Regenerative Braking Contributions to Energy Efficiency in Rail Transport

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Braking Evolution

The evolution of rail braking systems has been a crucial aspect of railway technology development, significantly impacting the safety, efficiency, and performance of trains. The journey began with primitive wooden block brakes in the early 19th century, which relied on manual operation and offered limited stopping power. As trains became faster and heavier, the need for more effective braking systems became apparent.

The introduction of cast iron brake shoes in the mid-19th century marked a significant improvement, providing better friction and wear resistance. This was followed by the development of air brakes in the 1860s by George Westinghouse, revolutionizing rail safety by allowing simultaneous braking of all cars in a train. The Westinghouse air brake system quickly became the industry standard and remains a fundamental component of modern rail braking.

The early 20th century saw the advent of dynamic braking in electric locomotives, where traction motors were used as generators to provide resistance. This system not only improved braking performance but also reduced wear on mechanical components. As diesel-electric locomotives gained popularity, dynamic braking was adapted for use in these engines as well.

In the latter half of the 20th century, disc brakes began to be introduced in rail applications, offering improved heat dissipation and more consistent performance compared to traditional tread brakes. This technology, borrowed from the automotive industry, has become increasingly common in high-speed and passenger rail services.

The concept of regenerative braking emerged as a significant advancement in rail technology. While the principle had been known since the early days of electric traction, practical implementation became more feasible with the development of power electronics in the late 20th century. Regenerative braking allows kinetic energy to be converted into electrical energy during deceleration, which can then be fed back into the power grid or used by other trains on the same network.

Recent decades have seen further refinements in braking technology, including the integration of computerized control systems for optimized brake application and the development of eddy current brakes for high-speed trains. These advancements have not only improved safety but also contributed to increased energy efficiency in rail transport.

The evolution of rail braking systems continues to this day, with ongoing research into new materials, such as carbon-carbon composites for brake discs, and the further optimization of regenerative braking systems. The focus has shifted towards not only improving stopping power and safety but also enhancing energy efficiency and reducing environmental impact, aligning with broader sustainability goals in the transportation sector.

The introduction of cast iron brake shoes in the mid-19th century marked a significant improvement, providing better friction and wear resistance. This was followed by the development of air brakes in the 1860s by George Westinghouse, revolutionizing rail safety by allowing simultaneous braking of all cars in a train. The Westinghouse air brake system quickly became the industry standard and remains a fundamental component of modern rail braking.

The early 20th century saw the advent of dynamic braking in electric locomotives, where traction motors were used as generators to provide resistance. This system not only improved braking performance but also reduced wear on mechanical components. As diesel-electric locomotives gained popularity, dynamic braking was adapted for use in these engines as well.

In the latter half of the 20th century, disc brakes began to be introduced in rail applications, offering improved heat dissipation and more consistent performance compared to traditional tread brakes. This technology, borrowed from the automotive industry, has become increasingly common in high-speed and passenger rail services.

The concept of regenerative braking emerged as a significant advancement in rail technology. While the principle had been known since the early days of electric traction, practical implementation became more feasible with the development of power electronics in the late 20th century. Regenerative braking allows kinetic energy to be converted into electrical energy during deceleration, which can then be fed back into the power grid or used by other trains on the same network.

Recent decades have seen further refinements in braking technology, including the integration of computerized control systems for optimized brake application and the development of eddy current brakes for high-speed trains. These advancements have not only improved safety but also contributed to increased energy efficiency in rail transport.

The evolution of rail braking systems continues to this day, with ongoing research into new materials, such as carbon-carbon composites for brake discs, and the further optimization of regenerative braking systems. The focus has shifted towards not only improving stopping power and safety but also enhancing energy efficiency and reducing environmental impact, aligning with broader sustainability goals in the transportation sector.

Energy Efficiency Demand

The demand for energy efficiency in rail transport has become increasingly critical in recent years, driven by environmental concerns, economic pressures, and regulatory requirements. As the global focus on sustainability intensifies, the rail industry faces mounting pressure to reduce its carbon footprint and operational costs. This has led to a growing interest in technologies that can enhance energy efficiency, with regenerative braking emerging as a key solution.

Rail operators worldwide are seeking ways to minimize energy consumption while maintaining or improving service quality. The European Union, for instance, has set ambitious targets to reduce greenhouse gas emissions from transport by 60% by 2050 compared to 1990 levels. In the United States, the Department of Energy's initiatives aim to improve freight rail energy efficiency by 15% by 2030. These regulatory pressures are compelling rail companies to invest in energy-efficient technologies.

The economic benefits of improved energy efficiency are substantial. Energy costs typically account for a significant portion of rail operators' operational expenses. By reducing energy consumption, companies can achieve considerable cost savings, enhancing their competitiveness in the transportation sector. Moreover, as energy prices continue to fluctuate, efficient energy management becomes crucial for long-term financial stability.

Passengers and freight customers are also increasingly conscious of environmental impacts, creating market demand for greener transportation options. This shift in consumer preferences is pushing rail operators to adopt more sustainable practices and technologies, including advanced energy recovery systems like regenerative braking.

Urban areas, in particular, are experiencing rapid growth in rail transit systems to address congestion and pollution issues. These new and expanding networks present opportunities for implementing cutting-edge energy efficiency technologies from the ground up, with regenerative braking being a key consideration in system design and procurement decisions.

The potential for energy savings through regenerative braking is significant. Studies have shown that regenerative braking systems can recover up to 30% of the energy used in train operations, depending on factors such as route profile, train configuration, and operational patterns. This substantial energy recovery potential has sparked intense interest among rail operators and transit authorities worldwide, driving research and development efforts to optimize regenerative braking technologies for various rail applications.

Rail operators worldwide are seeking ways to minimize energy consumption while maintaining or improving service quality. The European Union, for instance, has set ambitious targets to reduce greenhouse gas emissions from transport by 60% by 2050 compared to 1990 levels. In the United States, the Department of Energy's initiatives aim to improve freight rail energy efficiency by 15% by 2030. These regulatory pressures are compelling rail companies to invest in energy-efficient technologies.

The economic benefits of improved energy efficiency are substantial. Energy costs typically account for a significant portion of rail operators' operational expenses. By reducing energy consumption, companies can achieve considerable cost savings, enhancing their competitiveness in the transportation sector. Moreover, as energy prices continue to fluctuate, efficient energy management becomes crucial for long-term financial stability.

Passengers and freight customers are also increasingly conscious of environmental impacts, creating market demand for greener transportation options. This shift in consumer preferences is pushing rail operators to adopt more sustainable practices and technologies, including advanced energy recovery systems like regenerative braking.

Urban areas, in particular, are experiencing rapid growth in rail transit systems to address congestion and pollution issues. These new and expanding networks present opportunities for implementing cutting-edge energy efficiency technologies from the ground up, with regenerative braking being a key consideration in system design and procurement decisions.

The potential for energy savings through regenerative braking is significant. Studies have shown that regenerative braking systems can recover up to 30% of the energy used in train operations, depending on factors such as route profile, train configuration, and operational patterns. This substantial energy recovery potential has sparked intense interest among rail operators and transit authorities worldwide, driving research and development efforts to optimize regenerative braking technologies for various rail applications.

Regenerative Braking Tech

Regenerative braking technology has emerged as a significant contributor to energy efficiency in rail transport systems. This innovative approach harnesses the kinetic energy of a moving train during deceleration, converting it into electrical energy that can be reused within the system. The concept revolves around utilizing the traction motors as generators when the train is slowing down, effectively transforming mechanical energy into electrical energy.

The implementation of regenerative braking in rail transport offers substantial benefits in terms of energy conservation and operational efficiency. By recapturing energy that would otherwise be dissipated as heat through conventional friction braking, this technology can reduce overall energy consumption by up to 30% in some rail systems. This not only leads to significant cost savings but also contributes to reducing the carbon footprint of rail operations.

One of the key advantages of regenerative braking in rail transport is its ability to feed the recovered energy back into the power supply system. In electrified rail networks, this regenerated power can be immediately utilized by other trains on the same line, effectively creating a closed-loop energy system. This feature is particularly beneficial in urban metro systems with frequent stops and high traffic density, where the potential for energy recovery is maximized.

The effectiveness of regenerative braking varies depending on several factors, including the train's speed, weight, and the gradient of the track. Higher speeds and heavier trains generally yield more recoverable energy during braking. Additionally, the presence of energy storage systems, such as onboard batteries or trackside energy storage devices, can further enhance the efficiency of regenerative braking by storing excess energy for later use.

Recent advancements in power electronics and control systems have significantly improved the performance and reliability of regenerative braking systems. Modern systems can achieve energy recovery rates of up to 40% during braking, with some high-speed trains capable of even higher efficiencies. These improvements have made regenerative braking an increasingly attractive option for both new rail projects and retrofitting existing fleets.

Despite its benefits, the implementation of regenerative braking technology in rail transport faces certain challenges. These include the need for compatible infrastructure, potential issues with power quality in the supply network, and the initial investment costs. However, ongoing research and development efforts are addressing these challenges, focusing on optimizing energy management strategies and developing more efficient power conversion systems.

The implementation of regenerative braking in rail transport offers substantial benefits in terms of energy conservation and operational efficiency. By recapturing energy that would otherwise be dissipated as heat through conventional friction braking, this technology can reduce overall energy consumption by up to 30% in some rail systems. This not only leads to significant cost savings but also contributes to reducing the carbon footprint of rail operations.

One of the key advantages of regenerative braking in rail transport is its ability to feed the recovered energy back into the power supply system. In electrified rail networks, this regenerated power can be immediately utilized by other trains on the same line, effectively creating a closed-loop energy system. This feature is particularly beneficial in urban metro systems with frequent stops and high traffic density, where the potential for energy recovery is maximized.

The effectiveness of regenerative braking varies depending on several factors, including the train's speed, weight, and the gradient of the track. Higher speeds and heavier trains generally yield more recoverable energy during braking. Additionally, the presence of energy storage systems, such as onboard batteries or trackside energy storage devices, can further enhance the efficiency of regenerative braking by storing excess energy for later use.

Recent advancements in power electronics and control systems have significantly improved the performance and reliability of regenerative braking systems. Modern systems can achieve energy recovery rates of up to 40% during braking, with some high-speed trains capable of even higher efficiencies. These improvements have made regenerative braking an increasingly attractive option for both new rail projects and retrofitting existing fleets.

Despite its benefits, the implementation of regenerative braking technology in rail transport faces certain challenges. These include the need for compatible infrastructure, potential issues with power quality in the supply network, and the initial investment costs. However, ongoing research and development efforts are addressing these challenges, focusing on optimizing energy management strategies and developing more efficient power conversion systems.

Current Regen Solutions

01 Energy recovery systems in regenerative braking

Regenerative braking systems are designed to recover and store energy during deceleration. These systems convert kinetic energy into electrical energy, which can be stored in batteries or capacitors for later use. This process significantly improves the overall energy efficiency of vehicles, particularly in electric and hybrid vehicles.- Optimization of regenerative braking systems: Improving the efficiency of regenerative braking systems involves optimizing various components and control strategies. This includes enhancing energy recovery during deceleration, minimizing energy losses in the conversion process, and integrating advanced control algorithms to maximize the amount of energy that can be captured and stored for later use.

- Energy storage and management: Efficient energy storage and management are crucial for maximizing the benefits of regenerative braking. This involves developing advanced battery technologies, supercapacitors, or other energy storage devices capable of rapidly absorbing and releasing large amounts of energy. Additionally, intelligent energy management systems are employed to optimize the distribution and utilization of recovered energy.

- Integration with hybrid and electric vehicle powertrains: Integrating regenerative braking systems with hybrid and electric vehicle powertrains is essential for maximizing overall energy efficiency. This involves coordinating the regenerative braking system with electric motors, internal combustion engines, and power electronics to ensure seamless operation and optimal energy recovery across various driving conditions.

- Adaptive and predictive control strategies: Implementing adaptive and predictive control strategies can significantly enhance the energy efficiency of regenerative braking systems. These strategies utilize real-time data, machine learning algorithms, and predictive models to anticipate braking events, optimize energy recovery, and adjust system parameters based on driving conditions, vehicle load, and other relevant factors.

- Mechanical and hydraulic system improvements: Enhancing the mechanical and hydraulic components of regenerative braking systems can lead to improved energy efficiency. This includes developing advanced brake designs, reducing friction losses, optimizing hydraulic circuits, and implementing innovative materials and manufacturing techniques to minimize energy dissipation during the braking process.

02 Control strategies for optimizing regenerative braking

Advanced control algorithms are employed to maximize energy recovery during braking. These strategies consider factors such as vehicle speed, brake pedal position, and battery state of charge to determine the optimal balance between regenerative and friction braking. Such control systems aim to capture the maximum amount of energy while maintaining vehicle stability and driver comfort.Expand Specific Solutions03 Integration with hydraulic braking systems

Efficient regenerative braking often involves integration with conventional hydraulic braking systems. This integration allows for seamless transition between regenerative and friction braking, ensuring optimal energy recovery without compromising safety or braking performance. The system can distribute braking force between regenerative and hydraulic components based on various driving conditions.Expand Specific Solutions04 Energy storage and management

Effective energy storage and management are crucial for maximizing the benefits of regenerative braking. This includes the use of high-capacity batteries, supercapacitors, or flywheels to store recovered energy. Advanced energy management systems ensure efficient distribution and utilization of the stored energy, contributing to improved overall vehicle efficiency.Expand Specific Solutions05 Regenerative braking in electric motors

Electric motors used in regenerative braking systems are designed to function as generators during deceleration. These motors can efficiently convert mechanical energy back into electrical energy. The design and control of these motors play a crucial role in determining the overall efficiency of the regenerative braking system, impacting the amount of energy that can be recovered and reused.Expand Specific Solutions

Rail Industry Leaders

The regenerative braking technology in rail transport is in a mature development stage, with significant market potential due to increasing focus on energy efficiency. The global market size for this technology is expected to grow substantially in the coming years, driven by the need for sustainable transportation solutions. Companies like Hitachi Ltd., Siemens Mobility GmbH, and CRRC Qingdao Sifang Rolling Stock Research Institute are at the forefront of this technology, with advanced implementations in their rail systems. Academic institutions such as Southwest Jiaotong University and Beijing Jiaotong University are contributing to research and development, while major rail operators like Central Japan Railway Co. and Schweizerische Bundesbahnen SBB are actively adopting these systems to improve energy efficiency in their operations.

Hitachi Ltd.

Technical Solution: Hitachi has developed an advanced regenerative braking system for rail transport that significantly enhances energy efficiency. Their system utilizes high-capacity energy storage devices, such as lithium-ion batteries or supercapacitors, to capture and store braking energy more effectively[1]. The stored energy is then reused for acceleration or powering onboard systems, reducing overall energy consumption. Hitachi's solution also incorporates smart power management algorithms that optimize the distribution of regenerated energy across multiple trains on the same line, maximizing system-wide efficiency[2]. Additionally, their system features adaptive control mechanisms that adjust regenerative braking force based on track conditions and train speed, ensuring optimal energy recovery in various operational scenarios[3].

Strengths: High energy recovery efficiency, advanced energy storage integration, and intelligent power distribution. Weaknesses: Initial implementation costs and potential complexity in retrofitting existing rail systems.

CRRC Qingdao Sifang Rolling Stock Research Institute Co., Ltd.

Technical Solution: CRRC Qingdao Sifang has developed a cutting-edge regenerative braking system for rail transport that significantly improves energy efficiency. Their solution incorporates advanced power electronics and energy storage technologies, including high-capacity supercapacitors and lithium-ion battery packs[10]. This system allows for rapid capture and storage of braking energy, which can then be used for acceleration or powering auxiliary systems. CRRC's technology also features intelligent energy management algorithms that optimize the distribution of regenerated energy between onboard storage and the power grid, depending on operational conditions and energy demand[11]. Furthermore, their system includes adaptive control mechanisms that adjust regenerative braking force based on track gradients and train speed, ensuring maximum energy recovery across various operational scenarios. CRRC has also integrated their regenerative braking technology with broader train control systems, enabling seamless coordination with other energy-saving features[12].

Strengths: High energy recovery efficiency, flexible energy storage options, and intelligent energy management. Weaknesses: Potential complexity in retrofitting existing rolling stock and the need for significant initial investment.

Key Regen Innovations

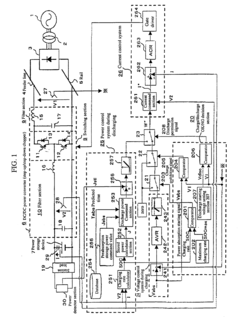

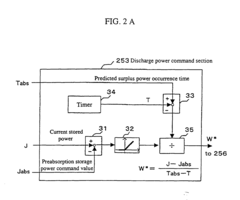

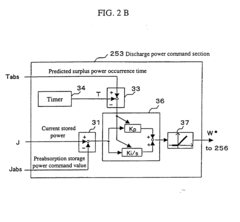

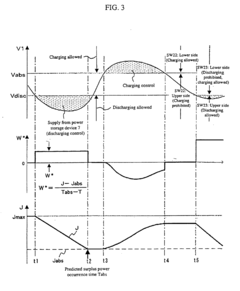

Railway regenerative power absorption control method, device thereof and power converter control device

PatentInactiveEP1538020A2

Innovation

- A power storage type regenerative power absorption control method and device that predicts voltage rises in the feeder line, discharging stored electrical power to prevent excessive voltage and optimize the utilization rate of power storage devices, using a DC/DC power converter with a switching section and control systems to manage charging and discharging based on predetermined voltage thresholds.

Method for supplying power to auxiliary units of a rail vehicle

PatentWO2023057302A1

Innovation

- Implementing regenerative braking in the towed rail vehicle to generate electrical power, which is then used to supply its auxiliary systems, reducing the need for power transmission from the towing vehicle and allowing for simpler coupling designs.

Environmental Impact

Regenerative braking in rail transport significantly contributes to environmental sustainability by reducing energy consumption and greenhouse gas emissions. This technology allows trains to recover and reuse kinetic energy that would otherwise be lost as heat during braking, leading to substantial improvements in overall energy efficiency.

The primary environmental benefit of regenerative braking is the reduction in energy consumption. By capturing and reusing energy that would typically be wasted, trains require less power from external sources, such as diesel engines or overhead electrical lines. This decrease in energy demand directly translates to lower fuel consumption for diesel-electric locomotives and reduced electricity usage for fully electric trains.

As a result of decreased energy consumption, regenerative braking systems contribute to a significant reduction in greenhouse gas emissions. For diesel-electric locomotives, the lower fuel consumption leads to fewer carbon dioxide emissions. In the case of electric trains, the reduced demand for electricity from the grid indirectly lowers emissions, especially in regions where electricity generation still relies heavily on fossil fuels.

The environmental impact of regenerative braking extends beyond energy savings and emission reductions. By minimizing the use of traditional friction brakes, this technology reduces wear and tear on brake components. This leads to less frequent replacement of brake pads and discs, resulting in decreased material consumption and waste generation associated with maintenance activities.

Furthermore, regenerative braking systems contribute to noise reduction in urban areas. Traditional braking methods often produce significant noise, particularly in densely populated regions. The use of regenerative braking allows for smoother deceleration with less reliance on friction brakes, thereby reducing noise pollution and improving the quality of life for communities near rail lines.

The adoption of regenerative braking technology also aligns with broader sustainability goals in the transportation sector. As governments and organizations worldwide push for greener transportation solutions, the implementation of energy-efficient technologies like regenerative braking helps rail transport maintain its position as one of the most environmentally friendly modes of mass transit.

In conclusion, the environmental impact of regenerative braking in rail transport is multifaceted and overwhelmingly positive. By significantly reducing energy consumption, lowering greenhouse gas emissions, minimizing waste from maintenance activities, and decreasing noise pollution, this technology plays a crucial role in enhancing the sustainability of rail transportation systems worldwide.

The primary environmental benefit of regenerative braking is the reduction in energy consumption. By capturing and reusing energy that would typically be wasted, trains require less power from external sources, such as diesel engines or overhead electrical lines. This decrease in energy demand directly translates to lower fuel consumption for diesel-electric locomotives and reduced electricity usage for fully electric trains.

As a result of decreased energy consumption, regenerative braking systems contribute to a significant reduction in greenhouse gas emissions. For diesel-electric locomotives, the lower fuel consumption leads to fewer carbon dioxide emissions. In the case of electric trains, the reduced demand for electricity from the grid indirectly lowers emissions, especially in regions where electricity generation still relies heavily on fossil fuels.

The environmental impact of regenerative braking extends beyond energy savings and emission reductions. By minimizing the use of traditional friction brakes, this technology reduces wear and tear on brake components. This leads to less frequent replacement of brake pads and discs, resulting in decreased material consumption and waste generation associated with maintenance activities.

Furthermore, regenerative braking systems contribute to noise reduction in urban areas. Traditional braking methods often produce significant noise, particularly in densely populated regions. The use of regenerative braking allows for smoother deceleration with less reliance on friction brakes, thereby reducing noise pollution and improving the quality of life for communities near rail lines.

The adoption of regenerative braking technology also aligns with broader sustainability goals in the transportation sector. As governments and organizations worldwide push for greener transportation solutions, the implementation of energy-efficient technologies like regenerative braking helps rail transport maintain its position as one of the most environmentally friendly modes of mass transit.

In conclusion, the environmental impact of regenerative braking in rail transport is multifaceted and overwhelmingly positive. By significantly reducing energy consumption, lowering greenhouse gas emissions, minimizing waste from maintenance activities, and decreasing noise pollution, this technology plays a crucial role in enhancing the sustainability of rail transportation systems worldwide.

Economic Feasibility

The economic feasibility of regenerative braking systems in rail transport is a critical factor in their widespread adoption. Initial implementation costs for regenerative braking technology can be substantial, including expenses for equipment upgrades, infrastructure modifications, and staff training. However, these upfront investments are often offset by long-term operational savings and environmental benefits.

Energy cost reduction is a primary economic advantage of regenerative braking systems. By recovering and reusing kinetic energy that would otherwise be lost as heat during braking, these systems can significantly reduce the overall energy consumption of rail vehicles. Studies have shown that regenerative braking can recover up to 30% of the energy used in train operations, leading to substantial reductions in electricity costs for electric rail systems.

Maintenance cost savings also contribute to the economic viability of regenerative braking. Traditional friction-based braking systems experience significant wear and tear, requiring frequent replacements of brake pads and other components. Regenerative braking reduces the reliance on mechanical brakes, thereby extending their lifespan and decreasing maintenance frequency and associated costs.

The economic benefits extend beyond direct operational savings. Improved energy efficiency can enhance the competitiveness of rail transport compared to other modes of transportation, potentially increasing ridership and revenue. Additionally, the reduced environmental impact of regenerative braking systems may lead to financial incentives from governments or regulatory bodies, such as carbon credits or tax benefits.

However, the economic feasibility of regenerative braking systems can vary depending on specific operational contexts. Factors such as the frequency of stops, route topography, and electricity prices play crucial roles in determining the potential energy savings and, consequently, the economic returns. Urban rail systems with frequent stops and starts generally see higher benefits from regenerative braking compared to long-distance, high-speed rail services.

The payback period for regenerative braking investments typically ranges from 3 to 7 years, depending on the scale of implementation and operational characteristics. This relatively short payback period, combined with the long lifespan of rail infrastructure, makes regenerative braking an economically attractive option for many rail operators.

In conclusion, while the initial investment in regenerative braking technology can be significant, the long-term economic benefits often justify the costs. The combination of energy savings, reduced maintenance expenses, and potential regulatory incentives contributes to a compelling economic case for the adoption of regenerative braking in rail transport systems.

Energy cost reduction is a primary economic advantage of regenerative braking systems. By recovering and reusing kinetic energy that would otherwise be lost as heat during braking, these systems can significantly reduce the overall energy consumption of rail vehicles. Studies have shown that regenerative braking can recover up to 30% of the energy used in train operations, leading to substantial reductions in electricity costs for electric rail systems.

Maintenance cost savings also contribute to the economic viability of regenerative braking. Traditional friction-based braking systems experience significant wear and tear, requiring frequent replacements of brake pads and other components. Regenerative braking reduces the reliance on mechanical brakes, thereby extending their lifespan and decreasing maintenance frequency and associated costs.

The economic benefits extend beyond direct operational savings. Improved energy efficiency can enhance the competitiveness of rail transport compared to other modes of transportation, potentially increasing ridership and revenue. Additionally, the reduced environmental impact of regenerative braking systems may lead to financial incentives from governments or regulatory bodies, such as carbon credits or tax benefits.

However, the economic feasibility of regenerative braking systems can vary depending on specific operational contexts. Factors such as the frequency of stops, route topography, and electricity prices play crucial roles in determining the potential energy savings and, consequently, the economic returns. Urban rail systems with frequent stops and starts generally see higher benefits from regenerative braking compared to long-distance, high-speed rail services.

The payback period for regenerative braking investments typically ranges from 3 to 7 years, depending on the scale of implementation and operational characteristics. This relatively short payback period, combined with the long lifespan of rail infrastructure, makes regenerative braking an economically attractive option for many rail operators.

In conclusion, while the initial investment in regenerative braking technology can be significant, the long-term economic benefits often justify the costs. The combination of energy savings, reduced maintenance expenses, and potential regulatory incentives contributes to a compelling economic case for the adoption of regenerative braking in rail transport systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!