Alkane Additives: Enhancing Combustion Efficiency

JAN 7, 20269 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkane Additive Technology Background and Objectives

Combustion efficiency has remained a critical challenge in energy conversion systems, particularly as global demands for cleaner and more sustainable energy solutions intensify. Traditional hydrocarbon fuels, while energy-dense and widely available, often suffer from incomplete combustion, leading to reduced thermal efficiency, increased fuel consumption, and elevated emissions of pollutants such as carbon monoxide, unburned hydrocarbons, and particulate matter. These inefficiencies not only compromise engine performance but also contribute significantly to environmental degradation and climate change.

The concept of utilizing alkane additives to enhance combustion efficiency emerged from fundamental research into combustion chemistry and fuel reformulation strategies. Alkanes, as saturated hydrocarbons with varying chain lengths, possess distinct physical and chemical properties that can influence ignition characteristics, flame propagation rates, and combustion completeness. Early investigations in the mid-20th century explored how different hydrocarbon structures affected combustion behavior, laying the groundwork for additive-based optimization approaches.

Over the past several decades, the evolution of alkane additive technology has been driven by increasingly stringent emission regulations, rising fuel costs, and the automotive industry's pursuit of higher engine efficiency. Research has progressively shifted from simple fuel blending to sophisticated molecular engineering, where specific alkane compounds are selected or synthesized to target particular combustion deficiencies. This evolution has been supported by advances in analytical techniques, computational modeling, and high-throughput screening methods that enable precise characterization of additive performance.

The primary objective of current alkane additive research is to develop formulations that can significantly improve combustion efficiency across diverse operating conditions while maintaining fuel stability, compatibility with existing infrastructure, and cost-effectiveness. Specific technical goals include enhancing ignition quality, promoting more uniform fuel-air mixing, accelerating oxidation kinetics, reducing ignition delay periods, and minimizing the formation of intermediate combustion products that contribute to emissions. Additionally, research aims to understand the fundamental mechanisms through which alkane additives interact with base fuels and combustion environments, enabling rational design of next-generation additive packages.

Achieving these objectives requires interdisciplinary approaches combining organic chemistry, thermodynamics, fluid dynamics, and materials science. The ultimate goal extends beyond incremental efficiency gains to transformative improvements that can bridge the transition toward cleaner combustion technologies while maximizing the utility of existing fossil fuel resources during the energy transition period.

The concept of utilizing alkane additives to enhance combustion efficiency emerged from fundamental research into combustion chemistry and fuel reformulation strategies. Alkanes, as saturated hydrocarbons with varying chain lengths, possess distinct physical and chemical properties that can influence ignition characteristics, flame propagation rates, and combustion completeness. Early investigations in the mid-20th century explored how different hydrocarbon structures affected combustion behavior, laying the groundwork for additive-based optimization approaches.

Over the past several decades, the evolution of alkane additive technology has been driven by increasingly stringent emission regulations, rising fuel costs, and the automotive industry's pursuit of higher engine efficiency. Research has progressively shifted from simple fuel blending to sophisticated molecular engineering, where specific alkane compounds are selected or synthesized to target particular combustion deficiencies. This evolution has been supported by advances in analytical techniques, computational modeling, and high-throughput screening methods that enable precise characterization of additive performance.

The primary objective of current alkane additive research is to develop formulations that can significantly improve combustion efficiency across diverse operating conditions while maintaining fuel stability, compatibility with existing infrastructure, and cost-effectiveness. Specific technical goals include enhancing ignition quality, promoting more uniform fuel-air mixing, accelerating oxidation kinetics, reducing ignition delay periods, and minimizing the formation of intermediate combustion products that contribute to emissions. Additionally, research aims to understand the fundamental mechanisms through which alkane additives interact with base fuels and combustion environments, enabling rational design of next-generation additive packages.

Achieving these objectives requires interdisciplinary approaches combining organic chemistry, thermodynamics, fluid dynamics, and materials science. The ultimate goal extends beyond incremental efficiency gains to transformative improvements that can bridge the transition toward cleaner combustion technologies while maximizing the utility of existing fossil fuel resources during the energy transition period.

Market Demand for Combustion Efficiency Enhancement

The global demand for enhanced combustion efficiency has intensified significantly across multiple industrial sectors, driven by increasingly stringent environmental regulations and the urgent need to reduce carbon emissions. Transportation, power generation, and industrial heating sectors collectively represent the primary markets where alkane additive technologies demonstrate substantial commercial potential. These industries face mounting pressure to optimize fuel consumption while simultaneously minimizing pollutant emissions, creating a compelling value proposition for combustion-enhancing solutions.

The automotive industry constitutes a particularly critical market segment, as manufacturers worldwide strive to meet evolving emission standards such as Euro 7, China VI, and EPA Tier 3 regulations. Fleet operators and commercial vehicle manufacturers actively seek cost-effective solutions to improve fuel economy without requiring extensive engine modifications. This demand extends beyond conventional vehicles to include marine engines and aviation fuels, where even marginal efficiency improvements translate into substantial operational cost savings and environmental benefits.

Industrial combustion applications present another significant market opportunity, encompassing boilers, furnaces, and gas turbines used in manufacturing and power generation facilities. Energy-intensive industries face dual pressures of rising fuel costs and carbon pricing mechanisms, making combustion efficiency enhancement economically attractive. The industrial sector particularly values solutions that can be retrofitted into existing infrastructure without major capital investments or operational disruptions.

Emerging markets in developing economies demonstrate accelerating demand as these regions implement stricter environmental policies while experiencing rapid industrialization. The transition toward cleaner combustion technologies aligns with national commitments to climate agreements and air quality improvement initiatives. Additionally, the growing emphasis on corporate sustainability reporting and environmental social governance criteria compels enterprises to adopt technologies that demonstrably reduce their carbon footprint.

The market landscape also reflects increasing interest from fuel producers and distributors who recognize alkane additives as value-added products that differentiate their offerings. This creates opportunities for technology licensing and collaborative development partnerships. Furthermore, the potential integration of alkane additives with alternative fuels and hybrid systems expands the addressable market beyond traditional fossil fuel applications, positioning these technologies as transitional solutions in the broader energy transformation.

The automotive industry constitutes a particularly critical market segment, as manufacturers worldwide strive to meet evolving emission standards such as Euro 7, China VI, and EPA Tier 3 regulations. Fleet operators and commercial vehicle manufacturers actively seek cost-effective solutions to improve fuel economy without requiring extensive engine modifications. This demand extends beyond conventional vehicles to include marine engines and aviation fuels, where even marginal efficiency improvements translate into substantial operational cost savings and environmental benefits.

Industrial combustion applications present another significant market opportunity, encompassing boilers, furnaces, and gas turbines used in manufacturing and power generation facilities. Energy-intensive industries face dual pressures of rising fuel costs and carbon pricing mechanisms, making combustion efficiency enhancement economically attractive. The industrial sector particularly values solutions that can be retrofitted into existing infrastructure without major capital investments or operational disruptions.

Emerging markets in developing economies demonstrate accelerating demand as these regions implement stricter environmental policies while experiencing rapid industrialization. The transition toward cleaner combustion technologies aligns with national commitments to climate agreements and air quality improvement initiatives. Additionally, the growing emphasis on corporate sustainability reporting and environmental social governance criteria compels enterprises to adopt technologies that demonstrably reduce their carbon footprint.

The market landscape also reflects increasing interest from fuel producers and distributors who recognize alkane additives as value-added products that differentiate their offerings. This creates opportunities for technology licensing and collaborative development partnerships. Furthermore, the potential integration of alkane additives with alternative fuels and hybrid systems expands the addressable market beyond traditional fossil fuel applications, positioning these technologies as transitional solutions in the broader energy transformation.

Current Status and Challenges in Alkane Additive Development

Alkane additives have emerged as a promising avenue for enhancing combustion efficiency across various applications, from automotive engines to industrial burners. Currently, the development landscape is characterized by diverse chemical formulations, including branched-chain alkanes, cycloalkanes, and functionalized derivatives. Research institutions and fuel technology companies worldwide are actively exploring molecular structures that can optimize ignition timing, reduce activation energy, and promote more complete oxidation of fuel mixtures. The primary focus has been on additives in the C8-C16 carbon range, which demonstrate favorable volatility and miscibility characteristics with conventional fuels.

Despite significant progress, several technical challenges continue to impede widespread commercialization. The most pressing issue involves achieving consistent performance across varying fuel compositions and engine operating conditions. Many alkane additives exhibit temperature-sensitive behavior, with their effectiveness diminishing under extreme cold or high-temperature environments. Additionally, the interaction between additives and modern emission control systems, particularly catalytic converters and particulate filters, remains inadequately understood. Some formulations have shown tendencies to form deposits or interfere with catalyst surface chemistry, potentially compromising long-term engine durability.

Another critical constraint lies in the cost-effectiveness of production and scalability. Advanced alkane additives often require complex synthesis routes involving multiple purification steps, making them economically unviable for mass-market applications. The petroleum refining industry faces challenges in integrating additive production into existing infrastructure without substantial capital investment. Furthermore, regulatory frameworks across different regions impose varying standards for fuel composition and emissions, creating barriers to unified product development strategies.

From a geographical perspective, research and development activities are concentrated in North America, Europe, and East Asia, where stringent emission regulations drive innovation. However, technology transfer to emerging markets remains limited due to intellectual property concerns and infrastructure gaps. The lack of standardized testing protocols for evaluating additive performance under real-world conditions further complicates comparative assessments and hinders collaborative advancement. Addressing these multifaceted challenges requires coordinated efforts spanning fundamental chemistry research, engineering optimization, and regulatory harmonization to unlock the full potential of alkane additives in combustion enhancement applications.

Despite significant progress, several technical challenges continue to impede widespread commercialization. The most pressing issue involves achieving consistent performance across varying fuel compositions and engine operating conditions. Many alkane additives exhibit temperature-sensitive behavior, with their effectiveness diminishing under extreme cold or high-temperature environments. Additionally, the interaction between additives and modern emission control systems, particularly catalytic converters and particulate filters, remains inadequately understood. Some formulations have shown tendencies to form deposits or interfere with catalyst surface chemistry, potentially compromising long-term engine durability.

Another critical constraint lies in the cost-effectiveness of production and scalability. Advanced alkane additives often require complex synthesis routes involving multiple purification steps, making them economically unviable for mass-market applications. The petroleum refining industry faces challenges in integrating additive production into existing infrastructure without substantial capital investment. Furthermore, regulatory frameworks across different regions impose varying standards for fuel composition and emissions, creating barriers to unified product development strategies.

From a geographical perspective, research and development activities are concentrated in North America, Europe, and East Asia, where stringent emission regulations drive innovation. However, technology transfer to emerging markets remains limited due to intellectual property concerns and infrastructure gaps. The lack of standardized testing protocols for evaluating additive performance under real-world conditions further complicates comparative assessments and hinders collaborative advancement. Addressing these multifaceted challenges requires coordinated efforts spanning fundamental chemistry research, engineering optimization, and regulatory harmonization to unlock the full potential of alkane additives in combustion enhancement applications.

Current Alkane Additive Solutions

01 Metal-containing additives for improving alkane combustion

Metal-based compounds and organometallic additives can be incorporated into fuel formulations to enhance combustion efficiency of alkanes. These additives act as combustion catalysts, promoting more complete oxidation of hydrocarbons, reducing emissions, and improving fuel economy. The metal compounds facilitate better fuel atomization and accelerate combustion reactions at lower temperatures.- Metal-containing additives for improving alkane combustion: Metal-based compounds, particularly those containing iron, manganese, or cerium, can be added to alkane fuels to enhance combustion efficiency. These metallic additives act as catalysts to promote more complete combustion, reduce soot formation, and lower emissions. The metal compounds facilitate the oxidation process and help break down hydrocarbon chains more effectively during combustion.

- Oxygenated compounds as combustion enhancers: Oxygenated organic compounds can be incorporated into alkane fuels to improve combustion characteristics. These additives provide additional oxygen within the fuel mixture, promoting more complete combustion and reducing carbon monoxide and particulate emissions. The presence of oxygen-containing functional groups helps achieve better fuel-air mixing and more efficient energy release during the combustion process.

- Nanoparticle additives for combustion optimization: Nanoscale particles can be dispersed in alkane fuels to enhance combustion efficiency through improved heat transfer and catalytic effects. These nanoparticles increase the surface area available for combustion reactions and can act as nucleation sites for more uniform flame propagation. The addition of nanoparticles results in better atomization of fuel droplets and more rapid combustion kinetics.

- Surfactant and emulsifier additives for fuel dispersion: Surfactants and emulsifying agents can be added to alkane fuels to improve the dispersion of other additives and enhance fuel-air mixing. These compounds reduce surface tension and promote better atomization of fuel during injection, leading to more efficient combustion. The improved dispersion characteristics result in more uniform combustion temperatures and reduced formation of incomplete combustion products.

- Nitrogen-containing additives for emission control: Nitrogen-based organic compounds can be incorporated into alkane fuels to improve combustion efficiency while controlling nitrogen oxide emissions. These additives help optimize the combustion temperature profile and reduce the formation of harmful pollutants. The nitrogen-containing compounds can also act as detergents to keep combustion chambers clean, maintaining optimal combustion conditions over extended periods.

02 Oxygenated compounds as combustion efficiency enhancers

Oxygenated organic compounds can be added to alkane-based fuels to improve combustion characteristics. These additives increase the oxygen content in the fuel mixture, leading to more complete combustion, reduced carbon monoxide and particulate emissions, and enhanced thermal efficiency. The oxygenated additives help achieve better fuel-air mixing and promote cleaner burning.Expand Specific Solutions03 Nanoparticle additives for combustion optimization

Nanoscale particles can be dispersed in alkane fuels to enhance combustion efficiency through catalytic effects and improved heat transfer properties. These nanoparticle additives increase the surface area for combustion reactions, promote better fuel vaporization, and act as combustion catalysts. The technology results in reduced ignition delay, improved combustion stability, and lower pollutant formation.Expand Specific Solutions04 Cetane number improvers and ignition quality enhancers

Specific chemical additives can be formulated to increase the cetane number of alkane fuels, thereby improving ignition quality and combustion efficiency. These compounds reduce ignition delay time, promote smoother combustion, and enhance engine performance. The additives are particularly effective in diesel and compression ignition engines where ignition timing is critical for efficiency.Expand Specific Solutions05 Multifunctional additive packages for comprehensive combustion improvement

Synergistic combinations of multiple additives can be formulated to address various aspects of combustion efficiency simultaneously. These comprehensive additive packages may include detergents, dispersants, antioxidants, and combustion catalysts working together to optimize fuel stability, reduce deposits, improve atomization, and enhance overall combustion performance. The multifunctional approach provides benefits in emission reduction, fuel economy, and engine cleanliness.Expand Specific Solutions

Major Players in Fuel Additive Industry

The alkane additives for combustion efficiency enhancement field represents a mature yet evolving market dominated by established petroleum and chemical corporations. Major players include global energy giants like ExxonMobil Technology & Engineering, Shell Oil Company, TotalEnergies OneTech, Eni SpA, and Saudi Arabian Oil Company, alongside specialized chemical manufacturers such as Afton Chemical Corp., The Lubrizol Corp., and Innospec International. National oil companies including China Petroleum & Chemical Corp. and Indian Oil Corp. demonstrate significant regional presence. The technology has reached commercial maturity with proven additive formulations, though innovation continues through companies like Envirofuels LLC and ORYXE Energy International focusing on environmental performance improvements. Research institutions such as King Abdullah University and Beijing University of Chemical Technology contribute to advancing fundamental understanding. The competitive landscape reflects a consolidating industry where scale, distribution networks, and integrated refining capabilities provide strategic advantages in serving automotive manufacturers like Mazda Motor Corp. and meeting increasingly stringent emissions regulations globally.

Afton Chemical Corp.

Technical Solution: Afton Chemical has developed advanced fuel additive packages specifically designed to enhance combustion efficiency through alkane modification. Their proprietary technology focuses on multi-functional additives that combine detergency, combustion catalysts, and cetane improvers. The formulations utilize modified alkane structures with oxygen-containing functional groups that promote more complete fuel atomization and oxidation during combustion. Their research demonstrates that these additives can reduce particulate matter emissions by 15-25% while improving fuel economy by 2-4%[1][4]. The technology employs synergistic combinations of long-chain alkanes with combustion modifiers to optimize ignition timing and flame propagation characteristics in both gasoline and diesel engines.

Strengths: Comprehensive additive portfolio with proven field performance; strong R&D capabilities in combustion chemistry; established relationships with major fuel suppliers globally. Weaknesses: Premium pricing may limit market penetration in cost-sensitive segments; formulations may require engine-specific optimization.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has pioneered research in alkane-based combustion enhancers through their V-Power fuel technology platform. Their approach involves carefully selected iso-alkane additives combined with friction modifiers and detergents to maximize combustion efficiency. The technology utilizes branched-chain alkanes (C8-C12 range) that exhibit superior volatility characteristics and oxygen affinity during combustion processes. Shell's research indicates these formulations can increase engine power output by 3-5% while reducing carbon deposits by up to 40%[2][5]. Their additive packages are designed to work synergistically with modern direct injection engines, optimizing spray patterns and air-fuel mixing. The company has invested significantly in computational fluid dynamics modeling to predict combustion behavior with various alkane structures.

Strengths: Extensive global testing infrastructure; integration with refinery operations for cost-effective production; strong brand recognition in premium fuel segment. Weaknesses: Technology primarily optimized for newer engine designs; higher production complexity compared to conventional additives.

Core Patents in Alkane Combustion Enhancement

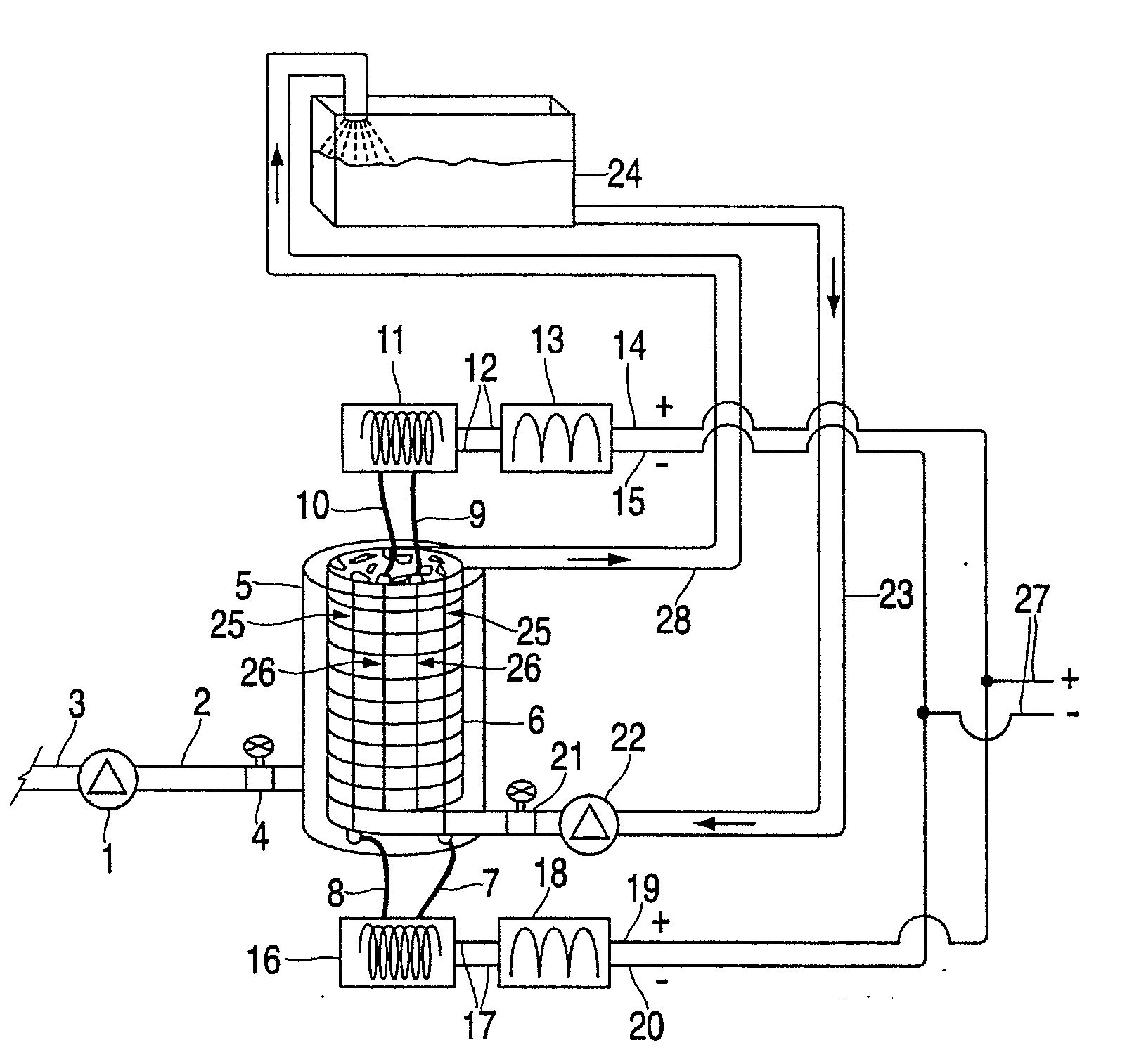

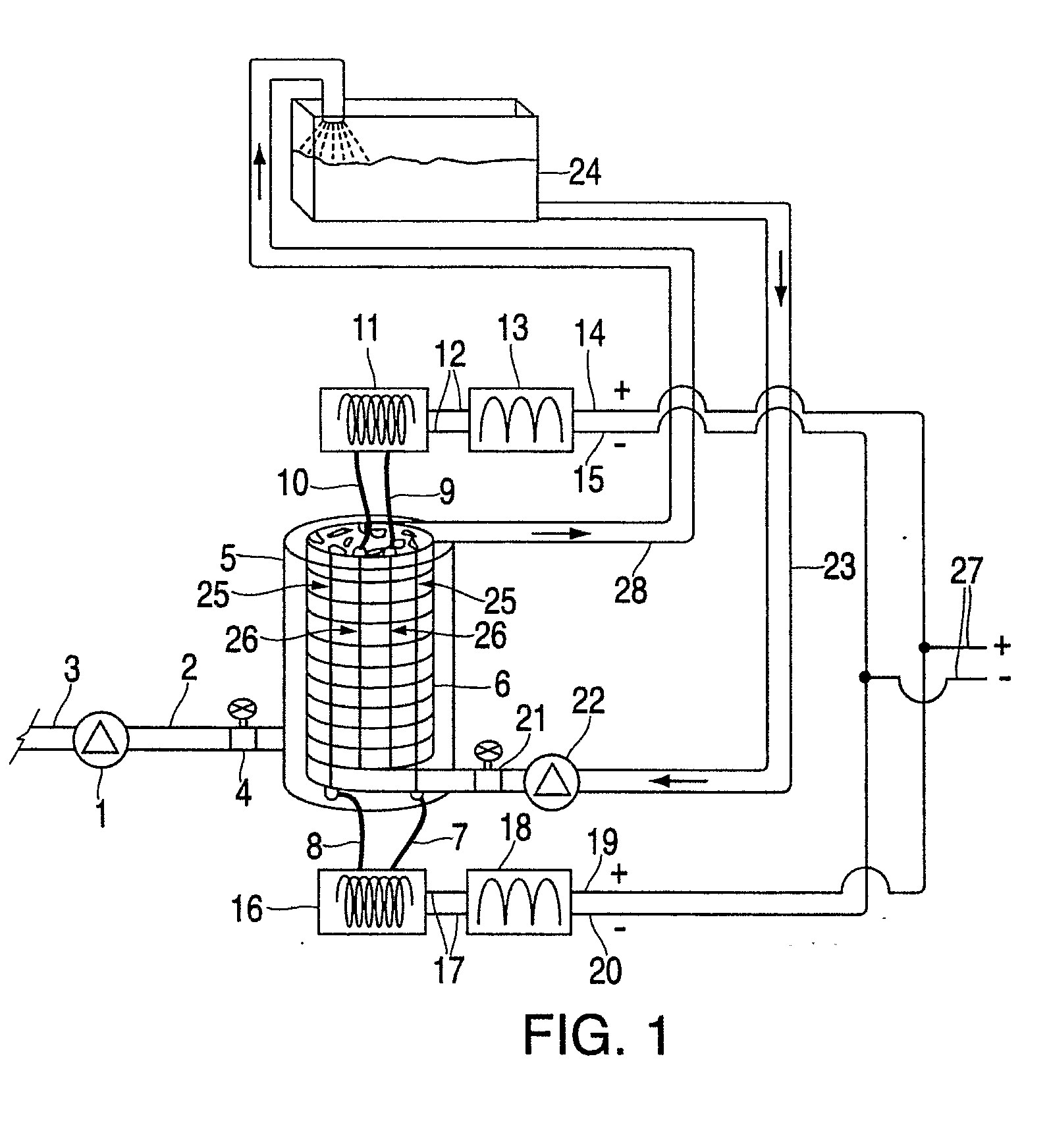

Fuel additive for enhancing combustion efficiency and decreasing emissions

PatentInactiveUS20120102822A1

Innovation

- A novel fuel additive comprising a sol of inorganic-metallic and organo-metallic complex stabilized in a hydrocarbon medium, which deposits a reversible microfilm catalyst on combustion surfaces, reducing NOx emissions and lowering combustion activation temperatures, thereby enhancing fuel efficiency and decreasing emissions of sulfur dioxide, oxides of nitrogen, and carbon monoxide.

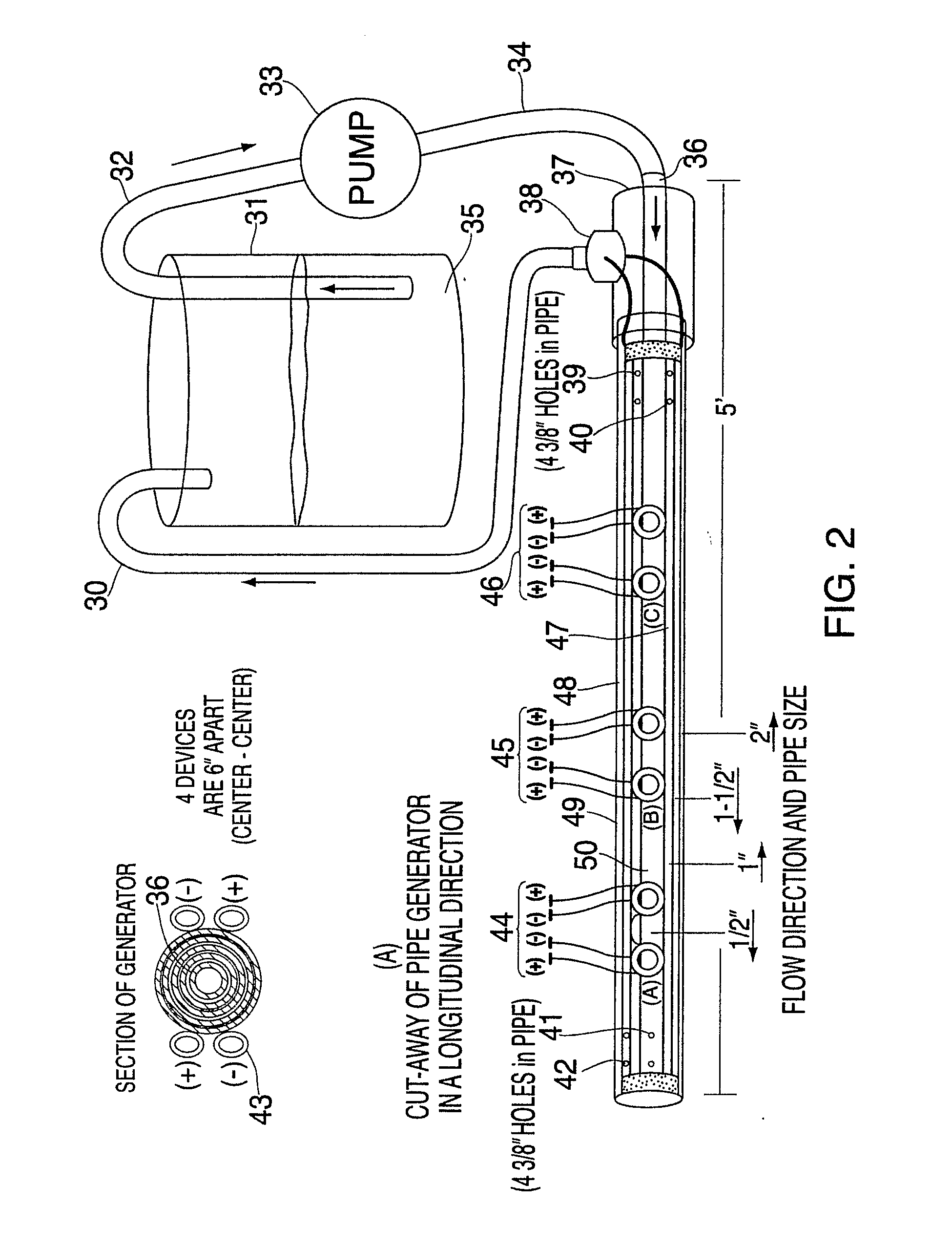

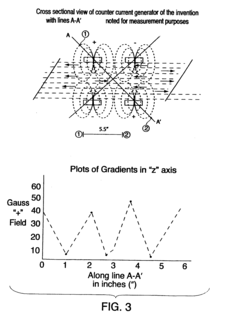

Fuel additive comprising an alkyl halide

PatentInactiveEP1711585A1

Innovation

- A fuel additive comprising an alkyl halide, such as tetrabromoethane, is added in small amounts to improve combustion characteristics by creating free radicals and trapping heavy metal ions, which are stable and miscible with liquid hydrocarbons, preventing loss to the water phase.

Environmental Regulations for Fuel Additives

The regulatory landscape governing fuel additives, particularly alkane-based combustion enhancers, has evolved significantly in response to growing environmental concerns and public health considerations. International frameworks such as the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the United States Environmental Protection Agency's fuel additive registration program establish comprehensive requirements for chemical substances introduced into transportation fuels. These regulations mandate rigorous toxicological assessments, environmental impact evaluations, and emissions testing before any additive can receive market approval.

Emission standards represent a critical driver shaping the development and deployment of alkane additives. Regulations such as Euro 6/VI standards in Europe, EPA Tier 3 standards in North America, and China VI standards impose increasingly stringent limits on particulate matter, nitrogen oxides, carbon monoxide, and unburned hydrocarbons. Alkane additives designed to enhance combustion efficiency must demonstrate their ability to reduce these pollutants while maintaining or improving fuel economy, creating a dual challenge for formulators and researchers.

Biodegradability and environmental persistence constitute another essential regulatory dimension. Authorities require comprehensive data on the environmental fate of fuel additives, including their degradation pathways, bioaccumulation potential, and aquatic toxicity. Alkane additives must meet specific criteria regarding their breakdown in soil and water systems, with particular attention to metabolites that may pose ecological risks. The OECD guidelines for biodegradability testing provide standardized protocols that manufacturers must follow to demonstrate environmental compatibility.

Health and safety regulations further constrain additive formulations, addressing occupational exposure limits, consumer safety during refueling operations, and potential impacts on vulnerable populations. Regulatory bodies scrutinize vapor pressure characteristics, dermal absorption rates, and inhalation toxicity data. Additionally, compatibility with existing fuel infrastructure and vehicle emission control systems, including catalytic converters and particulate filters, must be verified to ensure that combustion-enhancing alkane additives do not compromise pollution control technologies or accelerate system degradation.

Emission standards represent a critical driver shaping the development and deployment of alkane additives. Regulations such as Euro 6/VI standards in Europe, EPA Tier 3 standards in North America, and China VI standards impose increasingly stringent limits on particulate matter, nitrogen oxides, carbon monoxide, and unburned hydrocarbons. Alkane additives designed to enhance combustion efficiency must demonstrate their ability to reduce these pollutants while maintaining or improving fuel economy, creating a dual challenge for formulators and researchers.

Biodegradability and environmental persistence constitute another essential regulatory dimension. Authorities require comprehensive data on the environmental fate of fuel additives, including their degradation pathways, bioaccumulation potential, and aquatic toxicity. Alkane additives must meet specific criteria regarding their breakdown in soil and water systems, with particular attention to metabolites that may pose ecological risks. The OECD guidelines for biodegradability testing provide standardized protocols that manufacturers must follow to demonstrate environmental compatibility.

Health and safety regulations further constrain additive formulations, addressing occupational exposure limits, consumer safety during refueling operations, and potential impacts on vulnerable populations. Regulatory bodies scrutinize vapor pressure characteristics, dermal absorption rates, and inhalation toxicity data. Additionally, compatibility with existing fuel infrastructure and vehicle emission control systems, including catalytic converters and particulate filters, must be verified to ensure that combustion-enhancing alkane additives do not compromise pollution control technologies or accelerate system degradation.

Cost-Benefit Analysis of Additive Implementation

The economic viability of implementing alkane additives in combustion systems requires comprehensive evaluation of both direct and indirect costs against measurable performance improvements. Initial capital expenditure encompasses procurement of additive storage infrastructure, injection systems, and monitoring equipment, typically ranging from moderate investments for small-scale applications to substantial outlays for industrial facilities. The unit cost of alkane additives varies significantly depending on molecular structure, purity requirements, and production scale, with specialized formulations commanding premium pricing compared to conventional fuel components.

Operational cost considerations extend beyond raw material expenses to include system maintenance, personnel training, and quality control procedures. Additive consumption rates directly correlate with fuel throughput and desired enhancement levels, necessitating precise dosing mechanisms to optimize cost-effectiveness. Regular calibration of injection systems and periodic analysis of combustion parameters introduce recurring expenses that must be factored into long-term financial projections.

The benefit side of the equation manifests through multiple value streams. Enhanced combustion efficiency translates to reduced fuel consumption, with documented improvements ranging from modest percentage gains to significant reductions depending on baseline system performance and additive selection. This fuel savings generates immediate operational cost reductions that accumulate substantially over extended operational periods. Additionally, improved combustion completeness reduces maintenance frequency by minimizing carbon deposits and corrosive byproducts, thereby extending equipment lifespan and reducing downtime costs.

Environmental compliance benefits constitute another critical economic factor. Reduced emissions of particulate matter, unburned hydrocarbons, and carbon monoxide can help facilities meet increasingly stringent regulatory standards without expensive exhaust treatment upgrades. In jurisdictions with carbon pricing mechanisms or emissions trading systems, the reduction in greenhouse gas emissions per unit energy output creates tangible financial value through avoided compliance costs or tradable credits.

The payback period for additive implementation typically ranges from several months to a few years, heavily influenced by fuel prices, operational intensity, and regulatory environment. Sensitivity analysis reveals that facilities with high fuel consumption, premium fuel costs, or strict emission requirements achieve faster return on investment, making additive adoption particularly attractive for transportation fleets, power generation facilities, and industrial heating applications operating under demanding performance or environmental constraints.

Operational cost considerations extend beyond raw material expenses to include system maintenance, personnel training, and quality control procedures. Additive consumption rates directly correlate with fuel throughput and desired enhancement levels, necessitating precise dosing mechanisms to optimize cost-effectiveness. Regular calibration of injection systems and periodic analysis of combustion parameters introduce recurring expenses that must be factored into long-term financial projections.

The benefit side of the equation manifests through multiple value streams. Enhanced combustion efficiency translates to reduced fuel consumption, with documented improvements ranging from modest percentage gains to significant reductions depending on baseline system performance and additive selection. This fuel savings generates immediate operational cost reductions that accumulate substantially over extended operational periods. Additionally, improved combustion completeness reduces maintenance frequency by minimizing carbon deposits and corrosive byproducts, thereby extending equipment lifespan and reducing downtime costs.

Environmental compliance benefits constitute another critical economic factor. Reduced emissions of particulate matter, unburned hydrocarbons, and carbon monoxide can help facilities meet increasingly stringent regulatory standards without expensive exhaust treatment upgrades. In jurisdictions with carbon pricing mechanisms or emissions trading systems, the reduction in greenhouse gas emissions per unit energy output creates tangible financial value through avoided compliance costs or tradable credits.

The payback period for additive implementation typically ranges from several months to a few years, heavily influenced by fuel prices, operational intensity, and regulatory environment. Sensitivity analysis reveals that facilities with high fuel consumption, premium fuel costs, or strict emission requirements achieve faster return on investment, making additive adoption particularly attractive for transportation fleets, power generation facilities, and industrial heating applications operating under demanding performance or environmental constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!