Polycarbonate’s Role in Smart Grid Technology

JUL 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in Smart Grid: Background and Objectives

Polycarbonate, a versatile thermoplastic polymer, has emerged as a crucial material in the development and implementation of smart grid technology. The evolution of electrical grids towards more intelligent, efficient, and responsive systems has created a demand for advanced materials that can withstand the rigors of modern power distribution while offering enhanced functionality.

The smart grid concept represents a significant leap forward in the management and distribution of electrical power. It integrates digital technology with traditional power infrastructure to enable two-way communication between utility providers and consumers. This integration allows for real-time monitoring, automated control, and optimized energy distribution, resulting in improved reliability, efficiency, and sustainability of the power system.

Polycarbonate's role in this technological advancement is multifaceted. Its unique combination of properties, including high impact strength, excellent electrical insulation, transparency, and flame resistance, makes it an ideal material for various components within the smart grid ecosystem. From protective housings for smart meters to insulating components in transformers and switchgear, polycarbonate contributes to the durability and safety of critical infrastructure elements.

The primary objective of incorporating polycarbonate into smart grid technology is to enhance the overall performance and longevity of grid components. By utilizing this advanced polymer, manufacturers aim to create more resilient and weather-resistant enclosures for outdoor electrical equipment, reducing maintenance costs and improving reliability. Additionally, the material's transparency allows for easy visual inspection of internal components, facilitating quicker diagnostics and repairs.

Another key goal is to leverage polycarbonate's electrical properties to develop more efficient and compact power distribution components. Its high dielectric strength and low electrical conductivity make it suitable for insulating applications in high-voltage environments, contributing to the miniaturization of electrical devices without compromising safety or performance.

As smart grids continue to evolve, the demand for materials that can withstand extreme environmental conditions while maintaining their electrical and mechanical properties becomes increasingly critical. Polycarbonate's ability to perform consistently across a wide temperature range and resist degradation from UV exposure positions it as a material of choice for outdoor smart grid applications.

The integration of renewable energy sources and energy storage systems into the smart grid presents additional challenges and opportunities for polycarbonate utilization. The material's versatility allows for its application in solar panel frames, wind turbine components, and battery casings, further expanding its role in the sustainable energy landscape.

The smart grid concept represents a significant leap forward in the management and distribution of electrical power. It integrates digital technology with traditional power infrastructure to enable two-way communication between utility providers and consumers. This integration allows for real-time monitoring, automated control, and optimized energy distribution, resulting in improved reliability, efficiency, and sustainability of the power system.

Polycarbonate's role in this technological advancement is multifaceted. Its unique combination of properties, including high impact strength, excellent electrical insulation, transparency, and flame resistance, makes it an ideal material for various components within the smart grid ecosystem. From protective housings for smart meters to insulating components in transformers and switchgear, polycarbonate contributes to the durability and safety of critical infrastructure elements.

The primary objective of incorporating polycarbonate into smart grid technology is to enhance the overall performance and longevity of grid components. By utilizing this advanced polymer, manufacturers aim to create more resilient and weather-resistant enclosures for outdoor electrical equipment, reducing maintenance costs and improving reliability. Additionally, the material's transparency allows for easy visual inspection of internal components, facilitating quicker diagnostics and repairs.

Another key goal is to leverage polycarbonate's electrical properties to develop more efficient and compact power distribution components. Its high dielectric strength and low electrical conductivity make it suitable for insulating applications in high-voltage environments, contributing to the miniaturization of electrical devices without compromising safety or performance.

As smart grids continue to evolve, the demand for materials that can withstand extreme environmental conditions while maintaining their electrical and mechanical properties becomes increasingly critical. Polycarbonate's ability to perform consistently across a wide temperature range and resist degradation from UV exposure positions it as a material of choice for outdoor smart grid applications.

The integration of renewable energy sources and energy storage systems into the smart grid presents additional challenges and opportunities for polycarbonate utilization. The material's versatility allows for its application in solar panel frames, wind turbine components, and battery casings, further expanding its role in the sustainable energy landscape.

Smart Grid Market Demand Analysis

The smart grid market has been experiencing significant growth and transformation, driven by the increasing demand for efficient, reliable, and sustainable energy distribution systems. As countries worldwide aim to modernize their power infrastructure, the smart grid market is projected to expand substantially over the coming years. This growth is fueled by several factors, including the need for improved energy efficiency, integration of renewable energy sources, and enhanced grid reliability.

One of the primary drivers of smart grid market demand is the growing emphasis on energy conservation and sustainability. Governments and utilities are increasingly recognizing the importance of reducing carbon emissions and optimizing energy consumption. Smart grid technologies enable real-time monitoring and control of power distribution, allowing for more efficient energy management and reduced waste. This aligns with global initiatives to combat climate change and promote sustainable development.

The integration of renewable energy sources into existing power grids is another significant factor driving smart grid market demand. As solar, wind, and other renewable energy technologies become more prevalent, there is a growing need for advanced grid management systems that can handle the intermittent nature of these sources. Smart grids provide the necessary infrastructure to balance supply and demand, ensuring grid stability and reliability even with high penetration of renewable energy.

The increasing adoption of electric vehicles (EVs) is also contributing to the demand for smart grid technologies. As EV adoption rates rise, power grids must be equipped to handle the additional load and manage charging patterns efficiently. Smart grid solutions offer the capability to optimize EV charging schedules, prevent grid overload, and potentially utilize EVs as distributed energy storage units.

Cybersecurity concerns in the energy sector have further intensified the need for advanced smart grid technologies. With the growing interconnectedness of power systems, utilities are seeking robust solutions to protect critical infrastructure from cyber threats. This has led to increased investment in secure smart grid technologies that can safeguard against potential attacks and ensure the resilience of power distribution networks.

The market demand for smart grid technologies is also being driven by the need for improved grid reliability and reduced downtime. Smart grids enable faster fault detection, isolation, and restoration, minimizing the impact of power outages on consumers and businesses. This enhanced reliability is particularly crucial for industries that rely heavily on uninterrupted power supply, such as healthcare, data centers, and manufacturing.

Furthermore, the concept of microgrids and distributed energy resources is gaining traction, particularly in remote areas or regions prone to natural disasters. Smart grid technologies facilitate the integration and management of these localized power systems, enhancing energy independence and resilience. This trend is expected to contribute significantly to the overall growth of the smart grid market in the coming years.

One of the primary drivers of smart grid market demand is the growing emphasis on energy conservation and sustainability. Governments and utilities are increasingly recognizing the importance of reducing carbon emissions and optimizing energy consumption. Smart grid technologies enable real-time monitoring and control of power distribution, allowing for more efficient energy management and reduced waste. This aligns with global initiatives to combat climate change and promote sustainable development.

The integration of renewable energy sources into existing power grids is another significant factor driving smart grid market demand. As solar, wind, and other renewable energy technologies become more prevalent, there is a growing need for advanced grid management systems that can handle the intermittent nature of these sources. Smart grids provide the necessary infrastructure to balance supply and demand, ensuring grid stability and reliability even with high penetration of renewable energy.

The increasing adoption of electric vehicles (EVs) is also contributing to the demand for smart grid technologies. As EV adoption rates rise, power grids must be equipped to handle the additional load and manage charging patterns efficiently. Smart grid solutions offer the capability to optimize EV charging schedules, prevent grid overload, and potentially utilize EVs as distributed energy storage units.

Cybersecurity concerns in the energy sector have further intensified the need for advanced smart grid technologies. With the growing interconnectedness of power systems, utilities are seeking robust solutions to protect critical infrastructure from cyber threats. This has led to increased investment in secure smart grid technologies that can safeguard against potential attacks and ensure the resilience of power distribution networks.

The market demand for smart grid technologies is also being driven by the need for improved grid reliability and reduced downtime. Smart grids enable faster fault detection, isolation, and restoration, minimizing the impact of power outages on consumers and businesses. This enhanced reliability is particularly crucial for industries that rely heavily on uninterrupted power supply, such as healthcare, data centers, and manufacturing.

Furthermore, the concept of microgrids and distributed energy resources is gaining traction, particularly in remote areas or regions prone to natural disasters. Smart grid technologies facilitate the integration and management of these localized power systems, enhancing energy independence and resilience. This trend is expected to contribute significantly to the overall growth of the smart grid market in the coming years.

Current Challenges in Polycarbonate Smart Grid Applications

The integration of polycarbonate materials in smart grid technology has encountered several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the material's susceptibility to environmental degradation, particularly when exposed to prolonged UV radiation and extreme weather conditions. This vulnerability can lead to reduced lifespan and compromised structural integrity of smart grid components, potentially affecting the reliability of the entire system.

Another pressing challenge is the need for enhanced electrical insulation properties in polycarbonate materials used in smart grid applications. As power transmission and distribution systems become more complex and operate at higher voltages, the demand for superior dielectric strength and arc resistance in insulating materials has increased. Current polycarbonate formulations may not consistently meet these stringent requirements across all smart grid applications, necessitating further research and development.

The issue of fire safety also presents a significant hurdle in the use of polycarbonate in smart grid infrastructure. While polycarbonate is inherently flame-retardant, the addition of certain additives to enhance its electrical properties can sometimes compromise its fire resistance. Striking the right balance between electrical performance and fire safety remains a critical challenge for material scientists and engineers working in this field.

Furthermore, the integration of smart functionalities into polycarbonate components poses technical difficulties. Incorporating sensors, communication modules, and other smart features into polycarbonate housings or structures without compromising the material's mechanical and electrical properties requires advanced manufacturing techniques and careful design considerations. The challenge lies in developing seamless integration methods that maintain the integrity of both the polycarbonate material and the embedded smart technologies.

Recyclability and environmental sustainability of polycarbonate in smart grid applications also present ongoing challenges. As the push for more sustainable and circular economy practices grows, there is increasing pressure to develop polycarbonate formulations that are easier to recycle and have a lower environmental impact. This includes addressing issues related to the separation of polycarbonate from other materials in smart grid components at the end of their lifecycle, as well as developing more eco-friendly additives and manufacturing processes.

Lastly, the cost-effectiveness of using high-performance polycarbonate materials in large-scale smart grid deployments remains a significant hurdle. While polycarbonate offers numerous advantages, the expense associated with developing and manufacturing specialized grades for smart grid applications can be prohibitive, especially when competing with more traditional materials. Balancing the cost of these advanced materials with their long-term benefits and performance improvements is an ongoing challenge for both manufacturers and utility companies implementing smart grid technologies.

Another pressing challenge is the need for enhanced electrical insulation properties in polycarbonate materials used in smart grid applications. As power transmission and distribution systems become more complex and operate at higher voltages, the demand for superior dielectric strength and arc resistance in insulating materials has increased. Current polycarbonate formulations may not consistently meet these stringent requirements across all smart grid applications, necessitating further research and development.

The issue of fire safety also presents a significant hurdle in the use of polycarbonate in smart grid infrastructure. While polycarbonate is inherently flame-retardant, the addition of certain additives to enhance its electrical properties can sometimes compromise its fire resistance. Striking the right balance between electrical performance and fire safety remains a critical challenge for material scientists and engineers working in this field.

Furthermore, the integration of smart functionalities into polycarbonate components poses technical difficulties. Incorporating sensors, communication modules, and other smart features into polycarbonate housings or structures without compromising the material's mechanical and electrical properties requires advanced manufacturing techniques and careful design considerations. The challenge lies in developing seamless integration methods that maintain the integrity of both the polycarbonate material and the embedded smart technologies.

Recyclability and environmental sustainability of polycarbonate in smart grid applications also present ongoing challenges. As the push for more sustainable and circular economy practices grows, there is increasing pressure to develop polycarbonate formulations that are easier to recycle and have a lower environmental impact. This includes addressing issues related to the separation of polycarbonate from other materials in smart grid components at the end of their lifecycle, as well as developing more eco-friendly additives and manufacturing processes.

Lastly, the cost-effectiveness of using high-performance polycarbonate materials in large-scale smart grid deployments remains a significant hurdle. While polycarbonate offers numerous advantages, the expense associated with developing and manufacturing specialized grades for smart grid applications can be prohibitive, especially when competing with more traditional materials. Balancing the cost of these advanced materials with their long-term benefits and performance improvements is an ongoing challenge for both manufacturers and utility companies implementing smart grid technologies.

Existing Polycarbonate-based Smart Grid Technologies

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.- Polycarbonate synthesis and modification: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These combinations can result in materials with enhanced impact resistance, flame retardancy, or conductivity, expanding the application range of polycarbonates.

- Polycarbonate processing and manufacturing: Advancements in processing techniques and manufacturing methods for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final polycarbonate products.

- Polycarbonate surface treatments and coatings: Development of surface treatments and coatings for polycarbonate materials to enhance properties such as scratch resistance, UV stability, and anti-fogging capabilities. These treatments can significantly improve the durability and performance of polycarbonate products in various applications.

- Recycling and sustainability of polycarbonates: Innovations in recycling methods and sustainable production of polycarbonates, including chemical recycling processes, bio-based alternatives, and techniques to improve the recyclability of polycarbonate products. These advancements aim to reduce environmental impact and promote circular economy principles in polycarbonate use.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical properties, flame retardancy, or specific functionalities. These combinations often result in materials with enhanced characteristics suitable for various applications in electronics, automotive, and consumer goods industries.Expand Specific Solutions03 Optical applications of polycarbonates

Utilization of polycarbonates in optical applications, such as lenses, displays, and light-guiding components. Research focuses on improving optical clarity, UV resistance, and scratch resistance of polycarbonate materials for use in eyewear, automotive lighting, and electronic displays.Expand Specific Solutions04 Polycarbonate processing techniques

Advancements in processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods aim to enhance production efficiency, reduce defects, and enable the creation of complex shapes and structures while maintaining the material's desirable properties.Expand Specific Solutions05 Recycling and sustainability of polycarbonates

Development of methods for recycling polycarbonate materials and improving their environmental sustainability. This includes chemical recycling processes, biodegradable additives, and the use of bio-based monomers to create more eco-friendly polycarbonate alternatives.Expand Specific Solutions

Key Players in Polycarbonate Smart Grid Solutions

The polycarbonate smart grid technology market is in its growth phase, with increasing adoption driven by the need for more resilient and efficient power distribution systems. The global market size is projected to expand significantly in the coming years, fueled by investments in grid modernization. Technologically, the field is advancing rapidly, with major players like SABIC, Covestro, and LG Chem leading innovation in high-performance polycarbonate materials for smart grid applications. These companies are developing solutions with enhanced durability, insulation properties, and fire resistance. Emerging players such as Kingfa Sci. & Tech. and Wanhua Chemical are also making strides in this space, contributing to the overall maturation of the technology.

SABIC Global Technologies BV

Technical Solution: SABIC has developed high-performance polycarbonate resins specifically designed for smart grid applications. Their LEXAN™ resin series offers excellent electrical insulation properties and flame retardancy, crucial for smart meter housings and electrical components in grid infrastructure[1]. The material provides long-term UV resistance and dimensional stability, ensuring durability in outdoor installations. SABIC's polycarbonate compounds also incorporate anti-tracking additives, enhancing safety in high-voltage applications[2]. The company has focused on developing materials with improved impact resistance and weatherability, addressing the need for robust enclosures in smart grid deployments across various climatic conditions[3].

Strengths: Superior electrical insulation, flame retardancy, and UV resistance. Weaknesses: Potentially higher cost compared to traditional materials, which may impact large-scale adoption in cost-sensitive markets.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered the development of polycarbonate blends tailored for smart grid applications. Their Makrolon® TC series offers enhanced thermal conductivity, crucial for efficient heat dissipation in smart grid components[4]. This innovation addresses the challenge of managing heat generated by increasingly powerful electronics in grid infrastructure. Covestro's polycarbonates also feature high impact strength and flame retardancy, meeting UL94 V-0 standards at thin wall thicknesses[5]. The company has developed transparent polycarbonate grades for smart meter displays, combining clarity with durability. Additionally, Covestro's materials incorporate UV stabilizers and anti-hydrolysis agents, ensuring long-term performance in outdoor environments[6].

Strengths: Advanced thermal management properties, high impact resistance, and transparency options. Weaknesses: May require specialized processing techniques, potentially limiting manufacturing flexibility.

Innovative Polycarbonate Formulations for Smart Grids

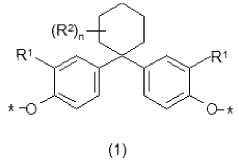

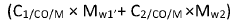

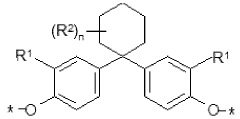

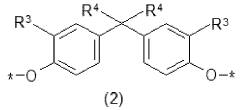

Polycarbonate composition with high comparative tracking index

PatentWO2022228952A1

Innovation

- A polycarbonate composition comprising 60-95 wt.% of a copolycarbonate with specific molecular weight ratios of units derived from bis(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane and bisphenol A, combined with 5-40 wt.% of a homopolycarbonate with a weight-average molecular weight of 24000-28000 g/mol, enhancing CTI to 600 V, transmittance to 86%, and Vicat softening temperature above 175 °C.

Non-bromine, non-chlorine flame retardant, glass filled polycarbonate with improved multi-axial impact strength

PatentActiveUS11926732B2

Innovation

- The compositions comprise 70-98 wt.% polycarbonate polymer, 0.01-1 wt.% non-bromine and/or chlorine-free flame retardant additive, 2-20 wt.% non-bonding glass fiber, and 0.001-5 wt.% stabilizer additive, such as butyl tosylate or bis(2,4-dicumylphenyl) pentaerythritol diphosphite, to achieve improved multi-axial impact strength and robust flame retardancy.

Environmental Impact of Polycarbonate in Smart Grids

The environmental impact of polycarbonate in smart grids is a multifaceted issue that requires careful consideration. Polycarbonate, a durable and versatile thermoplastic, plays a significant role in the development and implementation of smart grid technologies. However, its production, use, and disposal have both positive and negative environmental implications.

From a positive perspective, polycarbonate's durability and resistance to weathering contribute to the longevity of smart grid components, reducing the need for frequent replacements and minimizing waste generation. Its lightweight nature also helps in reducing transportation-related emissions during installation and maintenance of smart grid infrastructure.

The material's excellent electrical insulation properties enhance the safety and efficiency of smart grid systems, potentially leading to reduced energy losses and improved overall grid performance. This increased efficiency can indirectly contribute to lower greenhouse gas emissions by optimizing energy distribution and consumption.

However, the production of polycarbonate is energy-intensive and relies heavily on fossil fuel-derived raw materials, primarily bisphenol A (BPA) and phosgene. This dependency on non-renewable resources raises concerns about the long-term sustainability of polycarbonate use in smart grids. The manufacturing process also generates various pollutants and greenhouse gases, contributing to air and water pollution if not properly managed.

End-of-life considerations for polycarbonate components in smart grids present another environmental challenge. While polycarbonate is theoretically recyclable, the presence of additives and the complexity of smart grid components can make recycling difficult and energy-intensive. Improper disposal of polycarbonate waste can lead to long-term environmental contamination, as the material is not biodegradable.

The potential leaching of BPA from polycarbonate components exposed to environmental factors is another concern. Although the extent of this issue in smart grid applications is not fully understood, it highlights the need for ongoing research and monitoring of potential ecological impacts.

To mitigate these environmental concerns, efforts are being made to develop more sustainable alternatives and improve the recyclability of polycarbonate components in smart grids. Research into bio-based polycarbonates and advanced recycling technologies shows promise for reducing the environmental footprint of this material in future smart grid applications.

In conclusion, while polycarbonate offers significant benefits for smart grid technology, its environmental impact is complex and requires a balanced approach. Continued innovation in material science and lifecycle management will be crucial in maximizing the benefits of polycarbonate while minimizing its environmental drawbacks in smart grid systems.

From a positive perspective, polycarbonate's durability and resistance to weathering contribute to the longevity of smart grid components, reducing the need for frequent replacements and minimizing waste generation. Its lightweight nature also helps in reducing transportation-related emissions during installation and maintenance of smart grid infrastructure.

The material's excellent electrical insulation properties enhance the safety and efficiency of smart grid systems, potentially leading to reduced energy losses and improved overall grid performance. This increased efficiency can indirectly contribute to lower greenhouse gas emissions by optimizing energy distribution and consumption.

However, the production of polycarbonate is energy-intensive and relies heavily on fossil fuel-derived raw materials, primarily bisphenol A (BPA) and phosgene. This dependency on non-renewable resources raises concerns about the long-term sustainability of polycarbonate use in smart grids. The manufacturing process also generates various pollutants and greenhouse gases, contributing to air and water pollution if not properly managed.

End-of-life considerations for polycarbonate components in smart grids present another environmental challenge. While polycarbonate is theoretically recyclable, the presence of additives and the complexity of smart grid components can make recycling difficult and energy-intensive. Improper disposal of polycarbonate waste can lead to long-term environmental contamination, as the material is not biodegradable.

The potential leaching of BPA from polycarbonate components exposed to environmental factors is another concern. Although the extent of this issue in smart grid applications is not fully understood, it highlights the need for ongoing research and monitoring of potential ecological impacts.

To mitigate these environmental concerns, efforts are being made to develop more sustainable alternatives and improve the recyclability of polycarbonate components in smart grids. Research into bio-based polycarbonates and advanced recycling technologies shows promise for reducing the environmental footprint of this material in future smart grid applications.

In conclusion, while polycarbonate offers significant benefits for smart grid technology, its environmental impact is complex and requires a balanced approach. Continued innovation in material science and lifecycle management will be crucial in maximizing the benefits of polycarbonate while minimizing its environmental drawbacks in smart grid systems.

Regulatory Framework for Smart Grid Materials

The regulatory framework for smart grid materials, including polycarbonate components, is a critical aspect of the evolving smart grid technology landscape. As smart grids become increasingly prevalent, governments and regulatory bodies worldwide are developing comprehensive guidelines to ensure the safety, reliability, and efficiency of these advanced energy systems.

In the United States, the Federal Energy Regulatory Commission (FERC) plays a pivotal role in shaping the regulatory environment for smart grid materials. FERC has established standards for the interoperability and cybersecurity of smart grid systems, which directly impact the specifications for materials used in their construction, including polycarbonate components.

The National Institute of Standards and Technology (NIST) has also been instrumental in developing a framework for smart grid standards. Their guidelines encompass various aspects of smart grid technology, including the materials used in smart meters, sensors, and other grid components. These standards often reference specific material properties, such as durability, electrical insulation, and fire resistance, which are key attributes of polycarbonate.

At the international level, the International Electrotechnical Commission (IEC) has developed a series of standards specifically for smart grid technologies. These standards, such as IEC 61850 for communication networks and systems for power utility automation, indirectly influence the selection and application of materials like polycarbonate in smart grid infrastructure.

The European Union has implemented the Smart Grids Task Force, which works on developing regulatory recommendations for smart grid deployment. Their focus on data protection and privacy has implications for the design and materials used in smart grid components, particularly those that house sensitive electronic equipment.

In Asia, countries like China and Japan have their own regulatory bodies overseeing smart grid development. China's National Energy Administration has set forth guidelines for smart grid construction, which include specifications for materials used in various grid components. Japan's Ministry of Economy, Trade and Industry has similarly established regulations that impact the use of materials in smart grid applications.

Regulatory frameworks also address environmental concerns related to smart grid materials. Many jurisdictions now require lifecycle assessments of materials used in grid infrastructure, considering factors such as recyclability and environmental impact. Polycarbonate's recyclability and durability make it an attractive option under these regulatory considerations.

As smart grid technology continues to evolve, regulatory frameworks are likely to become more sophisticated, potentially leading to more specific requirements for materials like polycarbonate. This may include enhanced standards for weatherability, electromagnetic shielding, and long-term performance under various environmental conditions.

In the United States, the Federal Energy Regulatory Commission (FERC) plays a pivotal role in shaping the regulatory environment for smart grid materials. FERC has established standards for the interoperability and cybersecurity of smart grid systems, which directly impact the specifications for materials used in their construction, including polycarbonate components.

The National Institute of Standards and Technology (NIST) has also been instrumental in developing a framework for smart grid standards. Their guidelines encompass various aspects of smart grid technology, including the materials used in smart meters, sensors, and other grid components. These standards often reference specific material properties, such as durability, electrical insulation, and fire resistance, which are key attributes of polycarbonate.

At the international level, the International Electrotechnical Commission (IEC) has developed a series of standards specifically for smart grid technologies. These standards, such as IEC 61850 for communication networks and systems for power utility automation, indirectly influence the selection and application of materials like polycarbonate in smart grid infrastructure.

The European Union has implemented the Smart Grids Task Force, which works on developing regulatory recommendations for smart grid deployment. Their focus on data protection and privacy has implications for the design and materials used in smart grid components, particularly those that house sensitive electronic equipment.

In Asia, countries like China and Japan have their own regulatory bodies overseeing smart grid development. China's National Energy Administration has set forth guidelines for smart grid construction, which include specifications for materials used in various grid components. Japan's Ministry of Economy, Trade and Industry has similarly established regulations that impact the use of materials in smart grid applications.

Regulatory frameworks also address environmental concerns related to smart grid materials. Many jurisdictions now require lifecycle assessments of materials used in grid infrastructure, considering factors such as recyclability and environmental impact. Polycarbonate's recyclability and durability make it an attractive option under these regulatory considerations.

As smart grid technology continues to evolve, regulatory frameworks are likely to become more sophisticated, potentially leading to more specific requirements for materials like polycarbonate. This may include enhanced standards for weatherability, electromagnetic shielding, and long-term performance under various environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!