Polycarbonate Innovations for Sustainable Construction

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Evolution

Polycarbonate has undergone significant evolution since its inception in the 1950s, transforming from a novel polymer to a versatile material widely used in sustainable construction. The journey began with the discovery of its unique properties, including high impact resistance, optical clarity, and thermal stability. These characteristics quickly caught the attention of the construction industry, leading to its initial applications in glazing and roofing.

In the 1960s and 1970s, advancements in manufacturing processes allowed for the production of larger, more uniform polycarbonate sheets. This development expanded its use in architectural applications, particularly in skylights and greenhouse structures. The material's lightweight nature and durability made it an attractive alternative to traditional glass in many construction scenarios.

The 1980s and 1990s saw a focus on improving the weatherability of polycarbonate. Researchers developed UV-resistant coatings and additives, significantly extending the lifespan of polycarbonate products exposed to outdoor conditions. This innovation broadened its application in exterior building elements, including facades and canopies.

As sustainability became a growing concern in the construction industry, polycarbonate's evolution took a new direction in the early 2000s. Manufacturers began exploring ways to incorporate recycled content and improve the material's end-of-life recyclability. This period also saw the development of multi-wall polycarbonate sheets, which offered enhanced thermal insulation properties, aligning with the increasing demand for energy-efficient building materials.

In recent years, the focus has shifted towards enhancing polycarbonate's fire resistance and developing bio-based alternatives. Flame-retardant grades have been introduced, meeting stringent building safety standards. Simultaneously, research into polycarbonates derived from renewable resources has gained momentum, aiming to reduce the material's carbon footprint.

The latest innovations in polycarbonate technology for sustainable construction include smart glazing systems that can change opacity on demand, self-cleaning surfaces that reduce maintenance needs, and integration with photovoltaic cells for energy generation. These advancements are pushing the boundaries of what's possible in sustainable building design, positioning polycarbonate as a key material in the future of eco-friendly construction.

In the 1960s and 1970s, advancements in manufacturing processes allowed for the production of larger, more uniform polycarbonate sheets. This development expanded its use in architectural applications, particularly in skylights and greenhouse structures. The material's lightweight nature and durability made it an attractive alternative to traditional glass in many construction scenarios.

The 1980s and 1990s saw a focus on improving the weatherability of polycarbonate. Researchers developed UV-resistant coatings and additives, significantly extending the lifespan of polycarbonate products exposed to outdoor conditions. This innovation broadened its application in exterior building elements, including facades and canopies.

As sustainability became a growing concern in the construction industry, polycarbonate's evolution took a new direction in the early 2000s. Manufacturers began exploring ways to incorporate recycled content and improve the material's end-of-life recyclability. This period also saw the development of multi-wall polycarbonate sheets, which offered enhanced thermal insulation properties, aligning with the increasing demand for energy-efficient building materials.

In recent years, the focus has shifted towards enhancing polycarbonate's fire resistance and developing bio-based alternatives. Flame-retardant grades have been introduced, meeting stringent building safety standards. Simultaneously, research into polycarbonates derived from renewable resources has gained momentum, aiming to reduce the material's carbon footprint.

The latest innovations in polycarbonate technology for sustainable construction include smart glazing systems that can change opacity on demand, self-cleaning surfaces that reduce maintenance needs, and integration with photovoltaic cells for energy generation. These advancements are pushing the boundaries of what's possible in sustainable building design, positioning polycarbonate as a key material in the future of eco-friendly construction.

Sustainable Construction

Sustainable construction has emerged as a critical focus in the building industry, driven by the urgent need to address environmental challenges and promote long-term ecological balance. This approach encompasses a wide range of practices and technologies aimed at reducing the environmental impact of buildings throughout their lifecycle, from design and construction to operation and eventual demolition. The core principles of sustainable construction include energy efficiency, resource conservation, waste reduction, and the use of eco-friendly materials.

In recent years, there has been a significant shift towards incorporating innovative materials and technologies that can enhance the sustainability of buildings. One such material that has gained considerable attention is polycarbonate, known for its unique combination of strength, lightweight properties, and versatility. Polycarbonate innovations are playing an increasingly important role in sustainable construction, offering solutions that align with the industry's goals of reducing carbon footprint and improving energy efficiency.

Polycarbonate's application in sustainable construction spans various aspects of building design and functionality. Its excellent thermal insulation properties contribute to improved energy efficiency by reducing heat transfer and minimizing the need for artificial heating and cooling. This translates to lower energy consumption and reduced greenhouse gas emissions over the building's lifetime. Additionally, polycarbonate's high light transmission capabilities allow for the creation of translucent or transparent building elements that maximize natural daylighting, further reducing reliance on artificial lighting and associated energy costs.

The durability and longevity of polycarbonate materials also contribute to sustainability by extending the lifespan of building components and reducing the need for frequent replacements. This durability, combined with polycarbonate's recyclability, aligns with the principles of circular economy and waste reduction in construction. Innovative polycarbonate formulations are being developed to enhance these properties further, including improved UV resistance for prolonged outdoor use and increased fire resistance for safety compliance.

Moreover, the lightweight nature of polycarbonate materials offers advantages in transportation and installation, potentially reducing the overall carbon footprint associated with construction logistics. This characteristic also allows for the creation of innovative structural designs that may be challenging with traditional materials, opening up new possibilities for sustainable architectural solutions.

As the construction industry continues to evolve towards more sustainable practices, polycarbonate innovations are expected to play an increasingly significant role. Research and development efforts are focused on enhancing the material's eco-friendly attributes, such as incorporating recycled content, improving end-of-life recyclability, and developing bio-based polycarbonate alternatives. These advancements aim to further reduce the environmental impact of polycarbonate use in construction while maintaining or improving its performance characteristics.

In recent years, there has been a significant shift towards incorporating innovative materials and technologies that can enhance the sustainability of buildings. One such material that has gained considerable attention is polycarbonate, known for its unique combination of strength, lightweight properties, and versatility. Polycarbonate innovations are playing an increasingly important role in sustainable construction, offering solutions that align with the industry's goals of reducing carbon footprint and improving energy efficiency.

Polycarbonate's application in sustainable construction spans various aspects of building design and functionality. Its excellent thermal insulation properties contribute to improved energy efficiency by reducing heat transfer and minimizing the need for artificial heating and cooling. This translates to lower energy consumption and reduced greenhouse gas emissions over the building's lifetime. Additionally, polycarbonate's high light transmission capabilities allow for the creation of translucent or transparent building elements that maximize natural daylighting, further reducing reliance on artificial lighting and associated energy costs.

The durability and longevity of polycarbonate materials also contribute to sustainability by extending the lifespan of building components and reducing the need for frequent replacements. This durability, combined with polycarbonate's recyclability, aligns with the principles of circular economy and waste reduction in construction. Innovative polycarbonate formulations are being developed to enhance these properties further, including improved UV resistance for prolonged outdoor use and increased fire resistance for safety compliance.

Moreover, the lightweight nature of polycarbonate materials offers advantages in transportation and installation, potentially reducing the overall carbon footprint associated with construction logistics. This characteristic also allows for the creation of innovative structural designs that may be challenging with traditional materials, opening up new possibilities for sustainable architectural solutions.

As the construction industry continues to evolve towards more sustainable practices, polycarbonate innovations are expected to play an increasingly significant role. Research and development efforts are focused on enhancing the material's eco-friendly attributes, such as incorporating recycled content, improving end-of-life recyclability, and developing bio-based polycarbonate alternatives. These advancements aim to further reduce the environmental impact of polycarbonate use in construction while maintaining or improving its performance characteristics.

Technical Hurdles

Polycarbonate innovations for sustainable construction face several significant technical hurdles that need to be addressed to fully realize their potential in the industry. One of the primary challenges is improving the material's long-term durability and weathering resistance. While polycarbonate offers excellent impact strength and transparency, its susceptibility to UV degradation and scratching can limit its lifespan in outdoor applications.

Another major technical obstacle is enhancing the fire resistance of polycarbonate materials. Although polycarbonate is inherently flame-retardant, stricter building codes and safety regulations demand even better fire performance. Developing new flame-retardant additives or surface treatments that do not compromise the material's other desirable properties remains a significant challenge.

The thermal insulation properties of polycarbonate also present a hurdle for its widespread adoption in sustainable construction. While multi-wall polycarbonate sheets offer improved insulation compared to single-layer alternatives, there is still room for improvement to match the thermal performance of traditional building materials like glass or insulated panels.

Addressing the environmental impact of polycarbonate production is another critical technical challenge. The current manufacturing process is energy-intensive and relies on fossil fuel-based raw materials. Developing more sustainable production methods, such as using bio-based feedstocks or implementing closed-loop recycling systems, is essential for improving the material's overall environmental footprint.

The joining and sealing of polycarbonate components in construction applications also present technical difficulties. Traditional fastening methods may cause stress concentrations or compromise the material's integrity. Developing specialized adhesives, sealants, and connection systems that maintain the structural integrity and weathertightness of polycarbonate assemblies is crucial for expanding its use in building envelopes.

Furthermore, integrating smart technologies and functionalities into polycarbonate materials poses a significant technical challenge. Incorporating features such as electrochromic properties for dynamic shading, embedded sensors for building performance monitoring, or self-cleaning surfaces would greatly enhance the material's value proposition in sustainable construction.

Lastly, optimizing the acoustic performance of polycarbonate systems remains a hurdle, particularly in noise-sensitive environments. Developing innovative designs or composite structures that combine polycarbonate with sound-absorbing materials could significantly expand its applicability in urban and commercial settings.

Another major technical obstacle is enhancing the fire resistance of polycarbonate materials. Although polycarbonate is inherently flame-retardant, stricter building codes and safety regulations demand even better fire performance. Developing new flame-retardant additives or surface treatments that do not compromise the material's other desirable properties remains a significant challenge.

The thermal insulation properties of polycarbonate also present a hurdle for its widespread adoption in sustainable construction. While multi-wall polycarbonate sheets offer improved insulation compared to single-layer alternatives, there is still room for improvement to match the thermal performance of traditional building materials like glass or insulated panels.

Addressing the environmental impact of polycarbonate production is another critical technical challenge. The current manufacturing process is energy-intensive and relies on fossil fuel-based raw materials. Developing more sustainable production methods, such as using bio-based feedstocks or implementing closed-loop recycling systems, is essential for improving the material's overall environmental footprint.

The joining and sealing of polycarbonate components in construction applications also present technical difficulties. Traditional fastening methods may cause stress concentrations or compromise the material's integrity. Developing specialized adhesives, sealants, and connection systems that maintain the structural integrity and weathertightness of polycarbonate assemblies is crucial for expanding its use in building envelopes.

Furthermore, integrating smart technologies and functionalities into polycarbonate materials poses a significant technical challenge. Incorporating features such as electrochromic properties for dynamic shading, embedded sensors for building performance monitoring, or self-cleaning surfaces would greatly enhance the material's value proposition in sustainable construction.

Lastly, optimizing the acoustic performance of polycarbonate systems remains a hurdle, particularly in noise-sensitive environments. Developing innovative designs or composite structures that combine polycarbonate with sound-absorbing materials could significantly expand its applicability in urban and commercial settings.

Current Applications

01 Recycling and reuse of polycarbonate materials

Developing efficient methods for recycling and reusing polycarbonate materials to reduce waste and environmental impact. This includes improving collection systems, developing advanced sorting technologies, and implementing chemical recycling processes to break down polycarbonate into its base components for reuse in new products.- Recycling and reuse of polycarbonate materials: Developing methods for recycling and reusing polycarbonate materials to reduce waste and improve sustainability. This includes techniques for breaking down polycarbonate into its component materials, purifying recycled polycarbonate, and incorporating recycled content into new products.

- Bio-based and biodegradable polycarbonate alternatives: Research into bio-based and biodegradable alternatives to traditional polycarbonate materials. This involves developing new polymers from renewable resources that maintain the desirable properties of polycarbonate while being more environmentally friendly and easier to decompose at end-of-life.

- Energy-efficient production processes: Improving the energy efficiency of polycarbonate production processes to reduce the overall environmental impact. This includes optimizing reaction conditions, developing new catalysts, and implementing more efficient manufacturing technologies to minimize energy consumption and greenhouse gas emissions.

- Extended product lifespan and durability: Enhancing the durability and lifespan of polycarbonate products to reduce the need for frequent replacements. This involves developing additives and surface treatments that improve resistance to weathering, UV radiation, and chemical degradation, thereby extending the useful life of polycarbonate items.

- Sustainable packaging and product design: Designing polycarbonate products and packaging with sustainability in mind. This includes creating lightweight designs that use less material, developing easily disassembled products for better recycling, and incorporating recycled or bio-based content into new polycarbonate items.

02 Bio-based and biodegradable polycarbonate alternatives

Research and development of bio-based and biodegradable alternatives to traditional polycarbonate materials. This involves using renewable resources as feedstock and designing polymers that can decompose naturally in the environment, reducing the long-term environmental impact of polycarbonate products.Expand Specific Solutions03 Energy-efficient production processes

Implementing energy-efficient production processes for polycarbonate manufacturing to reduce carbon footprint and resource consumption. This includes optimizing reaction conditions, developing catalysts that work at lower temperatures, and integrating renewable energy sources into production facilities.Expand Specific Solutions04 Enhancing durability and lifespan of polycarbonate products

Improving the durability and lifespan of polycarbonate products to reduce the need for frequent replacements. This involves developing additives and surface treatments that enhance resistance to UV radiation, scratches, and chemical degradation, thereby extending the useful life of polycarbonate items.Expand Specific Solutions05 Sustainable supply chain and lifecycle assessment

Implementing sustainable supply chain practices and conducting comprehensive lifecycle assessments for polycarbonate products. This includes sourcing raw materials responsibly, optimizing transportation and logistics, and analyzing the environmental impact of polycarbonate products from production to disposal to identify areas for improvement.Expand Specific Solutions

Industry Leaders

The polycarbonate innovations for sustainable construction market is in a growth phase, driven by increasing demand for eco-friendly building materials. The global market size is projected to expand significantly in the coming years, fueled by sustainability initiatives and stringent environmental regulations. Technologically, the field is advancing rapidly, with major players like LG Chem, Covestro, and SABIC leading innovation. These companies are developing high-performance, sustainable polycarbonate solutions with improved durability, energy efficiency, and recyclability. Emerging players such as Kingfa Sci. & Tech. and Shanghai Kingfa are also making strides in eco-friendly polycarbonate technologies, intensifying competition and driving further innovation in the sector.

LG Chem Ltd.

Technical Solution: LG Chem has made significant strides in polycarbonate innovations for sustainable construction. Their high-performance polycarbonate sheets offer excellent light transmission and UV protection, making them ideal for skylights and facades in energy-efficient buildings[7]. LG Chem has also developed impact-resistant polycarbonate grades that enhance building safety while reducing material usage. The company's research into nano-additives has resulted in polycarbonate materials with improved weatherability and longevity, extending the lifespan of construction components and reducing replacement frequency[8].

Strengths: Advanced nanotechnology applications, focus on long-term durability, and expertise in light management for energy efficiency. Weaknesses: Potentially higher initial costs and limited applications in structural components.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative polycarbonate solutions for sustainable construction, focusing on energy efficiency and durability. Their Makrolon® polycarbonate sheets offer excellent thermal insulation properties, reducing energy consumption in buildings[1]. The company has also introduced bio-based polycarbonates, partially derived from plant-based raw materials, reducing the carbon footprint of construction materials[2]. Covestro's continuous fiber-reinforced thermoplastic (CFRTP) composites, which include polycarbonate-based materials, provide high strength-to-weight ratios for structural applications in construction, enabling lighter and more sustainable building designs[3].

Strengths: Advanced material science capabilities, strong focus on sustainability, and a wide range of polycarbonate products tailored for construction. Weaknesses: Potentially higher costs compared to traditional materials, and the need for specialized installation techniques.

Key Innovations

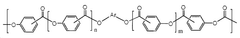

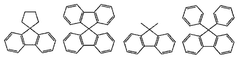

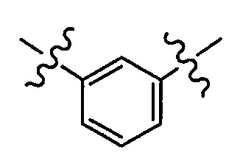

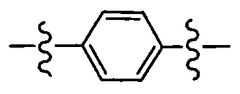

Polycarbonate and preparation method therefor

PatentWO2020032723A1

Innovation

- A polycarbonate with a novel structure containing specific repeating units, such as those represented by Formula 1, which includes arylene functional groups connected by ester groups, is developed, along with a method of polymerizing a composition containing a compound represented by Formula 3 and a carbonate precursor to enhance mechanical properties and weather resistance.

Process for producing high-performance biodegradable polycarbonates from carbon dioxide and epoxide using novel catalysts

PatentPendingIN202341024559A

Innovation

- Utilization of metal-organic framework (MOF) catalysts for eco-friendly production of biodegradable polycarbonates from CO2 and epoxide.

- Development of a sustainable polymerization process that reduces greenhouse gas emissions and utilizes readily available, renewable feedstocks.

- Production of naturally degradable polycarbonates suitable for various industrial applications, including automotive, medical devices, and packaging.

Environmental Impact

Polycarbonate innovations in sustainable construction have significant environmental implications, both positive and negative. On the positive side, polycarbonate materials offer excellent thermal insulation properties, which can lead to substantial energy savings in buildings. By reducing heat transfer, these materials help maintain comfortable indoor temperatures with less reliance on heating and cooling systems, thereby lowering energy consumption and associated greenhouse gas emissions.

Furthermore, polycarbonate sheets are lightweight yet durable, requiring less energy for transportation and installation compared to traditional building materials. This characteristic contributes to a reduced carbon footprint during the construction phase. The longevity of polycarbonate products also means fewer replacements over time, minimizing waste generation and resource consumption in the long term.

Polycarbonate's recyclability is another environmental advantage. Many polycarbonate products can be recycled at the end of their life cycle, reducing the amount of waste sent to landfills. Some manufacturers have implemented closed-loop recycling systems, where old polycarbonate materials are collected and reprocessed into new products, further enhancing sustainability.

However, the environmental impact of polycarbonate is not without concerns. The production of polycarbonate involves energy-intensive processes and the use of fossil fuel-based raw materials, contributing to carbon emissions and resource depletion. Additionally, the use of potentially harmful chemicals in the manufacturing process raises questions about toxicity and long-term environmental effects.

Microplastic pollution is another environmental issue associated with polycarbonate products. As these materials degrade over time, they can release microscopic plastic particles into the environment, potentially harming ecosystems and entering the food chain. This concern has led to increased research into biodegradable alternatives and improved recycling technologies.

To address these environmental challenges, researchers and manufacturers are exploring bio-based polycarbonates derived from renewable resources. These innovations aim to reduce reliance on fossil fuels and decrease the overall environmental footprint of polycarbonate production. Additionally, efforts are being made to develop more efficient manufacturing processes that minimize energy consumption and waste generation.

As the construction industry increasingly prioritizes sustainability, the environmental impact of polycarbonate innovations remains a critical consideration. Balancing the material's benefits with its potential drawbacks requires ongoing research, technological advancements, and responsible manufacturing practices to ensure that polycarbonate continues to contribute positively to sustainable construction efforts.

Furthermore, polycarbonate sheets are lightweight yet durable, requiring less energy for transportation and installation compared to traditional building materials. This characteristic contributes to a reduced carbon footprint during the construction phase. The longevity of polycarbonate products also means fewer replacements over time, minimizing waste generation and resource consumption in the long term.

Polycarbonate's recyclability is another environmental advantage. Many polycarbonate products can be recycled at the end of their life cycle, reducing the amount of waste sent to landfills. Some manufacturers have implemented closed-loop recycling systems, where old polycarbonate materials are collected and reprocessed into new products, further enhancing sustainability.

However, the environmental impact of polycarbonate is not without concerns. The production of polycarbonate involves energy-intensive processes and the use of fossil fuel-based raw materials, contributing to carbon emissions and resource depletion. Additionally, the use of potentially harmful chemicals in the manufacturing process raises questions about toxicity and long-term environmental effects.

Microplastic pollution is another environmental issue associated with polycarbonate products. As these materials degrade over time, they can release microscopic plastic particles into the environment, potentially harming ecosystems and entering the food chain. This concern has led to increased research into biodegradable alternatives and improved recycling technologies.

To address these environmental challenges, researchers and manufacturers are exploring bio-based polycarbonates derived from renewable resources. These innovations aim to reduce reliance on fossil fuels and decrease the overall environmental footprint of polycarbonate production. Additionally, efforts are being made to develop more efficient manufacturing processes that minimize energy consumption and waste generation.

As the construction industry increasingly prioritizes sustainability, the environmental impact of polycarbonate innovations remains a critical consideration. Balancing the material's benefits with its potential drawbacks requires ongoing research, technological advancements, and responsible manufacturing practices to ensure that polycarbonate continues to contribute positively to sustainable construction efforts.

Regulatory Framework

The regulatory framework surrounding polycarbonate innovations in sustainable construction plays a crucial role in shaping the adoption and implementation of these materials. As governments worldwide increasingly prioritize environmental sustainability, regulations are evolving to encourage the use of eco-friendly building materials and practices.

In many jurisdictions, building codes and standards are being updated to incorporate sustainability criteria, including energy efficiency, recyclability, and lifecycle assessments. Polycarbonate, with its lightweight properties and thermal insulation capabilities, is gaining recognition as a viable alternative to traditional construction materials. However, the regulatory landscape varies significantly across regions, presenting both opportunities and challenges for industry stakeholders.

Some countries have implemented green building certification systems, such as LEED (Leadership in Energy and Environmental Design) in the United States or BREEAM (Building Research Establishment Environmental Assessment Method) in the United Kingdom. These systems often award points for the use of sustainable materials like polycarbonate, incentivizing their adoption in construction projects.

Fire safety regulations are a critical aspect of the regulatory framework for polycarbonate in construction. While polycarbonate exhibits good fire resistance properties, specific requirements for flame retardancy and smoke emission must be met. Manufacturers are continually developing new formulations to comply with stringent fire safety standards across different markets.

Environmental regulations also impact the production and disposal of polycarbonate materials. Many countries have implemented restrictions on certain chemical additives, such as bisphenol A (BPA), prompting the development of BPA-free polycarbonate alternatives. Additionally, regulations promoting circular economy principles are driving innovations in recycling and reuse of polycarbonate products in the construction sector.

The regulatory landscape is not without challenges. The pace of technological innovation often outstrips regulatory updates, leading to potential gaps in standards for novel polycarbonate applications. This necessitates ongoing collaboration between industry, research institutions, and regulatory bodies to ensure that regulations remain relevant and supportive of sustainable innovations.

As the construction industry moves towards greater sustainability, regulatory frameworks are likely to continue evolving. Future regulations may focus on lifecycle carbon footprint, mandating the use of materials with lower environmental impact. This trend could further boost the adoption of polycarbonate innovations in sustainable construction, provided manufacturers can demonstrate compliance with increasingly stringent environmental and performance standards.

In many jurisdictions, building codes and standards are being updated to incorporate sustainability criteria, including energy efficiency, recyclability, and lifecycle assessments. Polycarbonate, with its lightweight properties and thermal insulation capabilities, is gaining recognition as a viable alternative to traditional construction materials. However, the regulatory landscape varies significantly across regions, presenting both opportunities and challenges for industry stakeholders.

Some countries have implemented green building certification systems, such as LEED (Leadership in Energy and Environmental Design) in the United States or BREEAM (Building Research Establishment Environmental Assessment Method) in the United Kingdom. These systems often award points for the use of sustainable materials like polycarbonate, incentivizing their adoption in construction projects.

Fire safety regulations are a critical aspect of the regulatory framework for polycarbonate in construction. While polycarbonate exhibits good fire resistance properties, specific requirements for flame retardancy and smoke emission must be met. Manufacturers are continually developing new formulations to comply with stringent fire safety standards across different markets.

Environmental regulations also impact the production and disposal of polycarbonate materials. Many countries have implemented restrictions on certain chemical additives, such as bisphenol A (BPA), prompting the development of BPA-free polycarbonate alternatives. Additionally, regulations promoting circular economy principles are driving innovations in recycling and reuse of polycarbonate products in the construction sector.

The regulatory landscape is not without challenges. The pace of technological innovation often outstrips regulatory updates, leading to potential gaps in standards for novel polycarbonate applications. This necessitates ongoing collaboration between industry, research institutions, and regulatory bodies to ensure that regulations remain relevant and supportive of sustainable innovations.

As the construction industry moves towards greater sustainability, regulatory frameworks are likely to continue evolving. Future regulations may focus on lifecycle carbon footprint, mandating the use of materials with lower environmental impact. This trend could further boost the adoption of polycarbonate innovations in sustainable construction, provided manufacturers can demonstrate compliance with increasingly stringent environmental and performance standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!