Polycarbonate in Smart Grid Components: An Emerging Field

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in Smart Grid: Background and Objectives

Polycarbonate, a versatile thermoplastic polymer, has emerged as a promising material in the development of smart grid components. The evolution of smart grids, which integrate advanced digital technologies with traditional power systems, has created a demand for materials that can withstand harsh environmental conditions while providing excellent electrical insulation properties. Polycarbonate's unique combination of durability, transparency, and electrical resistance has positioned it as an ideal candidate for various smart grid applications.

The smart grid concept has been evolving since the early 2000s, driven by the need for more efficient, reliable, and sustainable power distribution systems. As the grid infrastructure modernizes, the integration of renewable energy sources, advanced metering systems, and real-time monitoring capabilities has become paramount. This technological shift has led to increased interest in materials that can support these advancements, with polycarbonate emerging as a key player in this transformation.

Polycarbonate's journey in the smart grid sector began with its use in meter housings and electrical enclosures. Its ability to withstand extreme temperatures, resist impact, and provide clear visibility for meter readings made it an attractive choice for utility companies. As smart grid technologies advanced, the applications for polycarbonate expanded to include components such as transformer bushings, switchgear insulators, and solar panel frames.

The primary objective of incorporating polycarbonate into smart grid components is to enhance the overall performance, reliability, and longevity of the grid infrastructure. By leveraging polycarbonate's properties, manufacturers aim to develop components that can withstand environmental stressors, reduce maintenance requirements, and improve the overall efficiency of power distribution systems. Additionally, the material's recyclability aligns with the sustainability goals of modern smart grid initiatives.

Research and development efforts in this field are focused on optimizing polycarbonate formulations to meet the specific demands of smart grid applications. This includes improving its resistance to ultraviolet radiation, enhancing its flame-retardant properties, and developing conductive variants for specialized applications. The goal is to create a new generation of smart grid components that can adapt to the evolving needs of the energy sector while maintaining the highest standards of safety and performance.

As the smart grid market continues to grow, driven by factors such as increasing energy demand, government initiatives for grid modernization, and the integration of renewable energy sources, the role of polycarbonate is expected to expand further. The material's versatility and adaptability position it as a key enabler in the ongoing transformation of power distribution systems, supporting the transition towards more intelligent, efficient, and sustainable energy networks.

The smart grid concept has been evolving since the early 2000s, driven by the need for more efficient, reliable, and sustainable power distribution systems. As the grid infrastructure modernizes, the integration of renewable energy sources, advanced metering systems, and real-time monitoring capabilities has become paramount. This technological shift has led to increased interest in materials that can support these advancements, with polycarbonate emerging as a key player in this transformation.

Polycarbonate's journey in the smart grid sector began with its use in meter housings and electrical enclosures. Its ability to withstand extreme temperatures, resist impact, and provide clear visibility for meter readings made it an attractive choice for utility companies. As smart grid technologies advanced, the applications for polycarbonate expanded to include components such as transformer bushings, switchgear insulators, and solar panel frames.

The primary objective of incorporating polycarbonate into smart grid components is to enhance the overall performance, reliability, and longevity of the grid infrastructure. By leveraging polycarbonate's properties, manufacturers aim to develop components that can withstand environmental stressors, reduce maintenance requirements, and improve the overall efficiency of power distribution systems. Additionally, the material's recyclability aligns with the sustainability goals of modern smart grid initiatives.

Research and development efforts in this field are focused on optimizing polycarbonate formulations to meet the specific demands of smart grid applications. This includes improving its resistance to ultraviolet radiation, enhancing its flame-retardant properties, and developing conductive variants for specialized applications. The goal is to create a new generation of smart grid components that can adapt to the evolving needs of the energy sector while maintaining the highest standards of safety and performance.

As the smart grid market continues to grow, driven by factors such as increasing energy demand, government initiatives for grid modernization, and the integration of renewable energy sources, the role of polycarbonate is expected to expand further. The material's versatility and adaptability position it as a key enabler in the ongoing transformation of power distribution systems, supporting the transition towards more intelligent, efficient, and sustainable energy networks.

Smart Grid Market Demand Analysis

The smart grid market is experiencing significant growth and transformation, driven by the increasing demand for efficient, reliable, and sustainable energy distribution systems. As countries worldwide focus on modernizing their power infrastructure, the smart grid sector is poised for substantial expansion. Market research indicates that the global smart grid market is expected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, reflecting the urgent need for advanced energy management solutions.

The demand for smart grid components is primarily fueled by several key factors. Firstly, the integration of renewable energy sources into existing power networks necessitates more sophisticated grid management systems. As solar, wind, and other clean energy technologies become more prevalent, smart grids are essential for balancing supply and demand, managing intermittency, and ensuring grid stability. This trend is particularly pronounced in regions with ambitious renewable energy targets, such as the European Union and parts of Asia.

Secondly, the increasing electrification of transportation and heating systems is placing new demands on power grids. The rise of electric vehicles and smart buildings requires more flexible and responsive energy distribution networks. Smart grid technologies, including advanced metering infrastructure (AMI) and distribution automation systems, are crucial for managing these evolving load patterns and preventing grid overload.

Furthermore, the growing concern over energy security and resilience is driving investment in smart grid technologies. Utilities and governments are seeking ways to improve grid reliability, reduce outages, and enhance response times to power disruptions. This has led to increased demand for smart sensors, fault detection systems, and self-healing grid technologies, many of which incorporate polycarbonate materials for their durability and performance characteristics.

The market demand for smart grid components also reflects the push for greater energy efficiency and reduced carbon emissions. Smart meters, which often utilize polycarbonate in their construction, are being deployed at an accelerating rate globally. These devices enable more accurate billing, real-time energy consumption monitoring, and demand response programs, all of which contribute to more efficient energy use and reduced environmental impact.

In the industrial sector, there is a growing need for smart grid solutions that can support the concept of Industry 4.0 and the Industrial Internet of Things (IIoT). Manufacturing facilities and large-scale industrial operations are increasingly adopting smart energy management systems to optimize their power consumption, reduce costs, and improve operational efficiency. This trend is creating new opportunities for smart grid component manufacturers, including those specializing in polycarbonate-based products.

The demand for smart grid components is primarily fueled by several key factors. Firstly, the integration of renewable energy sources into existing power networks necessitates more sophisticated grid management systems. As solar, wind, and other clean energy technologies become more prevalent, smart grids are essential for balancing supply and demand, managing intermittency, and ensuring grid stability. This trend is particularly pronounced in regions with ambitious renewable energy targets, such as the European Union and parts of Asia.

Secondly, the increasing electrification of transportation and heating systems is placing new demands on power grids. The rise of electric vehicles and smart buildings requires more flexible and responsive energy distribution networks. Smart grid technologies, including advanced metering infrastructure (AMI) and distribution automation systems, are crucial for managing these evolving load patterns and preventing grid overload.

Furthermore, the growing concern over energy security and resilience is driving investment in smart grid technologies. Utilities and governments are seeking ways to improve grid reliability, reduce outages, and enhance response times to power disruptions. This has led to increased demand for smart sensors, fault detection systems, and self-healing grid technologies, many of which incorporate polycarbonate materials for their durability and performance characteristics.

The market demand for smart grid components also reflects the push for greater energy efficiency and reduced carbon emissions. Smart meters, which often utilize polycarbonate in their construction, are being deployed at an accelerating rate globally. These devices enable more accurate billing, real-time energy consumption monitoring, and demand response programs, all of which contribute to more efficient energy use and reduced environmental impact.

In the industrial sector, there is a growing need for smart grid solutions that can support the concept of Industry 4.0 and the Industrial Internet of Things (IIoT). Manufacturing facilities and large-scale industrial operations are increasingly adopting smart energy management systems to optimize their power consumption, reduce costs, and improve operational efficiency. This trend is creating new opportunities for smart grid component manufacturers, including those specializing in polycarbonate-based products.

Current State and Challenges of Polycarbonate Usage

Polycarbonate has emerged as a promising material in the development of smart grid components, offering a unique combination of properties that address the evolving needs of modern power distribution systems. The current state of polycarbonate usage in smart grid applications is characterized by increasing adoption, particularly in areas where durability, electrical insulation, and transparency are crucial.

In the realm of smart meters, polycarbonate has become a material of choice for housing and protective covers. Its high impact strength and weather resistance ensure longevity in outdoor installations, while its clarity allows for easy reading of digital displays. The material's inherent flame retardancy also contributes to the safety of these devices, which are often exposed to varying environmental conditions.

For transformer bushings and insulators, polycarbonate is gaining traction due to its excellent dielectric properties and resistance to electrical tracking. These components benefit from the material's ability to maintain performance under high voltage conditions and its resistance to degradation from electrical arcing.

In the domain of smart grid sensors and monitoring devices, polycarbonate enclosures provide robust protection against environmental factors while allowing for the integration of wireless communication technologies. The material's low weight compared to traditional alternatives like metal contributes to easier installation and maintenance of these devices across the grid infrastructure.

Despite its advantages, the widespread adoption of polycarbonate in smart grid components faces several challenges. One significant hurdle is the material's susceptibility to certain chemicals and solvents, which can limit its application in environments where exposure to these substances is likely. This necessitates careful consideration of the specific deployment conditions for polycarbonate components.

Another challenge lies in the thermal management of polycarbonate-encased electronic components. While the material offers good insulation properties, it can also trap heat, potentially affecting the performance and lifespan of sensitive electronic equipment within smart grid devices. This has led to ongoing research into enhanced polycarbonate formulations and design strategies to improve heat dissipation.

The recyclability of polycarbonate presents both an opportunity and a challenge. While the material is theoretically recyclable, the presence of additives and the complexity of smart grid components can complicate the recycling process. As sustainability becomes increasingly important in infrastructure development, improving the end-of-life management of polycarbonate components is a critical area for innovation.

Lastly, the cost of high-performance polycarbonate grades suitable for smart grid applications remains a consideration for widespread adoption. Balancing the material's performance benefits against economic factors is an ongoing challenge for manufacturers and utilities alike, driving efforts to optimize production processes and explore new formulations that offer cost-effective solutions without compromising on essential properties.

In the realm of smart meters, polycarbonate has become a material of choice for housing and protective covers. Its high impact strength and weather resistance ensure longevity in outdoor installations, while its clarity allows for easy reading of digital displays. The material's inherent flame retardancy also contributes to the safety of these devices, which are often exposed to varying environmental conditions.

For transformer bushings and insulators, polycarbonate is gaining traction due to its excellent dielectric properties and resistance to electrical tracking. These components benefit from the material's ability to maintain performance under high voltage conditions and its resistance to degradation from electrical arcing.

In the domain of smart grid sensors and monitoring devices, polycarbonate enclosures provide robust protection against environmental factors while allowing for the integration of wireless communication technologies. The material's low weight compared to traditional alternatives like metal contributes to easier installation and maintenance of these devices across the grid infrastructure.

Despite its advantages, the widespread adoption of polycarbonate in smart grid components faces several challenges. One significant hurdle is the material's susceptibility to certain chemicals and solvents, which can limit its application in environments where exposure to these substances is likely. This necessitates careful consideration of the specific deployment conditions for polycarbonate components.

Another challenge lies in the thermal management of polycarbonate-encased electronic components. While the material offers good insulation properties, it can also trap heat, potentially affecting the performance and lifespan of sensitive electronic equipment within smart grid devices. This has led to ongoing research into enhanced polycarbonate formulations and design strategies to improve heat dissipation.

The recyclability of polycarbonate presents both an opportunity and a challenge. While the material is theoretically recyclable, the presence of additives and the complexity of smart grid components can complicate the recycling process. As sustainability becomes increasingly important in infrastructure development, improving the end-of-life management of polycarbonate components is a critical area for innovation.

Lastly, the cost of high-performance polycarbonate grades suitable for smart grid applications remains a consideration for widespread adoption. Balancing the material's performance benefits against economic factors is an ongoing challenge for manufacturers and utilities alike, driving efforts to optimize production processes and explore new formulations that offer cost-effective solutions without compromising on essential properties.

Existing Polycarbonate Solutions for Smart Grid

01 Synthesis and modification of polycarbonates

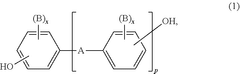

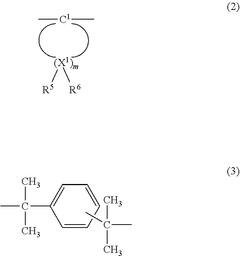

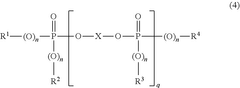

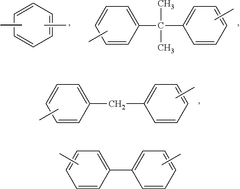

Various methods for synthesizing and modifying polycarbonates are explored, including novel catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties such as improved impact resistance, flame retardancy, or weatherability. These formulations expand the application range of polycarbonates in various industries.

- Polycarbonate processing and manufacturing: Advancements in processing techniques and manufacturing methods for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final products.

- Polycarbonate applications in electronics: Utilization of polycarbonates in electronic devices and components, such as display panels, housings, and insulating materials. The focus is on developing polycarbonate formulations with specific electrical and thermal properties suitable for electronic applications.

- Recycling and sustainability of polycarbonates: Methods for recycling polycarbonate materials and developing more sustainable production processes. This includes chemical recycling techniques, bio-based polycarbonates, and strategies to reduce the environmental impact of polycarbonate manufacturing and disposal.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blends and composites are tailored for various industrial and consumer applications.Expand Specific Solutions03 Polycarbonate processing and manufacturing

Advancements in processing and manufacturing techniques for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final products. Specialized equipment and process parameters are developed to optimize polycarbonate processing.Expand Specific Solutions04 Polycarbonate applications in electronics

Utilization of polycarbonates in electronic devices and components, such as display panels, housings, and insulating materials. The unique properties of polycarbonates, including transparency, electrical insulation, and heat resistance, make them suitable for various electronic applications. Specialized formulations are developed to meet the demanding requirements of the electronics industry.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Development of methods for recycling polycarbonate materials and improving their sustainability. This includes chemical recycling processes, biodegradable additives, and the use of renewable resources in polycarbonate production. These efforts aim to reduce the environmental impact of polycarbonate materials and promote circular economy principles in the plastics industry.Expand Specific Solutions

Key Players in Polycarbonate and Smart Grid Industries

The polycarbonate market in smart grid components is in an emerging phase, characterized by rapid technological advancements and growing market potential. The global smart grid market is expanding, driven by increasing energy demands and the need for efficient power distribution systems. While the technology is still evolving, major players like Covestro Deutschland AG, SABIC Global Technologies BV, and LG Chem Ltd. are investing heavily in research and development to improve polycarbonate applications in smart grid components. These companies, along with others such as Kingfa Sci. & Tech. Co., Ltd. and Teijin Ltd., are focusing on enhancing the material's properties to meet the specific requirements of smart grid applications, including durability, insulation, and weather resistance.

Covestro Deutschland AG

Technical Solution: Covestro has developed high-performance polycarbonate blends specifically designed for smart grid components. Their Makrolon® TC8030 grade offers excellent thermal conductivity (up to 20 W/m·K) [1], crucial for heat dissipation in smart meters and other grid devices. The material also provides high dimensional stability, flame retardancy (UL94 V-0 rating at 0.8mm) [2], and resistance to UV radiation and extreme weather conditions. Covestro's polycarbonate solutions incorporate advanced additives to enhance electrical insulation properties, making them suitable for high-voltage applications in smart grid infrastructure.

Strengths: Superior thermal management, excellent electrical insulation, and durability in harsh environments. Weaknesses: Potentially higher cost compared to traditional materials, and limited recyclability at end-of-life.

SABIC Global Technologies BV

Technical Solution: SABIC has introduced LEXAN™ EXL polycarbonate resin specifically for smart grid applications. This material offers exceptional impact resistance (Notched Izod Impact strength of 900 J/m at 23°C) [3] and maintains its properties across a wide temperature range (-40°C to 120°C). SABIC's polycarbonate solutions for smart grids feature advanced flame-retardant technologies that achieve UL94 V-0 rating at thin wall sections (down to 0.6mm) [4]. The company has also developed grades with enhanced UV stability and hydrolysis resistance, addressing the long-term durability requirements of outdoor smart grid components.

Strengths: High impact resistance, wide operating temperature range, and thin-wall flame retardancy. Weaknesses: May require special processing techniques, and potential for environmental stress cracking under certain conditions.

Core Innovations in Polycarbonate for Smart Grid

Interior train components having low smoke and low heat release, and methods of their manufacture

PatentActiveEP3094680A1

Innovation

- A polycarbonate composition comprising a combination of linear or branched polycarbonates, poly(carbonate-siloxane) copolymers, and glass fibers, where siloxane units are present in specific weight percentages, achieving low smoke density and heat release without compromising mechanical properties, and allowing for thermoforming or injection molding.

Polycarbonate-polyester composition and component having a high comparative tracking index

PatentPendingUS20250188273A1

Innovation

- A composition comprising 60% to 93% by weight of aromatic polycarbonate, 2% to 20% by weight of a polyester based on aromatic or cycloaliphatic dicarboxylic acid, and 1% to 10% by weight of a phosphorus-containing flame retardant, which improves tracking resistance and flame retardancy while maintaining mechanical properties.

Environmental Impact and Sustainability Considerations

The integration of polycarbonate in smart grid components brings significant environmental and sustainability considerations to the forefront. As a durable and versatile material, polycarbonate offers potential benefits in terms of longevity and reduced need for replacement, which can contribute to resource conservation and waste reduction in the long term.

However, the production of polycarbonate involves energy-intensive processes and the use of fossil fuel-based raw materials, raising concerns about its carbon footprint. The smart grid industry must carefully evaluate the life cycle environmental impact of polycarbonate components, from manufacturing to end-of-life disposal or recycling.

One of the key sustainability advantages of polycarbonate is its recyclability. Many polycarbonate grades used in smart grid applications can be recycled multiple times without significant loss of properties. This characteristic aligns well with circular economy principles and can help reduce the overall environmental impact of smart grid infrastructure.

The use of polycarbonate in smart grid components may also contribute to improved energy efficiency. Its lightweight nature can reduce transportation-related emissions, while its thermal insulation properties may enhance the performance of certain grid components, potentially leading to energy savings during operation.

As the smart grid sector evolves, there is growing interest in developing bio-based polycarbonates derived from renewable resources. These alternatives could potentially offer a more sustainable option, reducing dependence on fossil fuels and lowering the overall carbon footprint of smart grid systems.

The durability of polycarbonate components in smart grids can lead to extended service life, reducing the frequency of replacements and associated environmental impacts. However, this longevity also raises questions about end-of-life management and the need for effective recycling and disposal strategies to prevent environmental contamination.

In conclusion, while polycarbonate offers several sustainability benefits in smart grid applications, its environmental impact remains a complex issue. The industry must continue to invest in research and development to optimize the material's sustainability profile, explore eco-friendly alternatives, and establish robust recycling and waste management systems to maximize the environmental benefits of polycarbonate use in smart grid components.

However, the production of polycarbonate involves energy-intensive processes and the use of fossil fuel-based raw materials, raising concerns about its carbon footprint. The smart grid industry must carefully evaluate the life cycle environmental impact of polycarbonate components, from manufacturing to end-of-life disposal or recycling.

One of the key sustainability advantages of polycarbonate is its recyclability. Many polycarbonate grades used in smart grid applications can be recycled multiple times without significant loss of properties. This characteristic aligns well with circular economy principles and can help reduce the overall environmental impact of smart grid infrastructure.

The use of polycarbonate in smart grid components may also contribute to improved energy efficiency. Its lightweight nature can reduce transportation-related emissions, while its thermal insulation properties may enhance the performance of certain grid components, potentially leading to energy savings during operation.

As the smart grid sector evolves, there is growing interest in developing bio-based polycarbonates derived from renewable resources. These alternatives could potentially offer a more sustainable option, reducing dependence on fossil fuels and lowering the overall carbon footprint of smart grid systems.

The durability of polycarbonate components in smart grids can lead to extended service life, reducing the frequency of replacements and associated environmental impacts. However, this longevity also raises questions about end-of-life management and the need for effective recycling and disposal strategies to prevent environmental contamination.

In conclusion, while polycarbonate offers several sustainability benefits in smart grid applications, its environmental impact remains a complex issue. The industry must continue to invest in research and development to optimize the material's sustainability profile, explore eco-friendly alternatives, and establish robust recycling and waste management systems to maximize the environmental benefits of polycarbonate use in smart grid components.

Standardization and Regulatory Framework

The integration of polycarbonate materials in smart grid components is an emerging field that requires a robust standardization and regulatory framework to ensure safety, reliability, and interoperability. As this technology advances, regulatory bodies and industry stakeholders are working collaboratively to develop comprehensive standards that address the unique properties and applications of polycarbonate in smart grid systems.

One of the primary focuses of standardization efforts is the development of performance criteria for polycarbonate materials used in smart grid components. These standards aim to establish minimum requirements for mechanical strength, electrical insulation, thermal stability, and resistance to environmental factors such as UV radiation and moisture. By setting these benchmarks, manufacturers can ensure that polycarbonate-based components meet the rigorous demands of smart grid infrastructure.

Safety regulations play a crucial role in the adoption of polycarbonate materials in smart grid applications. Regulatory bodies are developing guidelines that address potential risks associated with the use of these materials, including fire resistance, toxicity, and long-term durability. These regulations are essential for protecting both utility workers and consumers, as well as ensuring the overall reliability of the smart grid system.

Interoperability standards are another key aspect of the regulatory framework for polycarbonate in smart grid components. As the smart grid ecosystem becomes increasingly complex, it is vital to ensure that polycarbonate-based components can seamlessly integrate with existing infrastructure and future technologies. Standards organizations are working to define protocols and interfaces that facilitate communication and compatibility between different smart grid elements.

Environmental regulations are also shaping the use of polycarbonate in smart grid applications. With a growing emphasis on sustainability, regulatory bodies are implementing guidelines for the lifecycle management of polycarbonate components, including recycling and disposal practices. These regulations aim to minimize the environmental impact of smart grid infrastructure and promote the use of eco-friendly materials.

As the field of polycarbonate in smart grid components continues to evolve, the standardization and regulatory framework will need to adapt to new technological advancements and market demands. Industry collaborations and public-private partnerships are playing a crucial role in driving the development of these standards, ensuring that they remain relevant and effective in supporting the growth of this emerging technology.

One of the primary focuses of standardization efforts is the development of performance criteria for polycarbonate materials used in smart grid components. These standards aim to establish minimum requirements for mechanical strength, electrical insulation, thermal stability, and resistance to environmental factors such as UV radiation and moisture. By setting these benchmarks, manufacturers can ensure that polycarbonate-based components meet the rigorous demands of smart grid infrastructure.

Safety regulations play a crucial role in the adoption of polycarbonate materials in smart grid applications. Regulatory bodies are developing guidelines that address potential risks associated with the use of these materials, including fire resistance, toxicity, and long-term durability. These regulations are essential for protecting both utility workers and consumers, as well as ensuring the overall reliability of the smart grid system.

Interoperability standards are another key aspect of the regulatory framework for polycarbonate in smart grid components. As the smart grid ecosystem becomes increasingly complex, it is vital to ensure that polycarbonate-based components can seamlessly integrate with existing infrastructure and future technologies. Standards organizations are working to define protocols and interfaces that facilitate communication and compatibility between different smart grid elements.

Environmental regulations are also shaping the use of polycarbonate in smart grid applications. With a growing emphasis on sustainability, regulatory bodies are implementing guidelines for the lifecycle management of polycarbonate components, including recycling and disposal practices. These regulations aim to minimize the environmental impact of smart grid infrastructure and promote the use of eco-friendly materials.

As the field of polycarbonate in smart grid components continues to evolve, the standardization and regulatory framework will need to adapt to new technological advancements and market demands. Industry collaborations and public-private partnerships are playing a crucial role in driving the development of these standards, ensuring that they remain relevant and effective in supporting the growth of this emerging technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!