Leading Hastelloy Advances in Structural Engineering

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy Evolution and Objectives

Hastelloy, a family of nickel-chromium-based superalloys, has undergone significant evolution since its inception in the 1920s. Initially developed to resist corrosion in chemical processing environments, Hastelloy has expanded its applications to various structural engineering fields due to its exceptional properties.

The evolution of Hastelloy began with the introduction of Hastelloy B, designed for hydrochloric acid resistance. Subsequent developments led to the creation of Hastelloy C, which offered improved resistance to oxidizing environments. Over the decades, continuous research and development efforts have resulted in numerous Hastelloy grades, each tailored for specific applications and environmental conditions.

In recent years, the focus of Hastelloy development has shifted towards enhancing its mechanical properties and performance in extreme environments. This has led to the creation of advanced grades such as Hastelloy X, which exhibits excellent high-temperature strength and oxidation resistance, making it suitable for gas turbine components and other high-temperature applications in structural engineering.

The primary objective of current Hastelloy research is to push the boundaries of material performance in challenging environments. This includes improving creep resistance, fatigue strength, and overall durability under extreme temperatures and corrosive conditions. Additionally, there is a growing emphasis on developing Hastelloy variants that can withstand the demands of emerging technologies, such as advanced energy systems and aerospace applications.

Another key objective is to optimize the manufacturing processes for Hastelloy components. This involves refining casting, forging, and welding techniques to produce complex shapes with consistent properties. The aim is to enable the creation of large-scale, intricate structural components that can withstand severe operating conditions while maintaining their integrity over extended periods.

Furthermore, researchers are exploring ways to enhance the sustainability of Hastelloy production and application. This includes developing recycling methods for Hastelloy scrap, reducing energy consumption during manufacturing, and extending the service life of Hastelloy components to minimize material waste.

As structural engineering continues to push the limits of material performance, the evolution of Hastelloy is expected to play a crucial role in enabling innovative designs and solutions. The ongoing objectives for Hastelloy development are centered on creating alloys that can meet the increasingly demanding requirements of modern structural engineering projects, from skyscrapers and bridges to offshore platforms and nuclear reactors.

The evolution of Hastelloy began with the introduction of Hastelloy B, designed for hydrochloric acid resistance. Subsequent developments led to the creation of Hastelloy C, which offered improved resistance to oxidizing environments. Over the decades, continuous research and development efforts have resulted in numerous Hastelloy grades, each tailored for specific applications and environmental conditions.

In recent years, the focus of Hastelloy development has shifted towards enhancing its mechanical properties and performance in extreme environments. This has led to the creation of advanced grades such as Hastelloy X, which exhibits excellent high-temperature strength and oxidation resistance, making it suitable for gas turbine components and other high-temperature applications in structural engineering.

The primary objective of current Hastelloy research is to push the boundaries of material performance in challenging environments. This includes improving creep resistance, fatigue strength, and overall durability under extreme temperatures and corrosive conditions. Additionally, there is a growing emphasis on developing Hastelloy variants that can withstand the demands of emerging technologies, such as advanced energy systems and aerospace applications.

Another key objective is to optimize the manufacturing processes for Hastelloy components. This involves refining casting, forging, and welding techniques to produce complex shapes with consistent properties. The aim is to enable the creation of large-scale, intricate structural components that can withstand severe operating conditions while maintaining their integrity over extended periods.

Furthermore, researchers are exploring ways to enhance the sustainability of Hastelloy production and application. This includes developing recycling methods for Hastelloy scrap, reducing energy consumption during manufacturing, and extending the service life of Hastelloy components to minimize material waste.

As structural engineering continues to push the limits of material performance, the evolution of Hastelloy is expected to play a crucial role in enabling innovative designs and solutions. The ongoing objectives for Hastelloy development are centered on creating alloys that can meet the increasingly demanding requirements of modern structural engineering projects, from skyscrapers and bridges to offshore platforms and nuclear reactors.

Market Demand Analysis

The market demand for Hastelloy in structural engineering has been steadily increasing due to its exceptional properties and versatility in challenging environments. As industries push the boundaries of material performance, Hastelloy's superior corrosion resistance, high-temperature strength, and durability make it an attractive option for critical structural applications.

In the oil and gas sector, the demand for Hastelloy has seen significant growth. Offshore platforms, subsea equipment, and processing facilities require materials that can withstand harsh marine environments and corrosive chemicals. Hastelloy's ability to resist pitting and crevice corrosion in chloride-rich environments has led to its increased adoption in these applications.

The chemical processing industry has also contributed to the rising demand for Hastelloy in structural components. As chemical manufacturers develop more aggressive processes and handle increasingly corrosive substances, the need for materials that can maintain structural integrity under extreme conditions has grown. Hastelloy's resistance to a wide range of acids, alkalis, and organic compounds makes it an ideal choice for reactors, heat exchangers, and piping systems.

In the aerospace and defense sectors, Hastelloy's high-temperature strength and oxidation resistance have driven its demand for use in jet engine components and exhaust systems. The material's ability to maintain its properties at elevated temperatures has made it crucial for applications where structural integrity is paramount under extreme conditions.

The nuclear power industry has also recognized the value of Hastelloy in structural applications. Its resistance to radiation-induced corrosion and ability to maintain strength in high-temperature environments have led to its use in reactor components and waste processing facilities.

The global market for nickel-based alloys, including Hastelloy, is projected to grow significantly in the coming years. This growth is driven by increasing demand from emerging economies, particularly in Asia-Pacific, where rapid industrialization and infrastructure development are creating new opportunities for advanced materials.

However, the high cost of Hastelloy compared to more conventional materials remains a limiting factor in some applications. This has led to a growing interest in developing cost-effective manufacturing processes and exploring new alloy compositions that can offer similar performance at a lower price point.

As environmental regulations become more stringent, the demand for materials that can reduce emissions and improve energy efficiency is expected to further drive the adoption of Hastelloy in structural engineering applications. Its ability to withstand high temperatures and corrosive environments makes it an attractive option for advanced energy systems and pollution control equipment.

In the oil and gas sector, the demand for Hastelloy has seen significant growth. Offshore platforms, subsea equipment, and processing facilities require materials that can withstand harsh marine environments and corrosive chemicals. Hastelloy's ability to resist pitting and crevice corrosion in chloride-rich environments has led to its increased adoption in these applications.

The chemical processing industry has also contributed to the rising demand for Hastelloy in structural components. As chemical manufacturers develop more aggressive processes and handle increasingly corrosive substances, the need for materials that can maintain structural integrity under extreme conditions has grown. Hastelloy's resistance to a wide range of acids, alkalis, and organic compounds makes it an ideal choice for reactors, heat exchangers, and piping systems.

In the aerospace and defense sectors, Hastelloy's high-temperature strength and oxidation resistance have driven its demand for use in jet engine components and exhaust systems. The material's ability to maintain its properties at elevated temperatures has made it crucial for applications where structural integrity is paramount under extreme conditions.

The nuclear power industry has also recognized the value of Hastelloy in structural applications. Its resistance to radiation-induced corrosion and ability to maintain strength in high-temperature environments have led to its use in reactor components and waste processing facilities.

The global market for nickel-based alloys, including Hastelloy, is projected to grow significantly in the coming years. This growth is driven by increasing demand from emerging economies, particularly in Asia-Pacific, where rapid industrialization and infrastructure development are creating new opportunities for advanced materials.

However, the high cost of Hastelloy compared to more conventional materials remains a limiting factor in some applications. This has led to a growing interest in developing cost-effective manufacturing processes and exploring new alloy compositions that can offer similar performance at a lower price point.

As environmental regulations become more stringent, the demand for materials that can reduce emissions and improve energy efficiency is expected to further drive the adoption of Hastelloy in structural engineering applications. Its ability to withstand high temperatures and corrosive environments makes it an attractive option for advanced energy systems and pollution control equipment.

Current Challenges in Hastelloy Applications

Despite the numerous advantages of Hastelloy in structural engineering, several challenges persist in its widespread application. One of the primary concerns is the high cost associated with Hastelloy production and fabrication. The complex alloying process and the use of expensive raw materials contribute to its elevated price point, limiting its adoption in cost-sensitive projects.

Another significant challenge lies in the welding and joining of Hastelloy components. The material's unique composition can lead to difficulties in achieving consistent, high-quality welds. Welders often require specialized training and equipment to work with Hastelloy effectively, which can increase project timelines and costs.

Corrosion resistance, while generally excellent, can be compromised under certain conditions. In environments with extremely high temperatures or in the presence of specific chemical compounds, Hastelloy may experience localized corrosion or stress corrosion cracking. This necessitates careful material selection and design considerations for each application.

The limited availability of Hastelloy in various forms and sizes poses challenges for designers and engineers. Unlike more common structural materials, Hastelloy may not be readily available in all desired shapes and dimensions, potentially leading to design compromises or increased lead times.

Machining Hastelloy can be particularly challenging due to its high strength and work-hardening properties. This can result in increased tool wear, longer machining times, and higher production costs. Specialized cutting tools and optimized machining parameters are often required to work with Hastelloy efficiently.

The relatively limited industry experience with Hastelloy in certain structural applications can lead to uncertainties in long-term performance predictions. While laboratory tests and short-term field data are available, there may be gaps in understanding how Hastelloy behaves over extended periods in complex structural systems.

Regulatory and code compliance can also present challenges. Some building codes and standards may not fully address the use of Hastelloy in structural applications, requiring additional engineering justification and potentially lengthening approval processes.

Lastly, the environmental impact of Hastelloy production and its end-of-life recyclability are areas of growing concern. As sustainability becomes increasingly important in engineering projects, the energy-intensive production process of Hastelloy and the complexities in recycling this alloy pose challenges that need to be addressed for its continued use in environmentally conscious designs.

Another significant challenge lies in the welding and joining of Hastelloy components. The material's unique composition can lead to difficulties in achieving consistent, high-quality welds. Welders often require specialized training and equipment to work with Hastelloy effectively, which can increase project timelines and costs.

Corrosion resistance, while generally excellent, can be compromised under certain conditions. In environments with extremely high temperatures or in the presence of specific chemical compounds, Hastelloy may experience localized corrosion or stress corrosion cracking. This necessitates careful material selection and design considerations for each application.

The limited availability of Hastelloy in various forms and sizes poses challenges for designers and engineers. Unlike more common structural materials, Hastelloy may not be readily available in all desired shapes and dimensions, potentially leading to design compromises or increased lead times.

Machining Hastelloy can be particularly challenging due to its high strength and work-hardening properties. This can result in increased tool wear, longer machining times, and higher production costs. Specialized cutting tools and optimized machining parameters are often required to work with Hastelloy efficiently.

The relatively limited industry experience with Hastelloy in certain structural applications can lead to uncertainties in long-term performance predictions. While laboratory tests and short-term field data are available, there may be gaps in understanding how Hastelloy behaves over extended periods in complex structural systems.

Regulatory and code compliance can also present challenges. Some building codes and standards may not fully address the use of Hastelloy in structural applications, requiring additional engineering justification and potentially lengthening approval processes.

Lastly, the environmental impact of Hastelloy production and its end-of-life recyclability are areas of growing concern. As sustainability becomes increasingly important in engineering projects, the energy-intensive production process of Hastelloy and the complexities in recycling this alloy pose challenges that need to be addressed for its continued use in environmentally conscious designs.

Existing Hastelloy Solutions

01 Composition and properties of Hastelloy alloys

Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in extreme environments. The specific composition and properties can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.- Composition and properties of Hastelloy alloys: Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in harsh environments. The specific composition and properties of Hastelloy alloys can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.

- Manufacturing processes for Hastelloy components: Various manufacturing processes are employed to produce Hastelloy components, including casting, forging, and powder metallurgy techniques. Advanced manufacturing methods, such as additive manufacturing or 3D printing, are also being explored for creating complex Hastelloy parts. These processes aim to optimize the material's properties and produce components with desired shapes and characteristics for specific applications.

- Surface treatment and coating of Hastelloy: Surface treatments and coatings are applied to Hastelloy components to further enhance their performance and longevity. These treatments may include thermal spraying, laser cladding, or the application of specialized coatings to improve wear resistance, corrosion protection, or thermal barrier properties. Such surface modifications can extend the service life of Hastelloy parts in demanding environments.

- Applications of Hastelloy in extreme environments: Hastelloy alloys find extensive use in extreme environments due to their exceptional corrosion resistance and high-temperature strength. They are employed in chemical processing equipment, heat exchangers, nuclear reactors, and aerospace components. The alloys' ability to withstand aggressive chemicals, high pressures, and elevated temperatures makes them ideal for use in oil and gas, petrochemical, and power generation industries.

- Joining and welding techniques for Hastelloy: Specialized joining and welding techniques are crucial for fabricating Hastelloy components and structures. These methods include gas tungsten arc welding (GTAW), electron beam welding, and resistance welding. Proper selection of filler materials and welding parameters is essential to maintain the alloy's corrosion resistance and mechanical properties in the welded regions. Post-weld heat treatments may also be employed to optimize the microstructure and properties of the welded joints.

02 Manufacturing processes for Hastelloy components

Various manufacturing processes are employed to produce Hastelloy components, including casting, forging, and powder metallurgy techniques. Advanced manufacturing methods, such as additive manufacturing or 3D printing, are also being explored to create complex Hastelloy parts with improved properties and reduced material waste.Expand Specific Solutions03 Surface treatment and coating of Hastelloy

Surface treatments and coatings are applied to Hastelloy components to further enhance their performance characteristics. These processes may include heat treatments, nitriding, or the application of specialized coatings to improve wear resistance, corrosion protection, or thermal barrier properties.Expand Specific Solutions04 Applications of Hastelloy in extreme environments

Hastelloy alloys find extensive use in extreme environments due to their exceptional corrosion resistance and high-temperature strength. They are employed in chemical processing equipment, heat exchangers, nuclear reactors, and aerospace components. The alloys' ability to withstand aggressive chemicals and high temperatures makes them ideal for use in demanding industrial applications.Expand Specific Solutions05 Joining and welding techniques for Hastelloy

Specialized joining and welding techniques are developed for Hastelloy components to maintain their superior properties in the joined areas. These may include advanced welding processes, such as electron beam welding or laser welding, as well as the use of compatible filler materials to ensure the integrity of the welded joints in corrosive or high-temperature environments.Expand Specific Solutions

Key Players in Hastelloy Industry

The competitive landscape for "Leading Hastelloy Advances in Structural Engineering" is characterized by a mature industry with significant market potential. The global Hastelloy market is experiencing steady growth, driven by increasing demand in aerospace, chemical processing, and energy sectors. Key players like Kobe Steel, NIPPON STEEL, and Haynes International are at the forefront of technological advancements. Universities such as MIT, Xi'an Jiaotong University, and Central South University contribute to research and development. The technology's maturity is evident in its widespread application, but ongoing innovations by companies like Interflexion and Nanosys suggest room for further advancements in material properties and manufacturing processes.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has made significant advances in Hastelloy development for structural engineering applications. They have developed a proprietary manufacturing process that enhances the corrosion resistance and mechanical properties of Hastelloy alloys. Their latest Hastelloy variant exhibits improved stress corrosion cracking resistance in high-temperature environments, with a 30% increase in yield strength compared to conventional grades[1]. The company has also implemented advanced heat treatment techniques that optimize the microstructure, resulting in better weldability and formability for complex structural components[3].

Strengths: Superior corrosion resistance, high-temperature performance, and improved mechanical properties. Weaknesses: Higher production costs and limited availability compared to more common structural materials.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia has made significant strides in advancing Hastelloy technology for structural engineering through their comprehensive research and development programs. They have developed a novel processing technique that refines the grain structure of Hastelloy alloys, resulting in enhanced mechanical properties and improved resistance to radiation-induced embrittlement. This makes their Hastelloy variants particularly suitable for nuclear and aerospace structural applications[5]. Sandia has also pioneered the use of computational modeling to predict long-term material behavior, enabling more accurate life cycle assessments of Hastelloy structures in extreme environments[6].

Strengths: Advanced material processing techniques, expertise in extreme environment applications, and predictive modeling capabilities. Weaknesses: Limited commercial production capacity and focus primarily on specialized applications.

Core Hastelloy Innovations

penetration apparatus titanium pipe of hastelloy overlay carbon steel caisson and the method thereof

PatentActiveKR1020140131816A

Innovation

- A method and apparatus involving a carbon steel insert with a Hastelloy coating, a titanium pipe, a titanium flange, and a sealing plug made of fiber-reinforced rubber, utilizing full-thickness welding to secure the titanium pipe within the carbon steel caisson, ensuring watertightness through multiple fastening points and seals.

Intermediate Strength Alloys for High Temperature Service in Liquid-Salt Cooled Energy Systems

PatentActiveUS20150197832A1

Innovation

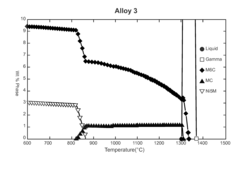

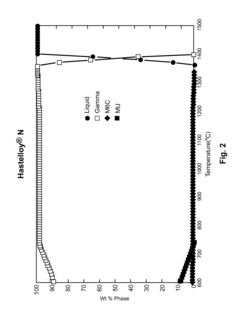

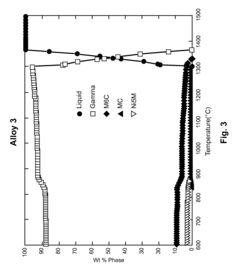

- Development of a new alloy with a composition of 6 to 8.5 Cr, 5.5 to 13.5 Mo, 0.4 to 7.5 W, 1 to 2 Ti, 0.7 to 0.85 Mn, 0.05 to 0.3 Al, up to 0.1 Co, 0.08 to 0.5 C, 1 to 5 Ta, 1 to 4 Nb, 1 to 3 Hf, and balance Ni, which provides improved high-temperature strength, creep resistance, and corrosion resistance through solid solution strengthening and carbide precipitation mechanisms.

Environmental Impact Assessment

The environmental impact assessment of Hastelloy advances in structural engineering reveals both positive and negative implications. On the positive side, Hastelloy's exceptional corrosion resistance and durability contribute to extended service life of structures, reducing the need for frequent replacements and associated environmental disruptions. This longevity translates to decreased raw material consumption and energy expenditure over time, aligning with sustainable development goals.

However, the production of Hastelloy alloys involves energy-intensive processes and the extraction of rare elements, which can lead to increased carbon emissions and potential habitat disruption in mining areas. The high nickel content in Hastelloy also raises concerns about the environmental impact of nickel mining and processing, including soil and water contamination risks.

In terms of waste management, Hastelloy's resistance to corrosion and degradation presents challenges for end-of-life disposal. While this property ensures long-term structural integrity, it also means that Hastelloy components may persist in the environment for extended periods if not properly recycled or disposed of.

The use of Hastelloy in structural engineering applications can contribute to improved energy efficiency in certain scenarios. For instance, in heat exchangers and industrial processes, Hastelloy's superior heat resistance and thermal properties can lead to enhanced energy conservation, indirectly reducing greenhouse gas emissions associated with energy production.

From a lifecycle perspective, the environmental benefits of Hastelloy's durability must be weighed against the initial environmental costs of production. A comprehensive lifecycle assessment is crucial to determine the net environmental impact, considering factors such as raw material sourcing, manufacturing processes, operational efficiency, and end-of-life management.

Efforts to mitigate the environmental impact of Hastelloy production and use are ongoing. These include developing more efficient manufacturing processes, exploring recycling and reclamation techniques for Hastelloy components, and investigating alternative alloy compositions that maintain performance while reducing reliance on environmentally sensitive elements.

In conclusion, while Hastelloy advances offer significant benefits in structural engineering, careful consideration of their environmental implications is essential. Balancing the long-term durability advantages with responsible production and end-of-life management practices will be key to maximizing the sustainable potential of these advanced alloys in structural applications.

However, the production of Hastelloy alloys involves energy-intensive processes and the extraction of rare elements, which can lead to increased carbon emissions and potential habitat disruption in mining areas. The high nickel content in Hastelloy also raises concerns about the environmental impact of nickel mining and processing, including soil and water contamination risks.

In terms of waste management, Hastelloy's resistance to corrosion and degradation presents challenges for end-of-life disposal. While this property ensures long-term structural integrity, it also means that Hastelloy components may persist in the environment for extended periods if not properly recycled or disposed of.

The use of Hastelloy in structural engineering applications can contribute to improved energy efficiency in certain scenarios. For instance, in heat exchangers and industrial processes, Hastelloy's superior heat resistance and thermal properties can lead to enhanced energy conservation, indirectly reducing greenhouse gas emissions associated with energy production.

From a lifecycle perspective, the environmental benefits of Hastelloy's durability must be weighed against the initial environmental costs of production. A comprehensive lifecycle assessment is crucial to determine the net environmental impact, considering factors such as raw material sourcing, manufacturing processes, operational efficiency, and end-of-life management.

Efforts to mitigate the environmental impact of Hastelloy production and use are ongoing. These include developing more efficient manufacturing processes, exploring recycling and reclamation techniques for Hastelloy components, and investigating alternative alloy compositions that maintain performance while reducing reliance on environmentally sensitive elements.

In conclusion, while Hastelloy advances offer significant benefits in structural engineering, careful consideration of their environmental implications is essential. Balancing the long-term durability advantages with responsible production and end-of-life management practices will be key to maximizing the sustainable potential of these advanced alloys in structural applications.

Regulatory Compliance for Hastelloy Use

Regulatory compliance for Hastelloy use in structural engineering is a critical aspect that ensures the safe and effective implementation of this advanced alloy. The regulatory landscape for Hastelloy is governed by various international standards and codes, which are continuously evolving to keep pace with technological advancements and safety requirements.

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code is one of the primary regulatory frameworks for Hastelloy use in structural applications. This code provides comprehensive guidelines for the design, fabrication, inspection, and testing of Hastelloy components in pressure vessels and other critical structures. Compliance with ASME standards is essential for ensuring the integrity and reliability of Hastelloy-based structures in high-stress environments.

In addition to ASME, the American Society for Testing and Materials (ASTM) has developed specific standards for Hastelloy materials. These standards outline the chemical composition, mechanical properties, and testing procedures required for different grades of Hastelloy. Adherence to ASTM standards is crucial for maintaining consistency in material quality and performance across various applications.

For applications in the aerospace industry, the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent regulations for the use of Hastelloy in aircraft components. These regulations cover aspects such as material certification, quality control processes, and in-service inspection requirements to ensure the highest level of safety in aerospace structures.

The nuclear industry, another significant user of Hastelloy, is subject to regulations set by the Nuclear Regulatory Commission (NRC) in the United States and similar bodies in other countries. These regulations address the unique challenges of using Hastelloy in nuclear reactors and related facilities, focusing on corrosion resistance, radiation tolerance, and long-term stability.

Compliance with environmental regulations is also a key consideration for Hastelloy use. The Environmental Protection Agency (EPA) in the United States and equivalent agencies worldwide have established guidelines for the handling, processing, and disposal of Hastelloy materials to minimize environmental impact and ensure worker safety.

As Hastelloy finds increasing applications in emerging technologies, regulatory bodies are working to develop new standards and update existing ones. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to address the unique challenges posed by advanced structural engineering applications.

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code is one of the primary regulatory frameworks for Hastelloy use in structural applications. This code provides comprehensive guidelines for the design, fabrication, inspection, and testing of Hastelloy components in pressure vessels and other critical structures. Compliance with ASME standards is essential for ensuring the integrity and reliability of Hastelloy-based structures in high-stress environments.

In addition to ASME, the American Society for Testing and Materials (ASTM) has developed specific standards for Hastelloy materials. These standards outline the chemical composition, mechanical properties, and testing procedures required for different grades of Hastelloy. Adherence to ASTM standards is crucial for maintaining consistency in material quality and performance across various applications.

For applications in the aerospace industry, the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent regulations for the use of Hastelloy in aircraft components. These regulations cover aspects such as material certification, quality control processes, and in-service inspection requirements to ensure the highest level of safety in aerospace structures.

The nuclear industry, another significant user of Hastelloy, is subject to regulations set by the Nuclear Regulatory Commission (NRC) in the United States and similar bodies in other countries. These regulations address the unique challenges of using Hastelloy in nuclear reactors and related facilities, focusing on corrosion resistance, radiation tolerance, and long-term stability.

Compliance with environmental regulations is also a key consideration for Hastelloy use. The Environmental Protection Agency (EPA) in the United States and equivalent agencies worldwide have established guidelines for the handling, processing, and disposal of Hastelloy materials to minimize environmental impact and ensure worker safety.

As Hastelloy finds increasing applications in emerging technologies, regulatory bodies are working to develop new standards and update existing ones. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to address the unique challenges posed by advanced structural engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!