Improving The Cycle Performance Of PVDF (Polyvinylidene Fluoride)

Technology Background And Goals

The primary objective of this report is to improve the cycle performance of PVDF (polyvinylidene fluoride), a widely used polymer material in various applications, particularly in energy storage devices such as lithium-ion batteries and supercapacitors.

PVDF exhibits excellent electrochemical stability, mechanical strength, and thermal resistance, making it a promising candidate for high-performance energy storage systems. However, its cycle performance, which refers to the ability to maintain consistent electrochemical properties over multiple charge-discharge cycles, remains a significant challenge. Enhancing the cycle performance of PVDF is crucial for extending the lifespan and improving the reliability of energy storage devices, ultimately contributing to the development of more sustainable and efficient energy solutions.

Market Demand Analysis

- Market Size and Growth

PVDF has a substantial and growing market, driven by its applications in lithium-ion batteries, membranes, and coatings. The global PVDF market is projected to reach $1.2 billion by 2027, with a CAGR of 6.2% from 2022 to 2027. - Key Application Areas

- Lithium-ion batteries: PVDF is widely used as a binder in electrodes, contributing to improved cycle performance and safety.

- Membranes: PVDF membranes are used in water treatment, chemical processing, and biomedical applications due to their chemical resistance and thermal stability.

- Coatings: PVDF coatings are employed in construction, automotive, and aerospace industries for their durability and weather resistance.

- Regional Market Dynamics

The Asia-Pacific region dominates the PVDF market, driven by the growing demand for lithium-ion batteries and membranes in countries like China, Japan, and South Korea. North America and Europe also exhibit significant demand, particularly in the construction and automotive sectors. - Emerging Trends

- Increasing demand for electric vehicles and renewable energy storage systems is driving the growth of the lithium-ion battery market, consequently boosting the demand for PVDF.

- The development of advanced membrane technologies for water treatment and desalination is creating new opportunities for PVDF membranes.

- The trend towards sustainable and eco-friendly construction materials is driving the adoption of PVDF coatings in the construction industry.

Technology Status And Challenges

- Current Technology Landscape

PVDF technology has seen significant advancements, with various applications in energy storage, sensors, and membranes. However, challenges remain in improving cycle performance and addressing issues like capacity fading and electrode degradation. - Key Technical Hurdles

Electrode/electrolyte interface instability, limited ionic conductivity, and structural changes during cycling are major obstacles hindering PVDF's cycle performance. Overcoming these challenges is crucial for enhancing durability and efficiency. - Geographical Distribution

Research on PVDF cycle performance is globally distributed, with major contributions from the United States, China, South Korea, and European countries. Collaborative efforts and knowledge sharing are essential for accelerating progress.

Current Technical Solutions

01 PVDF Electrode Binders

PVDF is used as a binder for electrode active materials, improving adhesion, conductivity, cycle performance, and stability through various compositions and preparation methods.- PVDF Electrode Binders: PVDF is used as a binder material in lithium-ion battery electrodes, improving adhesion and conductivity, leading to enhanced cycle performance and battery life.

- PVDF Gel Polymer Electrolytes: PVDF is used in gel polymer electrolytes, exhibiting good ionic conductivity and mechanical strength, contributing to improved cycle performance and safety.

- PVDF Battery Separators: PVDF is used as a coating or component in separators, providing mechanical strength, thermal stability, and electrolyte wettability, enhancing cycle performance and safety.

- PVDF Composite Electrodes: PVDF is combined with materials like carbon nanotubes or metal oxides to form composite electrodes with improved conductivity, mechanical strength, and electrochemical performance.

- PVDF Electrolyte Additives: PVDF or its derivatives are used as electrolyte additives, improving solid-electrolyte interphase formation, leading to enhanced cycle performance and battery life.

02 PVDF Battery Separators

PVDF is used as a polymer material for separators, exhibiting improved thermal stability, mechanical strength, and electrolyte wettability, enhancing cycle performance and safety.Expand Specific Solutions03 PVDF Gel Polymer Electrolytes

PVDF is used as a polymer matrix for gel polymer electrolytes, exhibiting improved ionic conductivity, mechanical strength, and interfacial stability, enhancing cycle performance and safety.Expand Specific Solutions04 PVDF Composite Electrodes

PVDF is combined with materials like carbon nanotubes or metal oxides to form composite electrodes with improved conductivity, structural stability, and electrochemical performance.Expand Specific Solutions05 PVDF Solid-State Electrolytes

PVDF is used as a polymer matrix for solid-state electrolytes, exhibiting improved ionic conductivity, mechanical strength, and interfacial stability, enhancing cycle performance and safety.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Zhonghao Chenguang Research Institute of Chemical Ind Co Ltd

Key Technology Interpretation

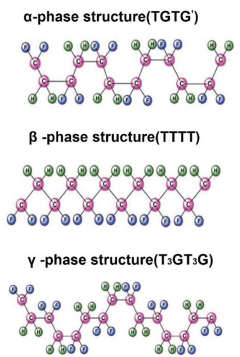

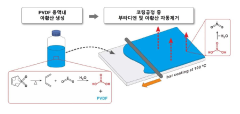

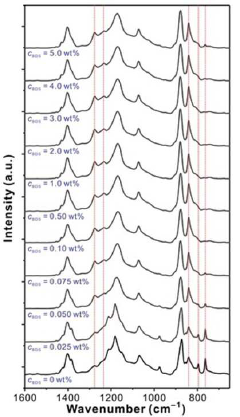

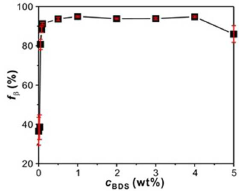

- Adding acid during the PVDF manufacturing process to increase the beta phase ratio without requiring an additional impurity removal step.

- The method allows for the production of high-beta phase PVDF with improved piezoelectricity, pyroelectricity, and ferroelectricity, enabling the manufacture of high-performance electronic devices.

- The acid is automatically removed during the manufacturing process, eliminating the need for an additional impurity removal step and preventing potential issues caused by impurities.

PVDF Cycle Performance Improvement Economic Impact

Improving the cycle performance of polyvinylidene fluoride (PVDF) could have significant economic impacts across various industries. PVDF is widely used in applications such as lithium-ion batteries, membranes, and coatings. Enhancing its cycle performance can lead to more durable and efficient products, potentially lowering replacement costs and maintenance for end-users. For instance, in the energy storage sector, better-performing PVDF could reduce the frequency of battery replacements, thus decreasing costs for manufacturers and consumers alike.

Additionally, industries that rely heavily on PVDF for its chemical resistance and mechanical properties may see increased efficiency and operational cost savings. The improved longevity and robustness of PVDF products can lead to longer service intervals and less frequent downtimes, which in turn can optimize productivity. This development can also stimulate market growth by extending PVDF's range of applications or enhancing its competitiveness against other materials, potentially resulting in increased market share and new business opportunities.

Overall, the economic impact of advancing PVDF's cycle performance is considerable, fostering innovation while providing financial advantages across several industrial domains.

PVDF Cycle Performance Improvement Policy And Regulatory Impact

The improvement of the cycle performance of PVDF (Polyvinylidene Fluoride) is significantly influenced by policy and regulatory frameworks that govern the materials and energy sectors. Regulations focusing on environmental impact and sustainability can drive innovation in the development of more efficient PVDF-based systems. As governments globally increase their commitments towards reducing carbon footprints and enhancing renewable energy sources, supportive policies could accelerate research and technological advancements in PVDF applications.

Furthermore, subsidies and tax incentives geared towards the chemical and polymer industries can encourage investment in advanced R&D for PVDF. Regulatory standards that emphasize recycling and the use of eco-friendly materials might push companies towards creating PVDF products that not only perform better but also align with circular economy principles.

International trade policies also impact the availability and cost-effectiveness of raw materials necessary for PVDF production, thus influencing its market dynamics. With growing concern over health and safety standards, ensuring compliance with stringent regulations is essential for the broader adoption of improved PVDF technologies. Overall, the intricate interplay of policy and regulatory measures can significantly shape the trajectory of advancements in PVDF cycle performance, spurring both challenges and opportunities for stakeholders in this sector.