Polycarbonate's Future in Virtual Reality Devices

JUL 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PC in VR: Background and Objectives

Polycarbonate (PC) has been a cornerstone material in the development of virtual reality (VR) devices since the inception of this technology. Its unique combination of properties, including high impact resistance, optical clarity, and lightweight nature, has made it an ideal choice for VR headset components. The evolution of PC in VR technology can be traced back to the early 1990s when the first commercial VR systems emerged.

Initially, PC was primarily used in the outer casings of VR headsets, providing durability and protection for the internal components. As VR technology progressed, the role of PC expanded to include critical optical elements such as lenses and display covers. This shift was driven by the increasing demand for higher resolution displays and more immersive visual experiences in VR applications.

The objectives for PC in VR devices have evolved significantly over the years. In the early stages, the focus was on basic functionality and durability. However, as VR technology matured, the goals shifted towards enhancing user experience and addressing key challenges in VR adoption. These objectives now include reducing the weight of VR headsets to improve comfort during extended use, enhancing optical performance to minimize visual distortions and maximize field of view, and improving thermal management to address heat dissipation issues.

Another critical objective for PC in VR is to support the miniaturization of devices. As VR technology moves towards more compact and portable form factors, PC manufacturers are challenged to develop thinner, lighter, yet equally durable materials. This trend is particularly evident in the emerging market of augmented reality (AR) glasses, where PC plays a crucial role in creating lightweight, transparent displays.

The development of PC for VR applications is also driven by the need for improved sustainability. As environmental concerns become more prominent, there is a growing emphasis on developing recyclable and bio-based polycarbonates that maintain the high performance required for VR applications. This aligns with the broader industry trend towards more environmentally friendly materials and manufacturing processes.

Looking ahead, the future objectives for PC in VR devices include further advancements in optical properties, such as enhanced light transmission and reduced chromatic aberration. There is also a push towards developing PC formulations with improved impact resistance at lower thicknesses, enabling the creation of even lighter and more compact VR headsets. Additionally, research is ongoing to enhance the scratch resistance of PC, addressing a common issue in VR devices that can impact long-term visual clarity.

Initially, PC was primarily used in the outer casings of VR headsets, providing durability and protection for the internal components. As VR technology progressed, the role of PC expanded to include critical optical elements such as lenses and display covers. This shift was driven by the increasing demand for higher resolution displays and more immersive visual experiences in VR applications.

The objectives for PC in VR devices have evolved significantly over the years. In the early stages, the focus was on basic functionality and durability. However, as VR technology matured, the goals shifted towards enhancing user experience and addressing key challenges in VR adoption. These objectives now include reducing the weight of VR headsets to improve comfort during extended use, enhancing optical performance to minimize visual distortions and maximize field of view, and improving thermal management to address heat dissipation issues.

Another critical objective for PC in VR is to support the miniaturization of devices. As VR technology moves towards more compact and portable form factors, PC manufacturers are challenged to develop thinner, lighter, yet equally durable materials. This trend is particularly evident in the emerging market of augmented reality (AR) glasses, where PC plays a crucial role in creating lightweight, transparent displays.

The development of PC for VR applications is also driven by the need for improved sustainability. As environmental concerns become more prominent, there is a growing emphasis on developing recyclable and bio-based polycarbonates that maintain the high performance required for VR applications. This aligns with the broader industry trend towards more environmentally friendly materials and manufacturing processes.

Looking ahead, the future objectives for PC in VR devices include further advancements in optical properties, such as enhanced light transmission and reduced chromatic aberration. There is also a push towards developing PC formulations with improved impact resistance at lower thicknesses, enabling the creation of even lighter and more compact VR headsets. Additionally, research is ongoing to enhance the scratch resistance of PC, addressing a common issue in VR devices that can impact long-term visual clarity.

VR Market Demand Analysis

The virtual reality (VR) market has experienced significant growth in recent years, driven by advancements in technology and increasing consumer interest. The demand for VR devices, including headsets and accessories, has been steadily rising across various sectors such as gaming, entertainment, education, and enterprise applications.

In the gaming sector, which remains the primary driver of VR adoption, the market has seen a surge in demand for high-quality, immersive experiences. Major gaming companies and independent developers are investing heavily in VR content creation, further fueling the need for advanced VR hardware. The entertainment industry has also embraced VR technology, with applications ranging from virtual concerts to interactive storytelling experiences, contributing to the overall market growth.

The education sector has recognized the potential of VR as a powerful learning tool. Universities, schools, and training institutions are increasingly incorporating VR technology into their curricula, creating a new market segment for specialized educational VR content and hardware. This trend is expected to continue as more institutions recognize the benefits of immersive learning experiences.

In the enterprise sector, VR has found applications in various industries, including architecture, engineering, healthcare, and manufacturing. Companies are utilizing VR for design visualization, remote collaboration, training simulations, and product prototyping. This diverse range of applications has led to a growing demand for enterprise-grade VR solutions, driving innovation in both hardware and software development.

The COVID-19 pandemic has further accelerated the adoption of VR technology, particularly in remote work and virtual collaboration scenarios. As businesses adapt to new ways of working, the demand for VR solutions that enable immersive virtual meetings and shared workspaces has increased significantly.

Consumer awareness and acceptance of VR technology have also improved, leading to a broader user base. The introduction of more affordable and user-friendly VR devices has made the technology more accessible to mainstream consumers, expanding the potential market size.

Looking ahead, the VR market is projected to continue its growth trajectory. Factors such as the rollout of 5G networks, advancements in display technology, and the development of more sophisticated haptic feedback systems are expected to enhance the VR experience and drive further adoption. Additionally, the increasing integration of artificial intelligence and machine learning in VR applications is likely to create new use cases and market opportunities.

In the gaming sector, which remains the primary driver of VR adoption, the market has seen a surge in demand for high-quality, immersive experiences. Major gaming companies and independent developers are investing heavily in VR content creation, further fueling the need for advanced VR hardware. The entertainment industry has also embraced VR technology, with applications ranging from virtual concerts to interactive storytelling experiences, contributing to the overall market growth.

The education sector has recognized the potential of VR as a powerful learning tool. Universities, schools, and training institutions are increasingly incorporating VR technology into their curricula, creating a new market segment for specialized educational VR content and hardware. This trend is expected to continue as more institutions recognize the benefits of immersive learning experiences.

In the enterprise sector, VR has found applications in various industries, including architecture, engineering, healthcare, and manufacturing. Companies are utilizing VR for design visualization, remote collaboration, training simulations, and product prototyping. This diverse range of applications has led to a growing demand for enterprise-grade VR solutions, driving innovation in both hardware and software development.

The COVID-19 pandemic has further accelerated the adoption of VR technology, particularly in remote work and virtual collaboration scenarios. As businesses adapt to new ways of working, the demand for VR solutions that enable immersive virtual meetings and shared workspaces has increased significantly.

Consumer awareness and acceptance of VR technology have also improved, leading to a broader user base. The introduction of more affordable and user-friendly VR devices has made the technology more accessible to mainstream consumers, expanding the potential market size.

Looking ahead, the VR market is projected to continue its growth trajectory. Factors such as the rollout of 5G networks, advancements in display technology, and the development of more sophisticated haptic feedback systems are expected to enhance the VR experience and drive further adoption. Additionally, the increasing integration of artificial intelligence and machine learning in VR applications is likely to create new use cases and market opportunities.

PC Challenges in VR

Polycarbonate (PC) has been a popular material in virtual reality (VR) devices due to its excellent optical properties, impact resistance, and lightweight nature. However, as VR technology advances, PC faces several significant challenges that may limit its future applications in this field.

One of the primary challenges for PC in VR devices is its thermal management capabilities. As VR headsets become more powerful and incorporate advanced features like eye-tracking and higher resolution displays, they generate more heat. PC's relatively low thermal conductivity can lead to heat buildup, potentially causing discomfort for users during extended use and affecting the performance of sensitive electronic components.

Another critical issue is PC's susceptibility to scratching and abrasion. VR headsets are subject to frequent handling and contact with various surfaces, including the user's face and hands. Over time, this can result in micro-scratches on the PC lenses, reducing optical clarity and potentially impacting the overall VR experience. While coatings can mitigate this issue to some extent, finding a long-lasting solution remains a challenge.

PC's chemical resistance also poses concerns in VR applications. Exposure to certain chemicals, such as those found in cosmetics, skincare products, or cleaning agents, can cause stress cracking or hazing of PC components. This vulnerability may lead to reduced durability and shortened lifespan of VR devices, particularly in high-use scenarios like public demonstrations or shared devices in educational settings.

The weight of PC, while relatively low compared to some materials, is still a factor in VR headset design. As manufacturers strive to create more comfortable and lightweight devices for extended use, there is pressure to find even lighter materials that can match or exceed PC's optical and mechanical properties.

Lastly, PC faces challenges in achieving the highest levels of optical clarity required for next-generation VR displays. While PC offers good transparency, advancements in display technology, such as higher pixel densities and wider field of view, demand materials with exceptional optical properties. Meeting these stringent requirements while maintaining other desirable characteristics like impact resistance and moldability is a significant hurdle for PC in VR applications.

These challenges collectively push researchers and manufacturers to explore alternative materials or develop advanced PC formulations to address the evolving needs of VR technology. The future of PC in VR devices will largely depend on innovations that can overcome these limitations while leveraging its existing strengths.

One of the primary challenges for PC in VR devices is its thermal management capabilities. As VR headsets become more powerful and incorporate advanced features like eye-tracking and higher resolution displays, they generate more heat. PC's relatively low thermal conductivity can lead to heat buildup, potentially causing discomfort for users during extended use and affecting the performance of sensitive electronic components.

Another critical issue is PC's susceptibility to scratching and abrasion. VR headsets are subject to frequent handling and contact with various surfaces, including the user's face and hands. Over time, this can result in micro-scratches on the PC lenses, reducing optical clarity and potentially impacting the overall VR experience. While coatings can mitigate this issue to some extent, finding a long-lasting solution remains a challenge.

PC's chemical resistance also poses concerns in VR applications. Exposure to certain chemicals, such as those found in cosmetics, skincare products, or cleaning agents, can cause stress cracking or hazing of PC components. This vulnerability may lead to reduced durability and shortened lifespan of VR devices, particularly in high-use scenarios like public demonstrations or shared devices in educational settings.

The weight of PC, while relatively low compared to some materials, is still a factor in VR headset design. As manufacturers strive to create more comfortable and lightweight devices for extended use, there is pressure to find even lighter materials that can match or exceed PC's optical and mechanical properties.

Lastly, PC faces challenges in achieving the highest levels of optical clarity required for next-generation VR displays. While PC offers good transparency, advancements in display technology, such as higher pixel densities and wider field of view, demand materials with exceptional optical properties. Meeting these stringent requirements while maintaining other desirable characteristics like impact resistance and moldability is a significant hurdle for PC in VR applications.

These challenges collectively push researchers and manufacturers to explore alternative materials or develop advanced PC formulations to address the evolving needs of VR technology. The future of PC in VR devices will largely depend on innovations that can overcome these limitations while leveraging its existing strengths.

Current PC Solutions for VR

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve improved mechanical, thermal, and chemical properties. These formulations can include flame retardants, impact modifiers, or other functional additives to tailor the material for specific end-use requirements.

- Optical applications of polycarbonates: Utilization of polycarbonates in optical applications, such as lenses, displays, and light-guiding components. This includes modifications to improve light transmission, reduce haze, and enhance durability for use in electronic devices, automotive lighting, and other optical systems.

- Polycarbonate processing techniques: Advanced processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on optimizing processing parameters to achieve desired material properties, surface finish, and dimensional stability in the final products.

- Recycling and sustainability of polycarbonates: Innovations in recycling and sustainable production of polycarbonates, including chemical recycling methods, bio-based alternatives, and processes to reduce environmental impact. These approaches aim to improve the lifecycle sustainability of polycarbonate materials and address growing environmental concerns.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These formulations often target specific applications such as electronics, automotive parts, or consumer goods, offering enhanced performance characteristics.Expand Specific Solutions03 Flame retardant polycarbonate formulations

Creation of flame retardant polycarbonate formulations through the incorporation of various additives or chemical modifications. These developments aim to improve fire safety in applications where polycarbonates are used, such as electronics housings or building materials.Expand Specific Solutions04 Optical and electronic applications of polycarbonates

Utilization of polycarbonates in optical and electronic applications, including the development of specialized grades for lenses, light guides, and electronic components. These formulations often focus on enhancing optical clarity, UV resistance, and dimensional stability.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Advancements in recycling technologies and sustainable production methods for polycarbonates, including chemical recycling processes, bio-based alternatives, and strategies to reduce environmental impact. These efforts aim to improve the lifecycle sustainability of polycarbonate materials.Expand Specific Solutions

Key VR PC Manufacturers

The market for polycarbonate in virtual reality devices is in a growth phase, driven by increasing demand for lightweight, durable materials in VR headsets. The global VR market is projected to reach $92.31 billion by 2027, with polycarbonate playing a crucial role. Technologically, polycarbonate is mature but continues to evolve for VR applications. Key players like Covestro, SABIC, and LG Chem are investing in R&D to enhance polycarbonate properties for VR, focusing on optical clarity, impact resistance, and heat management. Emerging companies like CTRL-Labs and Shenzhen Dlodlo Technologies are also contributing to innovation in VR hardware, potentially influencing polycarbonate demand and specifications.

Covestro Deutschland AG

Technical Solution: Covestro has developed high-performance polycarbonate materials specifically tailored for VR devices. Their Makrolon® VR series offers excellent optical clarity, impact resistance, and lightweight properties. The material features a high refractive index of 1.59, allowing for thinner lenses and reduced device weight[1]. Covestro's polycarbonate also provides UV protection and can be easily molded into complex shapes, enabling sleek and ergonomic VR headset designs. The company has implemented advanced coating technologies to enhance scratch resistance and reduce glare, improving the overall user experience[2]. Covestro's continuous innovation in polycarbonate formulations has led to improved heat resistance and durability, addressing the challenges of prolonged use and potential overheating in VR devices[3].

Strengths: Superior optical clarity, impact resistance, and lightweight properties. Excellent moldability for complex designs. Weaknesses: May be more expensive than some alternative materials. Potential for yellowing over time with prolonged UV exposure.

SABIC Global Technologies BV

Technical Solution: SABIC has developed LEXAN™ polycarbonate resins specifically for VR applications. Their advanced formulations offer high impact strength, optical clarity, and dimensional stability. SABIC's polycarbonate materials feature a low birefringence, crucial for reducing optical distortions in VR lenses[4]. The company has also introduced flame-retardant grades that meet stringent safety standards without compromising optical performance. SABIC's polycarbonate solutions incorporate proprietary UV stabilizers, extending the lifespan of VR devices exposed to various lighting conditions[5]. Their materials are compatible with various coating technologies, allowing for anti-fog and anti-scratch treatments essential for VR applications. SABIC has also focused on developing polycarbonate blends that offer improved chemical resistance, addressing concerns about the longevity of VR devices in contact with skin oils and cosmetics[6].

Strengths: High impact strength, excellent optical properties, and flame-retardant options. Extensive range of grades for different VR components. Weaknesses: May require additional coatings for optimal performance. Higher cost compared to some commodity plastics.

PC Innovations for VR

System and Method for Video-Captured Initialization of Peripheral Devices

PatentActiveUS20230386159A1

Innovation

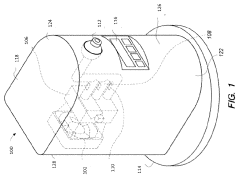

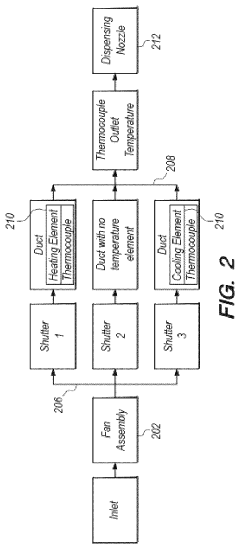

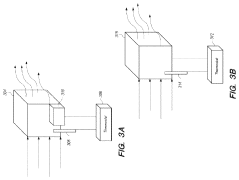

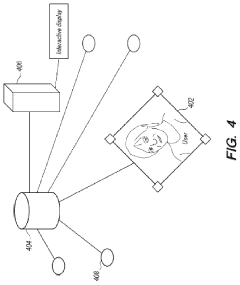

- A modular haptic system that includes a haptic tower with variable airflow and temperature control, integrated with learning-based algorithms and computer vision processing to deliver precise haptic effects based on user input and environmental data, allowing for plug-and-play integration with various audio/video sources and enabling customizable, low-latency experiences.

System and Method for a Surface-Optimized Tactile Transducer

PatentInactiveUS20220413614A1

Innovation

- A modular, universally integratable haptic system that includes a haptic tower with a fan assembly, temperature control, and sensor technology to deliver variable airflow and temperature, coupled with a learning-based approach to dynamically learn haptic events and predict haptic outputs, and directly integrates with audio or video signals to trigger haptic effects through computer vision processing.

Environmental Impact of PC in VR

The environmental impact of polycarbonate (PC) in virtual reality (VR) devices is a growing concern as the VR industry continues to expand. PC is widely used in VR headsets due to its durability, optical clarity, and impact resistance. However, its production and disposal pose significant environmental challenges.

The manufacturing process of PC is energy-intensive and relies heavily on fossil fuels. It involves the use of potentially harmful chemicals, including bisphenol A (BPA), which has been linked to various health and environmental issues. The production of PC also generates greenhouse gas emissions, contributing to climate change.

During the use phase, PC in VR devices has a relatively low environmental impact. Its durability ensures a longer lifespan for VR headsets, reducing the need for frequent replacements. However, the energy consumption of VR devices during operation is a consideration, as more powerful hardware often requires increased electricity usage.

The end-of-life stage presents significant environmental challenges for PC in VR devices. PC is not biodegradable and can persist in the environment for hundreds of years. While technically recyclable, the complex nature of VR headsets, which often contain multiple materials and components, makes recycling difficult and costly. As a result, many VR devices end up in landfills or are incinerated, releasing potentially harmful substances into the environment.

E-waste from VR devices containing PC is a growing concern. Improper disposal can lead to the leaching of toxic substances into soil and water systems, posing risks to ecosystems and human health. The global increase in VR adoption is likely to exacerbate this issue in the coming years.

To address these environmental concerns, the VR industry is exploring alternative materials and design strategies. Bioplastics and recycled materials are being investigated as potential substitutes for PC. Some manufacturers are adopting modular designs to facilitate easier repair and component replacement, extending the lifespan of VR devices and reducing waste.

Efforts are also being made to improve the recyclability of PC in VR devices. This includes developing new recycling technologies and implementing take-back programs to ensure proper disposal and recycling of end-of-life products. Additionally, research is ongoing to find ways to reduce the energy consumption and emissions associated with PC production.

As environmental regulations become more stringent, the VR industry will need to continue innovating to reduce the environmental footprint of PC and other materials used in their devices. This may involve a shift towards more sustainable materials, improved manufacturing processes, and enhanced end-of-life management strategies for VR hardware.

The manufacturing process of PC is energy-intensive and relies heavily on fossil fuels. It involves the use of potentially harmful chemicals, including bisphenol A (BPA), which has been linked to various health and environmental issues. The production of PC also generates greenhouse gas emissions, contributing to climate change.

During the use phase, PC in VR devices has a relatively low environmental impact. Its durability ensures a longer lifespan for VR headsets, reducing the need for frequent replacements. However, the energy consumption of VR devices during operation is a consideration, as more powerful hardware often requires increased electricity usage.

The end-of-life stage presents significant environmental challenges for PC in VR devices. PC is not biodegradable and can persist in the environment for hundreds of years. While technically recyclable, the complex nature of VR headsets, which often contain multiple materials and components, makes recycling difficult and costly. As a result, many VR devices end up in landfills or are incinerated, releasing potentially harmful substances into the environment.

E-waste from VR devices containing PC is a growing concern. Improper disposal can lead to the leaching of toxic substances into soil and water systems, posing risks to ecosystems and human health. The global increase in VR adoption is likely to exacerbate this issue in the coming years.

To address these environmental concerns, the VR industry is exploring alternative materials and design strategies. Bioplastics and recycled materials are being investigated as potential substitutes for PC. Some manufacturers are adopting modular designs to facilitate easier repair and component replacement, extending the lifespan of VR devices and reducing waste.

Efforts are also being made to improve the recyclability of PC in VR devices. This includes developing new recycling technologies and implementing take-back programs to ensure proper disposal and recycling of end-of-life products. Additionally, research is ongoing to find ways to reduce the energy consumption and emissions associated with PC production.

As environmental regulations become more stringent, the VR industry will need to continue innovating to reduce the environmental footprint of PC and other materials used in their devices. This may involve a shift towards more sustainable materials, improved manufacturing processes, and enhanced end-of-life management strategies for VR hardware.

PC Alternatives for VR

As the virtual reality (VR) industry continues to evolve, the search for alternative materials to polycarbonate (PC) in VR devices has become increasingly important. While PC has been a staple in VR headset manufacturing due to its durability and optical clarity, several limitations have prompted researchers and manufacturers to explore other options.

One promising alternative is polymethyl methacrylate (PMMA), also known as acrylic. PMMA offers excellent optical properties, including high light transmission and low dispersion, making it suitable for VR lenses. It is also lighter than PC, potentially reducing the overall weight of VR headsets. However, PMMA is less impact-resistant than PC, which may require additional protective measures in device design.

Another contender is cyclic olefin copolymer (COC), a transparent thermoplastic that combines high optical clarity with good chemical resistance. COC exhibits low birefringence, making it ideal for precision optics in VR applications. Its low moisture absorption properties also contribute to dimensional stability, which is crucial for maintaining optical alignment in VR devices.

Polyethylene terephthalate glycol (PETG) is gaining attention as a PC alternative due to its clarity, ease of processing, and good impact resistance. While not as tough as PC, PETG offers a balance of properties that make it suitable for certain VR components, particularly in less impact-prone areas of the headset.

Advances in nanocomposite materials are also opening new possibilities. By incorporating nanoparticles into polymer matrices, researchers are developing materials with enhanced optical and mechanical properties. These nanocomposites could potentially offer the clarity of PC with improved durability and lighter weight.

Biodegradable polymers, such as polylactic acid (PLA) blends, are being explored for their potential in creating more environmentally friendly VR devices. While current biodegradable options may not match PC's performance, ongoing research aims to improve their properties for VR applications.

As the VR industry pushes for higher resolution displays and wider fields of view, the demand for materials with superior optical properties continues to grow. This has led to increased interest in specialty optical polymers and hybrid materials that combine the benefits of different polymer types.

The development of these PC alternatives is not only driven by the need for improved performance but also by considerations of cost, manufacturability, and sustainability. As VR technology becomes more mainstream, the ability to produce devices with alternative materials could lead to more affordable and eco-friendly options for consumers.

One promising alternative is polymethyl methacrylate (PMMA), also known as acrylic. PMMA offers excellent optical properties, including high light transmission and low dispersion, making it suitable for VR lenses. It is also lighter than PC, potentially reducing the overall weight of VR headsets. However, PMMA is less impact-resistant than PC, which may require additional protective measures in device design.

Another contender is cyclic olefin copolymer (COC), a transparent thermoplastic that combines high optical clarity with good chemical resistance. COC exhibits low birefringence, making it ideal for precision optics in VR applications. Its low moisture absorption properties also contribute to dimensional stability, which is crucial for maintaining optical alignment in VR devices.

Polyethylene terephthalate glycol (PETG) is gaining attention as a PC alternative due to its clarity, ease of processing, and good impact resistance. While not as tough as PC, PETG offers a balance of properties that make it suitable for certain VR components, particularly in less impact-prone areas of the headset.

Advances in nanocomposite materials are also opening new possibilities. By incorporating nanoparticles into polymer matrices, researchers are developing materials with enhanced optical and mechanical properties. These nanocomposites could potentially offer the clarity of PC with improved durability and lighter weight.

Biodegradable polymers, such as polylactic acid (PLA) blends, are being explored for their potential in creating more environmentally friendly VR devices. While current biodegradable options may not match PC's performance, ongoing research aims to improve their properties for VR applications.

As the VR industry pushes for higher resolution displays and wider fields of view, the demand for materials with superior optical properties continues to grow. This has led to increased interest in specialty optical polymers and hybrid materials that combine the benefits of different polymer types.

The development of these PC alternatives is not only driven by the need for improved performance but also by considerations of cost, manufacturability, and sustainability. As VR technology becomes more mainstream, the ability to produce devices with alternative materials could lead to more affordable and eco-friendly options for consumers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!