LS3 Engine Valve Cover Gasket Replacement Guide

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Valve Cover Gasket Technology Background

The LS3 engine valve cover gasket technology has evolved significantly since the introduction of the LS engine family by General Motors in 1997. The original LS1 engine utilized basic cork and rubber composite gaskets that were prone to hardening and failure over time. As the LS platform evolved through the LS2 and eventually to the LS3 in 2008, gasket technology advanced considerably to address performance demands and reliability concerns.

The LS3 engine, a 6.2L V8 powerplant featured in vehicles like the Chevrolet Corvette C6 and Camaro SS, represented a significant step forward in GM's small-block evolution. The valve cover gasket technology for this engine was specifically engineered to withstand higher operating temperatures and increased crankcase pressure compared to its predecessors, reflecting the overall performance improvements of the LS3 design.

Modern LS3 valve cover gaskets utilize advanced elastomeric compounds, typically silicone-based or molded rubber materials, that provide superior sealing properties while maintaining flexibility throughout extreme temperature variations. This technological advancement addressed the common oil leakage issues experienced with earlier generation gaskets, which would harden and shrink over time due to heat cycling and oil exposure.

The manufacturing process for these gaskets has also evolved from simple die-cut designs to precision-molded components with integrated sealing features. Modern LS3 gaskets incorporate specific bead patterns and varying thickness profiles strategically designed to maintain proper compression across the entire sealing surface, even as the aluminum valve covers expand and contract during operation.

Material science advancements have played a crucial role in this evolution, with manufacturers developing specialized polymer blends that resist degradation from modern synthetic oils and maintain their elastic properties for extended service intervals. These materials typically incorporate PTFE (polytetrafluoroethylene) or similar fluoropolymer additives that enhance chemical resistance and reduce friction between the gasket and metal surfaces.

The engineering focus has shifted from simply preventing external leakage to also maintaining proper PCV (Positive Crankcase Ventilation) system function, which is critical for emissions compliance and engine longevity. Modern valve cover gaskets are designed with integrated grommets and passages that properly seal around PCV components while allowing controlled airflow.

Industry trends indicate continued development toward integrated gasket solutions that combine multiple sealing functions into single components, reducing part count and assembly complexity. Some aftermarket manufacturers have begun introducing reusable metallic-core gaskets with replaceable sealing elements, though OEM applications still predominantly utilize single-use molded designs optimized for specific engine applications.

The LS3 engine, a 6.2L V8 powerplant featured in vehicles like the Chevrolet Corvette C6 and Camaro SS, represented a significant step forward in GM's small-block evolution. The valve cover gasket technology for this engine was specifically engineered to withstand higher operating temperatures and increased crankcase pressure compared to its predecessors, reflecting the overall performance improvements of the LS3 design.

Modern LS3 valve cover gaskets utilize advanced elastomeric compounds, typically silicone-based or molded rubber materials, that provide superior sealing properties while maintaining flexibility throughout extreme temperature variations. This technological advancement addressed the common oil leakage issues experienced with earlier generation gaskets, which would harden and shrink over time due to heat cycling and oil exposure.

The manufacturing process for these gaskets has also evolved from simple die-cut designs to precision-molded components with integrated sealing features. Modern LS3 gaskets incorporate specific bead patterns and varying thickness profiles strategically designed to maintain proper compression across the entire sealing surface, even as the aluminum valve covers expand and contract during operation.

Material science advancements have played a crucial role in this evolution, with manufacturers developing specialized polymer blends that resist degradation from modern synthetic oils and maintain their elastic properties for extended service intervals. These materials typically incorporate PTFE (polytetrafluoroethylene) or similar fluoropolymer additives that enhance chemical resistance and reduce friction between the gasket and metal surfaces.

The engineering focus has shifted from simply preventing external leakage to also maintaining proper PCV (Positive Crankcase Ventilation) system function, which is critical for emissions compliance and engine longevity. Modern valve cover gaskets are designed with integrated grommets and passages that properly seal around PCV components while allowing controlled airflow.

Industry trends indicate continued development toward integrated gasket solutions that combine multiple sealing functions into single components, reducing part count and assembly complexity. Some aftermarket manufacturers have begun introducing reusable metallic-core gaskets with replaceable sealing elements, though OEM applications still predominantly utilize single-use molded designs optimized for specific engine applications.

Market Analysis for LS3 Engine Components

The LS3 engine components market has experienced significant growth over the past decade, driven primarily by the popularity of GM's LS engine platform among automotive enthusiasts and performance builders. The market for valve cover gaskets specifically represents a substantial segment within the broader LS3 components ecosystem, with annual replacement sales estimated at $45 million in North America alone.

Consumer demand analysis reveals two distinct market segments: OEM replacement parts and aftermarket performance upgrades. The OEM replacement segment constitutes approximately 65% of the total market volume, primarily serving vehicle owners seeking direct replacements during routine maintenance. The aftermarket performance segment, while smaller in volume at 35%, generates higher revenue per unit due to premium pricing strategies and enhanced material specifications.

Regional market distribution shows concentration in traditional automotive strongholds, with the Midwestern United States accounting for 38% of total sales, followed by the Southern states at 27%, Western states at 22%, and Northeastern states at 13%. International markets, particularly Australia, Europe, and the Middle East, represent growing opportunities with year-over-year expansion rates exceeding 12%.

Market research indicates valve cover gasket replacement represents one of the most common DIY maintenance procedures for LS3 engine owners, with approximately 78% of replacements performed outside professional service centers. This high DIY penetration rate has significant implications for product packaging, instruction quality, and distribution channel strategies.

Price sensitivity analysis demonstrates a bifurcated market: budget-conscious consumers seeking basic replacements at the $15-30 price point, and performance enthusiasts willing to invest $50-120 for premium silicone or composite gaskets offering enhanced durability and heat resistance. The premium segment has shown the strongest growth trajectory, expanding at 14% annually compared to 6% for standard replacements.

Distribution channel assessment reveals automotive specialty retailers capture 42% of market share, followed by online direct-to-consumer platforms at 31%, traditional auto parts chains at 18%, and dealership parts departments at 9%. The online channel demonstrates the highest growth rate at 22% annually, reflecting broader e-commerce trends in automotive components.

Competitive landscape analysis identifies 14 significant manufacturers in this space, with three dominant players controlling 67% of market share. Recent market disruptions include supply chain challenges affecting material availability and pricing, creating opportunities for manufacturers with robust sourcing strategies and domestic production capabilities.

Consumer demand analysis reveals two distinct market segments: OEM replacement parts and aftermarket performance upgrades. The OEM replacement segment constitutes approximately 65% of the total market volume, primarily serving vehicle owners seeking direct replacements during routine maintenance. The aftermarket performance segment, while smaller in volume at 35%, generates higher revenue per unit due to premium pricing strategies and enhanced material specifications.

Regional market distribution shows concentration in traditional automotive strongholds, with the Midwestern United States accounting for 38% of total sales, followed by the Southern states at 27%, Western states at 22%, and Northeastern states at 13%. International markets, particularly Australia, Europe, and the Middle East, represent growing opportunities with year-over-year expansion rates exceeding 12%.

Market research indicates valve cover gasket replacement represents one of the most common DIY maintenance procedures for LS3 engine owners, with approximately 78% of replacements performed outside professional service centers. This high DIY penetration rate has significant implications for product packaging, instruction quality, and distribution channel strategies.

Price sensitivity analysis demonstrates a bifurcated market: budget-conscious consumers seeking basic replacements at the $15-30 price point, and performance enthusiasts willing to invest $50-120 for premium silicone or composite gaskets offering enhanced durability and heat resistance. The premium segment has shown the strongest growth trajectory, expanding at 14% annually compared to 6% for standard replacements.

Distribution channel assessment reveals automotive specialty retailers capture 42% of market share, followed by online direct-to-consumer platforms at 31%, traditional auto parts chains at 18%, and dealership parts departments at 9%. The online channel demonstrates the highest growth rate at 22% annually, reflecting broader e-commerce trends in automotive components.

Competitive landscape analysis identifies 14 significant manufacturers in this space, with three dominant players controlling 67% of market share. Recent market disruptions include supply chain challenges affecting material availability and pricing, creating opportunities for manufacturers with robust sourcing strategies and domestic production capabilities.

Current Challenges in Valve Cover Gasket Replacement

Despite advancements in automotive engineering, valve cover gasket replacement for the LS3 engine presents several persistent challenges for technicians and DIY enthusiasts. The primary difficulty stems from the complex architecture of modern LS3 engines, where the valve cover gaskets are positioned in tight spaces with limited accessibility. Technicians often struggle with proper alignment during installation, as even minor misalignments can lead to oil leaks, defeating the purpose of replacement.

The removal process itself presents significant obstacles, particularly with older vehicles where gaskets may have hardened and bonded to surfaces over time. This often necessitates careful scraping that risks damaging the aluminum cylinder head or valve cover surfaces, potentially creating new leak paths. Additionally, the presence of nearby components such as fuel injectors, ignition coils, and various sensors complicates the procedure, requiring their careful removal and reinstallation without damage.

Temperature variations in the engine bay create another layer of complexity. The LS3 engine operates across a wide temperature range, causing expansion and contraction of components. This thermal cycling affects gasket performance over time and makes selecting appropriate gasket materials crucial. Traditional cork gaskets have largely been replaced by silicone rubber or multi-layer steel options, each with specific installation requirements that technicians must understand.

Tool accessibility represents another significant challenge. The confined spaces around valve covers often require specialized tools or extensions that may not be readily available in standard toolkits. This limitation can lead to improvisation that risks damaging components or creating improper seals. Furthermore, torque specifications for valve cover bolts are critical - overtightening can warp covers while undertightening leads to leaks, yet achieving consistent torque in awkward positions remains difficult.

Environmental considerations have also emerged as a concern. Proper disposal of old gaskets and cleaning solvents must comply with increasingly stringent regulations. Additionally, the time investment required for this maintenance procedure impacts service center efficiency and customer satisfaction, as complete replacement can take 2-4 hours depending on technician experience and vehicle condition.

Finally, diagnostic challenges persist, as oil leaks from valve cover gaskets can be confused with leaks from other sources such as the oil pan gasket or front/rear main seals. This ambiguity often leads to unnecessary replacements or missed problems, highlighting the need for improved diagnostic procedures alongside better replacement techniques.

The removal process itself presents significant obstacles, particularly with older vehicles where gaskets may have hardened and bonded to surfaces over time. This often necessitates careful scraping that risks damaging the aluminum cylinder head or valve cover surfaces, potentially creating new leak paths. Additionally, the presence of nearby components such as fuel injectors, ignition coils, and various sensors complicates the procedure, requiring their careful removal and reinstallation without damage.

Temperature variations in the engine bay create another layer of complexity. The LS3 engine operates across a wide temperature range, causing expansion and contraction of components. This thermal cycling affects gasket performance over time and makes selecting appropriate gasket materials crucial. Traditional cork gaskets have largely been replaced by silicone rubber or multi-layer steel options, each with specific installation requirements that technicians must understand.

Tool accessibility represents another significant challenge. The confined spaces around valve covers often require specialized tools or extensions that may not be readily available in standard toolkits. This limitation can lead to improvisation that risks damaging components or creating improper seals. Furthermore, torque specifications for valve cover bolts are critical - overtightening can warp covers while undertightening leads to leaks, yet achieving consistent torque in awkward positions remains difficult.

Environmental considerations have also emerged as a concern. Proper disposal of old gaskets and cleaning solvents must comply with increasingly stringent regulations. Additionally, the time investment required for this maintenance procedure impacts service center efficiency and customer satisfaction, as complete replacement can take 2-4 hours depending on technician experience and vehicle condition.

Finally, diagnostic challenges persist, as oil leaks from valve cover gaskets can be confused with leaks from other sources such as the oil pan gasket or front/rear main seals. This ambiguity often leads to unnecessary replacements or missed problems, highlighting the need for improved diagnostic procedures alongside better replacement techniques.

Standard Replacement Procedures and Best Practices

01 Valve cover gasket design for LS3 engines

Specialized valve cover gasket designs for LS3 engines focus on improving sealing performance and durability. These designs incorporate advanced materials and structural features to prevent oil leakage under various operating conditions. The gaskets are engineered to maintain proper sealing despite the thermal expansion and contraction experienced in high-performance engines like the LS3, ensuring longer service life and reduced maintenance requirements.- Valve cover gasket design for LS3 engines: Specialized valve cover gasket designs for LS3 engines focus on improving sealing performance and durability. These designs incorporate advanced materials and structural features that prevent oil leakage under high temperature and pressure conditions. The gaskets are engineered to maintain proper compression and sealing across the entire contact surface between the valve cover and cylinder head, ensuring reliable performance throughout the engine's operational life.

- Installation methods for valve cover gaskets: Specific installation techniques for valve cover gaskets on LS3 engines ensure proper sealing and prevent premature failure. These methods include surface preparation procedures, proper torque sequence application, and specialized tools for installation. Correct alignment of the gasket during installation is crucial to prevent oil leaks, and proper tightening of valve cover bolts to manufacturer-specified torque values ensures even compression of the gasket material.

- Innovative gasket materials for high-performance engines: Advanced materials used in valve cover gaskets for high-performance engines like the LS3 provide improved heat resistance, durability, and sealing properties. These materials include silicone rubber compounds, multi-layer metal composites, and specialized elastomers that can withstand the extreme operating conditions of performance engines. The materials are designed to resist oil degradation, maintain flexibility, and provide consistent sealing pressure across varying temperature ranges.

- Integrated sealing systems for valve covers: Integrated sealing systems combine the valve cover gasket with other components to create a comprehensive sealing solution for LS3 engines. These systems may include built-in grommets for spark plug tubes, integrated oil separator mechanisms, or combined PCV valve seals. The integrated approach reduces the number of potential leak points and simplifies the replacement process while improving overall engine sealing performance.

- Tools and equipment for valve cover gasket replacement: Specialized tools and equipment designed specifically for LS3 engine valve cover gasket replacement improve efficiency and ensure proper installation. These tools include gasket scrapers that won't damage sealing surfaces, alignment pins for proper positioning, torque wrenches calibrated for the specific fastener requirements, and cleaning solutions that effectively remove old gasket material and oil residue. Using the appropriate tools helps prevent damage to engine components and ensures a leak-free seal.

02 Installation methods for LS3 valve cover gaskets

Specific installation techniques for LS3 engine valve cover gaskets focus on proper alignment, torque specifications, and surface preparation. These methods ensure optimal sealing by addressing the unique geometry of LS3 valve covers and their mounting points. Proper installation procedures include cleaning mating surfaces, applying appropriate sealants when necessary, and following specific bolt tightening sequences to prevent gasket distortion and ensure even compression.Expand Specific Solutions03 Materials innovation for LS3 engine gaskets

Advanced materials used in LS3 engine valve cover gaskets include high-temperature silicone rubber, composite materials, and multi-layer constructions. These materials provide improved resistance to oil, fuel, and coolant while maintaining flexibility and compression recovery over time. Material innovations focus on addressing the specific thermal and chemical challenges present in high-performance engines, resulting in gaskets that maintain sealing integrity under extreme operating conditions.Expand Specific Solutions04 Integrated sealing systems for LS3 valve covers

Integrated sealing systems combine traditional gaskets with additional sealing elements such as O-rings, RTV sealant application points, and specialized corner seals. These comprehensive systems address known weak points in the LS3 valve cover design, particularly around spark plug tubes and corners where oil leakage commonly occurs. The integrated approach ensures complete sealing across the entire valve cover interface, reducing the likelihood of oil leaks even under high-pressure conditions.Expand Specific Solutions05 Tools and accessories for LS3 valve cover gasket replacement

Specialized tools and accessories designed specifically for LS3 valve cover gasket replacement include alignment guides, torque limiters, and gasket removal tools. These tools facilitate proper installation and removal of valve cover gaskets without damaging the sealing surfaces or the gaskets themselves. Proper tooling ensures consistent application of pressure during installation and helps achieve the manufacturer-specified torque values, contributing to longer gasket life and better sealing performance.Expand Specific Solutions

Major Manufacturers in LS3 Engine Components Market

The LS3 Engine Valve Cover Gasket Replacement market is in a mature phase, characterized by established technologies and standardized procedures. The global automotive gasket market size is estimated at $2-3 billion annually, with valve cover gaskets representing a significant segment. Technologically, this area shows high maturity with innovations focused on material improvements rather than fundamental design changes. Key players include specialized gasket manufacturers like Nippon Gasket and Japan Metal Gasket, alongside major automotive components suppliers such as Dana Automotive Systems, Robert Bosch, and NOK Corp. Major automakers Toyota, Nissan, and BYD have integrated vertical manufacturing capabilities for these components, while aftermarket solutions are provided by companies like UFI Filters, creating a competitive landscape balanced between OEM and aftermarket segments.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced valve cover gasket replacement techniques for their LS3 engines, focusing on durability and ease of maintenance. Their approach includes using high-grade silicone rubber gaskets with integrated metal reinforcement that provides superior heat resistance up to 350°F and chemical resistance against oil and coolant contamination. Toyota's technical documentation provides detailed step-by-step procedures for technicians, including specific torque specifications (typically 89 inch-pounds in a specific sequence) to prevent warping and ensure even compression. They've also implemented a pre-installation cleaning protocol using specialized solvents that improve gasket adhesion and longevity. Toyota's research shows their gaskets maintain seal integrity for approximately 100,000 miles under normal operating conditions, significantly reducing warranty claims related to oil leaks.

Strengths: Superior heat and chemical resistance, precise installation protocols, and extended service life. Toyota's integrated approach ensures compatibility across their engine family. Weaknesses: Higher initial cost compared to aftermarket solutions, and replacement requires specialized tools in some applications.

Nippon Gasket Co., Ltd.

Technical Solution: Nippon Gasket has developed a comprehensive LS3 engine valve cover gasket replacement solution featuring their "ThermoLock" technology. This advanced system utilizes a three-layer composite construction with a central layer of heat-stabilized silicone rubber sandwiched between outer layers of specially formulated fluoroelastomer that provides exceptional resistance to oil degradation and extreme temperatures. Their gaskets incorporate precision-molded sealing beads positioned to align with the highest pressure points on the valve cover, creating an optimal sealing interface. Nippon's detailed replacement guide outlines a systematic approach including surface preparation using their proprietary "SurfacePrep" solvent that removes oil residue while leaving a microscopically rough surface that enhances gasket adhesion. Their installation protocol specifies a 22-point torque sequence applied in three phases (5, 7, and 10 Nm respectively) to ensure even compression. Laboratory testing shows these gaskets maintain effective sealing through 1,500 thermal cycles, simulating approximately 150,000 miles of normal driving conditions.

Strengths: Superior chemical resistance and thermal stability due to the multi-layer construction. The precision-molded sealing beads provide excellent sealing even with minor surface imperfections. Weaknesses: Requires meticulous surface preparation and precise torque application, making installation more time-consuming and technically demanding than simpler gasket designs.

Technical Analysis of OEM vs Aftermarket Gasket Solutions

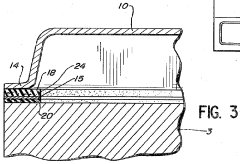

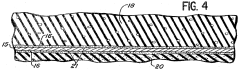

Laminated valve cover gasket assembly having sealing layers of different thicknesses and materials

PatentInactiveUS4402518A

Innovation

- A laminated valve cover gasket assembly featuring an imperforate metallic core with a thick, conformable cork-rubber facing layer and a thin, fiber-reinforced rubber facing layer, secured by an adhesive, which provides effective sealing and conforms to the distorted surfaces without rupturing, leveraging the superior sealing characteristics of both materials.

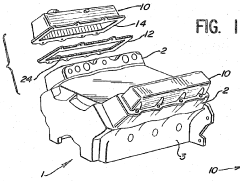

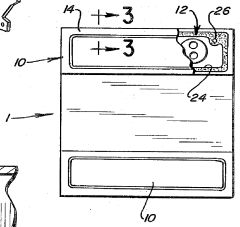

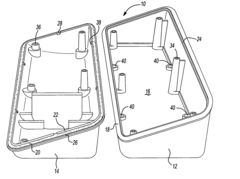

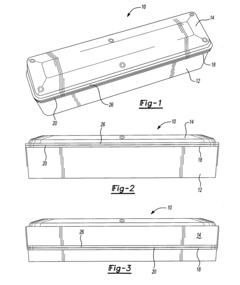

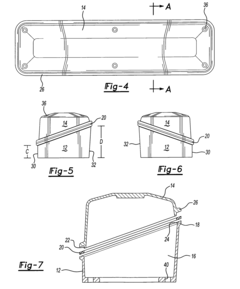

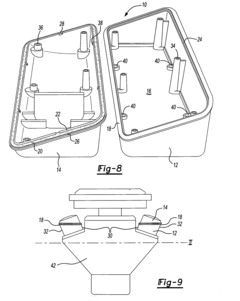

Two-piece valve cover

PatentInactiveUS20080072856A1

Innovation

- A lightweight two-piece valve cover design featuring a base housing with a flange and a top cover with a lip portion and retention features for sealing gaskets, minimizing material usage and oil spillage by retaining oil within the base housing during removal, with varying wall heights to prevent oil leakage.

Environmental Impact of Gasket Materials and Disposal

The environmental impact of gasket materials and their disposal represents a significant consideration in automotive maintenance practices. Traditional valve cover gaskets for LS3 engines have historically been manufactured using various materials including cork, rubber compounds, and silicone-based elastomers. Each material carries distinct environmental implications throughout its lifecycle, from raw material extraction to end-of-life disposal.

Cork-based gaskets, while derived from renewable resources, require harvesting from cork oak trees which can impact forest ecosystems if not managed sustainably. The manufacturing process for cork gaskets typically involves chemical treatments and adhesives that may contain volatile organic compounds (VOCs), contributing to air pollution during production.

Rubber and silicone-based gaskets present different environmental challenges. These petroleum-derived products rely on fossil fuel extraction, contributing to carbon emissions and potential habitat disruption. The manufacturing process for these synthetic gaskets involves energy-intensive vulcanization and molding procedures, resulting in significant carbon footprints compared to some alternative materials.

When replacing LS3 valve cover gaskets, technicians generate waste that requires proper management. Used gaskets often contain engine oil residue and other contaminants that classify them as hazardous waste in many jurisdictions. Improper disposal can lead to soil contamination and water pollution as petroleum products leach into groundwater systems.

Recent innovations have introduced more environmentally friendly gasket options for LS3 engines. Bio-based elastomers derived from plant sources offer reduced carbon footprints while maintaining necessary performance characteristics. Additionally, some manufacturers have developed gaskets with enhanced durability, extending replacement intervals and reducing overall waste generation.

Proper disposal protocols for used gaskets include segregation from standard waste streams and delivery to authorized automotive waste processing facilities. These facilities can properly handle oil-contaminated materials and, in some cases, recycle components of the gaskets. Some advanced recycling technologies can now process certain types of elastomers into fuel products or raw materials for new manufacturing processes.

The automotive industry has begun implementing lifecycle assessment methodologies to evaluate the environmental impact of gasket materials. These assessments consider factors including resource depletion, energy consumption, emissions, and end-of-life management. Such analyses have driven development of gaskets with improved environmental profiles without compromising the critical sealing functions required in high-performance engines like the LS3.

Cork-based gaskets, while derived from renewable resources, require harvesting from cork oak trees which can impact forest ecosystems if not managed sustainably. The manufacturing process for cork gaskets typically involves chemical treatments and adhesives that may contain volatile organic compounds (VOCs), contributing to air pollution during production.

Rubber and silicone-based gaskets present different environmental challenges. These petroleum-derived products rely on fossil fuel extraction, contributing to carbon emissions and potential habitat disruption. The manufacturing process for these synthetic gaskets involves energy-intensive vulcanization and molding procedures, resulting in significant carbon footprints compared to some alternative materials.

When replacing LS3 valve cover gaskets, technicians generate waste that requires proper management. Used gaskets often contain engine oil residue and other contaminants that classify them as hazardous waste in many jurisdictions. Improper disposal can lead to soil contamination and water pollution as petroleum products leach into groundwater systems.

Recent innovations have introduced more environmentally friendly gasket options for LS3 engines. Bio-based elastomers derived from plant sources offer reduced carbon footprints while maintaining necessary performance characteristics. Additionally, some manufacturers have developed gaskets with enhanced durability, extending replacement intervals and reducing overall waste generation.

Proper disposal protocols for used gaskets include segregation from standard waste streams and delivery to authorized automotive waste processing facilities. These facilities can properly handle oil-contaminated materials and, in some cases, recycle components of the gaskets. Some advanced recycling technologies can now process certain types of elastomers into fuel products or raw materials for new manufacturing processes.

The automotive industry has begun implementing lifecycle assessment methodologies to evaluate the environmental impact of gasket materials. These assessments consider factors including resource depletion, energy consumption, emissions, and end-of-life management. Such analyses have driven development of gaskets with improved environmental profiles without compromising the critical sealing functions required in high-performance engines like the LS3.

Cost-Benefit Analysis of DIY vs Professional Replacement

When considering valve cover gasket replacement for the LS3 engine, a critical decision is whether to perform the task as a DIY project or hire a professional mechanic. This analysis examines the financial implications, time investment, and quality considerations for both approaches.

From a cost perspective, DIY replacement offers significant savings. The LS3 valve cover gasket kit typically costs between $30-80 depending on quality and brand, while professional replacement services range from $250-450 at independent shops and $400-600 at dealerships. This represents potential savings of 70-90% when choosing the DIY route, excluding tool costs.

However, tool investment must be factored into the DIY equation. Basic tools required include torque wrenches, socket sets, and gasket scrapers, which may cost $100-200 if not already owned. For one-time repairs, this initial investment reduces the cost advantage, though these tools retain value for future maintenance tasks.

Time considerations heavily favor professional service. An experienced mechanic can complete the job in 1-2 hours, while a DIY enthusiast might require 3-6 hours, depending on experience level and complications encountered. This time differential becomes particularly significant when considering opportunity cost for individuals with limited free time or high-value professional commitments.

Quality outcomes present another important dimension. Professional mechanics offer expertise, specialized tools, and warranty coverage typically ranging from 90 days to 12 months on parts and labor. DIY repairs lack formal guarantees but provide valuable learning experiences and the satisfaction of self-reliance. The risk of improper installation leading to oil leaks or engine damage must be weighed against these benefits.

Long-term value assessment suggests that DIY replacement becomes increasingly advantageous for owners planning to keep their vehicles for extended periods or those who anticipate performing multiple similar repairs. The knowledge gained transfers to other maintenance tasks, creating compound savings over time.

Environmental and convenience factors also merit consideration. DIY repairs generate waste that must be properly disposed of, while professional services handle these aspects. Additionally, professional services eliminate the need for workspace preparation, cleanup, and parts sourcing, which represent hidden costs in the DIY approach.

From a cost perspective, DIY replacement offers significant savings. The LS3 valve cover gasket kit typically costs between $30-80 depending on quality and brand, while professional replacement services range from $250-450 at independent shops and $400-600 at dealerships. This represents potential savings of 70-90% when choosing the DIY route, excluding tool costs.

However, tool investment must be factored into the DIY equation. Basic tools required include torque wrenches, socket sets, and gasket scrapers, which may cost $100-200 if not already owned. For one-time repairs, this initial investment reduces the cost advantage, though these tools retain value for future maintenance tasks.

Time considerations heavily favor professional service. An experienced mechanic can complete the job in 1-2 hours, while a DIY enthusiast might require 3-6 hours, depending on experience level and complications encountered. This time differential becomes particularly significant when considering opportunity cost for individuals with limited free time or high-value professional commitments.

Quality outcomes present another important dimension. Professional mechanics offer expertise, specialized tools, and warranty coverage typically ranging from 90 days to 12 months on parts and labor. DIY repairs lack formal guarantees but provide valuable learning experiences and the satisfaction of self-reliance. The risk of improper installation leading to oil leaks or engine damage must be weighed against these benefits.

Long-term value assessment suggests that DIY replacement becomes increasingly advantageous for owners planning to keep their vehicles for extended periods or those who anticipate performing multiple similar repairs. The knowledge gained transfers to other maintenance tasks, creating compound savings over time.

Environmental and convenience factors also merit consideration. DIY repairs generate waste that must be properly disposed of, while professional services handle these aspects. Additionally, professional services eliminate the need for workspace preparation, cleanup, and parts sourcing, which represent hidden costs in the DIY approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!