PVDF-Based Piezoelectric Energy Harvesters For Improving Energy Harvesting Efficiency

Technology Background And Goals

The primary objective of this report is to explore and analyze the current status, challenges, and future development trends of PVDF-based piezoelectric energy harvesters for improving energy harvesting efficiency.

This technology has gained significant attention due to its potential in converting ambient mechanical energy into electrical energy for powering low-power devices. The report will delve into the key milestones and technological advancements in this field, highlighting the current state-of-the-art solutions and their limitations. Additionally, it will identify the major technical hurdles and constraints hindering the widespread adoption of these energy harvesters, while also examining the geographical distribution of research and development efforts in this domain.

Market Demand Analysis

- Market Size and Growth

The global market for piezoelectric energy harvesters is expected to witness significant growth, driven by the increasing demand for self-powered and sustainable energy solutions across various industries, including consumer electronics, industrial automation, and wireless sensor networks. - Key Application Areas

PVDF-based piezoelectric energy harvesters find applications in powering low-power devices, such as wireless sensors, wearable electronics, and remote monitoring systems, where traditional power sources are impractical or unavailable. - Emerging Trends

- Integration with Internet of Things (IoT) devices for energy-efficient operation

- Adoption in smart cities and infrastructure for powering sensors and monitoring systems

- Increasing demand for flexible and lightweight energy harvesters in wearable technology

- Market Drivers

- Growing need for sustainable and renewable energy sources

- Advancements in materials and fabrication techniques for improved efficiency

- Increasing demand for self-powered devices in remote or inaccessible locations

- Challenges and Opportunities

While the market faces challenges such as low power output and scalability issues, ongoing research and development efforts aim to improve energy conversion efficiency and explore new materials and designs, presenting opportunities for innovation and market growth.

Technology Status And Challenges

- Historical Development

Piezoelectric materials have been studied for over a century, with PVDF emerging as a promising polymer-based piezoelectric material in the 1960s. - Current Status

PVDF-based piezoelectric energy harvesters have gained significant attention due to their flexibility, lightweight, and biocompatibility. However, their energy conversion efficiency remains relatively low compared to ceramic-based counterparts. - Key Challenges

- Improving the piezoelectric properties of PVDF through material engineering and processing techniques

- Enhancing the mechanical-to-electrical energy conversion efficiency through device design and optimization

- Addressing issues related to long-term stability and durability of PVDF-based devices

- Geographic Distribution

Research on PVDF-based piezoelectric energy harvesters is widely distributed globally, with major contributions from institutions and companies in the United States, Europe, and Asia.

Current Technical Solutions

01 PVDF-based Piezoelectric Energy Harvesters

Devices that convert mechanical energy into electrical energy using piezoelectric properties of polyvinylidene fluoride (PVDF), generating electrical charge from mechanical stress or deformation, and powering low-power electronic devices.- PVDF-based Piezoelectric Energy Harvesters: Devices that convert mechanical energy into electrical energy using piezoelectric properties of polyvinylidene fluoride (PVDF), harvesting energy from vibrations or movements for powering small electronics or sensors.

- Enhancing Efficiency: Techniques like optimizing material properties, device structure, electrode configurations, mechanical amplification, resonance tuning, and energy storage circuits can improve energy harvesting efficiency.

- Flexible and Wearable Harvesters: PVDF-based harvesters can be designed as flexible and wearable devices, integrated into clothing or accessories, enabling self-powered wearable electronics and sensors for applications like health monitoring and fitness tracking.

- Vibration and Mechanical Stress Harvesting: These harvesters can harvest energy from various sources of vibrations and mechanical stress, such as machinery, vehicles, or structural vibrations, powering wireless sensor networks, structural health monitoring systems, or other applications where traditional power sources are impractical.

- Hybrid and Multi-Source Harvesters: PVDF-based piezoelectric harvesters can be combined with other energy harvesting technologies, like solar cells or thermoelectric generators, creating hybrid or multi-source systems that leverage multiple energy sources for improved efficiency and reliability.

02 Improving Efficiency

Techniques like optimizing material properties, device structure, design parameters, incorporating nanostructures, using composite materials, and novel device configurations have been explored to enhance energy harvesting efficiency.Expand Specific Solutions03 Energy Storage and Management Integration

Integration with energy storage systems like batteries, supercapacitors, and power conditioning circuits, along with energy management algorithms, is crucial for effective utilization of generated electrical energy.Expand Specific Solutions04 Applications

PVDF-based piezoelectric harvesters have potential applications in wearable electronics, wireless sensor networks, structural health monitoring, and self-powered systems, enabling powering of low-power electronics without traditional batteries.Expand Specific Solutions05 Fabrication and Manufacturing Techniques

Various fabrication and manufacturing techniques, such as spin-coating, electrospinning, and 3D printing, have been explored to produce PVDF-based piezoelectric films, fibers, or structures with desired properties and configurations, impacting performance and scalability.Expand Specific Solutions

Main Player Analysis

Evoke Medical LLC

Hong Kong Applied Science & Technology Research Institute

Key Technology Interpretation

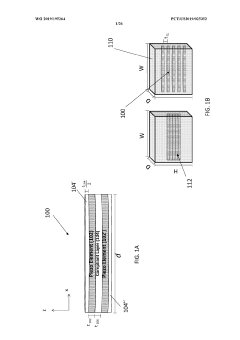

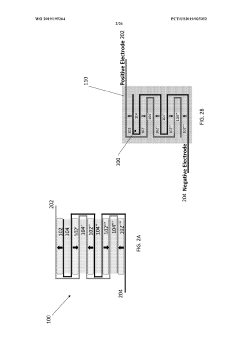

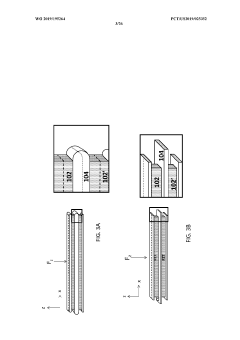

- A manufacturing method for piezoelectric energy harvesters that include piezoelectric elements stacked with compliant layers, resulting in increased power generation and durability.

- A stacked piezoelectric energy harvester with alternating layers of compliant layers and piezoelectric element layers, where the ratio of the volume or thickness of the layers is between about 1:8 to about 8:1.

- A method of increasing power production by layering a compliant layer between each piezoelectric element layer.

PVDF-Based Piezoelectric Energy Harvesters Efficiency Improvement Economic Impact

The economic impact of PVDF-based piezoelectric energy harvesters is potentially transformative across a variety of sectors. By converting mechanical energy from naturally occurring vibrations and movement into electrical energy, these devices can significantly enhance the energy efficiency of systems ranging from consumer electronics to industrial machinery. This technology contributes directly to reducing dependency on conventional power sources, thereby decreasing energy costs and environmental footprints. In consumer electronics, for instance, these harvesters can power wearable devices and sensors, extending battery life and reducing the frequency of recharging needs, which can significantly impact production costs and consumer satisfaction.

Moreover, in large-scale industrial applications, the integration of PVDF-based piezoelectric energy harvesters can facilitate the development of self-sufficient systems and smart infrastructures, potentially leading to substantial cost savings in energy management and maintenance. The harvesters support sustainable energy initiatives by enabling energy recycling and self-powered devices, aligning with global trends towards greener technologies. As a result, industries that adopt these energy harvesters can anticipate not only direct economic benefits from energy savings but also indirect advantages through enhanced brand reputation and increased competitiveness in markets increasingly favoring sustainable practices.

PVDF-Based Piezoelectric Energy Harvesters Efficiency Improvement Policy And Regulatory Impact

The development and deployment of PVDF-based piezoelectric energy harvesters are significantly influenced by policy and regulatory frameworks worldwide. Policies promoting renewable energy adoption and sustainable materials stimulate research and development in this field. Regulatory incentives, such as tax credits and subsidies for green technologies, encourage industries to explore and implement piezoelectric energy solutions. Additionally, environmental and safety standards shape the material choices and manufacturing processes of such harvesters, ensuring compliance with health and environmental protection guidelines. Global efforts toward energy efficiency and carbon footprint reduction further push policies favoring the integration of sustainable energy technologies into existing infrastructure.

Intellectual property regulations also play a crucial role, as patents protect innovation while encouraging competitive advancements in the field. Trade policies impact the supply chain of raw materials necessary for manufacturing PVDF-based components, potentially affecting cost and availability. Collaboration with international regulatory bodies can lead to harmonized standards, facilitating broader adoption and scalability of these technologies. Therefore, understanding and navigating the policy landscape is vital for effectively advancing and implementing PVDF-based piezoelectric energy harvesting technologies.