Polycarbonate Applications in the Telecommunication Sector

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in Telecom: Background and Objectives

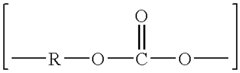

Polycarbonate, a versatile thermoplastic polymer, has been a game-changer in the telecommunication sector since its introduction in the 1950s. Its unique combination of properties, including high impact resistance, optical clarity, and thermal stability, has made it an ideal material for various applications in the rapidly evolving telecom industry.

The development of polycarbonate in telecommunications can be traced back to the early days of landline communication systems. As the industry progressed from copper wire networks to fiber optics and wireless technologies, polycarbonate found new applications and became an integral part of telecom infrastructure.

In recent years, the telecom sector has witnessed unprecedented growth, driven by the increasing demand for high-speed internet, mobile connectivity, and the emergence of 5G networks. This technological evolution has created new challenges and opportunities for materials like polycarbonate, pushing the boundaries of its applications and performance requirements.

The primary objective of exploring polycarbonate applications in the telecommunication sector is to identify and leverage its potential to address the industry's evolving needs. This includes enhancing the durability and performance of telecom equipment, improving signal transmission efficiency, and supporting the miniaturization of devices.

One of the key areas of focus is the development of polycarbonate formulations that can withstand the harsh environmental conditions often encountered in telecom installations. This includes resistance to UV radiation, extreme temperatures, and chemical exposure, ensuring the longevity and reliability of telecom infrastructure.

Another critical objective is to explore the use of polycarbonate in advanced optical applications, such as waveguides and optical connectors, to support the increasing demand for high-bandwidth data transmission. The material's optical clarity and moldability make it an attractive option for these applications, potentially offering cost-effective alternatives to traditional materials.

As the telecom industry moves towards more sustainable practices, there is also a growing interest in developing eco-friendly polycarbonate formulations. This includes exploring bio-based alternatives and improving the recyclability of polycarbonate components, aligning with the industry's sustainability goals.

The ongoing research and development in polycarbonate applications for telecommunications aim to push the boundaries of material performance, enabling the creation of more efficient, durable, and sustainable telecom solutions. By understanding the historical context and current objectives, we can better appreciate the pivotal role that polycarbonate plays in shaping the future of telecommunications technology.

The development of polycarbonate in telecommunications can be traced back to the early days of landline communication systems. As the industry progressed from copper wire networks to fiber optics and wireless technologies, polycarbonate found new applications and became an integral part of telecom infrastructure.

In recent years, the telecom sector has witnessed unprecedented growth, driven by the increasing demand for high-speed internet, mobile connectivity, and the emergence of 5G networks. This technological evolution has created new challenges and opportunities for materials like polycarbonate, pushing the boundaries of its applications and performance requirements.

The primary objective of exploring polycarbonate applications in the telecommunication sector is to identify and leverage its potential to address the industry's evolving needs. This includes enhancing the durability and performance of telecom equipment, improving signal transmission efficiency, and supporting the miniaturization of devices.

One of the key areas of focus is the development of polycarbonate formulations that can withstand the harsh environmental conditions often encountered in telecom installations. This includes resistance to UV radiation, extreme temperatures, and chemical exposure, ensuring the longevity and reliability of telecom infrastructure.

Another critical objective is to explore the use of polycarbonate in advanced optical applications, such as waveguides and optical connectors, to support the increasing demand for high-bandwidth data transmission. The material's optical clarity and moldability make it an attractive option for these applications, potentially offering cost-effective alternatives to traditional materials.

As the telecom industry moves towards more sustainable practices, there is also a growing interest in developing eco-friendly polycarbonate formulations. This includes exploring bio-based alternatives and improving the recyclability of polycarbonate components, aligning with the industry's sustainability goals.

The ongoing research and development in polycarbonate applications for telecommunications aim to push the boundaries of material performance, enabling the creation of more efficient, durable, and sustainable telecom solutions. By understanding the historical context and current objectives, we can better appreciate the pivotal role that polycarbonate plays in shaping the future of telecommunications technology.

Market Analysis for Polycarbonate in Telecommunications

The polycarbonate market in the telecommunications sector has experienced significant growth in recent years, driven by the increasing demand for high-performance materials in various applications. The global polycarbonate market for telecommunications is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) exceeding the overall industry average. This growth is primarily attributed to the expanding 5G infrastructure, the proliferation of smart devices, and the ongoing digital transformation across industries.

In the telecommunications sector, polycarbonate finds extensive use in a wide range of applications, including mobile phone casings, antenna components, fiber optic connectors, and network equipment housings. The material's unique combination of properties, such as high impact strength, excellent thermal stability, and optical clarity, makes it an ideal choice for these applications. As the demand for faster and more reliable communication networks continues to rise, the need for advanced materials like polycarbonate is expected to grow proportionally.

The Asia-Pacific region dominates the polycarbonate market in telecommunications, accounting for the largest share of global consumption. This is primarily due to the presence of major electronics and telecommunications equipment manufacturers in countries like China, South Korea, and Japan. North America and Europe follow closely, driven by the rapid adoption of 5G technology and the increasing focus on IoT (Internet of Things) devices.

Key market drivers include the ongoing expansion of 5G networks, which requires a significant upgrade of existing infrastructure and the deployment of new equipment. Polycarbonate's lightweight and durable nature makes it an excellent material for outdoor telecommunications equipment, capable of withstanding harsh environmental conditions. Additionally, the growing trend of miniaturization in electronic devices is fueling the demand for high-performance plastics that can meet stringent design requirements.

However, the market faces challenges such as fluctuating raw material prices and increasing environmental concerns regarding plastic waste. These factors have led to a push for more sustainable alternatives and recycling initiatives within the industry. Despite these challenges, the overall outlook for polycarbonate in the telecommunications sector remains positive, with innovations in material technology and the development of bio-based polycarbonates expected to drive future growth.

In the telecommunications sector, polycarbonate finds extensive use in a wide range of applications, including mobile phone casings, antenna components, fiber optic connectors, and network equipment housings. The material's unique combination of properties, such as high impact strength, excellent thermal stability, and optical clarity, makes it an ideal choice for these applications. As the demand for faster and more reliable communication networks continues to rise, the need for advanced materials like polycarbonate is expected to grow proportionally.

The Asia-Pacific region dominates the polycarbonate market in telecommunications, accounting for the largest share of global consumption. This is primarily due to the presence of major electronics and telecommunications equipment manufacturers in countries like China, South Korea, and Japan. North America and Europe follow closely, driven by the rapid adoption of 5G technology and the increasing focus on IoT (Internet of Things) devices.

Key market drivers include the ongoing expansion of 5G networks, which requires a significant upgrade of existing infrastructure and the deployment of new equipment. Polycarbonate's lightweight and durable nature makes it an excellent material for outdoor telecommunications equipment, capable of withstanding harsh environmental conditions. Additionally, the growing trend of miniaturization in electronic devices is fueling the demand for high-performance plastics that can meet stringent design requirements.

However, the market faces challenges such as fluctuating raw material prices and increasing environmental concerns regarding plastic waste. These factors have led to a push for more sustainable alternatives and recycling initiatives within the industry. Despite these challenges, the overall outlook for polycarbonate in the telecommunications sector remains positive, with innovations in material technology and the development of bio-based polycarbonates expected to drive future growth.

Current Challenges in Polycarbonate Telecom Applications

Despite the widespread adoption of polycarbonate in telecommunications, several challenges persist in its application within this sector. One of the primary issues is the material's susceptibility to environmental stress cracking, particularly in outdoor applications. This phenomenon can lead to premature failure of components exposed to harsh weather conditions, UV radiation, and chemical contaminants, potentially compromising the integrity of telecom infrastructure.

Another significant challenge is the balance between impact resistance and flame retardancy. While polycarbonate is renowned for its high impact strength, the addition of flame retardants to meet stringent fire safety standards can often compromise this property. This trade-off poses difficulties in designing components that must simultaneously withstand physical impacts and resist fire propagation, a crucial requirement in many telecom applications.

The increasing demand for miniaturization and lightweight designs in telecom devices presents another hurdle. As components become smaller and thinner, maintaining the structural integrity and performance of polycarbonate parts becomes more challenging. This is particularly evident in mobile devices and portable telecom equipment, where the material's limitations in achieving ultra-thin profiles while retaining strength are becoming apparent.

Thermal management is an ongoing concern in polycarbonate telecom applications. The material's relatively low thermal conductivity can lead to heat buildup in electronic components, potentially affecting performance and longevity. This issue is exacerbated by the trend towards higher-power, more compact devices in the telecom sector.

Additionally, the growing emphasis on sustainability and recyclability poses challenges for polycarbonate usage. While the material is technically recyclable, the presence of additives and coatings in telecom applications often complicates the recycling process. This difficulty aligns poorly with the increasing global focus on circular economy principles and the need for more environmentally friendly materials in the tech industry.

Lastly, the cost factor remains a persistent challenge. Although polycarbonate offers numerous advantages, its price point is higher compared to some alternative materials. This cost differential can be significant in large-scale telecom infrastructure projects, prompting ongoing research into more cost-effective formulations or alternative materials that can match polycarbonate's performance at a lower price point.

Another significant challenge is the balance between impact resistance and flame retardancy. While polycarbonate is renowned for its high impact strength, the addition of flame retardants to meet stringent fire safety standards can often compromise this property. This trade-off poses difficulties in designing components that must simultaneously withstand physical impacts and resist fire propagation, a crucial requirement in many telecom applications.

The increasing demand for miniaturization and lightweight designs in telecom devices presents another hurdle. As components become smaller and thinner, maintaining the structural integrity and performance of polycarbonate parts becomes more challenging. This is particularly evident in mobile devices and portable telecom equipment, where the material's limitations in achieving ultra-thin profiles while retaining strength are becoming apparent.

Thermal management is an ongoing concern in polycarbonate telecom applications. The material's relatively low thermal conductivity can lead to heat buildup in electronic components, potentially affecting performance and longevity. This issue is exacerbated by the trend towards higher-power, more compact devices in the telecom sector.

Additionally, the growing emphasis on sustainability and recyclability poses challenges for polycarbonate usage. While the material is technically recyclable, the presence of additives and coatings in telecom applications often complicates the recycling process. This difficulty aligns poorly with the increasing global focus on circular economy principles and the need for more environmentally friendly materials in the tech industry.

Lastly, the cost factor remains a persistent challenge. Although polycarbonate offers numerous advantages, its price point is higher compared to some alternative materials. This cost differential can be significant in large-scale telecom infrastructure projects, prompting ongoing research into more cost-effective formulations or alternative materials that can match polycarbonate's performance at a lower price point.

Existing Polycarbonate Solutions for Telecom Infrastructure

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including novel catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the performance and versatility of polycarbonate materials for different applications.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve improved mechanical, thermal, or electrical properties. These formulations can include flame retardants, impact modifiers, or other functional materials to tailor the characteristics of the final product for specific uses.

- Polycarbonate processing techniques: Advancements in processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on optimizing processing parameters, reducing defects, and improving the overall quality and consistency of polycarbonate products.

- Polycarbonate applications in electronics: Utilization of polycarbonates in electronic applications, such as in the manufacturing of components for smartphones, laptops, and other devices. This includes developments in polycarbonate formulations with enhanced properties suitable for electronic housings, display components, and protective coatings.

- Recycling and sustainability of polycarbonates: Innovations in recycling processes and sustainable production methods for polycarbonates. This includes chemical recycling techniques, bio-based polycarbonate alternatives, and strategies to improve the environmental footprint of polycarbonate manufacturing and end-of-life management.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blends and composites are tailored for various industrial and consumer applications.Expand Specific Solutions03 Polycarbonate processing and manufacturing

Advancements in processing techniques and manufacturing methods for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final products while minimizing environmental impact.Expand Specific Solutions04 Polycarbonate applications in electronics

Utilization of polycarbonates in electronic devices and components, such as housings, insulators, and optical elements. The focus is on developing polycarbonate formulations with improved heat resistance, dimensional stability, and electrical properties suitable for various electronic applications.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Methods for recycling polycarbonate materials and developing more sustainable production processes. This includes chemical recycling techniques, bio-based polycarbonate alternatives, and strategies to reduce the environmental impact of polycarbonate manufacturing and disposal.Expand Specific Solutions

Key Players in Polycarbonate Telecom Industry

The polycarbonate applications in the telecommunication sector are in a mature growth stage, with a significant market size driven by increasing demand for lightweight, durable, and high-performance materials in telecommunications infrastructure and devices. The technology has reached a high level of maturity, with key players like SABIC, Covestro, and BASF leading innovation. These companies, along with others such as Mitsubishi Engineering-Plastics and LG Chem, are continuously developing advanced polycarbonate formulations to meet the evolving needs of 5G networks, fiber optic systems, and mobile devices, focusing on improved thermal management, flame retardancy, and electromagnetic shielding properties.

SABIC Global Technologies BV

Technical Solution: SABIC has developed high-performance polycarbonate resins specifically for telecommunication applications. Their LEXAN™ EXL polycarbonate resin offers excellent impact resistance and low-temperature ductility, making it ideal for outdoor telecom equipment[1]. SABIC has also introduced flame-retardant polycarbonate blends that meet the stringent UL94 V-0 standard at just 0.8mm thickness, addressing the need for thinner, lighter components in 5G infrastructure[2]. Additionally, SABIC's polycarbonate materials are used in fiber optic connectors, providing high dimensional stability and resistance to signal loss[3].

Strengths: Excellent impact resistance, flame retardancy, and dimensional stability. Weaknesses: May be more expensive than some alternative materials, potential for yellowing under prolonged UV exposure.

Covestro Deutschland AG

Technical Solution: Covestro has developed Makrolon® TC polycarbonates specifically for thermal management in 5G base stations and other telecom equipment. These materials offer high thermal conductivity (up to 20 W/mK) while maintaining electrical insulation properties[4]. Covestro's polycarbonate solutions also include transparent, flame-retardant grades for 5G small cell radomes, providing excellent signal transparency and weather resistance[5]. Furthermore, they have introduced Makrolon® RE, a more sustainable polycarbonate made with up to 71% bio-circular attributed content, suitable for telecom applications[6].

Strengths: High thermal conductivity, excellent signal transparency, and sustainable options. Weaknesses: Potentially higher cost compared to traditional polycarbonates, limited track record for newer bio-based formulations.

Innovations in Polycarbonate for Telecom Applications

Coatings for polycarbonate windows

PatentInactiveEP1999196A1

Innovation

- A dual-cure coating composition for polycarbonate substrates that includes a radiation-curable component, a thermally curable binder, and a thermally curable crosslinking component, along with UV-absorbing additives, which can be applied and cured using actinic radiation and thermal energy, ensuring excellent adhesion and optical clarity without the need for intermediate primers.

Coatings for polycarbonate windows

PatentInactiveUS20070231577A1

Innovation

- A dual-cure coating composition that includes a radiation-curable component, a thermally curable binder, and a thermally curable crosslinking agent, along with UV-absorbing additives, applied to the polycarbonate substrate, which cures using both actinic radiation and thermal energy, ensuring excellent adhesion and optical clarity without the need for intermediate primers.

Environmental Impact of Polycarbonate in Telecom

The environmental impact of polycarbonate in the telecommunication sector is a critical consideration as the industry continues to expand and evolve. Polycarbonate, a versatile thermoplastic polymer, has become increasingly prevalent in telecom applications due to its durability, heat resistance, and electrical insulation properties. However, its widespread use also raises concerns about its ecological footprint throughout its lifecycle.

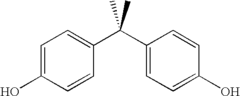

The production of polycarbonate involves energy-intensive processes and the use of potentially harmful chemicals, such as bisphenol A (BPA). These manufacturing processes contribute to greenhouse gas emissions and can lead to the release of toxic substances into the environment if not properly managed. Additionally, the extraction of raw materials for polycarbonate production, primarily petroleum-based resources, has implications for habitat disruption and resource depletion.

In the deployment phase, polycarbonate components in telecom infrastructure generally have a long lifespan, which can be seen as a positive environmental attribute. The material's durability reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption over time. However, the installation of telecom equipment containing polycarbonate can still impact local ecosystems, particularly when new infrastructure is built in sensitive areas.

The end-of-life management of polycarbonate in telecom applications presents both challenges and opportunities. While polycarbonate is theoretically recyclable, the presence of additives and the complexity of telecom equipment can make recycling processes difficult and less economically viable. Improper disposal of polycarbonate-containing devices can lead to pollution, as the material does not biodegrade and may persist in the environment for extended periods.

To mitigate these environmental concerns, the telecom industry is exploring several strategies. These include the development of more sustainable production methods for polycarbonate, such as using bio-based feedstocks or implementing closed-loop manufacturing systems. There is also a growing focus on designing telecom equipment for easier disassembly and recycling, as well as establishing more effective take-back and recycling programs for end-of-life products.

Furthermore, research is ongoing into alternative materials that could potentially replace polycarbonate in certain telecom applications, offering improved environmental profiles without compromising performance. These efforts, combined with advancements in circular economy practices, aim to reduce the overall environmental impact of polycarbonate use in the telecommunication sector, aligning with global sustainability goals and regulatory requirements.

The production of polycarbonate involves energy-intensive processes and the use of potentially harmful chemicals, such as bisphenol A (BPA). These manufacturing processes contribute to greenhouse gas emissions and can lead to the release of toxic substances into the environment if not properly managed. Additionally, the extraction of raw materials for polycarbonate production, primarily petroleum-based resources, has implications for habitat disruption and resource depletion.

In the deployment phase, polycarbonate components in telecom infrastructure generally have a long lifespan, which can be seen as a positive environmental attribute. The material's durability reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption over time. However, the installation of telecom equipment containing polycarbonate can still impact local ecosystems, particularly when new infrastructure is built in sensitive areas.

The end-of-life management of polycarbonate in telecom applications presents both challenges and opportunities. While polycarbonate is theoretically recyclable, the presence of additives and the complexity of telecom equipment can make recycling processes difficult and less economically viable. Improper disposal of polycarbonate-containing devices can lead to pollution, as the material does not biodegrade and may persist in the environment for extended periods.

To mitigate these environmental concerns, the telecom industry is exploring several strategies. These include the development of more sustainable production methods for polycarbonate, such as using bio-based feedstocks or implementing closed-loop manufacturing systems. There is also a growing focus on designing telecom equipment for easier disassembly and recycling, as well as establishing more effective take-back and recycling programs for end-of-life products.

Furthermore, research is ongoing into alternative materials that could potentially replace polycarbonate in certain telecom applications, offering improved environmental profiles without compromising performance. These efforts, combined with advancements in circular economy practices, aim to reduce the overall environmental impact of polycarbonate use in the telecommunication sector, aligning with global sustainability goals and regulatory requirements.

Regulatory Framework for Telecom Materials

The regulatory framework for telecom materials, particularly in the context of polycarbonate applications, is a complex and evolving landscape. Governments and international bodies have established stringent guidelines to ensure the safety, reliability, and environmental sustainability of materials used in telecommunications infrastructure.

One of the primary regulatory bodies overseeing this sector is the International Telecommunication Union (ITU), which sets global standards for telecommunications equipment and materials. The ITU's recommendations often form the basis for national regulations, ensuring a level of consistency across different countries.

In the United States, the Federal Communications Commission (FCC) plays a crucial role in regulating telecom materials. The FCC's Part 68 rules, for instance, set forth requirements for terminal equipment connected to the telephone network, including specifications for materials used in such equipment. These regulations often reference standards developed by organizations like ASTM International and Underwriters Laboratories (UL).

The European Union has its own set of regulations, primarily through the Radio Equipment Directive (RED) and the Restriction of Hazardous Substances (RoHS) Directive. These directives impose strict limits on the use of certain hazardous substances in electrical and electronic equipment, including telecom devices. Polycarbonate manufacturers must ensure their products comply with these regulations to be used in telecom applications within the EU market.

Environmental considerations are increasingly shaping the regulatory landscape. Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This has led to a growing emphasis on using recyclable and environmentally friendly materials in telecom equipment.

Fire safety is another critical aspect of telecom material regulations. Standards such as UL 94, which classifies plastics according to their burning characteristics, are widely adopted in the industry. Polycarbonate's inherent flame-retardant properties make it a favorable choice in meeting these stringent fire safety requirements.

Electromagnetic compatibility (EMC) regulations also play a significant role in the telecom sector. Materials used in telecom equipment must not interfere with the transmission of signals and must provide adequate shielding against electromagnetic interference. Polycarbonate's dielectric properties make it suitable for applications where EMC compliance is crucial.

As the telecommunications industry continues to evolve, particularly with the advent of 5G technology, regulatory frameworks are adapting to address new challenges. This includes regulations surrounding the use of materials in small cell deployments and the integration of telecom equipment into urban infrastructure.

One of the primary regulatory bodies overseeing this sector is the International Telecommunication Union (ITU), which sets global standards for telecommunications equipment and materials. The ITU's recommendations often form the basis for national regulations, ensuring a level of consistency across different countries.

In the United States, the Federal Communications Commission (FCC) plays a crucial role in regulating telecom materials. The FCC's Part 68 rules, for instance, set forth requirements for terminal equipment connected to the telephone network, including specifications for materials used in such equipment. These regulations often reference standards developed by organizations like ASTM International and Underwriters Laboratories (UL).

The European Union has its own set of regulations, primarily through the Radio Equipment Directive (RED) and the Restriction of Hazardous Substances (RoHS) Directive. These directives impose strict limits on the use of certain hazardous substances in electrical and electronic equipment, including telecom devices. Polycarbonate manufacturers must ensure their products comply with these regulations to be used in telecom applications within the EU market.

Environmental considerations are increasingly shaping the regulatory landscape. Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This has led to a growing emphasis on using recyclable and environmentally friendly materials in telecom equipment.

Fire safety is another critical aspect of telecom material regulations. Standards such as UL 94, which classifies plastics according to their burning characteristics, are widely adopted in the industry. Polycarbonate's inherent flame-retardant properties make it a favorable choice in meeting these stringent fire safety requirements.

Electromagnetic compatibility (EMC) regulations also play a significant role in the telecom sector. Materials used in telecom equipment must not interfere with the transmission of signals and must provide adequate shielding against electromagnetic interference. Polycarbonate's dielectric properties make it suitable for applications where EMC compliance is crucial.

As the telecommunications industry continues to evolve, particularly with the advent of 5G technology, regulatory frameworks are adapting to address new challenges. This includes regulations surrounding the use of materials in small cell deployments and the integration of telecom equipment into urban infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!