Improving The Transmission Efficiency Of Continuously Variable Transmissions (CVTs)

CVT Efficiency Improvement Goals

The primary objective of this report is to improve the transmission efficiency of continuously variable transmissions (CVTs), which are widely used in automotive applications. CVTs offer the advantage of continuously varying gear ratios, resulting in improved fuel efficiency and smoother acceleration compared to traditional automatic transmissions. However, CVTs face challenges in terms of power losses due to friction and belt slippage, leading to reduced overall transmission efficiency. Enhancing the transmission efficiency of CVTs can be achieved through various approaches, including optimizing the design and materials of the pulley system, reducing friction between the belt and pulleys, and implementing advanced control strategies. Potential solutions may involve the use of advanced materials with lower friction coefficients, innovative pulley geometries, and the integration of advanced sensors and control algorithms to dynamically adjust the transmission parameters for optimal efficiency.

Improving the transmission efficiency of CVTs not only contributes to better fuel economy and reduced emissions but also enhances the overall driving experience by providing smoother and more responsive acceleration. Successful advancements in this area could have significant implications for the automotive industry, promoting the wider adoption of CVTs and supporting the development of more efficient and environmentally friendly vehicles.

Market Demand for Efficient CVTs

- Growing Demand for Fuel Efficiency

Rising fuel costs and environmental concerns have driven the need for more efficient transmissions in vehicles. CVTs offer improved fuel economy compared to traditional automatic transmissions. - Emissions Regulations

Stringent emissions regulations, particularly in developed markets, have necessitated the adoption of technologies like CVTs that can reduce vehicle emissions. - Expanding Automotive Market

The growing automotive market, especially in emerging economies, presents a significant opportunity for CVTs as automakers seek to offer fuel-efficient and cost-effective vehicles. - Shift Towards Smaller Engines

The trend of downsizing engines to improve fuel efficiency has increased the demand for CVTs, which can better optimize the performance of smaller engines. - Competitive Advantage

Automakers are increasingly adopting CVTs as a competitive advantage, offering improved fuel economy and driving experience compared to traditional transmissions.

Current State and Challenges of CVT Efficiency Improvement

- Current Technological Limitations

CVTs face challenges in achieving high transmission efficiency, particularly at high torque loads and extreme speed ratios. Existing designs suffer from increased friction, wear, and energy losses. - Design Constraints

The complex geometry and kinematics of CVT components, such as pulleys and belts/chains, impose constraints on improving efficiency while maintaining durability and compactness. - Material Limitations

The materials used in CVT components, like metals and elastomers, have inherent limitations in terms of friction, wear resistance, and thermal properties, affecting overall efficiency. - Control System Challenges

Optimizing the control strategies for CVT operation to minimize energy losses across various driving conditions remains a complex task, requiring advanced algorithms and sensors. - Manufacturing Precision

Achieving high manufacturing precision for CVT components is crucial to minimize clearances and misalignments, which can contribute to energy losses and reduced efficiency.

Existing Solutions for CVT Efficiency

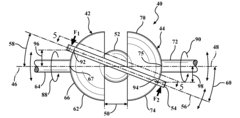

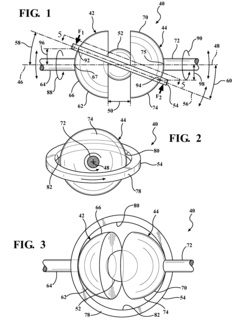

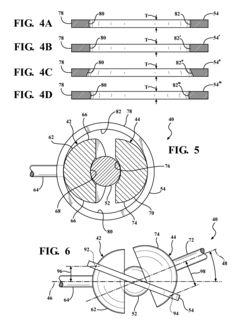

01 CVT Design and Structure

Various designs and structural configurations of Continuously Variable Transmissions (CVTs) have been proposed to improve transmission efficiency, including coaxial input/output arrangements, reduced friction losses, and enhanced torque transfer mechanisms.- CVT Design and Structure: Covers various designs and structural aspects of Continuously Variable Transmissions (CVTs) aimed at improving transmission efficiency, including coaxial input/output arrangements, reduced friction losses, thrust-type mechanical designs, and planetary gear configurations.

- CVT Control and Regulation: Focuses on control mechanisms, methods, and systems for regulating and optimizing the performance and efficiency of CVTs, such as electronic torque sensors, hydraulic control devices, and ratio control strategies.

- CVT Applications and Integration: Covers the integration of CVTs in various applications, such as electric vehicles, motorcycles, and hybrid systems, often involving specific design considerations and optimizations to enhance transmission efficiency.

- CVT Efficiency Improvements: Focuses on improving the transmission efficiency of CVTs through various techniques, such as reducing friction losses, enhancing torque transfer, and optimizing hydraulic systems.

- CVT Locking and Clutch Mechanisms: Covers locking mechanisms, clutches, and other components used in CVTs to control and optimize transmission efficiency under different operating conditions.

02 CVT Control and Regulation

Efficient control and regulation strategies have been developed for CVTs to optimize transmission efficiency, including methods for controlling transmission ratio, hydraulic control devices, and electronic control mechanisms.Expand Specific Solutions03 CVT Simulation and Testing

Simulation devices and testing methods have been developed to analyze and evaluate the transmission efficiency of CVTs, including simulation devices for studying CVT transmission principles and real-time efficiency measurement systems based on whole vehicle road tests.Expand Specific Solutions04 CVT Configurations for Specific Applications

Various CVT configurations have been designed for specific applications, such as electric vehicles, hybrid systems, and motorcycles, with a focus on improving transmission efficiency and energy savings.Expand Specific Solutions05 CVT Auxiliary Systems and Components

Auxiliary systems and components have been developed to enhance the efficiency of CVTs, such as temperature control systems, fluid control methods, and planetary gear arrangements.Expand Specific Solutions

Key Players in CVT Industry

Aisin KK

Daihatsu Motor Co., Ltd.

Core Innovations in CVT Technology

- The ability to provide more useable power, better fuel economy, and a smoother driving experience compared to traditional mechanical or automatic transmissions.

- A cvt allows for seamless and progressive changes in the transmission ratio, which sets it apart from other mechanical transmissions that offer a fixed number of gear ratios. this enables the engine to run at its most efficient rpm for a range of vehicle speeds, resulting in better fuel economy.cvts can also be used to maximize the performance of a vehicle by allowing the engine to turn at the rpm that produces peak power, which is typically higher than the rpm that achieves peak efficiency. this can create a more fuel-efficient vehicle. the nearly unlimited number of positions in the cvt helps ensure it is always using the appropriate amount of power.

Regulatory Landscape for Automotive Transmissions

The regulatory landscape for automotive transmissions is a dynamic and complex area focused on enhancing fuel efficiency, reducing emissions, and improving vehicle performance. Key frameworks like the Corporate Average Fuel Economy (CAFE) standards in the U.S. compel automakers to meet specific fuel economy targets, driving transmission manufacturers to innovate with technologies such as continuously variable transmissions (CVTs) to comply with these demands.

Emissions standards, set by agencies like the Environmental Protection Agency (EPA), impose strict limits on vehicle pollutants, necessitating transmissions that optimize engine efficiency to meet these criteria. Additionally, safety regulations require rigorous testing and certification of transmission components to ensure compliance with standards from bodies such as the National Highway Traffic Safety Administration (NHTSA) and the International Organization for Standardization (ISO).

With the rise of electric and hybrid vehicles, new regulatory challenges emerge, prompting the development of standards to address unique needs such as battery safety and energy efficiency. Transmission manufacturers must continuously adapt to these evolving regulations, developing innovative solutions to meet standards while maintaining a competitive edge.

Environmental Impact of CVT Technologies

The adoption of continuously variable transmissions (CVTs) has sparked concerns regarding their environmental impact, despite their advantages in fuel efficiency and reduced emissions. The production of CVTs involves energy-intensive processes for high-performance materials like steel and reinforced rubber, potentially generating hazardous waste. Additionally, specialized lubricants used in CVTs may contain harmful chemicals that risk contaminating the environment if not disposed of properly.

Addressing these environmental challenges involves strategies such as developing eco-friendly materials and lubricants and implementing closed-loop recycling systems for CVT components. Enhancing CVT durability can also decrease replacement frequency and its environmental burden. Regulatory bodies can further influence sustainable practices by setting stricter standards for CVT production, use, and disposal, encouraging manufacturers to invest in eco-friendly innovations. Overall, careful consideration and proactive measures are essential to mitigate the environmental impact of CVT technologies.