Quantum Computing Techniques for Optimizing Manufacturing System Efficiency

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Computing in Manufacturing: Background and Objectives

Quantum computing represents a paradigm shift in computational capabilities, leveraging the principles of quantum mechanics to perform complex calculations at unprecedented speeds. In the context of manufacturing, this emerging technology holds immense potential for optimizing system efficiency and revolutionizing production processes. The evolution of quantum computing can be traced back to the early 1980s when physicist Richard Feynman proposed the idea of using quantum systems to simulate quantum phenomena more efficiently than classical computers.

Over the past four decades, quantum computing has progressed from theoretical concepts to practical implementations, with significant milestones achieved in recent years. The development of quantum bits (qubits), quantum gates, and error correction techniques has paved the way for the creation of increasingly powerful quantum processors. Major tech companies and research institutions have made substantial investments in quantum computing research, driving rapid advancements in hardware and software capabilities.

In the manufacturing sector, the application of quantum computing techniques for optimizing system efficiency is a relatively new but promising field. The primary objective of this technological integration is to address complex optimization problems that are computationally intensive and time-consuming for classical computers. These include supply chain management, production scheduling, resource allocation, and quality control processes.

The potential of quantum computing in manufacturing lies in its ability to solve combinatorial optimization problems exponentially faster than classical computers. This capability can lead to significant improvements in operational efficiency, cost reduction, and overall productivity. For instance, quantum algorithms can be employed to optimize production schedules by considering multiple variables simultaneously, resulting in more efficient use of resources and reduced downtime.

Furthermore, quantum computing techniques can enhance predictive maintenance strategies by analyzing vast amounts of sensor data and identifying patterns that may indicate potential equipment failures. This proactive approach can minimize unplanned downtime and extend the lifespan of manufacturing assets. Additionally, quantum-inspired algorithms can optimize supply chain logistics, enabling manufacturers to respond more effectively to market demands and reduce inventory costs.

As quantum computing technology continues to mature, its integration into manufacturing systems is expected to accelerate. The long-term goal is to develop quantum-enhanced manufacturing processes that can adapt in real-time to changing conditions, optimize resource utilization, and minimize waste. This technological convergence has the potential to usher in a new era of smart manufacturing, characterized by unprecedented levels of efficiency, flexibility, and sustainability.

Over the past four decades, quantum computing has progressed from theoretical concepts to practical implementations, with significant milestones achieved in recent years. The development of quantum bits (qubits), quantum gates, and error correction techniques has paved the way for the creation of increasingly powerful quantum processors. Major tech companies and research institutions have made substantial investments in quantum computing research, driving rapid advancements in hardware and software capabilities.

In the manufacturing sector, the application of quantum computing techniques for optimizing system efficiency is a relatively new but promising field. The primary objective of this technological integration is to address complex optimization problems that are computationally intensive and time-consuming for classical computers. These include supply chain management, production scheduling, resource allocation, and quality control processes.

The potential of quantum computing in manufacturing lies in its ability to solve combinatorial optimization problems exponentially faster than classical computers. This capability can lead to significant improvements in operational efficiency, cost reduction, and overall productivity. For instance, quantum algorithms can be employed to optimize production schedules by considering multiple variables simultaneously, resulting in more efficient use of resources and reduced downtime.

Furthermore, quantum computing techniques can enhance predictive maintenance strategies by analyzing vast amounts of sensor data and identifying patterns that may indicate potential equipment failures. This proactive approach can minimize unplanned downtime and extend the lifespan of manufacturing assets. Additionally, quantum-inspired algorithms can optimize supply chain logistics, enabling manufacturers to respond more effectively to market demands and reduce inventory costs.

As quantum computing technology continues to mature, its integration into manufacturing systems is expected to accelerate. The long-term goal is to develop quantum-enhanced manufacturing processes that can adapt in real-time to changing conditions, optimize resource utilization, and minimize waste. This technological convergence has the potential to usher in a new era of smart manufacturing, characterized by unprecedented levels of efficiency, flexibility, and sustainability.

Market Demand for Quantum-Enhanced Manufacturing Optimization

The market demand for quantum-enhanced manufacturing optimization is rapidly growing as industries seek to leverage the power of quantum computing to revolutionize their production processes. Manufacturing companies across various sectors, including automotive, aerospace, pharmaceuticals, and electronics, are increasingly recognizing the potential of quantum computing to solve complex optimization problems that traditional computing methods struggle to address efficiently.

One of the primary drivers of this demand is the need for improved efficiency and cost reduction in manufacturing operations. Quantum computing techniques offer the promise of optimizing supply chain logistics, production scheduling, and resource allocation on an unprecedented scale. This capability is particularly attractive to large-scale manufacturers dealing with intricate supply networks and multi-faceted production lines.

The automotive industry, for instance, has shown significant interest in quantum-enhanced optimization for streamlining their just-in-time manufacturing processes. By utilizing quantum algorithms, car manufacturers aim to minimize inventory costs, reduce production bottlenecks, and enhance overall operational efficiency. Similarly, aerospace companies are exploring quantum computing to optimize aircraft design and manufacturing processes, potentially leading to lighter, more fuel-efficient planes and reduced production times.

In the pharmaceutical sector, the demand for quantum-enhanced manufacturing optimization is driven by the need to accelerate drug discovery and production processes. Quantum computing techniques can potentially optimize chemical reactions, improve drug formulation, and enhance quality control processes, leading to faster time-to-market for new medications and reduced production costs.

The electronics industry is another key player in driving the demand for quantum-enhanced manufacturing optimization. With the increasing complexity of semiconductor manufacturing processes, quantum computing offers the potential to optimize chip design, improve yield rates, and reduce energy consumption in production facilities.

Market analysts project substantial growth in the adoption of quantum computing for manufacturing optimization over the next decade. This growth is expected to be fueled by advancements in quantum hardware, the development of more sophisticated quantum algorithms, and increasing awareness of the technology's potential among industry leaders.

However, the market demand is not without challenges. The high cost of quantum computing infrastructure, the scarcity of skilled quantum computing professionals, and the current limitations of quantum hardware are factors that may slow down widespread adoption. Despite these challenges, many large manufacturing corporations are already investing in quantum computing research and development, indicating a strong belief in its future potential to transform manufacturing processes.

As quantum computing technology continues to mature, it is anticipated that small and medium-sized manufacturers will also begin to explore quantum-enhanced optimization solutions, further expanding the market demand. This trend is likely to be supported by the emergence of quantum computing as a service (QCaaS) offerings, making the technology more accessible to a broader range of businesses.

One of the primary drivers of this demand is the need for improved efficiency and cost reduction in manufacturing operations. Quantum computing techniques offer the promise of optimizing supply chain logistics, production scheduling, and resource allocation on an unprecedented scale. This capability is particularly attractive to large-scale manufacturers dealing with intricate supply networks and multi-faceted production lines.

The automotive industry, for instance, has shown significant interest in quantum-enhanced optimization for streamlining their just-in-time manufacturing processes. By utilizing quantum algorithms, car manufacturers aim to minimize inventory costs, reduce production bottlenecks, and enhance overall operational efficiency. Similarly, aerospace companies are exploring quantum computing to optimize aircraft design and manufacturing processes, potentially leading to lighter, more fuel-efficient planes and reduced production times.

In the pharmaceutical sector, the demand for quantum-enhanced manufacturing optimization is driven by the need to accelerate drug discovery and production processes. Quantum computing techniques can potentially optimize chemical reactions, improve drug formulation, and enhance quality control processes, leading to faster time-to-market for new medications and reduced production costs.

The electronics industry is another key player in driving the demand for quantum-enhanced manufacturing optimization. With the increasing complexity of semiconductor manufacturing processes, quantum computing offers the potential to optimize chip design, improve yield rates, and reduce energy consumption in production facilities.

Market analysts project substantial growth in the adoption of quantum computing for manufacturing optimization over the next decade. This growth is expected to be fueled by advancements in quantum hardware, the development of more sophisticated quantum algorithms, and increasing awareness of the technology's potential among industry leaders.

However, the market demand is not without challenges. The high cost of quantum computing infrastructure, the scarcity of skilled quantum computing professionals, and the current limitations of quantum hardware are factors that may slow down widespread adoption. Despite these challenges, many large manufacturing corporations are already investing in quantum computing research and development, indicating a strong belief in its future potential to transform manufacturing processes.

As quantum computing technology continues to mature, it is anticipated that small and medium-sized manufacturers will also begin to explore quantum-enhanced optimization solutions, further expanding the market demand. This trend is likely to be supported by the emergence of quantum computing as a service (QCaaS) offerings, making the technology more accessible to a broader range of businesses.

Current State and Challenges in Quantum Computing for Manufacturing

Quantum computing for manufacturing optimization is currently in a nascent stage, with significant potential but also facing substantial challenges. The current state of quantum computing in manufacturing is characterized by a mix of theoretical advancements and early-stage practical applications.

Several major tech companies and research institutions are actively exploring quantum computing's potential in manufacturing. IBM, Google, and D-Wave Systems have made notable progress in developing quantum hardware and software platforms. These advancements have enabled initial experiments in areas such as supply chain optimization, production scheduling, and quality control.

One of the primary challenges in applying quantum computing to manufacturing is the limited availability of quantum hardware with sufficient qubit count and coherence times. Most existing quantum computers have fewer than 100 qubits, which restricts their ability to solve complex manufacturing optimization problems that require thousands or millions of variables.

Another significant hurdle is the need for error correction and fault-tolerant quantum computing. Current quantum systems are highly susceptible to environmental noise and decoherence, limiting their ability to perform long, complex calculations required for manufacturing optimization. Developing robust error correction techniques is crucial for achieving practical quantum advantage in industrial settings.

The lack of standardized quantum software development tools and frameworks also poses a challenge. While quantum programming languages like Qiskit and Cirq exist, they are still evolving and require specialized knowledge, making it difficult for manufacturing engineers to adopt quantum computing techniques.

Bridging the gap between theoretical quantum algorithms and practical manufacturing applications remains a significant challenge. Many quantum algorithms that show promise for optimization problems are still theoretical and require adaptation for specific manufacturing use cases. This necessitates close collaboration between quantum physicists, computer scientists, and manufacturing experts.

The high cost and complexity of quantum computing systems present another barrier to widespread adoption in manufacturing. Current quantum computers require specialized infrastructure, including cryogenic cooling systems, which makes them impractical for on-site deployment in most manufacturing facilities.

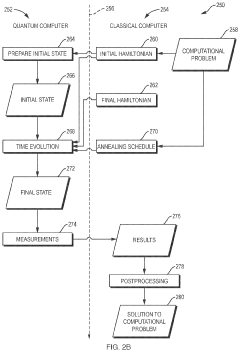

Despite these challenges, there are promising developments in quantum-inspired algorithms and hybrid quantum-classical approaches. These methods aim to leverage the strengths of both quantum and classical computing to solve manufacturing optimization problems, potentially offering near-term benefits while full-scale quantum computers are still under development.

Several major tech companies and research institutions are actively exploring quantum computing's potential in manufacturing. IBM, Google, and D-Wave Systems have made notable progress in developing quantum hardware and software platforms. These advancements have enabled initial experiments in areas such as supply chain optimization, production scheduling, and quality control.

One of the primary challenges in applying quantum computing to manufacturing is the limited availability of quantum hardware with sufficient qubit count and coherence times. Most existing quantum computers have fewer than 100 qubits, which restricts their ability to solve complex manufacturing optimization problems that require thousands or millions of variables.

Another significant hurdle is the need for error correction and fault-tolerant quantum computing. Current quantum systems are highly susceptible to environmental noise and decoherence, limiting their ability to perform long, complex calculations required for manufacturing optimization. Developing robust error correction techniques is crucial for achieving practical quantum advantage in industrial settings.

The lack of standardized quantum software development tools and frameworks also poses a challenge. While quantum programming languages like Qiskit and Cirq exist, they are still evolving and require specialized knowledge, making it difficult for manufacturing engineers to adopt quantum computing techniques.

Bridging the gap between theoretical quantum algorithms and practical manufacturing applications remains a significant challenge. Many quantum algorithms that show promise for optimization problems are still theoretical and require adaptation for specific manufacturing use cases. This necessitates close collaboration between quantum physicists, computer scientists, and manufacturing experts.

The high cost and complexity of quantum computing systems present another barrier to widespread adoption in manufacturing. Current quantum computers require specialized infrastructure, including cryogenic cooling systems, which makes them impractical for on-site deployment in most manufacturing facilities.

Despite these challenges, there are promising developments in quantum-inspired algorithms and hybrid quantum-classical approaches. These methods aim to leverage the strengths of both quantum and classical computing to solve manufacturing optimization problems, potentially offering near-term benefits while full-scale quantum computers are still under development.

Existing Quantum Solutions for Manufacturing Efficiency

01 Quantum Error Correction and Fault Tolerance

Techniques to improve the reliability and stability of quantum computations by detecting and correcting errors in quantum bits (qubits). This includes methods for implementing fault-tolerant quantum gates and circuits, as well as strategies for mitigating the effects of decoherence and noise in quantum systems.- Quantum Error Correction and Fault Tolerance: Techniques to improve the reliability and stability of quantum computations by detecting and correcting errors in quantum systems. This includes methods for implementing fault-tolerant quantum gates and circuits, as well as strategies for mitigating decoherence and noise in quantum processors.

- Quantum Circuit Optimization: Methods for optimizing quantum circuits to reduce gate count, depth, and overall complexity. This involves techniques for circuit compression, gate decomposition, and qubit mapping to improve the efficiency of quantum algorithms and reduce the resources required for quantum computations.

- Quantum-Classical Hybrid Algorithms: Development of algorithms that leverage both quantum and classical computing resources to solve complex problems more efficiently. These hybrid approaches aim to maximize the strengths of both quantum and classical systems, potentially leading to practical quantum advantage in various applications.

- Quantum Hardware Optimization: Advancements in quantum hardware design and implementation to improve the performance and scalability of quantum processors. This includes innovations in qubit technologies, quantum gate operations, and control systems to enhance the efficiency and reliability of quantum computations.

- Quantum Algorithm Speedup Techniques: Development of novel techniques to accelerate quantum algorithms and improve their efficiency. This involves methods for reducing the number of quantum operations, optimizing quantum state preparation and measurement, and leveraging quantum parallelism to achieve speedups over classical counterparts.

02 Quantum Circuit Optimization

Methods for optimizing quantum circuits to reduce the number of gates, minimize qubit usage, and improve overall computational efficiency. This includes techniques for circuit decomposition, gate synthesis, and compiler optimizations specific to quantum algorithms.Expand Specific Solutions03 Quantum-Classical Hybrid Algorithms

Development of algorithms that leverage both quantum and classical computing resources to solve complex problems more efficiently. This includes variational quantum algorithms, quantum-assisted optimization, and methods for interfacing quantum and classical systems.Expand Specific Solutions04 Quantum Hardware Efficiency

Advancements in quantum hardware design and implementation to improve the performance and scalability of quantum processors. This includes novel qubit architectures, improved control systems, and techniques for reducing crosstalk and increasing coherence times.Expand Specific Solutions05 Quantum Algorithm Speedup Techniques

Methods for enhancing the speed and efficiency of quantum algorithms, including techniques for parallel execution, quantum memory management, and optimized quantum state preparation and measurement. This also covers approaches for reducing the depth of quantum circuits and improving the overall runtime of quantum computations.Expand Specific Solutions

Key Players in Quantum Computing and Manufacturing Optimization

The quantum computing techniques for optimizing manufacturing system efficiency market is in its early growth stage, with significant potential for expansion. The global quantum computing market size is projected to reach billions of dollars by 2030, driven by increasing investments and advancements in quantum technologies. While the technology is still evolving, major players like IBM, Google, and Microsoft are making substantial progress in developing quantum systems and applications. Emerging companies such as IonQ, Rigetti, and D-Wave are also contributing to the competitive landscape. The technology's maturity varies across different aspects, with quantum hardware development progressing rapidly, while software and applications for manufacturing optimization are still in early stages of development and implementation.

Google LLC

Technical Solution: Google's approach to quantum computing for manufacturing optimization centers around their Sycamore processor and the development of quantum supremacy experiments. They focus on creating quantum algorithms that can outperform classical computers in specific manufacturing-related tasks. Google's quantum approximate optimization algorithm (QAOA) is particularly relevant for solving combinatorial optimization problems in manufacturing[4]. Their quantum hardware has demonstrated the ability to perform computations in 200 seconds that would take a state-of-the-art classical supercomputer 10,000 years[5]. Google also explores the use of tensor networks and quantum-inspired algorithms to bridge the gap between current quantum capabilities and practical manufacturing applications.

Strengths: Advanced quantum hardware, strong focus on quantum supremacy, and expertise in quantum algorithm development. Weaknesses: Limited commercial applications demonstrated so far, and challenges in scaling up quantum systems for complex manufacturing problems.

International Business Machines Corp.

Technical Solution: IBM's quantum computing approach for manufacturing optimization focuses on developing hybrid quantum-classical algorithms. They utilize Qiskit, an open-source quantum computing framework, to create quantum circuits that can solve complex optimization problems in manufacturing systems. IBM's quantum hardware, including their latest 127-qubit Eagle processor[1], is leveraged to tackle issues such as supply chain optimization, production scheduling, and quality control. Their Quantum Volume metric, which reached 64 in 2020[2], demonstrates the increasing capability of their quantum systems to handle real-world manufacturing challenges. IBM also employs error mitigation techniques and quantum-inspired algorithms to enhance the performance of their quantum solutions for manufacturing efficiency[3].

Strengths: Industry-leading quantum hardware, extensive research capabilities, and a robust ecosystem of partners. Weaknesses: Quantum systems still prone to errors, limited qubit coherence times, and scalability challenges for large-scale manufacturing problems.

Core Quantum Techniques for System Optimization

Quantum Computer with Improved Quantum Optimization by Exploiting Marginal Data

PatentPendingUS20230289636A1

Innovation

- A quantum optimization method that estimates the expectation value of a Hamiltonian on a classical computer and transforms either the Hamiltonian or the quantum state to reduce the expectation value, using techniques such as unitary transformations, fermionic rotations, and semidefinite programming, effectively increasing circuit depth without adding actual quantum gates, thereby improving the expressibility and coherence of quantum states.

Optimized quantum computing architecture for complex optimization problems

PatentPendingIN202441044532A

Innovation

- The development of optimized quantum computing architectures that leverage quantum mechanical principles such as superposition and entanglement to design efficient quantum circuits and algorithms, incorporating advanced error correction techniques and hardware advancements like superconducting qubits, to explore multiple solutions in parallel and minimize errors, thereby achieving exponential speedup over classical algorithms.

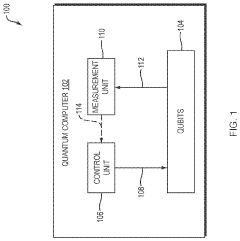

Quantum Computing Hardware Requirements for Manufacturing

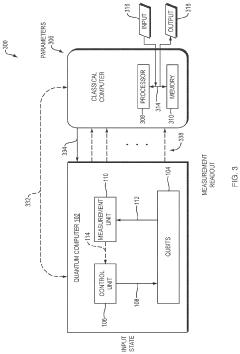

Quantum computing hardware for manufacturing applications requires specialized equipment capable of maintaining quantum states and performing complex quantum operations. The core component is the quantum processor, which utilizes quantum bits (qubits) instead of classical bits. These qubits can be implemented using various physical systems, such as superconducting circuits, trapped ions, or topological qubits.

For manufacturing optimization, quantum processors need to have a sufficient number of qubits to handle complex optimization problems. Current estimates suggest that 50-100 logical qubits may be necessary for meaningful manufacturing applications. However, due to the need for error correction, the number of physical qubits required could be significantly higher, potentially in the thousands.

Quantum processors must operate at extremely low temperatures, typically near absolute zero (-273.15°C), to maintain quantum coherence. This necessitates the use of sophisticated cooling systems, such as dilution refrigerators, which can achieve temperatures as low as a few millikelvins. The cooling infrastructure represents a significant portion of the quantum computing hardware requirements and poses challenges for integration into existing manufacturing environments.

In addition to the quantum processor and cooling system, quantum computers require precise control and measurement electronics. These systems generate and manipulate the electromagnetic pulses used to control qubit states and read out the results of quantum operations. The control electronics must be capable of generating signals with extremely low noise and high timing precision to maintain quantum coherence and perform accurate quantum gates.

Quantum error correction is another critical hardware requirement for manufacturing applications. This involves using multiple physical qubits to encode a single logical qubit, thereby improving the overall system's reliability. Implementing effective error correction schemes requires additional qubits and more sophisticated control systems, further increasing the hardware complexity.

Interfacing quantum computers with classical systems is essential for practical manufacturing applications. This requires high-speed data links and specialized hardware for converting between quantum and classical information. Additionally, hybrid quantum-classical algorithms often used in optimization problems necessitate efficient communication between quantum and classical processors.

As quantum computing technology advances, scalability becomes a crucial consideration. Manufacturing applications will likely require larger quantum systems with improved coherence times and gate fidelities. This scalability challenge encompasses not only the quantum processor itself but also the associated control systems, error correction mechanisms, and classical interfaces.

For manufacturing optimization, quantum processors need to have a sufficient number of qubits to handle complex optimization problems. Current estimates suggest that 50-100 logical qubits may be necessary for meaningful manufacturing applications. However, due to the need for error correction, the number of physical qubits required could be significantly higher, potentially in the thousands.

Quantum processors must operate at extremely low temperatures, typically near absolute zero (-273.15°C), to maintain quantum coherence. This necessitates the use of sophisticated cooling systems, such as dilution refrigerators, which can achieve temperatures as low as a few millikelvins. The cooling infrastructure represents a significant portion of the quantum computing hardware requirements and poses challenges for integration into existing manufacturing environments.

In addition to the quantum processor and cooling system, quantum computers require precise control and measurement electronics. These systems generate and manipulate the electromagnetic pulses used to control qubit states and read out the results of quantum operations. The control electronics must be capable of generating signals with extremely low noise and high timing precision to maintain quantum coherence and perform accurate quantum gates.

Quantum error correction is another critical hardware requirement for manufacturing applications. This involves using multiple physical qubits to encode a single logical qubit, thereby improving the overall system's reliability. Implementing effective error correction schemes requires additional qubits and more sophisticated control systems, further increasing the hardware complexity.

Interfacing quantum computers with classical systems is essential for practical manufacturing applications. This requires high-speed data links and specialized hardware for converting between quantum and classical information. Additionally, hybrid quantum-classical algorithms often used in optimization problems necessitate efficient communication between quantum and classical processors.

As quantum computing technology advances, scalability becomes a crucial consideration. Manufacturing applications will likely require larger quantum systems with improved coherence times and gate fidelities. This scalability challenge encompasses not only the quantum processor itself but also the associated control systems, error correction mechanisms, and classical interfaces.

Regulatory and Standardization Aspects of Quantum Manufacturing

The integration of quantum computing techniques into manufacturing systems necessitates a robust regulatory framework and standardization process to ensure safety, reliability, and interoperability. As quantum manufacturing technologies advance, regulatory bodies and industry stakeholders are working to establish guidelines and standards that address the unique challenges posed by quantum systems in industrial settings.

Regulatory agencies, such as the National Institute of Standards and Technology (NIST) in the United States and the European Telecommunications Standards Institute (ETSI) in Europe, are at the forefront of developing quantum-specific regulations. These organizations are focusing on creating standards for quantum key distribution, quantum random number generators, and quantum-safe cryptography to protect manufacturing systems from potential quantum-based attacks.

In the realm of manufacturing efficiency optimization, regulatory efforts are centered on ensuring the accuracy and reliability of quantum-enhanced algorithms and simulations. This includes establishing benchmarks for quantum advantage in specific manufacturing processes and defining protocols for validating quantum-optimized solutions against classical methods.

Standardization efforts are crucial for fostering interoperability between quantum and classical systems in manufacturing environments. The IEEE Quantum Computing Standards Working Group is developing standards for quantum computing architecture and software interfaces, which will be essential for seamless integration with existing manufacturing infrastructure.

Safety considerations are paramount in quantum manufacturing regulations. Guidelines are being developed to address potential risks associated with quantum sensors and quantum-enhanced control systems in industrial settings. These regulations aim to ensure that quantum technologies do not compromise worker safety or product quality.

Data privacy and security standards are evolving to accommodate the unique capabilities and vulnerabilities of quantum systems. Regulatory frameworks are being adapted to address quantum-resistant encryption methods and secure data transmission protocols for manufacturing environments where sensitive information is processed.

Certification and compliance processes for quantum manufacturing technologies are in the early stages of development. Industry consortia and government agencies are collaborating to establish certification programs that will verify the performance and reliability of quantum-enhanced manufacturing systems.

As the field of quantum manufacturing matures, international cooperation in regulatory and standardization efforts is becoming increasingly important. Global initiatives, such as the Quantum Economic Development Consortium (QED-C), are working to harmonize standards across borders and promote the responsible development and deployment of quantum technologies in industrial applications.

Regulatory agencies, such as the National Institute of Standards and Technology (NIST) in the United States and the European Telecommunications Standards Institute (ETSI) in Europe, are at the forefront of developing quantum-specific regulations. These organizations are focusing on creating standards for quantum key distribution, quantum random number generators, and quantum-safe cryptography to protect manufacturing systems from potential quantum-based attacks.

In the realm of manufacturing efficiency optimization, regulatory efforts are centered on ensuring the accuracy and reliability of quantum-enhanced algorithms and simulations. This includes establishing benchmarks for quantum advantage in specific manufacturing processes and defining protocols for validating quantum-optimized solutions against classical methods.

Standardization efforts are crucial for fostering interoperability between quantum and classical systems in manufacturing environments. The IEEE Quantum Computing Standards Working Group is developing standards for quantum computing architecture and software interfaces, which will be essential for seamless integration with existing manufacturing infrastructure.

Safety considerations are paramount in quantum manufacturing regulations. Guidelines are being developed to address potential risks associated with quantum sensors and quantum-enhanced control systems in industrial settings. These regulations aim to ensure that quantum technologies do not compromise worker safety or product quality.

Data privacy and security standards are evolving to accommodate the unique capabilities and vulnerabilities of quantum systems. Regulatory frameworks are being adapted to address quantum-resistant encryption methods and secure data transmission protocols for manufacturing environments where sensitive information is processed.

Certification and compliance processes for quantum manufacturing technologies are in the early stages of development. Industry consortia and government agencies are collaborating to establish certification programs that will verify the performance and reliability of quantum-enhanced manufacturing systems.

As the field of quantum manufacturing matures, international cooperation in regulatory and standardization efforts is becoming increasingly important. Global initiatives, such as the Quantum Economic Development Consortium (QED-C), are working to harmonize standards across borders and promote the responsible development and deployment of quantum technologies in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!