Polycarbonate's Role in Modern Urban Development

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Evolution

Polycarbonate has undergone a remarkable evolution since its discovery in 1953, playing an increasingly significant role in modern urban development. Initially developed as a high-performance plastic, polycarbonate's unique combination of properties quickly attracted attention across various industries.

In the early stages of its development, polycarbonate was primarily used in niche applications due to its high production costs. However, as manufacturing processes improved and economies of scale were achieved, its usage expanded rapidly. The 1960s and 1970s saw polycarbonate gaining traction in the automotive and electronics industries, where its impact resistance and optical clarity were highly valued.

The 1980s marked a turning point for polycarbonate in urban development. Architects and engineers began to recognize its potential as a lightweight, durable, and versatile building material. This period saw the introduction of polycarbonate sheets in roofing and glazing applications, offering an alternative to traditional glass in structures requiring natural light transmission while maintaining thermal insulation.

As environmental concerns grew in the 1990s and 2000s, polycarbonate's recyclability and energy-efficient properties became increasingly important. Its ability to reduce heating and cooling costs in buildings aligned with the growing emphasis on sustainable urban development. This period also saw advancements in UV-resistant formulations, extending the material's lifespan in outdoor applications.

The 21st century has witnessed a surge in polycarbonate's use in smart city initiatives. Its compatibility with LED technology has made it a preferred material for innovative lighting solutions in urban spaces. Additionally, the development of multi-wall polycarbonate sheets has further enhanced its insulation properties, contributing to energy-efficient building designs.

Recent years have seen a focus on enhancing polycarbonate's fire-resistant properties, addressing safety concerns in high-rise buildings. Researchers are also exploring ways to incorporate recycled polycarbonate into new products, aligning with circular economy principles in urban development.

The evolution of polycarbonate continues, with ongoing research into improving its properties and expanding its applications. As cities face challenges related to climate change and resource scarcity, polycarbonate's role in creating resilient, sustainable urban environments is likely to grow, cementing its position as a key material in modern urban development.

In the early stages of its development, polycarbonate was primarily used in niche applications due to its high production costs. However, as manufacturing processes improved and economies of scale were achieved, its usage expanded rapidly. The 1960s and 1970s saw polycarbonate gaining traction in the automotive and electronics industries, where its impact resistance and optical clarity were highly valued.

The 1980s marked a turning point for polycarbonate in urban development. Architects and engineers began to recognize its potential as a lightweight, durable, and versatile building material. This period saw the introduction of polycarbonate sheets in roofing and glazing applications, offering an alternative to traditional glass in structures requiring natural light transmission while maintaining thermal insulation.

As environmental concerns grew in the 1990s and 2000s, polycarbonate's recyclability and energy-efficient properties became increasingly important. Its ability to reduce heating and cooling costs in buildings aligned with the growing emphasis on sustainable urban development. This period also saw advancements in UV-resistant formulations, extending the material's lifespan in outdoor applications.

The 21st century has witnessed a surge in polycarbonate's use in smart city initiatives. Its compatibility with LED technology has made it a preferred material for innovative lighting solutions in urban spaces. Additionally, the development of multi-wall polycarbonate sheets has further enhanced its insulation properties, contributing to energy-efficient building designs.

Recent years have seen a focus on enhancing polycarbonate's fire-resistant properties, addressing safety concerns in high-rise buildings. Researchers are also exploring ways to incorporate recycled polycarbonate into new products, aligning with circular economy principles in urban development.

The evolution of polycarbonate continues, with ongoing research into improving its properties and expanding its applications. As cities face challenges related to climate change and resource scarcity, polycarbonate's role in creating resilient, sustainable urban environments is likely to grow, cementing its position as a key material in modern urban development.

Urban Market Demand

The demand for polycarbonate in urban development has seen a significant surge in recent years, driven by the material's unique properties and the evolving needs of modern cities. As urbanization continues to accelerate globally, the construction sector has become increasingly reliant on innovative materials that can meet the complex requirements of contemporary architecture and infrastructure.

Polycarbonate's lightweight nature, coupled with its exceptional strength and durability, has positioned it as a preferred material for various urban applications. In the building industry, there is a growing demand for polycarbonate sheets and panels for use in roofing, skylights, and facades. These applications benefit from the material's transparency, which allows natural light to penetrate buildings while providing thermal insulation, thus contributing to energy efficiency in urban structures.

The automotive sector within urban environments has also embraced polycarbonate, particularly for glazing applications. As cities implement stricter emissions regulations and push for lighter vehicles to improve fuel efficiency, polycarbonate offers a viable alternative to traditional glass, reducing overall vehicle weight without compromising safety or aesthetics.

Urban infrastructure projects have identified polycarbonate as a key material for noise barriers along highways and railways, as well as for public transportation shelters. The material's impact resistance and clarity make it ideal for these applications, enhancing safety and comfort for urban residents while maintaining visibility.

The electronics and telecommunications industries, which form the backbone of smart city initiatives, have increased their demand for polycarbonate in the production of casings for devices and equipment. The material's electrical insulation properties and ability to be molded into complex shapes make it suitable for the ever-expanding network of urban technological infrastructure.

As cities focus on sustainability and circular economy principles, the recyclability of polycarbonate has become a significant factor driving its demand. Urban planners and developers are increasingly seeking materials that can be repurposed or recycled at the end of their lifecycle, aligning with broader environmental goals.

The healthcare sector in urban areas has also contributed to the rising demand for polycarbonate. The material's biocompatibility and sterilization capabilities make it valuable for medical devices and equipment, which are crucial in city hospitals and clinics.

Market analysts project that the urban demand for polycarbonate will continue to grow, with the construction and automotive sectors leading this trend. The material's versatility in addressing multiple urban challenges, from energy efficiency to safety and sustainability, positions it as a critical component in the ongoing development and transformation of modern cities.

Polycarbonate's lightweight nature, coupled with its exceptional strength and durability, has positioned it as a preferred material for various urban applications. In the building industry, there is a growing demand for polycarbonate sheets and panels for use in roofing, skylights, and facades. These applications benefit from the material's transparency, which allows natural light to penetrate buildings while providing thermal insulation, thus contributing to energy efficiency in urban structures.

The automotive sector within urban environments has also embraced polycarbonate, particularly for glazing applications. As cities implement stricter emissions regulations and push for lighter vehicles to improve fuel efficiency, polycarbonate offers a viable alternative to traditional glass, reducing overall vehicle weight without compromising safety or aesthetics.

Urban infrastructure projects have identified polycarbonate as a key material for noise barriers along highways and railways, as well as for public transportation shelters. The material's impact resistance and clarity make it ideal for these applications, enhancing safety and comfort for urban residents while maintaining visibility.

The electronics and telecommunications industries, which form the backbone of smart city initiatives, have increased their demand for polycarbonate in the production of casings for devices and equipment. The material's electrical insulation properties and ability to be molded into complex shapes make it suitable for the ever-expanding network of urban technological infrastructure.

As cities focus on sustainability and circular economy principles, the recyclability of polycarbonate has become a significant factor driving its demand. Urban planners and developers are increasingly seeking materials that can be repurposed or recycled at the end of their lifecycle, aligning with broader environmental goals.

The healthcare sector in urban areas has also contributed to the rising demand for polycarbonate. The material's biocompatibility and sterilization capabilities make it valuable for medical devices and equipment, which are crucial in city hospitals and clinics.

Market analysts project that the urban demand for polycarbonate will continue to grow, with the construction and automotive sectors leading this trend. The material's versatility in addressing multiple urban challenges, from energy efficiency to safety and sustainability, positions it as a critical component in the ongoing development and transformation of modern cities.

Technical Challenges

Polycarbonate, a versatile thermoplastic polymer, has become increasingly prevalent in modern urban development. However, its widespread adoption faces several technical challenges that need to be addressed for its continued growth and sustainability in urban applications.

One of the primary technical hurdles is the material's susceptibility to UV degradation. When exposed to prolonged sunlight, polycarbonate can experience yellowing, loss of transparency, and reduced mechanical strength. This issue is particularly problematic in outdoor urban applications such as building facades, skylights, and public infrastructure. While UV stabilizers are commonly used to mitigate this problem, their effectiveness over extended periods remains a concern, especially in harsh urban environments with high pollution levels and intense solar radiation.

Another significant challenge lies in improving the fire resistance of polycarbonate. Although the material inherently possesses some flame-retardant properties, it can still contribute to the spread of fire in urban settings. Enhancing its fire performance without compromising other desirable properties, such as transparency and impact resistance, is a complex task that requires innovative solutions in polymer chemistry and material science.

The recyclability of polycarbonate presents another technical obstacle. While theoretically recyclable, the presence of additives, coatings, and mixed materials in many polycarbonate products complicates the recycling process. Developing efficient and cost-effective methods for separating and purifying polycarbonate from urban waste streams is crucial for improving its environmental footprint and aligning with circular economy principles in urban development.

Durability in extreme urban conditions is an ongoing challenge for polycarbonate applications. The material must withstand not only varying temperatures and humidity levels but also resist chemical exposure from urban pollutants and cleaning agents. Improving the material's resistance to scratching, abrasion, and chemical attack without sacrificing its lightweight nature and optical clarity remains a key area of research and development.

Lastly, the integration of smart functionalities into polycarbonate components poses a significant technical challenge. As cities move towards smarter, more connected infrastructure, there is a growing demand for materials that can incorporate sensors, lighting systems, and other electronic components. Developing polycarbonate formulations and manufacturing processes that allow for seamless integration of these technologies while maintaining the material's core properties is a complex undertaking that requires interdisciplinary collaboration between material scientists, electronic engineers, and urban planners.

Addressing these technical challenges is crucial for expanding polycarbonate's role in modern urban development. Overcoming these hurdles will not only enhance the material's performance and longevity but also contribute to more sustainable, resilient, and technologically advanced urban environments.

One of the primary technical hurdles is the material's susceptibility to UV degradation. When exposed to prolonged sunlight, polycarbonate can experience yellowing, loss of transparency, and reduced mechanical strength. This issue is particularly problematic in outdoor urban applications such as building facades, skylights, and public infrastructure. While UV stabilizers are commonly used to mitigate this problem, their effectiveness over extended periods remains a concern, especially in harsh urban environments with high pollution levels and intense solar radiation.

Another significant challenge lies in improving the fire resistance of polycarbonate. Although the material inherently possesses some flame-retardant properties, it can still contribute to the spread of fire in urban settings. Enhancing its fire performance without compromising other desirable properties, such as transparency and impact resistance, is a complex task that requires innovative solutions in polymer chemistry and material science.

The recyclability of polycarbonate presents another technical obstacle. While theoretically recyclable, the presence of additives, coatings, and mixed materials in many polycarbonate products complicates the recycling process. Developing efficient and cost-effective methods for separating and purifying polycarbonate from urban waste streams is crucial for improving its environmental footprint and aligning with circular economy principles in urban development.

Durability in extreme urban conditions is an ongoing challenge for polycarbonate applications. The material must withstand not only varying temperatures and humidity levels but also resist chemical exposure from urban pollutants and cleaning agents. Improving the material's resistance to scratching, abrasion, and chemical attack without sacrificing its lightweight nature and optical clarity remains a key area of research and development.

Lastly, the integration of smart functionalities into polycarbonate components poses a significant technical challenge. As cities move towards smarter, more connected infrastructure, there is a growing demand for materials that can incorporate sensors, lighting systems, and other electronic components. Developing polycarbonate formulations and manufacturing processes that allow for seamless integration of these technologies while maintaining the material's core properties is a complex undertaking that requires interdisciplinary collaboration between material scientists, electronic engineers, and urban planners.

Addressing these technical challenges is crucial for expanding polycarbonate's role in modern urban development. Overcoming these hurdles will not only enhance the material's performance and longevity but also contribute to more sustainable, resilient, and technologically advanced urban environments.

Current Applications

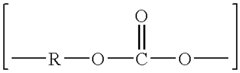

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including novel catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties such as improved impact resistance, flame retardancy, or weatherability. These formulations expand the application range of polycarbonates in various industries.

- Polycarbonate processing techniques: Advancements in processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on optimizing production efficiency, reducing defects, and enhancing the final product quality.

- Recycling and sustainability of polycarbonates: Innovations in recycling methods and sustainable production of polycarbonates, including chemical recycling, bio-based alternatives, and processes to reduce environmental impact. These developments aim to improve the lifecycle and eco-friendliness of polycarbonate materials.

- Polycarbonate applications in electronics and optics: Specialized polycarbonate formulations and treatments for applications in electronics and optics, such as light-guiding plates, optical discs, and electronic housings. These developments focus on enhancing optical properties, heat resistance, and durability for specific high-tech applications.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or additives to achieve improved mechanical, thermal, and chemical properties. These formulations can include flame retardants, impact modifiers, or other functional additives to tailor the material for specific end-use requirements.Expand Specific Solutions03 Polycarbonate processing and manufacturing

Advancements in processing techniques and manufacturing methods for polycarbonate products, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final polycarbonate products.Expand Specific Solutions04 Polycarbonate applications in electronics

Utilization of polycarbonates in electronic devices and components, such as housings, insulators, and protective layers. This includes developments in flame-retardant polycarbonate formulations, EMI shielding properties, and integration with other materials for improved performance in electronic applications.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Innovations in recycling processes and sustainable production methods for polycarbonates, including chemical recycling, bio-based precursors, and environmentally friendly additives. These developments aim to reduce the environmental impact of polycarbonate production and improve the material's overall lifecycle sustainability.Expand Specific Solutions

Industry Leaders

The polycarbonate market in modern urban development is in a mature growth phase, with a global market size expected to reach $25 billion by 2025. The technology has widespread applications in construction, automotive, and electronics industries, driving steady demand. Key players like SABIC, Covestro, and LG Chem dominate the market with established production capabilities and extensive R&D efforts. Emerging companies such as Wanhua Chemical and Lotte Advanced Materials are also making significant strides in product innovation and market expansion. The industry is characterized by ongoing advancements in material properties, sustainability, and application-specific formulations, indicating a high level of technological maturity and continued evolution to meet urban development needs.

LG Chem Ltd.

Technical Solution: LG Chem has developed high-performance polycarbonate materials specifically tailored for modern urban development. Their innovative approach includes the creation of transparent and impact-resistant polycarbonate sheets for architectural applications. These sheets offer excellent light transmission properties while providing superior durability and weather resistance[1]. LG Chem has also introduced flame-retardant polycarbonate grades that meet stringent building safety standards, making them ideal for high-rise constructions and public infrastructure[2]. Additionally, the company has invested in developing UV-resistant polycarbonate formulations, extending the lifespan of outdoor urban installations and reducing maintenance costs[3].

Strengths: Advanced material engineering capabilities, wide range of specialized polycarbonate products for urban applications. Weaknesses: Potential higher costs compared to traditional materials, limited biodegradability.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered the development of sustainable polycarbonate solutions for urban environments. Their LEXAN™ polycarbonate resin portfolio includes grades with up to 60% post-consumer recycled content, addressing the growing demand for eco-friendly building materials[4]. SABIC has also introduced polycarbonate sheets with advanced light diffusion properties, enhancing energy efficiency in urban structures by optimizing natural light distribution[5]. Furthermore, the company has developed polycarbonate composites that combine lightweight properties with high strength, enabling innovative designs in urban infrastructure and transportation systems[6].

Strengths: Strong focus on sustainability, diverse product range for various urban applications. Weaknesses: Dependency on petrochemical feedstocks, challenges in achieving 100% recyclability.

Key Innovations

Coatings for polycarbonate windows

PatentInactiveUS20070231577A1

Innovation

- A dual-cure coating composition that includes a radiation-curable component, a thermally curable binder, and a thermally curable crosslinking agent, along with UV-absorbing additives, applied to the polycarbonate substrate, which cures using both actinic radiation and thermal energy, ensuring excellent adhesion and optical clarity without the need for intermediate primers.

Coatings for polycarbonate windows

PatentInactiveEP1999196A1

Innovation

- A dual-cure coating composition for polycarbonate substrates that includes a radiation-curable component, a thermally curable binder, and a thermally curable crosslinking component, along with UV-absorbing additives, which can be applied and cured using actinic radiation and thermal energy, ensuring excellent adhesion and optical clarity without the need for intermediate primers.

Sustainability Aspects

Polycarbonate's sustainability aspects in modern urban development are multifaceted and increasingly significant. The material's durability and longevity contribute to reduced waste and replacement frequency, aligning with circular economy principles. Polycarbonate's lightweight nature leads to lower transportation emissions and reduced energy consumption during installation, supporting overall carbon footprint reduction in construction projects.

The recyclability of polycarbonate is a key sustainability feature. Many polycarbonate products can be recycled multiple times without significant loss of properties, promoting a closed-loop system in urban infrastructure. This recyclability helps conserve raw materials and energy, while reducing landfill waste associated with urban development.

Polycarbonate's energy efficiency properties play a crucial role in sustainable urban design. Its excellent insulation characteristics contribute to improved thermal performance in buildings, reducing heating and cooling demands. This translates to lower energy consumption and decreased greenhouse gas emissions over the lifecycle of urban structures.

The material's transparency and light transmission capabilities enable the integration of natural daylighting in architectural designs. This reduces the need for artificial lighting during daytime hours, further decreasing energy consumption in urban environments. Additionally, polycarbonate's UV resistance ensures long-term performance without degradation, maintaining these energy-saving benefits over extended periods.

In terms of water management, polycarbonate's application in rainwater harvesting systems and stormwater management infrastructure supports sustainable water use in urban areas. Its resistance to corrosion and chemical degradation makes it suitable for long-term water storage and distribution solutions, contributing to water conservation efforts in cities.

The production of polycarbonate, however, does raise some sustainability concerns. The manufacturing process can be energy-intensive and involves the use of fossil fuel-derived raw materials. Efforts are underway to develop bio-based alternatives and improve production efficiency to address these issues. Some manufacturers are exploring the use of recycled content in polycarbonate production, further enhancing its sustainability profile.

As urban planners and developers increasingly prioritize sustainability, the role of polycarbonate in green building certifications such as LEED and BREEAM is growing. Its contributions to energy efficiency, daylighting, and material conservation align with many of the criteria set forth in these sustainability rating systems, making it a valuable material for environmentally conscious urban development projects.

The recyclability of polycarbonate is a key sustainability feature. Many polycarbonate products can be recycled multiple times without significant loss of properties, promoting a closed-loop system in urban infrastructure. This recyclability helps conserve raw materials and energy, while reducing landfill waste associated with urban development.

Polycarbonate's energy efficiency properties play a crucial role in sustainable urban design. Its excellent insulation characteristics contribute to improved thermal performance in buildings, reducing heating and cooling demands. This translates to lower energy consumption and decreased greenhouse gas emissions over the lifecycle of urban structures.

The material's transparency and light transmission capabilities enable the integration of natural daylighting in architectural designs. This reduces the need for artificial lighting during daytime hours, further decreasing energy consumption in urban environments. Additionally, polycarbonate's UV resistance ensures long-term performance without degradation, maintaining these energy-saving benefits over extended periods.

In terms of water management, polycarbonate's application in rainwater harvesting systems and stormwater management infrastructure supports sustainable water use in urban areas. Its resistance to corrosion and chemical degradation makes it suitable for long-term water storage and distribution solutions, contributing to water conservation efforts in cities.

The production of polycarbonate, however, does raise some sustainability concerns. The manufacturing process can be energy-intensive and involves the use of fossil fuel-derived raw materials. Efforts are underway to develop bio-based alternatives and improve production efficiency to address these issues. Some manufacturers are exploring the use of recycled content in polycarbonate production, further enhancing its sustainability profile.

As urban planners and developers increasingly prioritize sustainability, the role of polycarbonate in green building certifications such as LEED and BREEAM is growing. Its contributions to energy efficiency, daylighting, and material conservation align with many of the criteria set forth in these sustainability rating systems, making it a valuable material for environmentally conscious urban development projects.

Regulatory Framework

The regulatory framework surrounding polycarbonate usage in modern urban development is complex and multifaceted, reflecting the material's widespread applications and potential environmental impacts. At the international level, organizations such as the International Organization for Standardization (ISO) have established guidelines for polycarbonate production, testing, and application in construction. These standards ensure consistency in quality and performance across global markets.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polycarbonate production and disposal. The agency has set strict guidelines for emissions control during manufacturing processes and has implemented recycling programs to mitigate environmental impact. Additionally, the Occupational Safety and Health Administration (OSHA) has established safety protocols for workers handling polycarbonate materials in construction and manufacturing settings.

The European Union has taken a proactive stance on polycarbonate regulation through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program. This comprehensive framework requires manufacturers and importers to assess and manage the risks associated with polycarbonate products, ensuring their safe use throughout the supply chain. The EU has also implemented stringent recycling targets for plastic materials, including polycarbonate, as part of its circular economy initiatives.

In Asia, countries like Japan and South Korea have developed advanced regulatory systems for polycarbonate use in urban development. These nations have focused on promoting energy-efficient building materials, with polycarbonate playing a significant role in meeting sustainability goals. China, as a major producer and consumer of polycarbonate, has recently tightened its environmental regulations, imposing stricter controls on production processes and waste management.

Building codes and standards across various countries have been updated to incorporate polycarbonate materials, recognizing their unique properties and potential in modern construction. These codes often specify requirements for fire resistance, impact strength, and thermal performance, ensuring that polycarbonate applications meet safety and efficiency standards in urban environments.

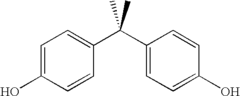

As urban development continues to evolve, regulatory frameworks are adapting to address emerging concerns. For instance, there is growing attention to the potential release of bisphenol A (BPA) from polycarbonate products, leading to new regulations on BPA content and exposure limits in certain applications, particularly those related to food contact and children's products.

The global trend towards sustainable urban development has also influenced polycarbonate regulations. Many jurisdictions now offer incentives for the use of recycled polycarbonate in construction projects, while others have implemented extended producer responsibility programs to encourage the recycling and proper disposal of polycarbonate products at the end of their lifecycle.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polycarbonate production and disposal. The agency has set strict guidelines for emissions control during manufacturing processes and has implemented recycling programs to mitigate environmental impact. Additionally, the Occupational Safety and Health Administration (OSHA) has established safety protocols for workers handling polycarbonate materials in construction and manufacturing settings.

The European Union has taken a proactive stance on polycarbonate regulation through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program. This comprehensive framework requires manufacturers and importers to assess and manage the risks associated with polycarbonate products, ensuring their safe use throughout the supply chain. The EU has also implemented stringent recycling targets for plastic materials, including polycarbonate, as part of its circular economy initiatives.

In Asia, countries like Japan and South Korea have developed advanced regulatory systems for polycarbonate use in urban development. These nations have focused on promoting energy-efficient building materials, with polycarbonate playing a significant role in meeting sustainability goals. China, as a major producer and consumer of polycarbonate, has recently tightened its environmental regulations, imposing stricter controls on production processes and waste management.

Building codes and standards across various countries have been updated to incorporate polycarbonate materials, recognizing their unique properties and potential in modern construction. These codes often specify requirements for fire resistance, impact strength, and thermal performance, ensuring that polycarbonate applications meet safety and efficiency standards in urban environments.

As urban development continues to evolve, regulatory frameworks are adapting to address emerging concerns. For instance, there is growing attention to the potential release of bisphenol A (BPA) from polycarbonate products, leading to new regulations on BPA content and exposure limits in certain applications, particularly those related to food contact and children's products.

The global trend towards sustainable urban development has also influenced polycarbonate regulations. Many jurisdictions now offer incentives for the use of recycled polycarbonate in construction projects, while others have implemented extended producer responsibility programs to encourage the recycling and proper disposal of polycarbonate products at the end of their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!