Improving The Safety Of PVDF-Based Gel Polymer Electrolytes For Lithium Batteries

PVDF-Based Gel Polymer Electrolytes Technology Background And Goals

Addressing these safety issues is crucial for the widespread adoption of PVDF-based GPEs in lithium batteries. Potential solutions may involve modifying the PVDF structure, incorporating additives or fillers, or exploring alternative polymer matrices with improved thermal stability and reduced gas emission. Comprehensive investigations into the degradation mechanisms, thermal behavior, and gas evolution characteristics of PVDF-based GPEs under various conditions are essential to develop effective strategies for enhancing their safety profile.

Market Demand Analysis

- Market Size and Growth

The market for PVDF-based gel polymer electrolytes for lithium batteries is expected to witness significant growth in the coming years, driven by the increasing demand for high-performance and safe energy storage solutions in various applications, including electric vehicles, consumer electronics, and renewable energy systems. - Key Applications

The primary applications driving the demand for PVDF-based gel polymer electrolytes include:- Electric Vehicles (EVs): The growing adoption of EVs and the need for high-energy-density and safe battery systems are fueling the demand for PVDF-based gel polymer electrolytes.

- Consumer Electronics: The increasing popularity of portable electronic devices, such as smartphones, laptops, and wearables, is driving the demand for compact and safe battery solutions.

- Renewable Energy Systems: The integration of energy storage systems with renewable energy sources, such as solar and wind power, is creating a demand for safe and efficient battery technologies.

- Market Trends and Drivers

The key trends and drivers influencing the market demand for PVDF-based gel polymer electrolytes include:- Stringent Safety Regulations: Increasing safety concerns and regulations regarding the use of flammable liquid electrolytes are driving the adoption of safer alternatives like PVDF-based gel polymer electrolytes.

- Demand for High-Performance Batteries: The growing need for high-energy-density, long-cycle-life, and high-temperature-resistant batteries is driving the demand for advanced electrolyte materials like PVDF-based gel polymer electrolytes.

- Technological Advancements: Ongoing research and development efforts to improve the performance and safety of PVDF-based gel polymer electrolytes are expected to drive market growth.

Technology Status And Challenges

- Technology Evolution

Tracing the development of PVDF-based gel polymer electrolytes, from initial research to current state-of-the-art solutions, highlighting key milestones and breakthroughs. - Safety Challenges

Identifying major safety concerns associated with PVDF-based gel polymer electrolytes, such as thermal runaway, electrolyte leakage, and interfacial instability. - Geographical Distribution

Analyzing the geographical distribution of research and development efforts in this field, highlighting leading institutions and regions contributing to advancements. - Technological Bottlenecks

Discussing the current technological bottlenecks and limitations hindering the widespread adoption of safer PVDF-based gel polymer electrolytes in lithium batteries.

Current Technical Solutions

01 Safety Enhancement

Incorporating flame retardants, overcharge protection additives, or other safety-enhancing components to prevent thermal runaway, fire hazards, and other safety issues associated with lithium-ion batteries.- Safety Enhancement: Incorporating flame retardants, overcharge protection additives, or other safety-enhancing components to prevent thermal runaway, reduce fire or explosion risks, and improve overall stability.

- Ionic Conductivity Improvement: Optimizing composition, incorporating ionic liquids or ceramic fillers, or modifying polymer structure to increase ionic conductivity for better battery performance and efficiency.

- Mechanical Property Enhancement: Incorporating reinforcing materials, crosslinking agents, or modifying polymer structure to improve tensile strength, flexibility, and dimensional stability for better durability and reliability.

- Thermal Stability Improvement: Incorporating heat-resistant additives, using high-temperature-resistant polymers, or modifying polymer structure to enhance thermal stability and prevent degradation under high-temperature conditions.

- Electrochemical Stability Enhancement: Incorporating redox-stable additives, using electrochemically stable solvents or salts, or modifying polymer structure to improve electrochemical stability, prevent side reactions, and extend cycle life.

02 Ionic Conductivity Improvement

Optimizing composition, incorporating ionic liquids or ceramic fillers, or modifying polymer structure to improve ionic conductivity for better battery performance and safety.Expand Specific Solutions03 Mechanical Property Enhancement

Enhancing mechanical properties like tensile strength, flexibility, and dimensional stability for better battery safety and durability under various operating conditions.Expand Specific Solutions04 Thermal Stability Improvement

Incorporating heat-resistant additives, crosslinking agents, or modifying polymer structure to improve thermal stability and prevent degradation and safety issues at high temperatures.Expand Specific Solutions05 Electrochemical Stability Enhancement

Incorporating additives, modifying polymer structure, or optimizing composition to improve electrochemical stability for better battery performance and cycle life.Expand Specific Solutions

Main Player Analysis

LG Energy Solution Ltd.

Samsung SDI Co., Ltd.

Key Technology Interpretation

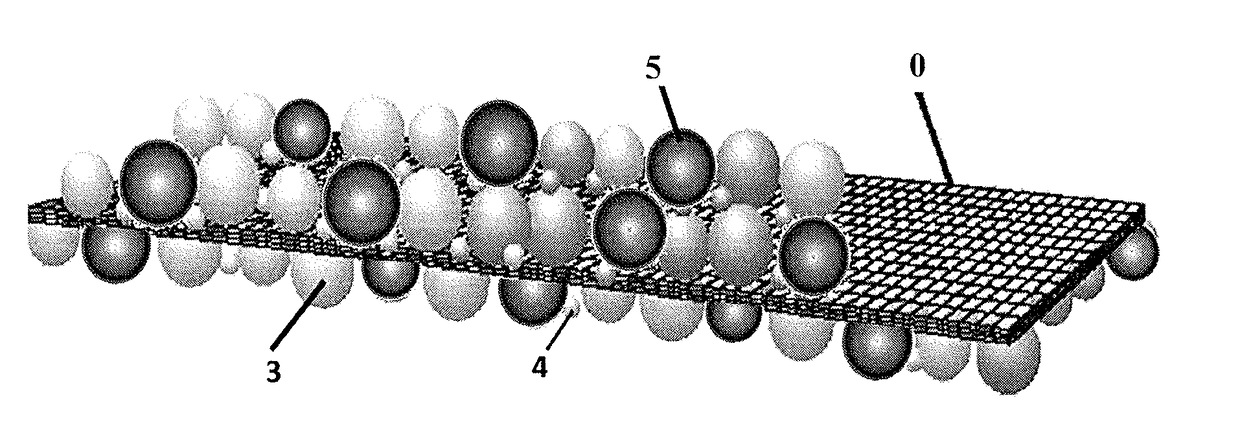

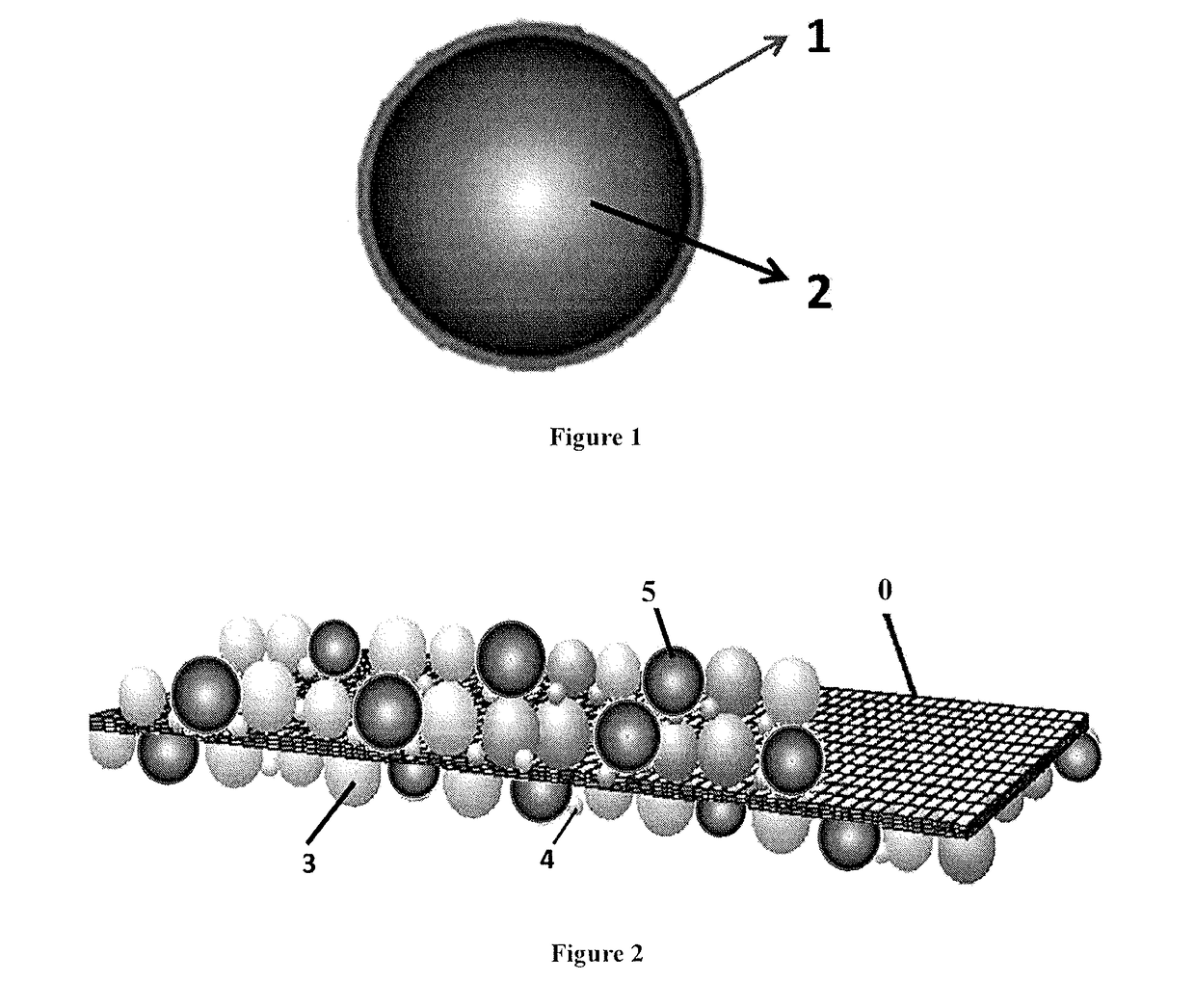

- Replacement of the traditional polyolefin diaphragm with a more durable and high-strength material, such as pvdf polymer. this improves the strength of the battery and reduces distortion under the action of external forces.

- Introducing adhesive into the battery to bond the electrode slices and the diaphragm, increasing the strength of the battery. the adhesive used in this scheme can withstand high-temperature drying and improve the hardness of the battery.

- Utilizing porous coatings and dot coatings to enhance the interface of the battery and improve the bonding force between different components. the porous coatings provide a suitable environment for the adhesion of rubber polymers, while the dot coatings add adhesion points and enhance the strength of the battery.

PVDF-Based Gel Polymer Electrolytes Safety Improvement Economic Analysis

The economic impact of PVDF-based gel polymer electrolytes (GPEs) in safer batteries is becoming increasingly significant as industries seek sustainable energy storage solutions. This technology presents considerable potential for cost reduction in battery manufacturing due to enhanced safety profiles, which can ultimately lower insurance and liability costs for producers and users. The safer nature of PVDF-based GPEs allows for broader market acceptance, potentially accelerating the adoption of lithium-ion batteries in sectors such as consumer electronics, electric vehicles, and renewable energy storage systems. Additionally, the increased safety can drive down regulatory hurdles, facilitating quicker market entry and expansion.

PVDF-based GPEs also contribute to the longevity and performance of batteries, thus improving the cost-efficiency of energy storage systems over time and reducing the frequency and costs associated with battery replacements. These economic benefits could lead to a competitive advantage for manufacturers, propelling further innovations and investments in this technology. Furthermore, as the demand for sustainable energy solutions rises globally, the proliferation of PVDF-based GPEs could stimulate job creation in high-tech manufacturing sectors, contributing positively to economic growth. Overall, the advancements in safer battery technologies like PVDF GPEs could significantly influence economic landscapes by enhancing value chains and supporting the transition towards cleaner energy solutions.

PVDF-Based Gel Polymer Electrolytes Safety Improvement Policy And Regulatory Impact

The development and application of PVDF-based gel polymer electrolytes for safer batteries are intricately linked with evolving policy and regulatory frameworks worldwide. These frameworks significantly influence the research, production, and commercialization rates of advanced battery technologies. Governments are increasingly imposing stringent safety regulations to mitigate risks associated with traditional liquid electrolytes, thereby encouraging the shift towards safer alternatives like PVDF-based electrolytes. Regulatory bodies are focusing on standards for material safety, thermal stability, and environmental impact, pushing manufacturers and researchers to prioritize these aspects in their innovations.

In addition to safety concerns, there is an increasing regulatory emphasis on sustainability and recyclability, which in turn directs the development paths of battery technologies towards more eco-friendly solutions. Financial incentives and research grants from government entities motivated by policy goals to reduce carbon emissions and promote green energy have also accelerated advancements in PVDF-based gel polymer electrolyte technologies.

However, navigating the complex landscape of differing international regulations presents challenges, necessitating a robust understanding of both local and global compliance requirements. For companies advancing in this field, aligning technological development with regulatory expectations is crucial not only for market entry but also for maintaining a competitive edge in the rapidly evolving battery sector.