Polycarbonate in Water Filtration Systems: The Future

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Filtration Evolution and Objectives

Polycarbonate has emerged as a revolutionary material in water filtration systems, marking a significant milestone in the evolution of water treatment technologies. The journey of polycarbonate in this field began in the late 20th century when its unique properties were first recognized for their potential in water purification applications. As a thermoplastic polymer, polycarbonate offers an exceptional combination of durability, transparency, and chemical resistance, making it an ideal candidate for water filtration components.

The evolution of polycarbonate in water filtration systems has been driven by the increasing global demand for clean, safe drinking water and the need for more efficient, cost-effective filtration solutions. Initially, polycarbonate was primarily used in housing units for filtration systems due to its strength and clarity. However, as technology advanced, researchers and engineers began to explore ways to leverage polycarbonate's properties to enhance the filtration process itself.

One of the key objectives in the development of polycarbonate-based filtration systems has been to improve the efficiency of water purification while maintaining the material's inherent advantages. This has led to innovations in membrane technology, where polycarbonate is used to create highly porous structures capable of removing contaminants at the molecular level. These advancements have significantly increased the flow rates and filtration capacity of water treatment systems, making them more suitable for large-scale applications.

Another critical goal in the evolution of polycarbonate filtration technology has been to enhance the material's resistance to fouling and degradation. Researchers have focused on developing surface modifications and coatings that can prevent the accumulation of contaminants on polycarbonate membranes, thereby extending their operational lifespan and reducing maintenance requirements. This objective aligns with the broader industry trend towards more sustainable and cost-effective water treatment solutions.

The future objectives for polycarbonate in water filtration systems are centered around further improving its performance and expanding its applications. One key area of focus is the development of nanocomposite polycarbonate materials that can offer enhanced selectivity in filtration, potentially allowing for the removal of specific contaminants while maintaining high flow rates. Additionally, there is ongoing research into making polycarbonate-based filtration systems more energy-efficient and environmentally friendly, aligning with global sustainability goals.

As we look towards the future, the integration of smart technologies with polycarbonate filtration systems presents exciting possibilities. Objectives include the development of sensors and monitoring systems that can be seamlessly incorporated into polycarbonate components, allowing for real-time water quality analysis and adaptive filtration processes. This convergence of materials science and digital technology promises to revolutionize water treatment, making it more responsive to changing environmental conditions and water quality requirements.

The evolution of polycarbonate in water filtration systems has been driven by the increasing global demand for clean, safe drinking water and the need for more efficient, cost-effective filtration solutions. Initially, polycarbonate was primarily used in housing units for filtration systems due to its strength and clarity. However, as technology advanced, researchers and engineers began to explore ways to leverage polycarbonate's properties to enhance the filtration process itself.

One of the key objectives in the development of polycarbonate-based filtration systems has been to improve the efficiency of water purification while maintaining the material's inherent advantages. This has led to innovations in membrane technology, where polycarbonate is used to create highly porous structures capable of removing contaminants at the molecular level. These advancements have significantly increased the flow rates and filtration capacity of water treatment systems, making them more suitable for large-scale applications.

Another critical goal in the evolution of polycarbonate filtration technology has been to enhance the material's resistance to fouling and degradation. Researchers have focused on developing surface modifications and coatings that can prevent the accumulation of contaminants on polycarbonate membranes, thereby extending their operational lifespan and reducing maintenance requirements. This objective aligns with the broader industry trend towards more sustainable and cost-effective water treatment solutions.

The future objectives for polycarbonate in water filtration systems are centered around further improving its performance and expanding its applications. One key area of focus is the development of nanocomposite polycarbonate materials that can offer enhanced selectivity in filtration, potentially allowing for the removal of specific contaminants while maintaining high flow rates. Additionally, there is ongoing research into making polycarbonate-based filtration systems more energy-efficient and environmentally friendly, aligning with global sustainability goals.

As we look towards the future, the integration of smart technologies with polycarbonate filtration systems presents exciting possibilities. Objectives include the development of sensors and monitoring systems that can be seamlessly incorporated into polycarbonate components, allowing for real-time water quality analysis and adaptive filtration processes. This convergence of materials science and digital technology promises to revolutionize water treatment, making it more responsive to changing environmental conditions and water quality requirements.

Water Purification Market Analysis

The global water purification market has been experiencing significant growth in recent years, driven by increasing concerns over water quality and scarcity. As of 2021, the market was valued at approximately $29.5 billion, with projections indicating a compound annual growth rate (CAGR) of 7.1% from 2022 to 2030. This growth is attributed to several factors, including rapid industrialization, urbanization, and population growth, which have led to increased water pollution and the need for advanced purification technologies.

The residential sector currently dominates the market, accounting for over 40% of the total revenue. This is primarily due to the rising awareness among consumers about the importance of clean drinking water and the increasing adoption of point-of-use (POU) water purification systems in households. The commercial and industrial sectors are also significant contributors to market growth, with industries such as pharmaceuticals, food and beverage, and electronics driving demand for high-purity water.

Geographically, North America and Europe have traditionally been the largest markets for water purification systems. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, with countries like China and India leading the way. This growth is fueled by rapid industrialization, increasing government initiatives for clean water access, and rising disposable incomes.

In terms of technology, membrane filtration systems, including reverse osmosis and ultrafiltration, currently hold the largest market share. These technologies are preferred due to their high efficiency in removing contaminants and their ability to produce high-quality water. However, emerging technologies such as UV disinfection and advanced oxidation processes are gaining traction due to their effectiveness in removing emerging contaminants and their lower environmental impact.

The market is characterized by the presence of several key players, including Pentair PLC, Culligan International Company, and 3M Company. These companies are focusing on product innovation and strategic partnerships to maintain their market position. The introduction of smart water purification systems, incorporating IoT and AI technologies, is a notable trend that is expected to shape the market in the coming years.

Looking ahead, the water purification market is poised for continued growth, driven by increasing water stress, stricter regulations on water quality, and growing awareness of waterborne diseases. The integration of polycarbonate materials in water filtration systems represents a promising development, offering potential improvements in durability, efficiency, and cost-effectiveness. As research and development in this area progress, polycarbonate-based filtration systems could play a significant role in shaping the future of the water purification market.

The residential sector currently dominates the market, accounting for over 40% of the total revenue. This is primarily due to the rising awareness among consumers about the importance of clean drinking water and the increasing adoption of point-of-use (POU) water purification systems in households. The commercial and industrial sectors are also significant contributors to market growth, with industries such as pharmaceuticals, food and beverage, and electronics driving demand for high-purity water.

Geographically, North America and Europe have traditionally been the largest markets for water purification systems. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, with countries like China and India leading the way. This growth is fueled by rapid industrialization, increasing government initiatives for clean water access, and rising disposable incomes.

In terms of technology, membrane filtration systems, including reverse osmosis and ultrafiltration, currently hold the largest market share. These technologies are preferred due to their high efficiency in removing contaminants and their ability to produce high-quality water. However, emerging technologies such as UV disinfection and advanced oxidation processes are gaining traction due to their effectiveness in removing emerging contaminants and their lower environmental impact.

The market is characterized by the presence of several key players, including Pentair PLC, Culligan International Company, and 3M Company. These companies are focusing on product innovation and strategic partnerships to maintain their market position. The introduction of smart water purification systems, incorporating IoT and AI technologies, is a notable trend that is expected to shape the market in the coming years.

Looking ahead, the water purification market is poised for continued growth, driven by increasing water stress, stricter regulations on water quality, and growing awareness of waterborne diseases. The integration of polycarbonate materials in water filtration systems represents a promising development, offering potential improvements in durability, efficiency, and cost-effectiveness. As research and development in this area progress, polycarbonate-based filtration systems could play a significant role in shaping the future of the water purification market.

Polycarbonate Filtration: Current State and Challenges

Polycarbonate filtration technology has made significant strides in recent years, yet it still faces several challenges in its widespread adoption and optimization for water treatment systems. The current state of polycarbonate filtration is characterized by its high durability, chemical resistance, and transparency, making it an attractive option for various filtration applications. However, the technology is not without its limitations and areas for improvement.

One of the primary challenges in polycarbonate filtration is the potential for fouling and biofouling. As water passes through the filtration membranes, organic matter, minerals, and microorganisms can accumulate on the surface, reducing the efficiency of the filtration process over time. This necessitates frequent cleaning and maintenance, which can increase operational costs and downtime for water treatment facilities.

Another significant challenge is the trade-off between filtration efficiency and flow rate. While polycarbonate membranes can be engineered to have very fine pore sizes for excellent filtration, this often comes at the cost of reduced water throughput. Balancing these competing factors to achieve optimal performance remains an ongoing challenge for researchers and engineers in the field.

The environmental impact of polycarbonate production and disposal is also a concern. Although polycarbonate is recyclable, the process is not always economically viable or widely implemented. Additionally, there are concerns about the potential leaching of bisphenol A (BPA) from polycarbonate materials, which has led to increased scrutiny and the need for alternative formulations.

From a technical standpoint, the development of more advanced surface modification techniques for polycarbonate membranes is an area of active research. These modifications aim to enhance the membrane's hydrophilicity, reduce fouling, and improve overall filtration performance. However, achieving long-term stability of these surface modifications under various water conditions remains challenging.

The integration of polycarbonate filtration systems with other water treatment technologies, such as UV disinfection or advanced oxidation processes, is another area that requires further development. While polycarbonate's transparency makes it suitable for UV applications, optimizing the synergy between different treatment methods is crucial for creating more efficient and comprehensive water purification systems.

Lastly, the scalability of polycarbonate filtration technology from laboratory settings to large-scale industrial applications presents its own set of challenges. Issues such as maintaining uniform pore size distribution, ensuring mechanical integrity under high-pressure operations, and developing cost-effective manufacturing processes for large membrane areas are all critical factors that need to be addressed.

One of the primary challenges in polycarbonate filtration is the potential for fouling and biofouling. As water passes through the filtration membranes, organic matter, minerals, and microorganisms can accumulate on the surface, reducing the efficiency of the filtration process over time. This necessitates frequent cleaning and maintenance, which can increase operational costs and downtime for water treatment facilities.

Another significant challenge is the trade-off between filtration efficiency and flow rate. While polycarbonate membranes can be engineered to have very fine pore sizes for excellent filtration, this often comes at the cost of reduced water throughput. Balancing these competing factors to achieve optimal performance remains an ongoing challenge for researchers and engineers in the field.

The environmental impact of polycarbonate production and disposal is also a concern. Although polycarbonate is recyclable, the process is not always economically viable or widely implemented. Additionally, there are concerns about the potential leaching of bisphenol A (BPA) from polycarbonate materials, which has led to increased scrutiny and the need for alternative formulations.

From a technical standpoint, the development of more advanced surface modification techniques for polycarbonate membranes is an area of active research. These modifications aim to enhance the membrane's hydrophilicity, reduce fouling, and improve overall filtration performance. However, achieving long-term stability of these surface modifications under various water conditions remains challenging.

The integration of polycarbonate filtration systems with other water treatment technologies, such as UV disinfection or advanced oxidation processes, is another area that requires further development. While polycarbonate's transparency makes it suitable for UV applications, optimizing the synergy between different treatment methods is crucial for creating more efficient and comprehensive water purification systems.

Lastly, the scalability of polycarbonate filtration technology from laboratory settings to large-scale industrial applications presents its own set of challenges. Issues such as maintaining uniform pore size distribution, ensuring mechanical integrity under high-pressure operations, and developing cost-effective manufacturing processes for large membrane areas are all critical factors that need to be addressed.

Existing Polycarbonate Filtration Solutions

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including novel catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blends are tailored for various industrial and consumer applications.

- Polycarbonate processing and manufacturing: Advancements in processing techniques and manufacturing methods for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final products while minimizing environmental impact.

- Polycarbonate applications in electronics: Utilization of polycarbonates in electronic devices and components, such as housings, displays, and insulating materials. The focus is on developing polycarbonate formulations with improved heat resistance, dimensional stability, and electrical properties suitable for modern electronic applications.

- Recycling and sustainability of polycarbonates: Methods for recycling polycarbonate materials and developing more sustainable production processes. This includes chemical recycling techniques, bio-based polycarbonate alternatives, and strategies to reduce the environmental footprint of polycarbonate manufacturing and disposal.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These combinations can result in materials with enhanced impact resistance, flame retardancy, or conductivity for specific applications.Expand Specific Solutions03 Optical applications of polycarbonates

Utilization of polycarbonates in optical applications, such as lenses, displays, and light-guiding components. This includes modifications to improve light transmission, reduce haze, and enhance durability for use in electronic devices and automotive lighting systems.Expand Specific Solutions04 Polycarbonate processing techniques

Advancements in processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on improving production efficiency, reducing defects, and achieving desired surface properties or structures in the final products.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Development of methods for recycling polycarbonate materials and improving their environmental sustainability. This includes chemical recycling processes, biodegradable additives, and the use of bio-based monomers to create more eco-friendly polycarbonate alternatives.Expand Specific Solutions

Key Players in Polycarbonate Filtration Industry

The polycarbonate water filtration market is in a growth phase, driven by increasing demand for clean water solutions globally. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like 3M, Covestro, and SABIC leading innovation. These firms, along with others such as LG Chem and BASF, are developing more efficient and sustainable polycarbonate-based filtration systems. The technology's maturity varies, with established players refining existing solutions while newer entrants like Harvey Environmental Technology explore novel applications. Overall, the competitive landscape is dynamic, with a mix of large chemical conglomerates and specialized water treatment companies vying for market share.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced polycarbonate-based water filtration systems that utilize a proprietary blend of polycarbonate and other materials to create high-performance membranes. These membranes are designed with nanoscale pores that effectively remove contaminants while maintaining high water flow rates. The company's technology incorporates a unique surface modification process that enhances the membrane's fouling resistance and longevity[1]. 3M's filtration systems also feature a modular design, allowing for easy scalability and customization to meet various water treatment needs[2]. The polycarbonate-based membranes are engineered to withstand harsh chemical environments and high temperatures, making them suitable for industrial and municipal water treatment applications[3].

Strengths: High filtration efficiency, durability, and scalability. Weaknesses: Potentially higher initial costs compared to traditional filtration materials and limited biodegradability.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered the development of high-performance polycarbonate membranes for water filtration systems. Their technology focuses on creating ultra-thin, yet robust membranes that maximize water flux while maintaining excellent selectivity. Covestro's approach involves the use of specially formulated polycarbonate blends that enhance the material's hydrophilicity and resistance to fouling[4]. The company has also developed a novel manufacturing process that allows for precise control of membrane porosity and thickness, resulting in optimized filtration performance[5]. Additionally, Covestro's polycarbonate membranes incorporate antimicrobial properties, which help prevent biofouling and extend the operational life of the filtration systems[6].

Strengths: High water flux, excellent selectivity, and improved fouling resistance. Weaknesses: Potential limitations in extremely high-pressure applications and higher production costs.

Innovative Polycarbonate Membrane Technologies

Hybrid water filter

PatentWO2017190265A1

Innovation

- Hybrid design combining polypropylene and activated carbon stages for more efficient use of materials and space.

- Incorporation of activated carbon fiber and polyolefin fiber with grafted chelating groups for improved contaminant removal.

- Radial water flow design for more complete utilization of the filter cartridge.

Liquid and gas porous plastic filter and methods of use

PatentInactiveUS7112272B2

Innovation

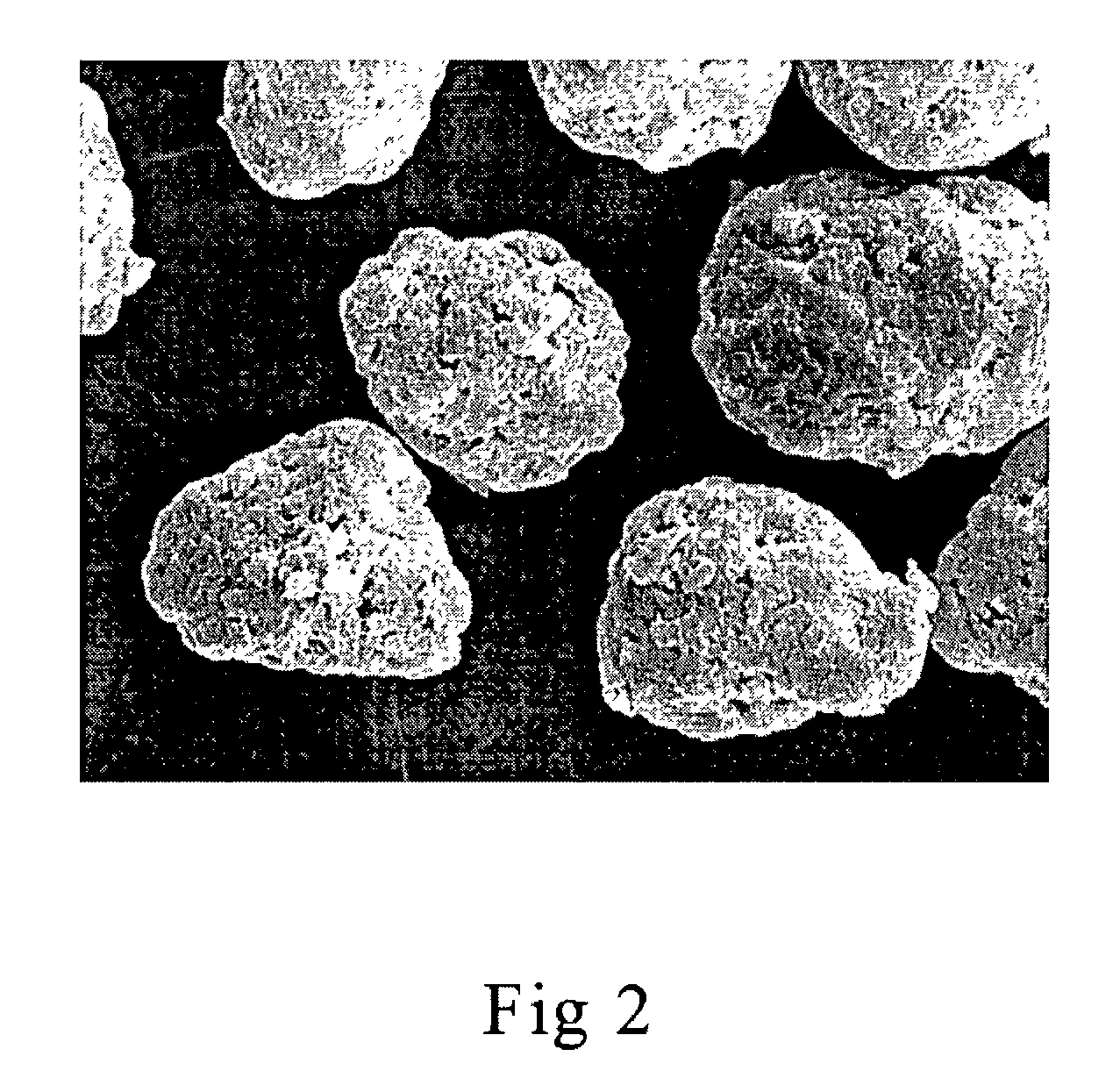

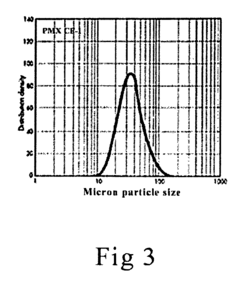

- A filtration device is developed using a unique method of vibration and sintering of polymers with distinct morphologies to create a structural matrix that can accommodate various filtering materials, allowing for superior filtration performance, depth filtration, and low pressure drop, with the ability to incorporate any filtering material of any particle size.

Environmental Impact of Polycarbonate Filters

The environmental impact of polycarbonate filters in water filtration systems is a complex and multifaceted issue that requires careful consideration. Polycarbonate, a durable and versatile plastic material, has gained popularity in water filtration applications due to its strength, transparency, and resistance to heat and chemicals. However, its use also raises concerns about potential environmental consequences.

One of the primary environmental benefits of polycarbonate filters is their longevity and durability. These filters can withstand repeated use and cleaning cycles, reducing the frequency of replacement and, consequently, the amount of waste generated. This extended lifespan contributes to a reduction in the overall environmental footprint of water filtration systems.

However, the production of polycarbonate involves energy-intensive processes and the use of fossil fuel-derived raw materials. The manufacturing process releases greenhouse gases and other pollutants, contributing to climate change and air quality issues. Additionally, the extraction and processing of raw materials for polycarbonate production can lead to habitat destruction and ecosystem disruption.

The disposal of polycarbonate filters at the end of their life cycle presents another environmental challenge. While polycarbonate is technically recyclable, the recycling infrastructure for this material is not as well-established as for other plastics. As a result, many used polycarbonate filters end up in landfills or incinerators, contributing to waste accumulation and potential soil and air pollution.

There are also concerns about the potential leaching of chemicals from polycarbonate filters into the water they are meant to purify. Bisphenol A (BPA), a chemical used in the production of polycarbonate, has been linked to various health and environmental issues. While many manufacturers now produce BPA-free polycarbonate, the long-term environmental impacts of alternative chemicals used in these formulations are not yet fully understood.

On the positive side, the efficiency of polycarbonate filters in removing contaminants from water can have indirect environmental benefits. By providing access to clean water, these filters can reduce reliance on bottled water, thereby decreasing plastic waste and the carbon footprint associated with bottled water production and transportation.

Research is ongoing to develop more environmentally friendly alternatives to traditional polycarbonate filters. Biodegradable polymers and bio-based materials are being explored as potential substitutes, aiming to maintain the performance benefits of polycarbonate while reducing environmental impact. Additionally, advancements in recycling technologies and the development of closed-loop systems for polycarbonate filter production and disposal could significantly mitigate their environmental footprint in the future.

One of the primary environmental benefits of polycarbonate filters is their longevity and durability. These filters can withstand repeated use and cleaning cycles, reducing the frequency of replacement and, consequently, the amount of waste generated. This extended lifespan contributes to a reduction in the overall environmental footprint of water filtration systems.

However, the production of polycarbonate involves energy-intensive processes and the use of fossil fuel-derived raw materials. The manufacturing process releases greenhouse gases and other pollutants, contributing to climate change and air quality issues. Additionally, the extraction and processing of raw materials for polycarbonate production can lead to habitat destruction and ecosystem disruption.

The disposal of polycarbonate filters at the end of their life cycle presents another environmental challenge. While polycarbonate is technically recyclable, the recycling infrastructure for this material is not as well-established as for other plastics. As a result, many used polycarbonate filters end up in landfills or incinerators, contributing to waste accumulation and potential soil and air pollution.

There are also concerns about the potential leaching of chemicals from polycarbonate filters into the water they are meant to purify. Bisphenol A (BPA), a chemical used in the production of polycarbonate, has been linked to various health and environmental issues. While many manufacturers now produce BPA-free polycarbonate, the long-term environmental impacts of alternative chemicals used in these formulations are not yet fully understood.

On the positive side, the efficiency of polycarbonate filters in removing contaminants from water can have indirect environmental benefits. By providing access to clean water, these filters can reduce reliance on bottled water, thereby decreasing plastic waste and the carbon footprint associated with bottled water production and transportation.

Research is ongoing to develop more environmentally friendly alternatives to traditional polycarbonate filters. Biodegradable polymers and bio-based materials are being explored as potential substitutes, aiming to maintain the performance benefits of polycarbonate while reducing environmental impact. Additionally, advancements in recycling technologies and the development of closed-loop systems for polycarbonate filter production and disposal could significantly mitigate their environmental footprint in the future.

Regulatory Framework for Water Filtration Materials

The regulatory framework for water filtration materials plays a crucial role in ensuring the safety and efficacy of water treatment systems. In the context of polycarbonate usage in water filtration, several key regulations and standards govern its application and implementation.

At the international level, the World Health Organization (WHO) provides guidelines for drinking water quality, which serve as a basis for many national regulations. These guidelines address the potential health impacts of various materials used in water treatment, including polycarbonate. The WHO emphasizes the importance of assessing the leaching potential of materials and their long-term stability in water systems.

In the United States, the Environmental Protection Agency (EPA) regulates drinking water quality through the Safe Drinking Water Act (SDWA). The EPA's National Primary Drinking Water Regulations set legally enforceable standards for contaminants in drinking water, which indirectly influence the materials used in filtration systems. Additionally, the NSF International, in collaboration with the American National Standards Institute (ANSI), has developed specific standards for drinking water treatment units, such as NSF/ANSI 53 for drinking water treatment units.

The European Union has established the Drinking Water Directive (98/83/EC), which sets quality standards for drinking water and, by extension, influences the materials used in water treatment. The European Committee for Standardization (CEN) has also developed standards for products in contact with drinking water, including those used in filtration systems.

In Asia, countries like Japan and South Korea have their own regulatory bodies and standards for water treatment materials. The Japanese Industrial Standards (JIS) and the Korean Agency for Technology and Standards (KATS) provide guidelines for water treatment equipment and materials.

Specific to polycarbonate, regulations often focus on the potential leaching of bisphenol A (BPA), a compound used in polycarbonate production. Many jurisdictions have set limits on BPA levels in drinking water and have regulations regarding its use in water contact materials. For instance, the European Food Safety Authority (EFSA) has established a tolerable daily intake for BPA, which influences its use in water filtration systems.

As the use of polycarbonate in water filtration systems evolves, regulatory frameworks are likely to adapt. Future regulations may focus on the long-term durability of polycarbonate filters, their resistance to microbial growth, and their ability to withstand various water treatment processes. Additionally, as research on microplastics continues, regulations may emerge addressing the potential release of microscopic polycarbonate particles into treated water.

At the international level, the World Health Organization (WHO) provides guidelines for drinking water quality, which serve as a basis for many national regulations. These guidelines address the potential health impacts of various materials used in water treatment, including polycarbonate. The WHO emphasizes the importance of assessing the leaching potential of materials and their long-term stability in water systems.

In the United States, the Environmental Protection Agency (EPA) regulates drinking water quality through the Safe Drinking Water Act (SDWA). The EPA's National Primary Drinking Water Regulations set legally enforceable standards for contaminants in drinking water, which indirectly influence the materials used in filtration systems. Additionally, the NSF International, in collaboration with the American National Standards Institute (ANSI), has developed specific standards for drinking water treatment units, such as NSF/ANSI 53 for drinking water treatment units.

The European Union has established the Drinking Water Directive (98/83/EC), which sets quality standards for drinking water and, by extension, influences the materials used in water treatment. The European Committee for Standardization (CEN) has also developed standards for products in contact with drinking water, including those used in filtration systems.

In Asia, countries like Japan and South Korea have their own regulatory bodies and standards for water treatment materials. The Japanese Industrial Standards (JIS) and the Korean Agency for Technology and Standards (KATS) provide guidelines for water treatment equipment and materials.

Specific to polycarbonate, regulations often focus on the potential leaching of bisphenol A (BPA), a compound used in polycarbonate production. Many jurisdictions have set limits on BPA levels in drinking water and have regulations regarding its use in water contact materials. For instance, the European Food Safety Authority (EFSA) has established a tolerable daily intake for BPA, which influences its use in water filtration systems.

As the use of polycarbonate in water filtration systems evolves, regulatory frameworks are likely to adapt. Future regulations may focus on the long-term durability of polycarbonate filters, their resistance to microbial growth, and their ability to withstand various water treatment processes. Additionally, as research on microplastics continues, regulations may emerge addressing the potential release of microscopic polycarbonate particles into treated water.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!