Polycarbonate in Agricultural Technology: Innovations and Applications

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in AgTech: Evolution and Objectives

Polycarbonate has emerged as a revolutionary material in agricultural technology, transforming various aspects of farming and crop production. The evolution of polycarbonate in AgTech can be traced back to the mid-20th century when it was first synthesized. Initially, its applications in agriculture were limited, primarily used in simple greenhouse structures due to its transparency and durability.

As research and development progressed, the potential of polycarbonate in agriculture became increasingly apparent. The 1970s and 1980s saw a significant expansion in its use, particularly in advanced greenhouse designs that could withstand harsh weather conditions while providing optimal light transmission for plant growth. This period marked the beginning of polycarbonate's journey as a key material in controlled environment agriculture.

The 1990s and early 2000s witnessed a surge in innovations utilizing polycarbonate in AgTech. Manufacturers began developing specialized grades of polycarbonate tailored for agricultural applications, offering enhanced UV resistance, improved thermal insulation, and better light diffusion properties. These advancements led to the widespread adoption of polycarbonate in various agricultural structures, including greenhouses, polytunnels, and crop protection systems.

In recent years, the objectives of polycarbonate use in AgTech have evolved to address the growing challenges in modern agriculture. Climate change, resource scarcity, and the need for sustainable farming practices have driven the development of more sophisticated polycarbonate-based solutions. Current objectives focus on creating smart, energy-efficient agricultural environments that can optimize crop yields while minimizing environmental impact.

One of the primary goals is to enhance the material's ability to regulate temperature and humidity within agricultural structures. Research is underway to develop polycarbonate sheets with advanced thermal management properties, capable of adapting to changing environmental conditions. This includes the integration of phase-change materials and smart coatings that can dynamically adjust light transmission and heat retention.

Another key objective is to improve the longevity and recyclability of polycarbonate in agricultural applications. Efforts are being made to develop more durable formulations that can withstand prolonged exposure to UV radiation and harsh weather conditions, thereby extending the lifespan of agricultural structures. Additionally, there is a growing focus on creating closed-loop recycling systems for polycarbonate agricultural products, aligning with the principles of circular economy.

The future of polycarbonate in AgTech is poised for further innovation. Objectives include the development of bio-based polycarbonates derived from renewable resources, reducing the reliance on petroleum-based raw materials. There is also a push towards integrating polycarbonate with other advanced technologies, such as embedded sensors and smart materials, to create intelligent agricultural systems that can monitor and respond to crop needs in real-time.

As research and development progressed, the potential of polycarbonate in agriculture became increasingly apparent. The 1970s and 1980s saw a significant expansion in its use, particularly in advanced greenhouse designs that could withstand harsh weather conditions while providing optimal light transmission for plant growth. This period marked the beginning of polycarbonate's journey as a key material in controlled environment agriculture.

The 1990s and early 2000s witnessed a surge in innovations utilizing polycarbonate in AgTech. Manufacturers began developing specialized grades of polycarbonate tailored for agricultural applications, offering enhanced UV resistance, improved thermal insulation, and better light diffusion properties. These advancements led to the widespread adoption of polycarbonate in various agricultural structures, including greenhouses, polytunnels, and crop protection systems.

In recent years, the objectives of polycarbonate use in AgTech have evolved to address the growing challenges in modern agriculture. Climate change, resource scarcity, and the need for sustainable farming practices have driven the development of more sophisticated polycarbonate-based solutions. Current objectives focus on creating smart, energy-efficient agricultural environments that can optimize crop yields while minimizing environmental impact.

One of the primary goals is to enhance the material's ability to regulate temperature and humidity within agricultural structures. Research is underway to develop polycarbonate sheets with advanced thermal management properties, capable of adapting to changing environmental conditions. This includes the integration of phase-change materials and smart coatings that can dynamically adjust light transmission and heat retention.

Another key objective is to improve the longevity and recyclability of polycarbonate in agricultural applications. Efforts are being made to develop more durable formulations that can withstand prolonged exposure to UV radiation and harsh weather conditions, thereby extending the lifespan of agricultural structures. Additionally, there is a growing focus on creating closed-loop recycling systems for polycarbonate agricultural products, aligning with the principles of circular economy.

The future of polycarbonate in AgTech is poised for further innovation. Objectives include the development of bio-based polycarbonates derived from renewable resources, reducing the reliance on petroleum-based raw materials. There is also a push towards integrating polycarbonate with other advanced technologies, such as embedded sensors and smart materials, to create intelligent agricultural systems that can monitor and respond to crop needs in real-time.

Market Demand Analysis for AgTech Polycarbonate Solutions

The market demand for polycarbonate solutions in agricultural technology has been experiencing significant growth in recent years. This surge is driven by the increasing need for sustainable and efficient farming practices, coupled with the versatility and durability of polycarbonate materials. The global agricultural film market, which includes polycarbonate products, is projected to reach substantial market value in the coming years, with a notable compound annual growth rate.

One of the primary drivers of market demand is the growing adoption of greenhouse and tunnel farming. These controlled environment agriculture techniques require materials that can withstand harsh weather conditions while providing optimal light transmission for crop growth. Polycarbonate sheets and panels have emerged as preferred choices due to their excellent light diffusion properties, UV resistance, and thermal insulation capabilities.

The demand for polycarbonate in hydroponics and vertical farming systems is also on the rise. As urban agriculture gains traction, the need for lightweight, durable, and customizable materials for growing structures has increased. Polycarbonate's versatility in forming various shapes and sizes makes it an ideal material for these innovative farming methods.

In the livestock sector, polycarbonate solutions are gaining popularity for animal housing and shelter applications. The material's impact resistance, ease of cleaning, and ability to maintain stable internal temperatures contribute to improved animal welfare and productivity. This trend is particularly evident in regions with extreme weather conditions, where protecting livestock from environmental stresses is crucial.

The agricultural equipment market is another area driving demand for polycarbonate solutions. Tractor cab windows, equipment covers, and protective shields increasingly utilize polycarbonate materials due to their superior impact resistance and optical clarity compared to traditional glass or other plastics.

Environmental concerns and sustainability initiatives are also influencing market demand. Polycarbonate's recyclability and long lifespan align with the growing emphasis on reducing plastic waste in agriculture. Manufacturers are developing bio-based polycarbonate alternatives to cater to the environmentally conscious segment of the market.

Regionally, Asia-Pacific is expected to witness the highest growth in demand for agricultural polycarbonate solutions. This is attributed to the rapid modernization of farming practices in countries like China and India, coupled with government initiatives to promote protected cultivation. North America and Europe continue to be significant markets, driven by the adoption of precision agriculture and the need for energy-efficient farming structures.

One of the primary drivers of market demand is the growing adoption of greenhouse and tunnel farming. These controlled environment agriculture techniques require materials that can withstand harsh weather conditions while providing optimal light transmission for crop growth. Polycarbonate sheets and panels have emerged as preferred choices due to their excellent light diffusion properties, UV resistance, and thermal insulation capabilities.

The demand for polycarbonate in hydroponics and vertical farming systems is also on the rise. As urban agriculture gains traction, the need for lightweight, durable, and customizable materials for growing structures has increased. Polycarbonate's versatility in forming various shapes and sizes makes it an ideal material for these innovative farming methods.

In the livestock sector, polycarbonate solutions are gaining popularity for animal housing and shelter applications. The material's impact resistance, ease of cleaning, and ability to maintain stable internal temperatures contribute to improved animal welfare and productivity. This trend is particularly evident in regions with extreme weather conditions, where protecting livestock from environmental stresses is crucial.

The agricultural equipment market is another area driving demand for polycarbonate solutions. Tractor cab windows, equipment covers, and protective shields increasingly utilize polycarbonate materials due to their superior impact resistance and optical clarity compared to traditional glass or other plastics.

Environmental concerns and sustainability initiatives are also influencing market demand. Polycarbonate's recyclability and long lifespan align with the growing emphasis on reducing plastic waste in agriculture. Manufacturers are developing bio-based polycarbonate alternatives to cater to the environmentally conscious segment of the market.

Regionally, Asia-Pacific is expected to witness the highest growth in demand for agricultural polycarbonate solutions. This is attributed to the rapid modernization of farming practices in countries like China and India, coupled with government initiatives to promote protected cultivation. North America and Europe continue to be significant markets, driven by the adoption of precision agriculture and the need for energy-efficient farming structures.

Current Challenges in Agricultural Polycarbonate Applications

Despite the numerous advantages of polycarbonate in agricultural applications, several challenges persist in its widespread adoption and optimal utilization. One of the primary concerns is the material's susceptibility to UV degradation over time. Prolonged exposure to sunlight can lead to yellowing, reduced light transmission, and structural weakening of polycarbonate panels used in greenhouses and other agricultural structures. This degradation not only affects the aesthetic appeal but also compromises the material's functional properties, potentially impacting crop yield and quality.

Another significant challenge is the environmental impact of polycarbonate production and disposal. The manufacturing process of polycarbonate is energy-intensive and relies on petroleum-based raw materials, raising concerns about its carbon footprint. Additionally, the end-of-life management of polycarbonate products in agriculture poses recycling and waste management challenges, as these materials often become contaminated with soil, pesticides, and other agricultural residues.

The high initial cost of polycarbonate compared to traditional materials like glass or polyethylene films remains a barrier for many farmers, especially in developing regions. While the long-term benefits may outweigh the upfront investment, the initial capital required can be prohibitive for small-scale farmers or those operating on tight budgets. This economic factor often leads to the continued use of less efficient or less durable materials in agricultural applications.

Thermal management is another area of concern in polycarbonate applications. While the material offers excellent insulation properties, it can sometimes lead to overheating in greenhouse environments, particularly in warmer climates or during peak summer months. This necessitates the implementation of additional ventilation systems or cooling mechanisms, adding to the overall complexity and cost of agricultural structures.

The chemical resistance of polycarbonate, while generally good, can be compromised by exposure to certain agrochemicals and cleaning agents commonly used in agricultural settings. This can lead to stress cracking, reduced clarity, or even structural failure of polycarbonate components, requiring careful selection of compatible chemicals and regular maintenance protocols.

Lastly, the standardization and quality control of polycarbonate products for agricultural use remain inconsistent across different manufacturers and regions. This variability can lead to performance discrepancies and makes it challenging for farmers and agricultural professionals to make informed decisions when selecting polycarbonate materials for specific applications. Addressing these challenges through innovative solutions and continued research is crucial for maximizing the potential of polycarbonate in advancing agricultural technology and sustainability.

Another significant challenge is the environmental impact of polycarbonate production and disposal. The manufacturing process of polycarbonate is energy-intensive and relies on petroleum-based raw materials, raising concerns about its carbon footprint. Additionally, the end-of-life management of polycarbonate products in agriculture poses recycling and waste management challenges, as these materials often become contaminated with soil, pesticides, and other agricultural residues.

The high initial cost of polycarbonate compared to traditional materials like glass or polyethylene films remains a barrier for many farmers, especially in developing regions. While the long-term benefits may outweigh the upfront investment, the initial capital required can be prohibitive for small-scale farmers or those operating on tight budgets. This economic factor often leads to the continued use of less efficient or less durable materials in agricultural applications.

Thermal management is another area of concern in polycarbonate applications. While the material offers excellent insulation properties, it can sometimes lead to overheating in greenhouse environments, particularly in warmer climates or during peak summer months. This necessitates the implementation of additional ventilation systems or cooling mechanisms, adding to the overall complexity and cost of agricultural structures.

The chemical resistance of polycarbonate, while generally good, can be compromised by exposure to certain agrochemicals and cleaning agents commonly used in agricultural settings. This can lead to stress cracking, reduced clarity, or even structural failure of polycarbonate components, requiring careful selection of compatible chemicals and regular maintenance protocols.

Lastly, the standardization and quality control of polycarbonate products for agricultural use remain inconsistent across different manufacturers and regions. This variability can lead to performance discrepancies and makes it challenging for farmers and agricultural professionals to make informed decisions when selecting polycarbonate materials for specific applications. Addressing these challenges through innovative solutions and continued research is crucial for maximizing the potential of polycarbonate in advancing agricultural technology and sustainability.

Existing Polycarbonate Solutions in Agriculture

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These combinations can result in materials with enhanced impact resistance, flame retardancy, or specific functional characteristics for various applications.

- Optical applications of polycarbonates: Utilization of polycarbonates in optical applications, such as lenses, displays, and light-guiding components. This includes modifications to improve optical clarity, UV resistance, and scratch resistance, as well as techniques for molding and shaping polycarbonates for specific optical uses.

- Polycarbonate recycling and sustainability: Methods for recycling polycarbonates and improving their environmental sustainability. This includes techniques for breaking down polycarbonates into reusable monomers, developing bio-based alternatives, and creating more easily recyclable polycarbonate formulations.

- Polycarbonate surface treatments and coatings: Development of surface treatments and coatings for polycarbonates to enhance properties such as scratch resistance, chemical resistance, and weatherability. This includes plasma treatments, application of protective layers, and surface modification techniques to improve the durability and performance of polycarbonate products.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blending process and composition ratios are crucial for optimizing material performance.Expand Specific Solutions03 Polycarbonate processing techniques

Advanced processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on improving production efficiency, reducing defects, and enhancing the final product quality. Specialized equipment and process parameters are developed to optimize polycarbonate processing for various applications.Expand Specific Solutions04 Polycarbonate surface treatments and coatings

Techniques for modifying polycarbonate surfaces through treatments or coatings to enhance properties such as scratch resistance, UV stability, and anti-fogging capabilities. These methods can involve chemical treatments, plasma processes, or the application of specialized coating materials to improve the durability and functionality of polycarbonate products.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Innovations in polycarbonate recycling and sustainable production methods. This includes developing efficient recycling processes, creating bio-based polycarbonates, and improving the overall environmental impact of polycarbonate production and use. Techniques for separating and purifying recycled polycarbonates are also explored to maintain material quality.Expand Specific Solutions

Key Players in Agricultural Polycarbonate Industry

The polycarbonate agricultural technology market is in a growth phase, driven by increasing demand for sustainable and efficient farming solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with major players like SABIC, LG Chem, and Covestro leading innovations. These companies are developing high-performance polycarbonate materials tailored for agricultural applications, such as greenhouse panels and hydroponic systems. Emerging players like Wanhua Chemical and Idemitsu Kosan are also contributing to technological advancements, particularly in areas of durability and light transmission. The competitive landscape is characterized by ongoing R&D efforts to improve material properties and expand application areas, indicating a moderate to high level of technological maturity with room for further innovation.

SABIC Global Technologies BV

Technical Solution: SABIC has developed innovative polycarbonate solutions for agricultural technology, focusing on greenhouse applications. Their LEXAN™ polycarbonate sheets offer high light transmission (up to 89%) and UV protection, enhancing crop growth and yield[1]. The company has also introduced a new grade of polycarbonate specifically designed for agricultural films, which provides improved durability and weather resistance[2]. SABIC's polycarbonate materials are used in creating lightweight, impact-resistant panels for greenhouses and hydroponic systems, allowing for better temperature control and energy efficiency[3]. Additionally, they have developed anti-drip coatings for their polycarbonate sheets, reducing condensation issues in greenhouse environments[4].

Strengths: High light transmission, UV protection, durability, and energy efficiency. Weaknesses: Higher initial cost compared to traditional materials, potential for yellowing over extended periods of extreme UV exposure.

LG Chem Ltd.

Technical Solution: LG Chem has innovated in the field of polycarbonate for agricultural technology, focusing on high-performance materials for greenhouse applications. Their LUPOY® polycarbonate sheets offer superior impact resistance and light transmission, making them ideal for durable greenhouse structures[1]. LG Chem has developed polycarbonate grades with enhanced UV stability, extending the lifespan of agricultural structures exposed to harsh sunlight[2]. The company has also introduced polycarbonate-based films with anti-drip properties, improving light transmission and reducing disease risks in greenhouse environments[3]. Additionally, LG Chem has created polycarbonate composites with improved thermal insulation properties, contributing to energy-efficient agricultural structures[4].

Strengths: High-performance materials, focus on durability and energy efficiency, strong R&D capabilities. Weaknesses: Relatively high cost of materials, limited biodegradability options in their current polycarbonate portfolio.

Core Innovations in AgTech Polycarbonate Materials

Polycarbonate, and method for preparing same

PatentPendingEP4286450A1

Innovation

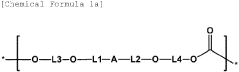

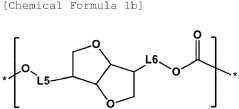

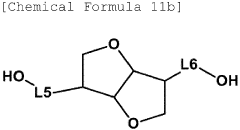

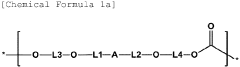

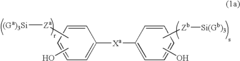

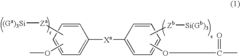

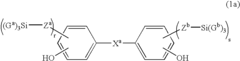

- A polycarbonate composition incorporating specific chemical units represented by Chemical Formulae 1a and 1b, which are polymerized with a carbonate precursor to enhance hardness and heat resistance, including a method that involves copolymerizing compounds like HO-L3-O-L1-A-L2-O-L4-OH, where A is a phenylene or arylene, and L1-6 are various alkylene or arylene groups, to improve impact strength and reduce free volume.

Silylated polycarbonate polymers, method of making, and articles

PatentInactiveUS20080306294A1

Innovation

- Development of silylated polycarbonates with specific carbonate units and dihydroxy aromatic compounds that enhance surface contact angle, scratch resistance, and transparency, achieved through interfacial or melt polymerization processes.

Environmental Impact of Polycarbonate in Agriculture

The environmental impact of polycarbonate in agriculture is a complex issue that requires careful consideration. Polycarbonate, a versatile and durable plastic material, has found widespread use in agricultural applications, particularly in greenhouse construction and protective structures. While it offers numerous benefits, its environmental implications are significant and multifaceted.

One of the primary environmental concerns associated with polycarbonate use in agriculture is its long-term persistence in the environment. Polycarbonate is not biodegradable and can remain in ecosystems for hundreds of years. This longevity contributes to the accumulation of plastic waste in agricultural settings, potentially leading to soil and water pollution if not properly managed or disposed of at the end of its lifecycle.

The production process of polycarbonate also raises environmental issues. The manufacturing of polycarbonate involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. Additionally, the production may release harmful chemicals and pollutants into the air and water, impacting local ecosystems and human health if not properly controlled.

However, it is important to note that polycarbonate's use in agriculture can also have positive environmental impacts. Its durability and light transmission properties allow for the creation of efficient greenhouse structures that can extend growing seasons, reduce water consumption, and minimize the need for pesticides. This can lead to more sustainable and resource-efficient agricultural practices, potentially offsetting some of the negative environmental impacts associated with its production and disposal.

The recycling of polycarbonate presents both challenges and opportunities. While technically recyclable, the process is often complex and not widely implemented in many regions. Improving recycling infrastructure and technologies for polycarbonate could significantly reduce its environmental footprint in agricultural applications.

As the agricultural sector continues to adopt polycarbonate technologies, there is a growing focus on developing more environmentally friendly alternatives. Biodegradable plastics and bio-based polycarbonates are emerging as potential substitutes, although their performance and cost-effectiveness compared to traditional polycarbonate are still being evaluated.

In conclusion, the environmental impact of polycarbonate in agriculture is a balance between its beneficial applications and the challenges posed by its production and end-of-life management. As the industry moves forward, there is a clear need for continued research and innovation to mitigate the negative environmental effects while maximizing the sustainable benefits of polycarbonate use in agricultural technologies.

One of the primary environmental concerns associated with polycarbonate use in agriculture is its long-term persistence in the environment. Polycarbonate is not biodegradable and can remain in ecosystems for hundreds of years. This longevity contributes to the accumulation of plastic waste in agricultural settings, potentially leading to soil and water pollution if not properly managed or disposed of at the end of its lifecycle.

The production process of polycarbonate also raises environmental issues. The manufacturing of polycarbonate involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. Additionally, the production may release harmful chemicals and pollutants into the air and water, impacting local ecosystems and human health if not properly controlled.

However, it is important to note that polycarbonate's use in agriculture can also have positive environmental impacts. Its durability and light transmission properties allow for the creation of efficient greenhouse structures that can extend growing seasons, reduce water consumption, and minimize the need for pesticides. This can lead to more sustainable and resource-efficient agricultural practices, potentially offsetting some of the negative environmental impacts associated with its production and disposal.

The recycling of polycarbonate presents both challenges and opportunities. While technically recyclable, the process is often complex and not widely implemented in many regions. Improving recycling infrastructure and technologies for polycarbonate could significantly reduce its environmental footprint in agricultural applications.

As the agricultural sector continues to adopt polycarbonate technologies, there is a growing focus on developing more environmentally friendly alternatives. Biodegradable plastics and bio-based polycarbonates are emerging as potential substitutes, although their performance and cost-effectiveness compared to traditional polycarbonate are still being evaluated.

In conclusion, the environmental impact of polycarbonate in agriculture is a balance between its beneficial applications and the challenges posed by its production and end-of-life management. As the industry moves forward, there is a clear need for continued research and innovation to mitigate the negative environmental effects while maximizing the sustainable benefits of polycarbonate use in agricultural technologies.

Regulatory Framework for AgTech Materials

The regulatory framework for AgTech materials, particularly polycarbonate in agricultural applications, is a complex and evolving landscape. Governments and international organizations have established various regulations and standards to ensure the safety, efficacy, and environmental sustainability of agricultural technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating AgTech materials. The Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) provides the legal framework for the regulation of pesticides, including those incorporating polycarbonate technologies. The EPA evaluates the potential environmental and health impacts of these materials before granting approval for their use in agriculture.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in agricultural technologies. This comprehensive regulatory system aims to protect human health and the environment while promoting innovation in the chemical industry.

In addition to national and regional regulations, international standards organizations such as the International Organization for Standardization (ISO) have developed specific guidelines for AgTech materials. ISO 22000, for instance, addresses food safety management systems, which includes the use of materials like polycarbonate in agricultural applications.

The Food and Agriculture Organization (FAO) of the United Nations has established the Codex Alimentarius, a collection of internationally recognized standards for food safety. These standards include guidelines for the use of materials in food production and processing, which can impact the development and application of polycarbonate technologies in agriculture.

Regulatory bodies are increasingly focusing on the environmental impact of AgTech materials. The concept of circular economy and sustainable agriculture has led to the development of regulations promoting biodegradable and recyclable materials. This trend is influencing the research and development of polycarbonate applications in agriculture, pushing for more environmentally friendly alternatives.

As nanotechnology becomes more prevalent in AgTech, regulatory frameworks are adapting to address the unique challenges posed by nanomaterials. The Organization for Economic Co-operation and Development (OECD) has developed guidelines for the testing and assessment of manufactured nanomaterials, which may apply to certain polycarbonate-based agricultural technologies.

The regulatory landscape for AgTech materials is continuously evolving to keep pace with technological advancements. Policymakers and industry stakeholders are working together to develop regulations that balance innovation with safety and environmental concerns. This collaborative approach is essential for the responsible development and implementation of polycarbonate technologies in agriculture.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating AgTech materials. The Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) provides the legal framework for the regulation of pesticides, including those incorporating polycarbonate technologies. The EPA evaluates the potential environmental and health impacts of these materials before granting approval for their use in agriculture.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in agricultural technologies. This comprehensive regulatory system aims to protect human health and the environment while promoting innovation in the chemical industry.

In addition to national and regional regulations, international standards organizations such as the International Organization for Standardization (ISO) have developed specific guidelines for AgTech materials. ISO 22000, for instance, addresses food safety management systems, which includes the use of materials like polycarbonate in agricultural applications.

The Food and Agriculture Organization (FAO) of the United Nations has established the Codex Alimentarius, a collection of internationally recognized standards for food safety. These standards include guidelines for the use of materials in food production and processing, which can impact the development and application of polycarbonate technologies in agriculture.

Regulatory bodies are increasingly focusing on the environmental impact of AgTech materials. The concept of circular economy and sustainable agriculture has led to the development of regulations promoting biodegradable and recyclable materials. This trend is influencing the research and development of polycarbonate applications in agriculture, pushing for more environmentally friendly alternatives.

As nanotechnology becomes more prevalent in AgTech, regulatory frameworks are adapting to address the unique challenges posed by nanomaterials. The Organization for Economic Co-operation and Development (OECD) has developed guidelines for the testing and assessment of manufactured nanomaterials, which may apply to certain polycarbonate-based agricultural technologies.

The regulatory landscape for AgTech materials is continuously evolving to keep pace with technological advancements. Policymakers and industry stakeholders are working together to develop regulations that balance innovation with safety and environmental concerns. This collaborative approach is essential for the responsible development and implementation of polycarbonate technologies in agriculture.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!