Polycarbonate's Role in Future Residential Technologies

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Evolution

Polycarbonate has undergone a remarkable evolution since its discovery in 1953, transforming from a novel polymer into a versatile material with widespread applications in residential technologies. The journey of polycarbonate's development can be traced through several key stages, each marked by significant advancements in manufacturing processes and material properties.

In its early years, polycarbonate was primarily used in industrial applications due to its high production costs and limited processing capabilities. However, as manufacturing techniques improved and economies of scale were achieved, polycarbonate began to find its way into consumer products, including residential applications.

The 1970s and 1980s saw a surge in polycarbonate's use in the construction industry, particularly in glazing applications. Its superior impact resistance and optical clarity made it an attractive alternative to traditional glass in windows, skylights, and conservatories. This period also witnessed the development of UV-resistant grades of polycarbonate, extending its outdoor durability and expanding its potential in residential exteriors.

The 1990s marked a significant leap in polycarbonate technology with the introduction of multiwall sheets. These structured panels offered improved insulation properties while maintaining the material's characteristic strength and light transmission. This innovation opened new avenues for energy-efficient building designs, particularly in roofing and wall systems for residential structures.

As environmental concerns gained prominence in the 2000s, the polycarbonate industry responded with eco-friendly innovations. Manufacturers began incorporating recycled content into their products and developing bio-based polycarbonates derived from renewable resources. These advancements aligned with the growing demand for sustainable building materials in residential construction.

The past decade has seen polycarbonate evolve further with the integration of smart technologies. The development of thermochromic and photochromic polycarbonate grades has enabled the creation of adaptive glazing solutions that can automatically adjust their light transmission properties based on environmental conditions. This fusion of material science and smart technology represents a new frontier in residential comfort and energy efficiency.

Looking ahead, the evolution of polycarbonate in residential technologies is poised to continue. Ongoing research into nanocomposites and advanced polymer blends promises to yield polycarbonate materials with even greater strength, thermal performance, and functionality. The potential integration of polycarbonate with emerging technologies such as embedded sensors and energy harvesting systems could revolutionize the concept of smart homes, positioning this versatile polymer at the forefront of future residential innovations.

In its early years, polycarbonate was primarily used in industrial applications due to its high production costs and limited processing capabilities. However, as manufacturing techniques improved and economies of scale were achieved, polycarbonate began to find its way into consumer products, including residential applications.

The 1970s and 1980s saw a surge in polycarbonate's use in the construction industry, particularly in glazing applications. Its superior impact resistance and optical clarity made it an attractive alternative to traditional glass in windows, skylights, and conservatories. This period also witnessed the development of UV-resistant grades of polycarbonate, extending its outdoor durability and expanding its potential in residential exteriors.

The 1990s marked a significant leap in polycarbonate technology with the introduction of multiwall sheets. These structured panels offered improved insulation properties while maintaining the material's characteristic strength and light transmission. This innovation opened new avenues for energy-efficient building designs, particularly in roofing and wall systems for residential structures.

As environmental concerns gained prominence in the 2000s, the polycarbonate industry responded with eco-friendly innovations. Manufacturers began incorporating recycled content into their products and developing bio-based polycarbonates derived from renewable resources. These advancements aligned with the growing demand for sustainable building materials in residential construction.

The past decade has seen polycarbonate evolve further with the integration of smart technologies. The development of thermochromic and photochromic polycarbonate grades has enabled the creation of adaptive glazing solutions that can automatically adjust their light transmission properties based on environmental conditions. This fusion of material science and smart technology represents a new frontier in residential comfort and energy efficiency.

Looking ahead, the evolution of polycarbonate in residential technologies is poised to continue. Ongoing research into nanocomposites and advanced polymer blends promises to yield polycarbonate materials with even greater strength, thermal performance, and functionality. The potential integration of polycarbonate with emerging technologies such as embedded sensors and energy harvesting systems could revolutionize the concept of smart homes, positioning this versatile polymer at the forefront of future residential innovations.

Residential Tech Demand

The demand for advanced residential technologies is experiencing a significant upswing, driven by the increasing desire for smart, sustainable, and comfortable living spaces. Polycarbonate, with its unique properties, is poised to play a crucial role in meeting these evolving needs. The residential tech market is witnessing a surge in demand for energy-efficient solutions, particularly in the areas of lighting, insulation, and structural components.

Smart home technologies are at the forefront of this demand, with consumers seeking integrated systems that offer improved control over their living environments. Polycarbonate's versatility makes it an ideal material for manufacturing smart home devices, from touchscreens and sensor housings to transparent conductive surfaces for interactive walls and windows. The material's durability and electrical insulation properties are particularly valuable in these applications.

Energy efficiency remains a top priority in residential technology, and polycarbonate's excellent thermal insulation properties are driving its adoption in advanced window systems and building envelopes. The market is showing increased interest in multi-wall polycarbonate sheets that offer superior insulation while allowing natural light transmission, contributing to reduced energy consumption for heating, cooling, and lighting.

The growing focus on sustainable living is also influencing residential tech demand. Polycarbonate's recyclability and long lifespan align well with this trend, making it a preferred material for eco-conscious consumers and developers. There is a rising demand for polycarbonate-based solar energy solutions, such as lightweight and durable solar panel components and innovative solar thermal collectors.

Safety and security technologies for homes are another area where polycarbonate is seeing increased demand. Its impact resistance and clarity make it an excellent choice for security windows, doors, and protective barriers. The material is also being incorporated into advanced fire safety systems and smoke detectors due to its flame-retardant properties.

The aging population in many countries is driving demand for assistive technologies in homes. Polycarbonate's lightweight nature and formability make it suitable for creating ergonomic devices, mobility aids, and safety features that cater to the needs of older residents while maintaining aesthetic appeal.

As urban populations grow and living spaces become more compact, there is an increasing demand for modular and multifunctional furniture and fixtures. Polycarbonate's ability to be molded into complex shapes while maintaining strength makes it an attractive option for innovative space-saving solutions and transformable living environments.

Smart home technologies are at the forefront of this demand, with consumers seeking integrated systems that offer improved control over their living environments. Polycarbonate's versatility makes it an ideal material for manufacturing smart home devices, from touchscreens and sensor housings to transparent conductive surfaces for interactive walls and windows. The material's durability and electrical insulation properties are particularly valuable in these applications.

Energy efficiency remains a top priority in residential technology, and polycarbonate's excellent thermal insulation properties are driving its adoption in advanced window systems and building envelopes. The market is showing increased interest in multi-wall polycarbonate sheets that offer superior insulation while allowing natural light transmission, contributing to reduced energy consumption for heating, cooling, and lighting.

The growing focus on sustainable living is also influencing residential tech demand. Polycarbonate's recyclability and long lifespan align well with this trend, making it a preferred material for eco-conscious consumers and developers. There is a rising demand for polycarbonate-based solar energy solutions, such as lightweight and durable solar panel components and innovative solar thermal collectors.

Safety and security technologies for homes are another area where polycarbonate is seeing increased demand. Its impact resistance and clarity make it an excellent choice for security windows, doors, and protective barriers. The material is also being incorporated into advanced fire safety systems and smoke detectors due to its flame-retardant properties.

The aging population in many countries is driving demand for assistive technologies in homes. Polycarbonate's lightweight nature and formability make it suitable for creating ergonomic devices, mobility aids, and safety features that cater to the needs of older residents while maintaining aesthetic appeal.

As urban populations grow and living spaces become more compact, there is an increasing demand for modular and multifunctional furniture and fixtures. Polycarbonate's ability to be molded into complex shapes while maintaining strength makes it an attractive option for innovative space-saving solutions and transformable living environments.

Polycarbonate Challenges

Despite its numerous advantages, polycarbonate faces several challenges in its application to future residential technologies. One of the primary concerns is its environmental impact. While polycarbonate is recyclable, the recycling process is complex and energy-intensive, leading to limited recycling rates. Additionally, the production of polycarbonate involves the use of bisphenol A (BPA), a chemical that has raised health concerns, particularly regarding its potential endocrine-disrupting effects.

Durability issues also present challenges for polycarbonate in residential applications. Although generally tough, polycarbonate can be susceptible to scratching and yellowing over time when exposed to UV radiation. This degradation can affect both the aesthetic appeal and functional properties of polycarbonate-based products in residential settings, potentially limiting their long-term viability.

Cost considerations pose another hurdle for widespread adoption of polycarbonate in residential technologies. While prices have decreased over time, polycarbonate remains more expensive than some traditional building materials. This cost differential can be a significant barrier, especially for large-scale residential projects or budget-conscious consumers.

Technical limitations in certain areas also challenge polycarbonate's role in future residential technologies. For instance, its thermal insulation properties, while good, are not as effective as some specialized insulating materials. This may necessitate additional layers or treatments in applications where energy efficiency is paramount, potentially increasing complexity and cost.

Fire safety is another critical concern for residential applications. Although polycarbonate is self-extinguishing, it can still melt and produce toxic fumes when exposed to high temperatures. Meeting stringent fire safety regulations for residential buildings may require additional fire-retardant treatments or protective measures, adding to the overall cost and complexity of implementation.

Compatibility with other materials and integration into existing construction methods present further challenges. Polycarbonate's unique properties may require specialized installation techniques or modifications to traditional building practices, potentially increasing labor costs and requiring additional training for construction professionals.

Lastly, public perception and acceptance of polycarbonate as a primary material in residential technologies remain a challenge. Overcoming the stigma associated with "plastic" materials in housing and convincing consumers of polycarbonate's benefits and safety will require significant educational and marketing efforts. Addressing these multifaceted challenges will be crucial for realizing the full potential of polycarbonate in shaping the future of residential technologies.

Durability issues also present challenges for polycarbonate in residential applications. Although generally tough, polycarbonate can be susceptible to scratching and yellowing over time when exposed to UV radiation. This degradation can affect both the aesthetic appeal and functional properties of polycarbonate-based products in residential settings, potentially limiting their long-term viability.

Cost considerations pose another hurdle for widespread adoption of polycarbonate in residential technologies. While prices have decreased over time, polycarbonate remains more expensive than some traditional building materials. This cost differential can be a significant barrier, especially for large-scale residential projects or budget-conscious consumers.

Technical limitations in certain areas also challenge polycarbonate's role in future residential technologies. For instance, its thermal insulation properties, while good, are not as effective as some specialized insulating materials. This may necessitate additional layers or treatments in applications where energy efficiency is paramount, potentially increasing complexity and cost.

Fire safety is another critical concern for residential applications. Although polycarbonate is self-extinguishing, it can still melt and produce toxic fumes when exposed to high temperatures. Meeting stringent fire safety regulations for residential buildings may require additional fire-retardant treatments or protective measures, adding to the overall cost and complexity of implementation.

Compatibility with other materials and integration into existing construction methods present further challenges. Polycarbonate's unique properties may require specialized installation techniques or modifications to traditional building practices, potentially increasing labor costs and requiring additional training for construction professionals.

Lastly, public perception and acceptance of polycarbonate as a primary material in residential technologies remain a challenge. Overcoming the stigma associated with "plastic" materials in housing and convincing consumers of polycarbonate's benefits and safety will require significant educational and marketing efforts. Addressing these multifaceted challenges will be crucial for realizing the full potential of polycarbonate in shaping the future of residential technologies.

Current Applications

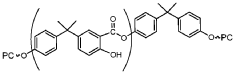

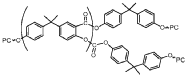

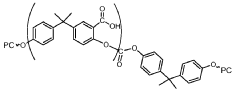

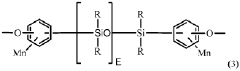

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.- Synthesis and modification of polycarbonates: This category focuses on the methods for synthesizing polycarbonates and modifying their properties. It includes techniques for polymerization, copolymerization, and the incorporation of various additives to enhance specific characteristics of the polymer. The processes aim to improve the physical, chemical, and mechanical properties of polycarbonates for diverse applications.

- Polycarbonate blends and composites: This area covers the development of polycarbonate blends and composites with other materials to create new materials with enhanced properties. These blends can improve characteristics such as impact resistance, heat resistance, or flame retardancy. The research in this field aims to expand the application range of polycarbonates in various industries.

- Polycarbonate applications in electronics: This category explores the use of polycarbonates in electronic applications. It includes the development of polycarbonate-based materials for electronic components, housings, and insulation. The research focuses on improving the electrical properties, heat resistance, and durability of polycarbonates for use in electronic devices and equipment.

- Recycling and sustainability of polycarbonates: This area focuses on developing methods for recycling polycarbonates and improving their environmental sustainability. It includes techniques for breaking down polycarbonates into their constituent monomers, purification processes, and the development of biodegradable polycarbonate alternatives. The aim is to reduce the environmental impact of polycarbonate production and waste.

- Surface treatment and coating of polycarbonates: This category covers methods for modifying the surface properties of polycarbonates through various treatment and coating techniques. It includes processes to improve scratch resistance, UV stability, and adhesion properties. The research in this area aims to enhance the durability and appearance of polycarbonate products for various applications.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These combinations can result in materials with enhanced impact resistance, flame retardancy, or conductivity, expanding the application range of polycarbonates.Expand Specific Solutions03 Polycarbonate processing and manufacturing

Advancements in processing techniques and manufacturing methods for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final polycarbonate products.Expand Specific Solutions04 Polycarbonate applications in electronics

Utilization of polycarbonates in electronic devices and components, such as display panels, circuit boards, and protective casings. The focus is on developing polycarbonate formulations with specific properties suited for electronic applications, including heat resistance, dimensional stability, and insulation characteristics.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Methods for recycling polycarbonate materials and developing more sustainable production processes. This includes chemical recycling techniques, bio-based polycarbonate alternatives, and strategies to reduce the environmental impact of polycarbonate manufacturing and disposal.Expand Specific Solutions

Industry Leaders

The polycarbonate market for future residential technologies is in a growth phase, driven by increasing demand for sustainable and energy-efficient building materials. The global market size is projected to expand significantly in the coming years, with a compound annual growth rate exceeding 5%. Technologically, polycarbonate applications are advancing rapidly, with companies like SABIC, Covestro, and Wanhua Chemical Group leading innovation in areas such as improved thermal insulation, impact resistance, and UV protection. Emerging players like Trinseo and Idemitsu Kosan are also contributing to market dynamism. The technology's maturity varies across applications, with established uses in windows and roofing, while newer areas like smart glazing and integrated solar solutions are still evolving.

SABIC Global Technologies BV

Technical Solution: SABIC has developed innovative polycarbonate solutions for future residential technologies, focusing on sustainability and energy efficiency. Their LEXAN™ polycarbonate sheets offer superior impact resistance and thermal insulation properties, making them ideal for smart windows and building-integrated photovoltaics (BIPV) [1]. SABIC's polycarbonate resins are also being used in advanced LED lighting systems, providing better light transmission and heat management [2]. The company has introduced polycarbonate grades with enhanced UV resistance for outdoor applications, extending the lifespan of residential exterior components [3].

Strengths: High impact resistance, thermal insulation, and UV resistance. Versatility in applications from smart windows to LED lighting. Weaknesses: Higher cost compared to traditional materials, potential for yellowing over time in certain applications.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered the development of polycarbonate materials for smart home technologies. Their Makrolon® polycarbonate is being used in the creation of transparent, touch-sensitive surfaces for smart home control panels and displays [4]. The company has also developed flame-retardant polycarbonate blends for use in electrical and electronic components of smart home systems, ensuring safety and durability [5]. Covestro's polycarbonate materials are being integrated into IoT devices for home automation, leveraging their combination of toughness and design flexibility [6].

Strengths: Excellent transparency and touch sensitivity for smart interfaces, flame-retardant properties for safety, design flexibility for IoT devices. Weaknesses: Potential for scratching in high-touch applications, higher cost compared to some alternative plastics.

Key Innovations

Housings for consumer devices including polycarbonate-polycarbonate/polysiloxane compositions having high flow, high impact. and good release properties

PatentWO2018037301A1

Innovation

- The use of thermoplastic compositions comprising 49.5 wt% to 97.95 wt% polycarbonate polymer, 2.0 wt% to 49.5 wt% polycarbonate-siloxane copolymer, and 0.05 wt% to 1.0 wt% release agent, which exhibit a melt volume flow rate of at least 25 cm^3/10 min, a ductile/brittle transition temperature of ≤10 °C, and a tensile yield strength retention of 80% after exposure to sunscreen, enabling improved flow, impact, and release characteristics.

Coatings for polycarbonate windows

PatentInactiveEP1999196A1

Innovation

- A dual-cure coating composition for polycarbonate substrates that includes a radiation-curable component, a thermally curable binder, and a thermally curable crosslinking component, along with UV-absorbing additives, which can be applied and cured using actinic radiation and thermal energy, ensuring excellent adhesion and optical clarity without the need for intermediate primers.

Environmental Impact

The environmental impact of polycarbonate in future residential technologies is a critical consideration as the material gains prominence in construction and design. Polycarbonate offers several environmental benefits, including its lightweight nature, which reduces transportation emissions and energy consumption during installation. Its durability and long lifespan contribute to reduced waste generation and resource consumption over time.

However, the production of polycarbonate involves energy-intensive processes and the use of fossil fuel-derived raw materials, which can contribute to greenhouse gas emissions. Efforts are underway to develop more sustainable production methods, including the use of bio-based feedstocks and renewable energy sources in manufacturing.

Polycarbonate's excellent insulation properties can significantly improve the energy efficiency of residential buildings. When used in windows, skylights, and roofing systems, it helps reduce heat transfer, leading to lower heating and cooling costs. This energy-saving potential indirectly contributes to reduced carbon emissions from residential energy consumption.

Recyclability is another important aspect of polycarbonate's environmental profile. The material can be recycled multiple times without significant loss of properties, supporting circular economy principles. However, the current recycling infrastructure for polycarbonate is limited in many regions, and improvements in collection and processing systems are needed to maximize its recycling potential.

The use of polycarbonate in residential technologies also raises concerns about potential chemical leaching, particularly of bisphenol A (BPA). While studies have shown that the leaching of BPA from polycarbonate is minimal under normal conditions, ongoing research is focused on developing BPA-free alternatives to address these concerns and improve the material's environmental safety profile.

As polycarbonate becomes more prevalent in residential applications, its impact on indoor air quality and the potential for off-gassing of volatile organic compounds (VOCs) are areas of ongoing study. Manufacturers are working to develop low-VOC formulations and improve production processes to minimize these potential environmental and health impacts.

The end-of-life management of polycarbonate products in residential settings is an emerging area of focus. Developing effective strategies for the collection, sorting, and recycling of polycarbonate components from demolished or renovated buildings will be crucial in minimizing the material's long-term environmental footprint and ensuring its sustainability in the construction sector.

However, the production of polycarbonate involves energy-intensive processes and the use of fossil fuel-derived raw materials, which can contribute to greenhouse gas emissions. Efforts are underway to develop more sustainable production methods, including the use of bio-based feedstocks and renewable energy sources in manufacturing.

Polycarbonate's excellent insulation properties can significantly improve the energy efficiency of residential buildings. When used in windows, skylights, and roofing systems, it helps reduce heat transfer, leading to lower heating and cooling costs. This energy-saving potential indirectly contributes to reduced carbon emissions from residential energy consumption.

Recyclability is another important aspect of polycarbonate's environmental profile. The material can be recycled multiple times without significant loss of properties, supporting circular economy principles. However, the current recycling infrastructure for polycarbonate is limited in many regions, and improvements in collection and processing systems are needed to maximize its recycling potential.

The use of polycarbonate in residential technologies also raises concerns about potential chemical leaching, particularly of bisphenol A (BPA). While studies have shown that the leaching of BPA from polycarbonate is minimal under normal conditions, ongoing research is focused on developing BPA-free alternatives to address these concerns and improve the material's environmental safety profile.

As polycarbonate becomes more prevalent in residential applications, its impact on indoor air quality and the potential for off-gassing of volatile organic compounds (VOCs) are areas of ongoing study. Manufacturers are working to develop low-VOC formulations and improve production processes to minimize these potential environmental and health impacts.

The end-of-life management of polycarbonate products in residential settings is an emerging area of focus. Developing effective strategies for the collection, sorting, and recycling of polycarbonate components from demolished or renovated buildings will be crucial in minimizing the material's long-term environmental footprint and ensuring its sustainability in the construction sector.

Smart Home Integration

Polycarbonate's integration into smart home technologies is revolutionizing the way we interact with our living spaces. This versatile material is becoming increasingly prevalent in various smart home devices and systems, enhancing their functionality, durability, and aesthetic appeal.

In the realm of smart lighting, polycarbonate is being utilized to create innovative diffusers and housings for LED fixtures. These components not only protect the delicate electronics within but also help to distribute light more evenly and efficiently. The material's optical clarity and ability to be molded into complex shapes allow for the creation of sleek, modern designs that seamlessly blend with contemporary home decor.

Smart home security systems are also benefiting from polycarbonate's unique properties. Outdoor surveillance cameras and motion sensors are being encased in polycarbonate shells, providing excellent protection against harsh weather conditions and potential physical damage. The material's impact resistance and UV stability ensure that these critical security devices remain functional and reliable over extended periods.

In the domain of smart appliances, polycarbonate is finding applications in touchscreen interfaces and control panels. Its durability and resistance to chemicals make it an ideal choice for kitchen appliances and laundry equipment, where exposure to moisture and cleaning agents is common. The material's ability to be molded with precise tolerances also allows for the integration of capacitive touch sensors directly into the surface, creating seamless and intuitive user interfaces.

Smart thermostats and environmental control systems are incorporating polycarbonate in their construction to achieve a balance between aesthetics and functionality. The material's thermal insulation properties help in maintaining accurate temperature readings, while its moldability allows for the creation of ergonomic designs that are both visually appealing and user-friendly.

The integration of polycarbonate in smart home technologies extends to wireless charging stations and power management systems. Its electrical insulation properties make it an excellent choice for creating safe and efficient charging surfaces for various smart devices. Additionally, the material's transparency can be leveraged to create illuminated charging areas that serve both functional and decorative purposes.

As smart home technologies continue to evolve, polycarbonate is playing a crucial role in enabling the miniaturization and integration of sensors and actuators throughout the living space. From smart mirrors to voice-activated assistants, the material's versatility is allowing designers to push the boundaries of what's possible in creating interconnected and responsive home environments.

In the realm of smart lighting, polycarbonate is being utilized to create innovative diffusers and housings for LED fixtures. These components not only protect the delicate electronics within but also help to distribute light more evenly and efficiently. The material's optical clarity and ability to be molded into complex shapes allow for the creation of sleek, modern designs that seamlessly blend with contemporary home decor.

Smart home security systems are also benefiting from polycarbonate's unique properties. Outdoor surveillance cameras and motion sensors are being encased in polycarbonate shells, providing excellent protection against harsh weather conditions and potential physical damage. The material's impact resistance and UV stability ensure that these critical security devices remain functional and reliable over extended periods.

In the domain of smart appliances, polycarbonate is finding applications in touchscreen interfaces and control panels. Its durability and resistance to chemicals make it an ideal choice for kitchen appliances and laundry equipment, where exposure to moisture and cleaning agents is common. The material's ability to be molded with precise tolerances also allows for the integration of capacitive touch sensors directly into the surface, creating seamless and intuitive user interfaces.

Smart thermostats and environmental control systems are incorporating polycarbonate in their construction to achieve a balance between aesthetics and functionality. The material's thermal insulation properties help in maintaining accurate temperature readings, while its moldability allows for the creation of ergonomic designs that are both visually appealing and user-friendly.

The integration of polycarbonate in smart home technologies extends to wireless charging stations and power management systems. Its electrical insulation properties make it an excellent choice for creating safe and efficient charging surfaces for various smart devices. Additionally, the material's transparency can be leveraged to create illuminated charging areas that serve both functional and decorative purposes.

As smart home technologies continue to evolve, polycarbonate is playing a crucial role in enabling the miniaturization and integration of sensors and actuators throughout the living space. From smart mirrors to voice-activated assistants, the material's versatility is allowing designers to push the boundaries of what's possible in creating interconnected and responsive home environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!