Optimized Pulley And Chain Designs - Eureka

JUN 17, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pulley and Chain Design Goals

The primary objective is to explore the current state and challenges of optimized pulley and chain designs, as well as identify the key technical hurdles and constraints hindering their advancement. This section will provide a comprehensive assessment of the development status of these technologies globally, highlighting the geographical distribution of expertise and innovation hubs. Particular emphasis will be placed on pinpointing the major technical bottlenecks that must be overcome to achieve breakthroughs in optimized pulley and chain designs.

The analysis will encompass a thorough examination of the existing technical limitations, such as material constraints, manufacturing challenges, and performance trade-offs. Additionally, it will delve into the regulatory and environmental factors that may impact the adoption and implementation of these technologies across various industries and applications.

The analysis will encompass a thorough examination of the existing technical limitations, such as material constraints, manufacturing challenges, and performance trade-offs. Additionally, it will delve into the regulatory and environmental factors that may impact the adoption and implementation of these technologies across various industries and applications.

Market Demand for Optimized Pulley Systems

- Growing Demand for Efficiency

Optimized pulley systems are in high demand due to the need for increased efficiency and reduced energy consumption in various industries, such as manufacturing, transportation, and construction. - Expanding Applications

The market for optimized pulley systems is expanding as they find applications in new areas, such as renewable energy systems (e.g., wind turbines) and robotics. - Cost Savings

Optimized pulley systems offer cost savings through reduced maintenance requirements, longer service life, and improved energy efficiency. - Environmental Considerations

The demand for environmentally friendly and sustainable solutions is driving the adoption of optimized pulley systems, which can contribute to reducing carbon footprints. - Regulatory Compliance

Stricter regulations and standards related to energy efficiency and emissions are prompting industries to adopt optimized pulley systems to comply with legal requirements.

Current State and Challenges in Pulley and Chain Technology

- Current Technological Limitations

Existing pulley and chain systems face challenges in terms of efficiency, durability, and noise reduction. Friction, wear, and lubrication issues can lead to energy losses and premature component failure. - Material Constraints

Traditional materials used in pulleys and chains have inherent limitations in strength, weight, and corrosion resistance, hindering performance and longevity in demanding applications. - Design Complexities

Optimizing the intricate geometry and dynamics of pulley and chain systems for specific use cases remains a complex engineering challenge, often requiring trade-offs between various design parameters. - Environmental Factors

Extreme temperatures, harsh environments, and exposure to contaminants can adversely affect the performance and reliability of pulley and chain systems, necessitating robust designs. - Maintenance and Monitoring

Effective maintenance and condition monitoring techniques are crucial for ensuring the safe and efficient operation of pulley and chain systems, particularly in critical applications.

Existing Solutions for Pulley and Chain Optimization

01 Chain Pulley Designs for Improved Transmission

Optimizing chain and pulley interaction for efficient power transmission with specialized chain links, pulley tooth profiles, and materials to enhance grip and reduce wear.- Chain Pulley Designs for Load Handling: Enhancing chain pulleys for hoists, winches, and load-handling applications with improved chain guides, guards, and tensioning mechanisms for smooth and reliable operation.

- Chain and Pulley Designs for CVTs: Specialized chain link designs, pulley profiles, and tensioning mechanisms for continuously variable transmissions (CVTs), particularly in automotive applications, enabling smooth and efficient power transmission.

- Optimized Pulley Designs for Specific Applications: Optimizing pulley structures and configurations for specific applications like carding machines, jacquard mechanisms, or lumber collection systems, with improved lubrication, material selection, or structural modifications for enhanced performance and durability.

- Chain and Pulley Designs for Conveyor Systems: Specialized pulley designs, chain guides, and tensioning mechanisms for efficient and reliable material transportation in conveyor systems like bucket chain conveyors or roller chain conveyors.

- Chain and Pulley Designs for Bicycle Applications: Specialized chain link designs, pulley profiles, and derailleur mechanisms for smooth and efficient gear shifting in bicycle applications, including derailleurs or continuously variable transmissions.

02 Chain and Pulley Assemblies for Hoists and Lifting

Improving safety, load-bearing capacity, and ease of operation in hoists, winches, and lifting mechanisms through chain guides, pulley guards, and specialized pulley block configurations.Expand Specific Solutions03 Pulley Designs for Chain Conveyors and Material Handling

Optimizing pulley configurations for chain conveyors, bucket elevators, and material handling systems with specialized pulley shapes, lubrication systems, and wear-resistant materials.Expand Specific Solutions04 Chain and Pulley Systems for Textile Machinery

Improving efficiency, reducing wear, and optimizing lubrication in textile machinery like carding machines, spinning frames, and jacquard looms through specialized chain and pulley systems.Expand Specific Solutions05 Pulley Designs for Bicycle and Vehicle Transmissions

Optimizing pulley configurations for bicycle derailleurs, continuously variable transmissions (CVTs), and vehicle transmission systems with specialized pulley shapes, chain guides, and tensioning mechanisms.Expand Specific Solutions

Key Players in Pulley and Chain Manufacturing

The competitive landscape for optimized pulley and chain designs features established players and newcomers. Companies like Schaeffler, Shimano, and SKF lead with advanced R&D. The market is growing, driven by demand for efficient mechanical systems across sectors. While JTEKT and Gates have well-established products, others like Purdue Research Foundation and Jilin University contribute to the evolving landscape.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler focuses on advanced pulley and chain designs, incorporating high-precision manufacturing and innovative materials for enhanced durability and efficiency, including self-lubricating chains and optimized pulley geometries.

Strength: High precision and durability. Weakness: High cost of advanced materials.

Shimano, Inc.

Technical Solution: Shimano specializes in bicycle components, including optimized pulley and chain systems, emphasizing lightweight materials and smooth shifting mechanisms for high-performance cycling.

Strength: Lightweight and efficient. Weakness: Primarily focused on cycling applications.

Core Innovations in Pulley and Chain Design

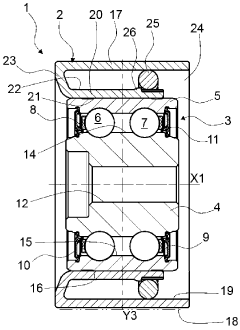

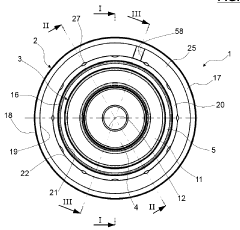

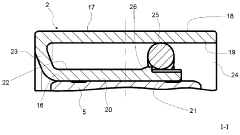

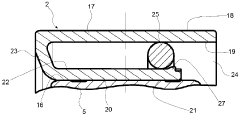

pulley device, especially for an idler pulley or idler pulley

PatentPendingDE102017223681A1

Innovation

- The pulley device has a C-shaped pulley with an inner portion and an outer portion, and a stiffening means arranged radially between the inner and outer portions to prevent axial displacement.

- At least one surface below the outer surface of the inner section and the inner surface of the outer section of the pulley part has at least one radially overhanging section that cooperates with the stiffening means to prevent axial displacement.

- The stiffening means and the overhanging sections provide a simple and effective way to prevent axial displacement of the pulley parts.

Regulatory Standards for Pulley and Chain Systems

Optimized pulley and chain designs are crucial for efficient power transmission in various industrial applications. This technology aims to enhance the performance and durability of pulley-chain systems through innovative designs and materials. The market demand for optimized pulley and chain solutions is driven by the need for increased productivity, energy efficiency, and reduced maintenance costs across industries such as manufacturing, agriculture, and transportation. Key challenges include minimizing friction, wear, and vibration while maximizing load-bearing capacity and service life. Potential innovation directions involve advanced materials, optimized geometries, and integrated monitoring systems for predictive maintenance.

Environmental Impact of Pulley and Chain Materials

Optimized pulley and chain designs are crucial for efficient power transmission in various industrial applications. This technology aims to enhance the performance and durability of pulley-chain systems through innovative designs and materials. The market demand for optimized pulley and chain solutions is driven by the need for increased productivity, energy efficiency, and reduced maintenance costs across industries such as manufacturing, agriculture, and construction. Key challenges include minimizing friction, wear, and vibration while maximizing load-bearing capacity and service life. Potential innovation directions involve advanced materials, optimized geometries, and integrated monitoring systems for predictive maintenance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!