Quantum Computing in Enhancing Manufacturing Process Control

JUL 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Computing in Manufacturing: Background and Objectives

Quantum computing represents a paradigm shift in computational capabilities, leveraging the principles of quantum mechanics to perform complex calculations at unprecedented speeds. In the context of manufacturing process control, this emerging technology holds immense potential to revolutionize various aspects of production, quality assurance, and supply chain management.

The evolution of quantum computing can be traced back to the early 1980s when physicist Richard Feynman proposed the idea of using quantum systems to simulate quantum phenomena. Since then, the field has progressed rapidly, with significant milestones achieved in the development of quantum hardware, algorithms, and error correction techniques.

In recent years, the manufacturing industry has shown increasing interest in harnessing the power of quantum computing to address complex optimization problems, enhance predictive maintenance, and improve overall process efficiency. The convergence of quantum computing with advanced manufacturing technologies, such as Industry 4.0 and the Industrial Internet of Things (IIoT), presents a unique opportunity to transform traditional manufacturing paradigms.

The primary objective of integrating quantum computing into manufacturing process control is to achieve unprecedented levels of precision, efficiency, and adaptability in production systems. By leveraging quantum algorithms, manufacturers aim to optimize resource allocation, minimize waste, and enhance product quality through real-time analysis of vast amounts of data generated throughout the production lifecycle.

One of the key areas where quantum computing is expected to make a significant impact is in the optimization of complex manufacturing processes. Traditional computing methods often struggle with the exponential complexity of large-scale optimization problems, leading to suboptimal solutions or excessive computational time. Quantum algorithms, such as quantum annealing and quantum approximate optimization algorithm (QAOA), offer the potential to solve these problems more efficiently, enabling manufacturers to make better decisions in real-time.

Another crucial objective is to enhance predictive maintenance capabilities in manufacturing environments. Quantum machine learning algorithms can potentially analyze sensor data from industrial equipment with greater accuracy and speed, allowing for early detection of potential failures and more precise scheduling of maintenance activities. This proactive approach can significantly reduce downtime, extend equipment lifespan, and improve overall operational efficiency.

Furthermore, quantum computing aims to revolutionize quality control processes in manufacturing. By simulating molecular structures and material properties at the quantum level, manufacturers can develop new materials with enhanced characteristics, optimize product designs, and improve the overall quality of finished goods. This capability is particularly valuable in industries such as aerospace, automotive, and pharmaceuticals, where material performance and product reliability are critical.

As the field of quantum computing continues to advance, its integration into manufacturing process control is expected to drive innovation, increase competitiveness, and pave the way for more sustainable and efficient production methods. The realization of these objectives, however, depends on overcoming several technical challenges and developing practical, industry-specific quantum applications.

The evolution of quantum computing can be traced back to the early 1980s when physicist Richard Feynman proposed the idea of using quantum systems to simulate quantum phenomena. Since then, the field has progressed rapidly, with significant milestones achieved in the development of quantum hardware, algorithms, and error correction techniques.

In recent years, the manufacturing industry has shown increasing interest in harnessing the power of quantum computing to address complex optimization problems, enhance predictive maintenance, and improve overall process efficiency. The convergence of quantum computing with advanced manufacturing technologies, such as Industry 4.0 and the Industrial Internet of Things (IIoT), presents a unique opportunity to transform traditional manufacturing paradigms.

The primary objective of integrating quantum computing into manufacturing process control is to achieve unprecedented levels of precision, efficiency, and adaptability in production systems. By leveraging quantum algorithms, manufacturers aim to optimize resource allocation, minimize waste, and enhance product quality through real-time analysis of vast amounts of data generated throughout the production lifecycle.

One of the key areas where quantum computing is expected to make a significant impact is in the optimization of complex manufacturing processes. Traditional computing methods often struggle with the exponential complexity of large-scale optimization problems, leading to suboptimal solutions or excessive computational time. Quantum algorithms, such as quantum annealing and quantum approximate optimization algorithm (QAOA), offer the potential to solve these problems more efficiently, enabling manufacturers to make better decisions in real-time.

Another crucial objective is to enhance predictive maintenance capabilities in manufacturing environments. Quantum machine learning algorithms can potentially analyze sensor data from industrial equipment with greater accuracy and speed, allowing for early detection of potential failures and more precise scheduling of maintenance activities. This proactive approach can significantly reduce downtime, extend equipment lifespan, and improve overall operational efficiency.

Furthermore, quantum computing aims to revolutionize quality control processes in manufacturing. By simulating molecular structures and material properties at the quantum level, manufacturers can develop new materials with enhanced characteristics, optimize product designs, and improve the overall quality of finished goods. This capability is particularly valuable in industries such as aerospace, automotive, and pharmaceuticals, where material performance and product reliability are critical.

As the field of quantum computing continues to advance, its integration into manufacturing process control is expected to drive innovation, increase competitiveness, and pave the way for more sustainable and efficient production methods. The realization of these objectives, however, depends on overcoming several technical challenges and developing practical, industry-specific quantum applications.

Market Demand for Quantum-Enhanced Process Control

The market demand for quantum-enhanced process control in manufacturing is experiencing a significant upward trajectory, driven by the increasing complexity of production processes and the need for higher precision and efficiency. As industries strive to optimize their operations, quantum computing offers unprecedented capabilities in handling complex calculations and simulations that are beyond the reach of classical computers.

In the automotive sector, major manufacturers are exploring quantum-enhanced process control to optimize production line efficiency and reduce defects. The ability to simulate and optimize complex assembly processes in real-time could lead to substantial cost savings and improved product quality. Similarly, in the aerospace industry, quantum computing is being investigated for its potential to enhance the design and manufacturing of advanced materials and components, potentially revolutionizing aircraft production.

The semiconductor industry, facing ever-increasing demands for smaller and more powerful chips, is another key market for quantum-enhanced process control. Quantum algorithms could significantly improve the accuracy of lithography processes and optimize the layout of integrated circuits, addressing critical challenges in nanoscale manufacturing.

In the pharmaceutical sector, quantum computing's potential to simulate molecular interactions and optimize chemical processes is driving interest in quantum-enhanced process control for drug discovery and manufacturing. This could lead to more efficient production of pharmaceuticals and accelerate the development of new drugs.

The energy sector, particularly in oil and gas refining, is exploring quantum computing to optimize complex chemical processes and improve yield. The ability to model and simulate intricate molecular interactions could result in more efficient refining processes and reduced energy consumption.

While the market for quantum-enhanced process control is still in its early stages, industry analysts project rapid growth in the coming years. Early adopters are already investing in research and development, partnering with quantum computing companies to explore potential applications. As quantum hardware continues to advance and become more accessible, the demand for quantum-enhanced process control solutions is expected to surge across various manufacturing sectors.

However, challenges remain in terms of quantum hardware scalability and the development of industry-specific quantum algorithms. The market's growth will depend on overcoming these technical hurdles and demonstrating clear return on investment for manufacturing companies. Despite these challenges, the potential for quantum computing to revolutionize process control in manufacturing is driving significant interest and investment, positioning it as a key technology for the future of industrial optimization.

In the automotive sector, major manufacturers are exploring quantum-enhanced process control to optimize production line efficiency and reduce defects. The ability to simulate and optimize complex assembly processes in real-time could lead to substantial cost savings and improved product quality. Similarly, in the aerospace industry, quantum computing is being investigated for its potential to enhance the design and manufacturing of advanced materials and components, potentially revolutionizing aircraft production.

The semiconductor industry, facing ever-increasing demands for smaller and more powerful chips, is another key market for quantum-enhanced process control. Quantum algorithms could significantly improve the accuracy of lithography processes and optimize the layout of integrated circuits, addressing critical challenges in nanoscale manufacturing.

In the pharmaceutical sector, quantum computing's potential to simulate molecular interactions and optimize chemical processes is driving interest in quantum-enhanced process control for drug discovery and manufacturing. This could lead to more efficient production of pharmaceuticals and accelerate the development of new drugs.

The energy sector, particularly in oil and gas refining, is exploring quantum computing to optimize complex chemical processes and improve yield. The ability to model and simulate intricate molecular interactions could result in more efficient refining processes and reduced energy consumption.

While the market for quantum-enhanced process control is still in its early stages, industry analysts project rapid growth in the coming years. Early adopters are already investing in research and development, partnering with quantum computing companies to explore potential applications. As quantum hardware continues to advance and become more accessible, the demand for quantum-enhanced process control solutions is expected to surge across various manufacturing sectors.

However, challenges remain in terms of quantum hardware scalability and the development of industry-specific quantum algorithms. The market's growth will depend on overcoming these technical hurdles and demonstrating clear return on investment for manufacturing companies. Despite these challenges, the potential for quantum computing to revolutionize process control in manufacturing is driving significant interest and investment, positioning it as a key technology for the future of industrial optimization.

Current State and Challenges in Quantum Manufacturing

Quantum computing in manufacturing process control is currently in its nascent stages, with significant potential for revolutionizing the industry. The current state of quantum manufacturing is characterized by a mix of promising advancements and formidable challenges. While quantum computers have demonstrated their ability to solve complex optimization problems faster than classical computers, their application in real-world manufacturing scenarios remains limited.

One of the primary challenges in quantum manufacturing is the issue of quantum coherence. Quantum systems are extremely sensitive to environmental disturbances, which can cause decoherence and lead to errors in computations. This sensitivity poses a significant hurdle in maintaining the stability required for precise manufacturing process control. Researchers are actively working on developing error correction techniques and more robust quantum hardware to address this challenge.

Another major obstacle is the scalability of quantum systems. Current quantum computers have a limited number of qubits, which restricts their ability to handle the large-scale optimization problems typical in manufacturing environments. Scaling up quantum systems while maintaining their coherence and computational accuracy is a key focus area for researchers and industry players.

The integration of quantum computing with existing manufacturing infrastructure presents another significant challenge. Many manufacturing processes rely on classical computing systems and software, which are not directly compatible with quantum algorithms. Developing hybrid quantum-classical systems and bridging the gap between quantum and classical computing paradigms is crucial for the widespread adoption of quantum technologies in manufacturing.

Despite these challenges, there have been notable advancements in quantum manufacturing. Quantum algorithms for optimization problems, such as those used in supply chain management and production scheduling, have shown promising results in simulations. Some early-stage implementations have demonstrated the potential for quantum-enhanced process control in areas like chemical manufacturing and materials science.

The current landscape of quantum manufacturing is marked by intense research and development efforts from both academic institutions and industry leaders. Companies like IBM, Google, and D-Wave are at the forefront of developing quantum hardware and software solutions tailored for industrial applications. Collaborations between quantum technology providers and manufacturing companies are becoming more common, driving the development of industry-specific quantum applications.

However, the gap between theoretical quantum advantages and practical implementations remains significant. Many of the proposed quantum solutions for manufacturing are still in the proof-of-concept stage and require further refinement before they can be deployed in real-world production environments. The lack of standardization in quantum technologies also poses a challenge for widespread adoption in the manufacturing sector.

One of the primary challenges in quantum manufacturing is the issue of quantum coherence. Quantum systems are extremely sensitive to environmental disturbances, which can cause decoherence and lead to errors in computations. This sensitivity poses a significant hurdle in maintaining the stability required for precise manufacturing process control. Researchers are actively working on developing error correction techniques and more robust quantum hardware to address this challenge.

Another major obstacle is the scalability of quantum systems. Current quantum computers have a limited number of qubits, which restricts their ability to handle the large-scale optimization problems typical in manufacturing environments. Scaling up quantum systems while maintaining their coherence and computational accuracy is a key focus area for researchers and industry players.

The integration of quantum computing with existing manufacturing infrastructure presents another significant challenge. Many manufacturing processes rely on classical computing systems and software, which are not directly compatible with quantum algorithms. Developing hybrid quantum-classical systems and bridging the gap between quantum and classical computing paradigms is crucial for the widespread adoption of quantum technologies in manufacturing.

Despite these challenges, there have been notable advancements in quantum manufacturing. Quantum algorithms for optimization problems, such as those used in supply chain management and production scheduling, have shown promising results in simulations. Some early-stage implementations have demonstrated the potential for quantum-enhanced process control in areas like chemical manufacturing and materials science.

The current landscape of quantum manufacturing is marked by intense research and development efforts from both academic institutions and industry leaders. Companies like IBM, Google, and D-Wave are at the forefront of developing quantum hardware and software solutions tailored for industrial applications. Collaborations between quantum technology providers and manufacturing companies are becoming more common, driving the development of industry-specific quantum applications.

However, the gap between theoretical quantum advantages and practical implementations remains significant. Many of the proposed quantum solutions for manufacturing are still in the proof-of-concept stage and require further refinement before they can be deployed in real-world production environments. The lack of standardization in quantum technologies also poses a challenge for widespread adoption in the manufacturing sector.

Existing Quantum Solutions for Process Control

01 Quantum error correction and fault tolerance

Quantum computing systems employ error correction and fault tolerance techniques to maintain coherence and improve the reliability of quantum operations. These methods involve detecting and correcting errors caused by decoherence and other quantum noise sources, enabling more stable and accurate quantum computations.- Quantum error correction and fault tolerance: Quantum computing systems employ error correction and fault tolerance techniques to maintain the integrity of quantum information during processing. These methods involve encoding quantum states, detecting and correcting errors, and implementing fault-tolerant gate operations to mitigate the effects of decoherence and noise in quantum circuits.

- Quantum circuit optimization and compilation: Optimization and compilation techniques are crucial for efficient quantum process control. These methods involve transforming high-level quantum algorithms into optimized quantum circuits, reducing gate count, minimizing circuit depth, and adapting algorithms to specific quantum hardware architectures to improve overall performance and reliability.

- Quantum-classical hybrid algorithms: Hybrid quantum-classical algorithms combine the strengths of quantum and classical computing to solve complex problems. These approaches involve iterative processes where quantum and classical components work together, with the classical part optimizing parameters for the quantum circuit or processing measurement results to guide further quantum operations.

- Quantum state preparation and measurement: Efficient methods for preparing desired quantum states and performing accurate measurements are essential for quantum process control. These techniques involve initializing qubits, implementing quantum gates to create specific superpositions or entangled states, and developing robust measurement protocols to extract information from the quantum system.

- Quantum feedback control: Quantum feedback control involves continuously monitoring the quantum system and applying corrective actions based on measurement results. This approach helps maintain desired quantum states, suppress decoherence, and improve the overall stability and performance of quantum processes by dynamically adjusting control parameters in real-time.

02 Quantum gate optimization and control

Optimization of quantum gates and their control sequences is crucial for efficient quantum process control. This involves developing algorithms and techniques to minimize gate errors, reduce execution time, and enhance the overall performance of quantum circuits. Advanced control methods are employed to precisely manipulate qubits and implement complex quantum operations.Expand Specific Solutions03 Quantum measurement and feedback control

Quantum measurement and feedback control techniques are essential for monitoring and adjusting quantum states during computation. These methods involve performing measurements on quantum systems and using the results to guide subsequent operations, enabling adaptive control and error mitigation in quantum processes.Expand Specific Solutions04 Quantum-classical hybrid algorithms

Hybrid quantum-classical algorithms combine the strengths of quantum and classical computing to solve complex problems. These algorithms involve partitioning tasks between quantum and classical processors, optimizing resource allocation, and developing efficient interfaces for data exchange between the two paradigms.Expand Specific Solutions05 Quantum process tomography and characterization

Quantum process tomography and characterization techniques are used to analyze and validate quantum operations. These methods involve systematically probing quantum systems to reconstruct their behavior, assess the fidelity of quantum gates, and identify sources of errors in quantum processes. This information is crucial for optimizing quantum control strategies and improving overall system performance.Expand Specific Solutions

Key Players in Quantum Computing for Manufacturing

The quantum computing landscape in manufacturing process control is evolving rapidly, with the industry currently in its early growth phase. The market size is expanding, driven by increasing investments and collaborations between tech giants and manufacturing firms. While still nascent, the technology's maturity is progressing, with companies like Google, IBM, and Intel leading in quantum hardware development. Startups such as Rigetti and IQM are focusing on specialized quantum solutions for industrial applications. Established manufacturers like BASF and Bosch are exploring quantum computing's potential to optimize complex processes. As the technology advances, we can expect increased adoption and integration of quantum computing in manufacturing, potentially revolutionizing process control and efficiency.

Google LLC

Technical Solution: Google's approach to quantum computing in manufacturing process control leverages their Sycamore processor, which achieved quantum supremacy in 2019[5]. They are developing quantum algorithms for simulating chemical reactions and materials, which can be applied to optimize manufacturing processes[6]. Google's quantum error correction techniques, such as surface codes, aim to improve the stability of quantum computations in industrial applications[7]. Their focus on quantum machine learning algorithms could potentially enhance predictive maintenance and quality control in manufacturing[8].

Strengths: Advanced quantum hardware with demonstrated supremacy, strong focus on error correction and quantum ML. Weaknesses: Limited commercial availability of their quantum systems, still in early stages of industrial application development.

Intel Corp.

Technical Solution: Intel's quantum computing strategy for manufacturing process control centers on their spin qubit technology, which operates at higher temperatures than superconducting qubits[9]. They are developing cryogenic control chips to integrate quantum and classical computing elements, potentially enabling more efficient process control systems[10]. Intel's Horse Ridge II quantum control chip aims to simplify the control electronics for quantum systems, making them more suitable for industrial environments[11]. They are also exploring quantum-inspired algorithms for classical computers to optimize manufacturing processes in the near term[12].

Strengths: Integration with existing semiconductor manufacturing infrastructure, focus on scalable qubit technologies. Weaknesses: Relatively new entrant in quantum computing, still developing full-stack quantum solutions.

Core Quantum Algorithms for Manufacturing Optimization

Modular control in a quantum computing system

PatentPendingEP4421647A3

Innovation

- Modular assignment of qubit devices to respective cores in a quantum processor, enabling parallel processing and improved scalability.

- Identification and management of boundary qubit devices between cores, facilitating efficient communication and coordination between modular units.

- Generation of core-specific control sequences, allowing for tailored operations within each modular unit of the quantum processor.

System and method for controlling quantum processing elements

PatentPendingUS20240363738A1

Innovation

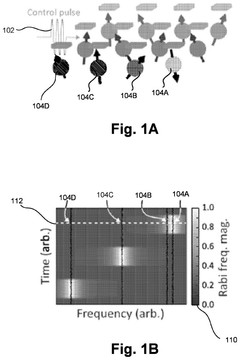

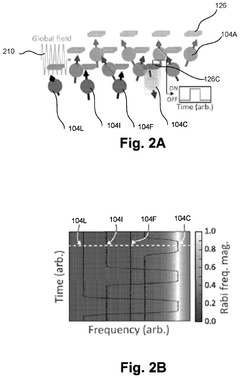

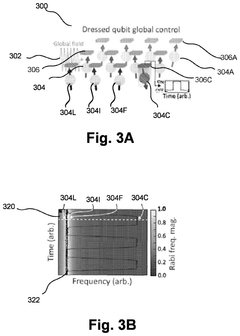

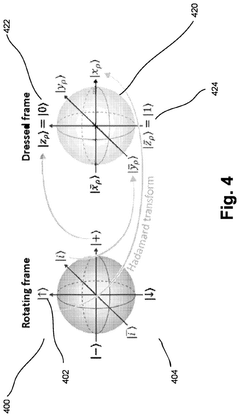

- The method involves generating an amplitude modulated AC electromagnetic field that keeps qubits on resonance, allowing for individual control of qubit frequencies through the Larmor frequency modulation, and applying an always-on AC electromagnetic field to perform operations leveraging Pauli's exclusion principle, enhancing noise resilience with the SMART technique.

Quantum-Classical Integration in Industrial Systems

The integration of quantum computing with classical systems in industrial environments represents a significant leap forward in manufacturing process control. This hybrid approach leverages the strengths of both quantum and classical computing paradigms to enhance efficiency, accuracy, and optimization in complex industrial operations.

Quantum-classical integration in industrial systems typically involves using quantum algorithms to solve specific, computationally intensive problems while classical computers handle the overall process control and data management. This synergy allows for tackling challenges that were previously intractable with classical computing alone.

One key application area is in optimization problems, where quantum algorithms can rapidly explore vast solution spaces to find optimal or near-optimal solutions for manufacturing processes. This can lead to significant improvements in resource allocation, scheduling, and supply chain management. For instance, quantum-assisted optimization can help in minimizing energy consumption, reducing waste, and maximizing production output.

Another promising area is in the realm of machine learning and artificial intelligence for industrial applications. Quantum machine learning algorithms can potentially process complex datasets more efficiently, leading to more accurate predictive maintenance models, quality control systems, and process optimization techniques. This can result in reduced downtime, improved product quality, and increased overall equipment effectiveness.

Quantum sensors integrated with classical control systems offer enhanced precision in measurements critical to manufacturing processes. These sensors can detect minute changes in environmental conditions, material properties, or equipment performance, enabling more responsive and precise control mechanisms.

However, the implementation of quantum-classical integrated systems in industrial environments faces several challenges. The need for specialized hardware, including quantum processors that can operate reliably in industrial settings, is a significant hurdle. Additionally, developing quantum algorithms that can seamlessly interface with existing classical systems requires substantial expertise and research.

Despite these challenges, the potential benefits of quantum-classical integration in industrial systems are driving continued investment and research. As quantum technologies mature and become more accessible, we can expect to see an increasing number of industrial applications leveraging this powerful combination to drive innovation and efficiency in manufacturing process control.

Quantum-classical integration in industrial systems typically involves using quantum algorithms to solve specific, computationally intensive problems while classical computers handle the overall process control and data management. This synergy allows for tackling challenges that were previously intractable with classical computing alone.

One key application area is in optimization problems, where quantum algorithms can rapidly explore vast solution spaces to find optimal or near-optimal solutions for manufacturing processes. This can lead to significant improvements in resource allocation, scheduling, and supply chain management. For instance, quantum-assisted optimization can help in minimizing energy consumption, reducing waste, and maximizing production output.

Another promising area is in the realm of machine learning and artificial intelligence for industrial applications. Quantum machine learning algorithms can potentially process complex datasets more efficiently, leading to more accurate predictive maintenance models, quality control systems, and process optimization techniques. This can result in reduced downtime, improved product quality, and increased overall equipment effectiveness.

Quantum sensors integrated with classical control systems offer enhanced precision in measurements critical to manufacturing processes. These sensors can detect minute changes in environmental conditions, material properties, or equipment performance, enabling more responsive and precise control mechanisms.

However, the implementation of quantum-classical integrated systems in industrial environments faces several challenges. The need for specialized hardware, including quantum processors that can operate reliably in industrial settings, is a significant hurdle. Additionally, developing quantum algorithms that can seamlessly interface with existing classical systems requires substantial expertise and research.

Despite these challenges, the potential benefits of quantum-classical integration in industrial systems are driving continued investment and research. As quantum technologies mature and become more accessible, we can expect to see an increasing number of industrial applications leveraging this powerful combination to drive innovation and efficiency in manufacturing process control.

Quantum Computing Security in Manufacturing

Quantum computing security in manufacturing presents unique challenges and opportunities as the technology advances. The integration of quantum computing in manufacturing process control necessitates robust security measures to protect sensitive data and intellectual property. Traditional encryption methods may become vulnerable to quantum attacks, requiring the development of quantum-resistant cryptographic algorithms.

One of the primary security concerns in quantum-enhanced manufacturing is the protection of quantum algorithms and data used in process optimization. These algorithms often contain proprietary information that could provide significant competitive advantages. Implementing secure quantum key distribution (QKD) systems can help safeguard communication channels between quantum computers and manufacturing equipment, ensuring that sensitive information remains confidential.

Another critical aspect of quantum computing security in manufacturing is the integrity of quantum computations. Quantum error correction techniques must be employed to mitigate the effects of decoherence and maintain the reliability of quantum operations. This is particularly important in manufacturing processes where precision and accuracy are paramount.

The potential for quantum-enabled attacks on manufacturing systems also raises concerns. Adversaries with access to quantum computers could potentially break current encryption standards, compromising industrial control systems and supply chain management. To address this, post-quantum cryptography (PQC) algorithms are being developed and standardized to provide security against both classical and quantum attacks.

Quantum sensing technologies used in manufacturing for quality control and process monitoring also require security considerations. These sensors can detect minute changes in environmental conditions, making them valuable for precision manufacturing but also potentially vulnerable to interference or manipulation. Implementing secure authentication protocols for quantum sensors and their data streams is essential to maintain the integrity of manufacturing processes.

As quantum computing becomes more prevalent in manufacturing, workforce training and security awareness programs will be crucial. Employees must understand the unique security implications of quantum technologies and adhere to new protocols designed to protect quantum-enhanced systems. This includes proper handling of quantum keys, awareness of potential quantum-based social engineering attacks, and understanding the limitations of current security measures in a post-quantum world.

Standardization efforts for quantum computing security in manufacturing are ongoing, with organizations like NIST working to establish guidelines for quantum-safe cryptography. Manufacturers must stay informed about these developments and be prepared to implement new security standards as they emerge. Collaboration between industry, academia, and government agencies will be essential in developing comprehensive security frameworks for quantum-enhanced manufacturing environments.

One of the primary security concerns in quantum-enhanced manufacturing is the protection of quantum algorithms and data used in process optimization. These algorithms often contain proprietary information that could provide significant competitive advantages. Implementing secure quantum key distribution (QKD) systems can help safeguard communication channels between quantum computers and manufacturing equipment, ensuring that sensitive information remains confidential.

Another critical aspect of quantum computing security in manufacturing is the integrity of quantum computations. Quantum error correction techniques must be employed to mitigate the effects of decoherence and maintain the reliability of quantum operations. This is particularly important in manufacturing processes where precision and accuracy are paramount.

The potential for quantum-enabled attacks on manufacturing systems also raises concerns. Adversaries with access to quantum computers could potentially break current encryption standards, compromising industrial control systems and supply chain management. To address this, post-quantum cryptography (PQC) algorithms are being developed and standardized to provide security against both classical and quantum attacks.

Quantum sensing technologies used in manufacturing for quality control and process monitoring also require security considerations. These sensors can detect minute changes in environmental conditions, making them valuable for precision manufacturing but also potentially vulnerable to interference or manipulation. Implementing secure authentication protocols for quantum sensors and their data streams is essential to maintain the integrity of manufacturing processes.

As quantum computing becomes more prevalent in manufacturing, workforce training and security awareness programs will be crucial. Employees must understand the unique security implications of quantum technologies and adhere to new protocols designed to protect quantum-enhanced systems. This includes proper handling of quantum keys, awareness of potential quantum-based social engineering attacks, and understanding the limitations of current security measures in a post-quantum world.

Standardization efforts for quantum computing security in manufacturing are ongoing, with organizations like NIST working to establish guidelines for quantum-safe cryptography. Manufacturers must stay informed about these developments and be prepared to implement new security standards as they emerge. Collaboration between industry, academia, and government agencies will be essential in developing comprehensive security frameworks for quantum-enhanced manufacturing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!