotive industry continues to evolve towards electrification, the demand for VGTs is expected to remain strong in the medium term. Hybrid powertrains, which combine internal combustion engines with electric motors, often utilize turbocharging technology to optimize the performance of the combustion engine. This hybrid application presents a new market opportunity for VGT manufacturers, especially as the industry transitions towards full electrification.

Technical Challenges

Variable Geometry Turbochargers (VGTs) represent a significant advancement in turbocharging technology, offering improved engine performance and efficiency. However, the integration of throttle body control with VGTs presents several technical challenges that require careful consideration and innovative solutions.

One of the primary challenges lies in the complex interaction between the throttle body and the variable geometry mechanism of the turbocharger. The throttle body's response must be precisely coordinated with the adjustments in the turbocharger's geometry to maintain optimal airflow and pressure throughout the engine's operating range. This coordination becomes particularly challenging during rapid transient conditions, such as sudden acceleration or deceleration.

The response time of the throttle body is a critical factor that impacts the overall system performance. Traditional throttle bodies may not be sufficiently responsive to match the rapid adjustments possible in VGTs. Engineers must develop faster-acting throttle mechanisms or implement predictive control algorithms to anticipate and compensate for any lag in throttle response.

Another significant challenge is the development of robust control systems that can effectively manage the interplay between the throttle body and the VGT. These systems must account for a wide range of operating conditions, including variations in altitude, temperature, and engine load. The control algorithms need to be sophisticated enough to optimize performance while maintaining stability and preventing issues such as compressor surge or excessive backpressure.

The integration of electronic control units (ECUs) capable of handling the complex calculations and rapid adjustments required for VGT and throttle body coordination presents its own set of challenges. These ECUs must process data from multiple sensors, make real-time decisions, and execute precise commands to both the throttle body and the VGT actuators. The development of such advanced ECUs requires significant computational power and highly optimized software.

Durability and reliability are also major concerns in the development of throttle body systems for VGTs. The components must withstand high temperatures, rapid pressure changes, and potential contamination from exhaust gases. Engineers must design robust mechanisms and select materials that can maintain consistent performance over the vehicle's lifetime.

Furthermore, the cost-effectiveness of implementing advanced throttle body systems in VGTs is a significant challenge. While the technology offers performance benefits, it must be balanced against manufacturing costs to ensure commercial viability. This often requires innovative design approaches and material choices to achieve the desired performance at an acceptable price point.

One of the primary challenges lies in the complex interaction between the throttle body and the variable geometry mechanism of the turbocharger. The throttle body's response must be precisely coordinated with the adjustments in the turbocharger's geometry to maintain optimal airflow and pressure throughout the engine's operating range. This coordination becomes particularly challenging during rapid transient conditions, such as sudden acceleration or deceleration.

The response time of the throttle body is a critical factor that impacts the overall system performance. Traditional throttle bodies may not be sufficiently responsive to match the rapid adjustments possible in VGTs. Engineers must develop faster-acting throttle mechanisms or implement predictive control algorithms to anticipate and compensate for any lag in throttle response.

Another significant challenge is the development of robust control systems that can effectively manage the interplay between the throttle body and the VGT. These systems must account for a wide range of operating conditions, including variations in altitude, temperature, and engine load. The control algorithms need to be sophisticated enough to optimize performance while maintaining stability and preventing issues such as compressor surge or excessive backpressure.

The integration of electronic control units (ECUs) capable of handling the complex calculations and rapid adjustments required for VGT and throttle body coordination presents its own set of challenges. These ECUs must process data from multiple sensors, make real-time decisions, and execute precise commands to both the throttle body and the VGT actuators. The development of such advanced ECUs requires significant computational power and highly optimized software.

Durability and reliability are also major concerns in the development of throttle body systems for VGTs. The components must withstand high temperatures, rapid pressure changes, and potential contamination from exhaust gases. Engineers must design robust mechanisms and select materials that can maintain consistent performance over the vehicle's lifetime.

Furthermore, the cost-effectiveness of implementing advanced throttle body systems in VGTs is a significant challenge. While the technology offers performance benefits, it must be balanced against manufacturing costs to ensure commercial viability. This often requires innovative design approaches and material choices to achieve the desired performance at an acceptable price point.

Current VGT Solutions

01 Variable geometry turbocharger design

Variable geometry turbochargers (VGTs) are designed to optimize engine performance across a wide range of operating conditions. They feature adjustable vanes or nozzles that can alter the flow of exhaust gases, allowing for better control of boost pressure and improved throttle response. This design helps to reduce turbo lag and enhance overall engine efficiency.- Variable geometry turbocharger design: Variable geometry turbochargers (VGTs) are designed to optimize engine performance across a wide range of operating conditions. They feature adjustable vanes or nozzles that can alter the flow of exhaust gases, allowing for better control of boost pressure and improved throttle response. This design helps to reduce turbo lag and enhance overall engine efficiency.

- Integration with electronic throttle control: The integration of VGTs with electronic throttle control systems allows for more precise management of airflow and boost pressure. This combination enables faster throttle response and better coordination between the turbocharger and engine management system, resulting in improved drivability and performance across various engine speeds and loads.

- Boost pressure control strategies: Advanced control strategies are employed to optimize boost pressure in VGT systems. These strategies may involve predictive algorithms, real-time sensor data, and adaptive learning to anticipate and respond to changes in engine demand. By fine-tuning boost pressure, the system can enhance throttle response while maintaining efficiency and emissions compliance.

- Turbocharger bypass and wastegate systems: VGT systems often incorporate bypass or wastegate mechanisms to regulate exhaust gas flow and prevent over-boosting. These systems can be electronically controlled to work in conjunction with the variable geometry components, allowing for rapid adjustments to throttle inputs and changing engine conditions. This coordination helps to maintain optimal throttle response across the engine's operating range.

- Sensor and actuator technology: Advanced sensors and actuators play a crucial role in VGT throttle body response. High-precision sensors monitor various parameters such as intake air temperature, pressure, and mass airflow. Fast-acting actuators adjust the turbocharger geometry and throttle position in real-time. The integration of these components with sophisticated control algorithms enables rapid and accurate responses to driver inputs and changing engine conditions.

02 Integration with electronic throttle control

The integration of VGTs with electronic throttle control systems allows for more precise management of airflow and boost pressure. This combination enables faster throttle response and better coordination between the turbocharger and engine management system, resulting in improved overall performance and drivability.Expand Specific Solutions03 Adaptive control algorithms

Advanced control algorithms are employed to optimize the operation of VGTs in real-time. These algorithms take into account various engine parameters, such as speed, load, and exhaust gas temperature, to adjust the turbocharger geometry and throttle position for optimal performance and efficiency across different driving conditions.Expand Specific Solutions04 Turbocharger bypass systems

Bypass systems are incorporated into VGT designs to manage exhaust gas flow and pressure. These systems can help improve throttle response by allowing excess exhaust gases to bypass the turbine under certain conditions, reducing backpressure and enhancing engine responsiveness.Expand Specific Solutions05 Sensor integration and feedback control

VGT systems incorporate various sensors to monitor engine and turbocharger performance. These sensors provide real-time data on parameters such as boost pressure, exhaust gas temperature, and mass airflow. The feedback from these sensors is used to continuously adjust the turbocharger geometry and throttle position, ensuring optimal response and performance.Expand Specific Solutions

Key Industry Players

The investigation of throttle body response in variable geometry turbochargers is at a mature stage of development, with significant market growth and technological advancements. The global market for variable geometry turbochargers is expanding rapidly, driven by increasing demand for fuel-efficient vehicles and stringent emission regulations. Key players like BorgWarner, Honeywell, and Garrett Motion are leading the technological innovation in this field, with a focus on improving throttle response and overall engine performance. These companies, along with automotive giants such as Toyota, Ford, and Hyundai, are investing heavily in research and development to enhance turbocharger efficiency and responsiveness, indicating a highly competitive and evolving market landscape.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an advanced Variable Geometry Turbocharger (VGT) system with integrated electronic throttle control. This system utilizes a high-precision actuator to dynamically adjust the turbine geometry and throttle position based on real-time engine data. The VGT incorporates a dual-wall turbine housing design that improves thermal management and reduces lag[1]. Honeywell's solution also features a proprietary vane design that optimizes airflow across a wide range of engine speeds, enhancing both low-end torque and high-end power[3]. The system's electronic control unit (ECU) employs predictive algorithms to anticipate throttle demand, further improving response times and overall engine efficiency[5].

Strengths: Industry-leading actuator precision, advanced thermal management, and predictive control algorithms. Weaknesses: Potentially higher cost due to complex components and may require more frequent maintenance.

BorgWarner, Inc.

Technical Solution: BorgWarner's approach to improving throttle body response in VGTs involves their patented dual-volute turbine technology. This design separates the exhaust flow into two channels, allowing for better pulse energy utilization and improved low-end torque[2]. The company has also developed a rapid-response electronic actuator that can adjust vane positions in milliseconds, significantly reducing turbo lag[4]. BorgWarner's system integrates with the engine's ECU to optimize throttle mapping based on various parameters such as altitude, temperature, and driving conditions. Additionally, they have implemented a low-inertia turbine wheel design that further enhances responsiveness across the entire RPM range[6].

Strengths: Dual-volute technology for improved low-end performance, rapid-response actuators, and comprehensive ECU integration. Weaknesses: Complexity of the dual-volute system may lead to higher manufacturing costs.

Core VGT Innovations

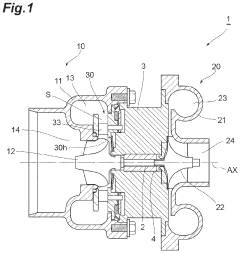

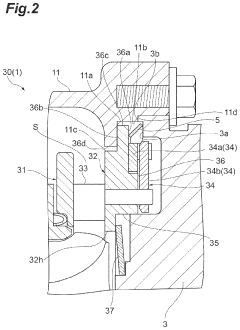

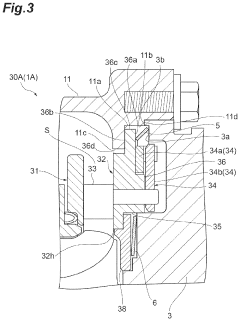

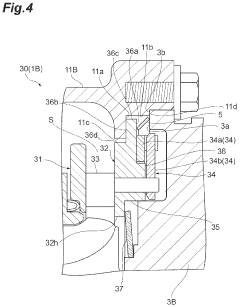

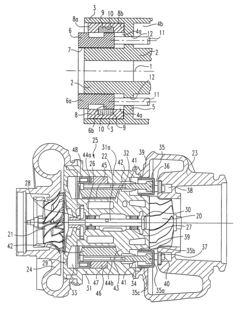

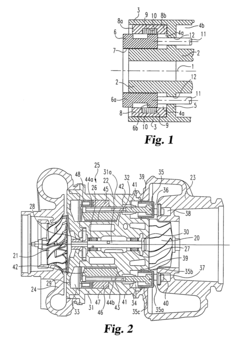

Turbocharger with variable geometric fluid guide mechanism

PatentActiveUS20230287798A1

Innovation

- The turbocharger design incorporates a spring member held by the variable geometry mechanism and the bearing housing, with a specific configuration that includes an outer circumferential portion contacting the spring member and a second end face pressing against the turbine housing, distributing the pressing force to reduce bending stress and allow for linear expansion, thereby enhancing reliability.

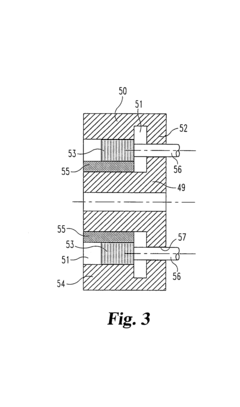

Variable geometry turbine

PatentInactiveUS7140849B2

Innovation

- A tubular linear electric motor is integrated within the turbocharger's bearing housing, featuring a fixed annular stator ring and an axially movable forcer ring, which directly actuates the variable geometry mechanism, improving positional accuracy and controllability by reducing backlash and hysteresis.

Emissions Regulations Impact

Emissions regulations have become increasingly stringent worldwide, significantly impacting the development and implementation of variable geometry turbochargers (VGTs) and throttle body technologies in automotive applications. These regulations aim to reduce harmful emissions, particularly nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2), which are major contributors to air pollution and climate change.

The introduction of Euro 6 standards in Europe and similar regulations in other regions has pushed manufacturers to adopt more advanced technologies to meet these strict requirements. VGTs play a crucial role in this context, as they offer improved engine efficiency and reduced emissions across a wide range of operating conditions. The ability to adjust turbocharger geometry allows for optimized air flow and pressure, resulting in better combustion control and reduced emissions.

Throttle body response in VGTs has become a critical area of focus due to its direct impact on emissions performance. Precise control of air intake is essential for maintaining the ideal air-fuel ratio, which is crucial for minimizing emissions while maximizing engine efficiency. As regulations tighten, manufacturers are investing heavily in research and development to improve throttle body response times and accuracy.

The implementation of real-world driving emissions (RDE) tests has further emphasized the importance of throttle body response in VGTs. These tests require vehicles to perform efficiently and maintain low emissions under various driving conditions, not just in laboratory settings. This has led to the development of more sophisticated control algorithms and sensor technologies to ensure optimal throttle body operation across diverse scenarios.

Emissions regulations have also driven the integration of VGTs with other emission control technologies, such as exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR). This integration requires careful coordination of throttle body response to maintain the delicate balance between performance and emissions reduction. As a result, advanced control systems and software have become increasingly important in managing these complex interactions.

The push for electrification and hybrid powertrains has introduced new challenges and opportunities for VGT and throttle body technologies. While fully electric vehicles do not require traditional turbochargers, hybrid systems often incorporate advanced turbocharging solutions to maximize efficiency and reduce emissions during combustion engine operation. This has led to the development of electric-assisted turbochargers and more responsive throttle bodies to meet the unique demands of hybrid powertrains.

Looking ahead, upcoming emissions regulations, such as Euro 7, are expected to further tighten restrictions on vehicle emissions. This will likely drive continued innovation in VGT and throttle body technologies, with a focus on even faster response times, greater precision, and improved durability to meet these challenging standards while maintaining vehicle performance and efficiency.

The introduction of Euro 6 standards in Europe and similar regulations in other regions has pushed manufacturers to adopt more advanced technologies to meet these strict requirements. VGTs play a crucial role in this context, as they offer improved engine efficiency and reduced emissions across a wide range of operating conditions. The ability to adjust turbocharger geometry allows for optimized air flow and pressure, resulting in better combustion control and reduced emissions.

Throttle body response in VGTs has become a critical area of focus due to its direct impact on emissions performance. Precise control of air intake is essential for maintaining the ideal air-fuel ratio, which is crucial for minimizing emissions while maximizing engine efficiency. As regulations tighten, manufacturers are investing heavily in research and development to improve throttle body response times and accuracy.

The implementation of real-world driving emissions (RDE) tests has further emphasized the importance of throttle body response in VGTs. These tests require vehicles to perform efficiently and maintain low emissions under various driving conditions, not just in laboratory settings. This has led to the development of more sophisticated control algorithms and sensor technologies to ensure optimal throttle body operation across diverse scenarios.

Emissions regulations have also driven the integration of VGTs with other emission control technologies, such as exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR). This integration requires careful coordination of throttle body response to maintain the delicate balance between performance and emissions reduction. As a result, advanced control systems and software have become increasingly important in managing these complex interactions.

The push for electrification and hybrid powertrains has introduced new challenges and opportunities for VGT and throttle body technologies. While fully electric vehicles do not require traditional turbochargers, hybrid systems often incorporate advanced turbocharging solutions to maximize efficiency and reduce emissions during combustion engine operation. This has led to the development of electric-assisted turbochargers and more responsive throttle bodies to meet the unique demands of hybrid powertrains.

Looking ahead, upcoming emissions regulations, such as Euro 7, are expected to further tighten restrictions on vehicle emissions. This will likely drive continued innovation in VGT and throttle body technologies, with a focus on even faster response times, greater precision, and improved durability to meet these challenging standards while maintaining vehicle performance and efficiency.

VGT Performance Metrics

Variable Geometry Turbocharger (VGT) performance metrics are crucial for evaluating the effectiveness and efficiency of these advanced turbocharging systems. These metrics provide quantitative measures to assess how well a VGT responds to varying engine conditions and throttle inputs. One of the primary performance indicators is boost pressure response time, which measures how quickly the turbocharger can increase intake air pressure following a sudden increase in throttle demand. This metric is typically expressed in milliseconds and is critical for reducing turbo lag and improving overall engine responsiveness.

Another key metric is boost pressure stability, which evaluates the turbocharger's ability to maintain consistent boost pressure across different engine speeds and loads. This is particularly important for ensuring smooth power delivery and preventing sudden fluctuations in engine performance. The boost pressure range is also a significant metric, indicating the turbocharger's capability to provide adequate boost across a wide spectrum of engine operating conditions.

Fuel efficiency improvement is a crucial performance metric for VGTs, as one of their primary advantages is the potential for better fuel economy compared to fixed geometry turbochargers. This metric is typically measured as a percentage reduction in fuel consumption under standardized test conditions. Similarly, emissions reduction is an essential performance indicator, particularly in the context of increasingly stringent environmental regulations. VGTs are evaluated based on their ability to reduce NOx emissions and particulate matter, often quantified as a percentage reduction compared to baseline engine configurations.

Turbocharger efficiency is another critical metric, encompassing both compressor and turbine efficiencies. This is usually expressed as a percentage and indicates how effectively the turbocharger converts exhaust energy into intake air compression. A higher efficiency translates to better overall engine performance and fuel economy. The operating range of the VGT is also a key performance metric, defining the span of engine speeds and loads over which the turbocharger can effectively operate.

Durability and reliability metrics are equally important, although these are typically assessed over longer periods. These include factors such as thermal cycling resistance, wear resistance of moving components, and overall system lifespan under various operating conditions. Additionally, noise, vibration, and harshness (NVH) metrics are becoming increasingly relevant, as they impact the overall driving experience and perceived quality of the vehicle.

Finally, control system responsiveness is a critical performance metric specific to VGTs. This evaluates how quickly and accurately the turbocharger's geometry can be adjusted in response to changing engine conditions and driver inputs. It is typically measured in terms of actuation speed and precision, and plays a significant role in optimizing overall system performance across various driving scenarios.

Another key metric is boost pressure stability, which evaluates the turbocharger's ability to maintain consistent boost pressure across different engine speeds and loads. This is particularly important for ensuring smooth power delivery and preventing sudden fluctuations in engine performance. The boost pressure range is also a significant metric, indicating the turbocharger's capability to provide adequate boost across a wide spectrum of engine operating conditions.

Fuel efficiency improvement is a crucial performance metric for VGTs, as one of their primary advantages is the potential for better fuel economy compared to fixed geometry turbochargers. This metric is typically measured as a percentage reduction in fuel consumption under standardized test conditions. Similarly, emissions reduction is an essential performance indicator, particularly in the context of increasingly stringent environmental regulations. VGTs are evaluated based on their ability to reduce NOx emissions and particulate matter, often quantified as a percentage reduction compared to baseline engine configurations.

Turbocharger efficiency is another critical metric, encompassing both compressor and turbine efficiencies. This is usually expressed as a percentage and indicates how effectively the turbocharger converts exhaust energy into intake air compression. A higher efficiency translates to better overall engine performance and fuel economy. The operating range of the VGT is also a key performance metric, defining the span of engine speeds and loads over which the turbocharger can effectively operate.

Durability and reliability metrics are equally important, although these are typically assessed over longer periods. These include factors such as thermal cycling resistance, wear resistance of moving components, and overall system lifespan under various operating conditions. Additionally, noise, vibration, and harshness (NVH) metrics are becoming increasingly relevant, as they impact the overall driving experience and perceived quality of the vehicle.

Finally, control system responsiveness is a critical performance metric specific to VGTs. This evaluates how quickly and accurately the turbocharger's geometry can be adjusted in response to changing engine conditions and driver inputs. It is typically measured in terms of actuation speed and precision, and plays a significant role in optimizing overall system performance across various driving scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!