Polycarbonate in Food Packaging: Safety and Sustainability

JUL 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Evolution

Polycarbonate, a versatile thermoplastic polymer, has undergone significant evolution since its discovery in 1953 by Dr. Hermann Schnell. Initially developed for electrical insulation and household goods, its application in food packaging emerged in the 1960s due to its unique properties of transparency, durability, and heat resistance.

The 1970s and 1980s saw a rapid expansion of polycarbonate use in food containers, particularly in reusable water bottles and baby bottles. This growth was driven by the material's ability to withstand repeated use and sterilization, making it an attractive option for both consumers and manufacturers. However, this period also marked the beginning of concerns regarding the safety of bisphenol A (BPA), a key component in polycarbonate production.

The 1990s brought increased scrutiny of polycarbonate safety, as research began to suggest potential health risks associated with BPA leaching. This led to a pivotal moment in the early 2000s when several countries, including Canada and the European Union, banned BPA in baby bottles. This shift prompted the industry to explore alternative materials and manufacturing processes.

In response to these challenges, the 2010s witnessed significant innovations in polycarbonate technology. Manufacturers developed BPA-free polycarbonates and explored new monomers to create safer alternatives. Simultaneously, advancements in coating technologies emerged to minimize leaching risks while maintaining the desirable properties of polycarbonate.

Recent years have seen a focus on sustainability in polycarbonate evolution. Efforts to improve recyclability and develop bio-based polycarbonates have gained traction. These initiatives aim to address environmental concerns while preserving the material's beneficial characteristics for food packaging applications.

The evolution of polycarbonate in food packaging reflects a complex interplay between technological advancement, safety concerns, and sustainability goals. As research continues and regulatory standards evolve, the industry faces ongoing challenges in balancing the material's performance benefits with safety and environmental considerations. This dynamic landscape continues to drive innovation in polycarbonate technology, shaping its future in food packaging applications.

The 1970s and 1980s saw a rapid expansion of polycarbonate use in food containers, particularly in reusable water bottles and baby bottles. This growth was driven by the material's ability to withstand repeated use and sterilization, making it an attractive option for both consumers and manufacturers. However, this period also marked the beginning of concerns regarding the safety of bisphenol A (BPA), a key component in polycarbonate production.

The 1990s brought increased scrutiny of polycarbonate safety, as research began to suggest potential health risks associated with BPA leaching. This led to a pivotal moment in the early 2000s when several countries, including Canada and the European Union, banned BPA in baby bottles. This shift prompted the industry to explore alternative materials and manufacturing processes.

In response to these challenges, the 2010s witnessed significant innovations in polycarbonate technology. Manufacturers developed BPA-free polycarbonates and explored new monomers to create safer alternatives. Simultaneously, advancements in coating technologies emerged to minimize leaching risks while maintaining the desirable properties of polycarbonate.

Recent years have seen a focus on sustainability in polycarbonate evolution. Efforts to improve recyclability and develop bio-based polycarbonates have gained traction. These initiatives aim to address environmental concerns while preserving the material's beneficial characteristics for food packaging applications.

The evolution of polycarbonate in food packaging reflects a complex interplay between technological advancement, safety concerns, and sustainability goals. As research continues and regulatory standards evolve, the industry faces ongoing challenges in balancing the material's performance benefits with safety and environmental considerations. This dynamic landscape continues to drive innovation in polycarbonate technology, shaping its future in food packaging applications.

Food Packaging Demand

The demand for food packaging has been steadily increasing due to changing consumer lifestyles, urbanization, and the growth of the food and beverage industry. Polycarbonate, a versatile plastic material, has gained significant attention in the food packaging sector due to its unique properties. The global food packaging market is projected to reach substantial growth in the coming years, driven by factors such as the rise in packaged and convenience foods, increased focus on food safety, and the need for extended shelf life of products.

In recent years, there has been a notable shift towards sustainable and eco-friendly packaging solutions, which has impacted the demand for traditional plastic materials like polycarbonate. Consumers are becoming more environmentally conscious, leading to a growing preference for recyclable and biodegradable packaging options. This trend has prompted food manufacturers and packaging companies to explore alternative materials and innovative packaging designs that align with sustainability goals while maintaining the functional benefits of polycarbonate.

The food packaging industry is witnessing a surge in demand for transparent, lightweight, and durable packaging solutions, areas where polycarbonate has traditionally excelled. However, concerns regarding the safety of polycarbonate, particularly related to the potential leaching of bisphenol A (BPA), have led to increased scrutiny and regulatory measures in some regions. This has resulted in a complex market dynamic where the demand for polycarbonate in food packaging is influenced by both its advantageous properties and safety considerations.

The COVID-19 pandemic has further reshaped the food packaging landscape, with an increased emphasis on hygiene and safety. This has led to a rise in demand for packaged foods and beverages, potentially boosting the use of materials like polycarbonate that offer good barrier properties and protection against contamination. However, the pandemic has also accelerated the trend towards sustainable packaging, as consumers become more aware of the environmental impact of their purchasing decisions.

In the context of polycarbonate use in food packaging, market demand is being shaped by a balance between performance requirements and safety concerns. While some segments of the food industry continue to value the durability and clarity of polycarbonate, others are actively seeking alternatives that address both safety and sustainability issues. This has created opportunities for innovation in food packaging materials and designs, driving research and development efforts to find solutions that meet the evolving demands of consumers, regulators, and environmental advocates.

In recent years, there has been a notable shift towards sustainable and eco-friendly packaging solutions, which has impacted the demand for traditional plastic materials like polycarbonate. Consumers are becoming more environmentally conscious, leading to a growing preference for recyclable and biodegradable packaging options. This trend has prompted food manufacturers and packaging companies to explore alternative materials and innovative packaging designs that align with sustainability goals while maintaining the functional benefits of polycarbonate.

The food packaging industry is witnessing a surge in demand for transparent, lightweight, and durable packaging solutions, areas where polycarbonate has traditionally excelled. However, concerns regarding the safety of polycarbonate, particularly related to the potential leaching of bisphenol A (BPA), have led to increased scrutiny and regulatory measures in some regions. This has resulted in a complex market dynamic where the demand for polycarbonate in food packaging is influenced by both its advantageous properties and safety considerations.

The COVID-19 pandemic has further reshaped the food packaging landscape, with an increased emphasis on hygiene and safety. This has led to a rise in demand for packaged foods and beverages, potentially boosting the use of materials like polycarbonate that offer good barrier properties and protection against contamination. However, the pandemic has also accelerated the trend towards sustainable packaging, as consumers become more aware of the environmental impact of their purchasing decisions.

In the context of polycarbonate use in food packaging, market demand is being shaped by a balance between performance requirements and safety concerns. While some segments of the food industry continue to value the durability and clarity of polycarbonate, others are actively seeking alternatives that address both safety and sustainability issues. This has created opportunities for innovation in food packaging materials and designs, driving research and development efforts to find solutions that meet the evolving demands of consumers, regulators, and environmental advocates.

Safety Challenges

The use of polycarbonate in food packaging presents several significant safety challenges that require careful consideration and ongoing research. One of the primary concerns is the potential leaching of bisphenol A (BPA), a key component in polycarbonate production, into food and beverages. BPA has been linked to various health issues, including endocrine disruption, reproductive problems, and developmental effects in children. This has led to increased scrutiny and regulatory action in many countries, with some banning BPA in certain products, particularly those intended for infants and young children.

Temperature and pH conditions can exacerbate the leaching of BPA and other chemicals from polycarbonate packaging. Exposure to high temperatures, such as during microwave heating or hot filling processes, can accelerate the migration of these substances into food. Similarly, acidic or alkaline foods may interact with the polycarbonate material, potentially increasing the release of harmful compounds. These factors complicate the use of polycarbonate in a wide range of food packaging applications and necessitate careful consideration of usage conditions.

The long-term effects of exposure to low doses of BPA and other chemicals that may leach from polycarbonate packaging remain a subject of ongoing scientific debate. While some studies suggest potential health risks, others argue that the levels of exposure from food packaging are too low to cause significant harm. This uncertainty poses challenges for regulators, manufacturers, and consumers in making informed decisions about the safety of polycarbonate food packaging.

Another safety concern is the potential for polycarbonate to absorb and retain odors and flavors from foods, which can affect the quality and safety of subsequently stored items. This cross-contamination risk is particularly problematic in reusable containers and may lead to the growth of harmful bacteria if not properly cleaned and maintained.

The recycling and disposal of polycarbonate food packaging also present safety challenges. Improper recycling can lead to the contamination of recycled materials with BPA and other additives, potentially reintroducing these substances into new products. Additionally, the environmental persistence of polycarbonate and its additives raises concerns about long-term ecological impacts and potential reentry into the food chain through environmental contamination.

Addressing these safety challenges requires a multifaceted approach, including continued research into alternative materials, improved manufacturing processes to minimize chemical leaching, and the development of more sensitive testing methods to detect and quantify potential contaminants. Regulatory bodies must also stay abreast of emerging scientific evidence to update safety standards and guidelines for the use of polycarbonate in food packaging.

Temperature and pH conditions can exacerbate the leaching of BPA and other chemicals from polycarbonate packaging. Exposure to high temperatures, such as during microwave heating or hot filling processes, can accelerate the migration of these substances into food. Similarly, acidic or alkaline foods may interact with the polycarbonate material, potentially increasing the release of harmful compounds. These factors complicate the use of polycarbonate in a wide range of food packaging applications and necessitate careful consideration of usage conditions.

The long-term effects of exposure to low doses of BPA and other chemicals that may leach from polycarbonate packaging remain a subject of ongoing scientific debate. While some studies suggest potential health risks, others argue that the levels of exposure from food packaging are too low to cause significant harm. This uncertainty poses challenges for regulators, manufacturers, and consumers in making informed decisions about the safety of polycarbonate food packaging.

Another safety concern is the potential for polycarbonate to absorb and retain odors and flavors from foods, which can affect the quality and safety of subsequently stored items. This cross-contamination risk is particularly problematic in reusable containers and may lead to the growth of harmful bacteria if not properly cleaned and maintained.

The recycling and disposal of polycarbonate food packaging also present safety challenges. Improper recycling can lead to the contamination of recycled materials with BPA and other additives, potentially reintroducing these substances into new products. Additionally, the environmental persistence of polycarbonate and its additives raises concerns about long-term ecological impacts and potential reentry into the food chain through environmental contamination.

Addressing these safety challenges requires a multifaceted approach, including continued research into alternative materials, improved manufacturing processes to minimize chemical leaching, and the development of more sensitive testing methods to detect and quantify potential contaminants. Regulatory bodies must also stay abreast of emerging scientific evidence to update safety standards and guidelines for the use of polycarbonate in food packaging.

Current Safety Solutions

01 Safety features of polycarbonate materials

Polycarbonate materials are known for their high impact resistance and durability, making them safer for various applications. They are often used in safety equipment, protective gear, and shatter-resistant products. The material's ability to withstand high temperatures and resist breakage contributes to its safety profile in consumer and industrial products.- Safety features of polycarbonate materials: Polycarbonate materials are known for their high impact resistance and durability, making them safer for various applications. They are often used in safety equipment, protective gear, and shatter-resistant products. The material's ability to withstand high temperatures and resist breakage contributes to its safety profile in consumer and industrial products.

- Sustainable production and recycling of polycarbonates: Efforts are being made to improve the sustainability of polycarbonate production and increase recycling rates. This includes developing bio-based alternatives, implementing closed-loop recycling systems, and improving the energy efficiency of manufacturing processes. Innovations in chemical recycling techniques are also being explored to break down polycarbonates into their original monomers for reuse.

- Environmental impact and lifecycle assessment: Research is ongoing to assess the full lifecycle environmental impact of polycarbonates, from production to disposal. This includes evaluating carbon footprint, energy consumption, and potential for biodegradation. Studies are also focusing on comparing polycarbonates with alternative materials to determine their overall sustainability in different applications.

- Innovations in polycarbonate additives for enhanced properties: New additives and formulations are being developed to enhance the safety and sustainability of polycarbonates. These include flame retardants that reduce fire hazards, UV stabilizers to extend product life, and antimicrobial agents for improved hygiene. Some additives aim to improve the material's recyclability or biodegradability without compromising its mechanical properties.

- Applications of polycarbonates in sustainable technologies: Polycarbonates are finding new applications in sustainable technologies due to their unique properties. They are being used in solar panel components, electric vehicle parts, and energy-efficient building materials. The material's lightweight nature and durability contribute to improved fuel efficiency in transportation and longevity in various products, supporting overall sustainability goals.

02 Sustainable production and recycling of polycarbonates

Efforts are being made to improve the sustainability of polycarbonate production and use. This includes developing more eco-friendly manufacturing processes, using renewable resources as raw materials, and enhancing recycling techniques. Innovations in chemical recycling and circular economy approaches are being explored to reduce the environmental impact of polycarbonate products.Expand Specific Solutions03 Polycarbonate alternatives and blends for improved sustainability

Research is ongoing to develop alternatives to traditional polycarbonates or create blends that maintain desirable properties while improving sustainability. This includes exploring bio-based polymers, creating composite materials, and developing new formulations that reduce environmental impact without compromising performance.Expand Specific Solutions04 Safety regulations and compliance for polycarbonate products

The use of polycarbonates in various industries is subject to safety regulations and compliance standards. This includes testing for chemical leaching, ensuring food-contact safety, and meeting specific industry requirements. Manufacturers are developing processes and products that adhere to these regulations while maintaining the beneficial properties of polycarbonates.Expand Specific Solutions05 Innovations in polycarbonate applications for safety and sustainability

New applications of polycarbonates are being developed with a focus on enhancing safety and sustainability. This includes their use in energy-efficient building materials, advanced medical devices, and sustainable packaging solutions. Innovations aim to leverage the material's properties while addressing environmental concerns and safety requirements.Expand Specific Solutions

Industry Leaders

The polycarbonate food packaging market is in a mature stage, with a global market size estimated to reach $3.5 billion by 2027. The industry is characterized by intense competition among established players like SABIC, Covestro, and BASF, who are focusing on developing safer and more sustainable alternatives. Technological advancements are driving the market, with companies investing in research to address safety concerns and improve recyclability. The market is also seeing increased collaboration between industry players and research institutions like the University of Tokyo and MIT to develop innovative solutions. As sustainability becomes a key focus, companies are exploring bio-based polycarbonates and alternative materials to meet evolving consumer and regulatory demands.

SABIC Global Technologies BV

Technical Solution: SABIC has developed LEXAN™ polycarbonate resins for food packaging applications, focusing on safety and sustainability. Their technology incorporates advanced additives to enhance the material's resistance to hydrolysis and improve its clarity and impact strength. SABIC's polycarbonate solutions for food packaging are BPA-free, addressing concerns about potential health risks [1]. The company has also introduced bio-based polycarbonates, derived partially from renewable resources, reducing the carbon footprint of their products [2]. SABIC's polycarbonate technology for food packaging includes a proprietary coating process that enhances chemical resistance and extends the shelf life of packaged foods [3].

Strengths: BPA-free formulations, improved chemical resistance, and bio-based options. Weaknesses: Higher production costs compared to traditional plastics, and potential challenges in recycling coated polycarbonate products.

Covestro Deutschland AG

Technical Solution: Covestro has developed Makrolon® polycarbonate for food packaging applications, emphasizing safety and sustainability. Their technology focuses on creating high-performance, food-grade polycarbonate that meets stringent regulatory requirements. Covestro's polycarbonate solutions offer excellent transparency, impact resistance, and temperature stability [1]. The company has also introduced partially bio-based polycarbonates, reducing reliance on fossil resources [2]. Covestro's technology includes a special grade of polycarbonate designed for reusable food containers, promoting a circular economy approach [3]. They have also developed additives that enhance the material's resistance to chemicals and UV radiation, extending the lifespan of food packaging products [4].

Strengths: High-performance properties, partially bio-based options, and focus on reusability. Weaknesses: Potential concerns about chemical leaching in certain conditions, and challenges in widespread recycling infrastructure for polycarbonate.

Key Innovations

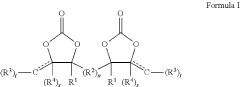

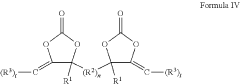

Polycyclocarbonate compounds and polymers formed therefrom

PatentActiveUS20200361892A1

Innovation

- Development of polycyclocarbonate compounds and polymers, specifically dicyclocarbonate compounds with a carbonate linkage, which are synthesized through reacting carbonyl-functional compounds with carbon-carbon triple bond-containing compounds and carbon dioxide, forming a polymer with a glass transition temperature of at least 40°C and suitable for use in food-contact coatings.

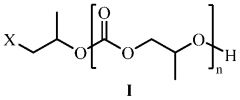

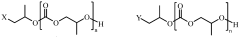

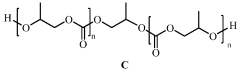

Aliphatic polycarbonate extrusion coatings

PatentWO2013013132A1

Innovation

- The use of aliphatic polycarbonate extrusion coatings, specifically poly(propylene carbonate) and poly(ethylene carbonate), which are applied directly to paper or paperboard without a tie layer, offering enhanced oxygen barrier properties and improved processing characteristics through precise control of reaction parameters, resulting in higher strength, reduced thermal deformation, and increased glass transition temperatures.

Regulatory Framework

The regulatory framework surrounding polycarbonate in food packaging is complex and multifaceted, involving various international, national, and regional bodies. At the forefront of global regulations is the Food and Drug Administration (FDA) in the United States, which has approved polycarbonate as a food contact material under specific conditions. The FDA continually monitors scientific research and updates its guidelines accordingly to ensure public safety.

In the European Union, the European Food Safety Authority (EFSA) plays a crucial role in assessing the safety of food contact materials, including polycarbonate. The EU has established specific migration limits for bisphenol A (BPA), a key component in polycarbonate production, through Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Many countries have adopted their own regulatory measures regarding polycarbonate in food packaging. For instance, Canada has banned BPA in baby bottles, while Japan has established voluntary industry guidelines for reducing BPA exposure. These diverse approaches reflect the ongoing debate about the safety of polycarbonate and its components in food contact applications.

Sustainability considerations have also begun to influence the regulatory landscape. The European Union's Circular Economy Action Plan, for example, aims to promote sustainable packaging materials and reduce plastic waste. This initiative may impact future regulations on polycarbonate use in food packaging, potentially encouraging the development of more environmentally friendly alternatives.

International organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) provide guidance and recommendations that often inform national regulatory decisions. These bodies emphasize the importance of a science-based approach to assessing the safety and environmental impact of food packaging materials.

As scientific understanding evolves, regulatory frameworks continue to adapt. Recent focus areas include the potential endocrine-disrupting effects of BPA and the environmental persistence of polycarbonate plastics. This has led to increased scrutiny and, in some cases, stricter regulations or voluntary phase-outs of certain polycarbonate products in the food packaging industry.

The regulatory landscape also encompasses labeling requirements, which vary by jurisdiction. Some regions mandate the disclosure of polycarbonate or BPA content in food packaging, while others have implemented warning labels for certain consumer groups, such as pregnant women and infants.

In the European Union, the European Food Safety Authority (EFSA) plays a crucial role in assessing the safety of food contact materials, including polycarbonate. The EU has established specific migration limits for bisphenol A (BPA), a key component in polycarbonate production, through Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Many countries have adopted their own regulatory measures regarding polycarbonate in food packaging. For instance, Canada has banned BPA in baby bottles, while Japan has established voluntary industry guidelines for reducing BPA exposure. These diverse approaches reflect the ongoing debate about the safety of polycarbonate and its components in food contact applications.

Sustainability considerations have also begun to influence the regulatory landscape. The European Union's Circular Economy Action Plan, for example, aims to promote sustainable packaging materials and reduce plastic waste. This initiative may impact future regulations on polycarbonate use in food packaging, potentially encouraging the development of more environmentally friendly alternatives.

International organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) provide guidance and recommendations that often inform national regulatory decisions. These bodies emphasize the importance of a science-based approach to assessing the safety and environmental impact of food packaging materials.

As scientific understanding evolves, regulatory frameworks continue to adapt. Recent focus areas include the potential endocrine-disrupting effects of BPA and the environmental persistence of polycarbonate plastics. This has led to increased scrutiny and, in some cases, stricter regulations or voluntary phase-outs of certain polycarbonate products in the food packaging industry.

The regulatory landscape also encompasses labeling requirements, which vary by jurisdiction. Some regions mandate the disclosure of polycarbonate or BPA content in food packaging, while others have implemented warning labels for certain consumer groups, such as pregnant women and infants.

Environmental Impact

The environmental impact of polycarbonate in food packaging is a complex issue that requires careful consideration. Polycarbonate, a durable and versatile plastic, has been widely used in food packaging due to its excellent physical properties. However, its production, use, and disposal have significant environmental implications.

The manufacturing process of polycarbonate is energy-intensive and relies heavily on fossil fuels, contributing to greenhouse gas emissions and climate change. The production also involves the use of potentially harmful chemicals, such as bisphenol A (BPA), which can have adverse effects on ecosystems if released into the environment.

During its use phase, polycarbonate food packaging offers some environmental benefits. Its durability and reusability can reduce the need for single-use plastics, potentially decreasing overall plastic waste. However, the long lifespan of polycarbonate products can also be problematic, as they persist in the environment for extended periods when improperly disposed of.

End-of-life management of polycarbonate food packaging presents significant challenges. While theoretically recyclable, the recycling rates for polycarbonate remain low due to limited infrastructure and the complexity of separating it from other plastics. When incinerated, polycarbonate can release toxic substances, including dioxins and furans, which pose risks to air quality and human health.

The persistence of polycarbonate in the environment is a growing concern. As it slowly degrades, it can fragment into microplastics, which have been found in various ecosystems, including oceans, soil, and even the air. These microplastics can harm wildlife through ingestion and may also accumulate toxic substances, potentially entering the food chain.

Efforts to mitigate the environmental impact of polycarbonate in food packaging are ongoing. Research into more sustainable production methods, such as using renewable energy sources and developing bio-based alternatives, shows promise. Additionally, improved recycling technologies and infrastructure could increase the circularity of polycarbonate products, reducing their environmental footprint.

In conclusion, while polycarbonate offers certain advantages in food packaging, its environmental impact throughout its lifecycle is significant. Balancing its benefits with sustainability concerns remains a challenge for the industry, necessitating continued research and innovation in more environmentally friendly alternatives and improved waste management strategies.

The manufacturing process of polycarbonate is energy-intensive and relies heavily on fossil fuels, contributing to greenhouse gas emissions and climate change. The production also involves the use of potentially harmful chemicals, such as bisphenol A (BPA), which can have adverse effects on ecosystems if released into the environment.

During its use phase, polycarbonate food packaging offers some environmental benefits. Its durability and reusability can reduce the need for single-use plastics, potentially decreasing overall plastic waste. However, the long lifespan of polycarbonate products can also be problematic, as they persist in the environment for extended periods when improperly disposed of.

End-of-life management of polycarbonate food packaging presents significant challenges. While theoretically recyclable, the recycling rates for polycarbonate remain low due to limited infrastructure and the complexity of separating it from other plastics. When incinerated, polycarbonate can release toxic substances, including dioxins and furans, which pose risks to air quality and human health.

The persistence of polycarbonate in the environment is a growing concern. As it slowly degrades, it can fragment into microplastics, which have been found in various ecosystems, including oceans, soil, and even the air. These microplastics can harm wildlife through ingestion and may also accumulate toxic substances, potentially entering the food chain.

Efforts to mitigate the environmental impact of polycarbonate in food packaging are ongoing. Research into more sustainable production methods, such as using renewable energy sources and developing bio-based alternatives, shows promise. Additionally, improved recycling technologies and infrastructure could increase the circularity of polycarbonate products, reducing their environmental footprint.

In conclusion, while polycarbonate offers certain advantages in food packaging, its environmental impact throughout its lifecycle is significant. Balancing its benefits with sustainability concerns remains a challenge for the industry, necessitating continued research and innovation in more environmentally friendly alternatives and improved waste management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!