Optimizing Flow Path Design Of Check Valves To Improve Flow Efficiency

NOV 8, 20243 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Check Valve Flow Path Design Optimization: Technology Background And Goals

The primary objective is to optimize the flow path design of check valves to enhance their flow efficiency, thereby reducing energy losses and improving overall system performance. This involves a comprehensive analysis of the current state of check valve technology, identifying key challenges and bottlenecks that hinder efficient fluid flow.

Particular emphasis will be placed on exploring innovative design approaches and computational fluid dynamics (CFD) simulations to streamline the internal geometry and flow paths within check valves. Potential solutions may include optimizing the valve body shape, modifying the valve seat and disc configurations, or incorporating advanced flow control mechanisms to minimize turbulence and pressure drops.

Particular emphasis will be placed on exploring innovative design approaches and computational fluid dynamics (CFD) simulations to streamline the internal geometry and flow paths within check valves. Potential solutions may include optimizing the valve body shape, modifying the valve seat and disc configurations, or incorporating advanced flow control mechanisms to minimize turbulence and pressure drops.

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, and water treatment. Key factors fueling this demand include the need for efficient fluid control, prevention of backflow, and compliance with safety regulations. - Industry Trends

Trends shaping the check valve market include the adoption of advanced materials for improved durability and corrosion resistance, the integration of smart technologies for remote monitoring and predictive maintenance, and the demand for compact and lightweight designs for space-constrained applications. - Application Sectors

Check valves find widespread applications across various sectors, including:- Oil and gas: Used in pipelines, refineries, and offshore platforms for controlling fluid flow and preventing backflow.

- Chemical processing: Essential for ensuring safe and efficient fluid transfer in chemical plants and processing facilities.

- Water and wastewater treatment: Employed in water distribution systems, sewage treatment plants, and desalination facilities.

- Power generation: Utilized in power plants, boilers, and steam systems for regulating fluid flow and preventing backflow.

Check Valve Flow Path Design Optimization: Technology Status And Challenges

- Valve Design Evolution

Tracing the development of check valve designs, from traditional swing and lift check valves to advanced designs like tilting disc, double disc, and nozzle check valves. - Flow Efficiency Challenges

Identifying key challenges in optimizing flow efficiency, such as minimizing pressure drop, preventing flow reversal, reducing turbulence and cavitation. - Material and Manufacturing Constraints

Discussing material selection and manufacturing limitations that impact flow path design, such as corrosion resistance, machining precision, and cost considerations. - Computational Fluid Dynamics (CFD) Modeling

Highlighting the role of CFD simulations in analyzing and optimizing flow paths, enabling virtual prototyping and design iterations.

Check Valve Flow Path Design Optimization: Current Technical Solutions

01 Streamlined Design

Optimizing check valve design features, such as streamlined body shapes, valve seat geometries, and reduced flow obstructions, can enhance flow efficiency by minimizing pressure drops and turbulence.- Optimized Valve Design: Streamlining the valve body shape, reducing turbulence, and minimizing flow restrictions through design optimization can enhance flow efficiency in check valves.

- Strategic Valve Positioning: Proper positioning and orientation of check valves within the fluid system, aligned with the flow direction, can minimize pressure drops and turbulence, improving overall flow performance.

- Low-Friction Materials and Coatings: Selecting materials with low friction coefficients and applying coatings that reduce turbulence can enhance fluid flow through the check valve.

- Optimized Valve Configurations: Different check valve configurations, such as swing, tilting disc, or lift mechanisms, offer varying flow characteristics, allowing for optimization based on application requirements.

- Maintenance and Monitoring: Regular inspections, cleaning, and replacement of worn components can prevent issues like leakage or valve sticking, maintaining optimal flow efficiency over time.

02 Low-Friction Materials

Using low-friction materials or coatings for check valve components can reduce surface roughness and minimize flow resistance, improving flow efficiency.Expand Specific Solutions03 Optimized Configurations

Different check valve configurations, like swing, tilting disc, or ball valves, offer varying flow characteristics, allowing selection based on application requirements for optimal flow efficiency.Expand Specific Solutions04 Sizing and Flow Path Optimization

Proper sizing of check valves and optimization of the flow path, including minimizing obstructions and optimizing inlet/outlet geometries, can enhance flow efficiency.Expand Specific Solutions05 Flow Control Mechanisms

Incorporating flow control or regulation mechanisms in check valves can help maintain optimal flow rates, prevent backflow, or regulate pressure drops, improving flow efficiency under varying conditions.Expand Specific Solutions

Check Valve Flow Path Design Optimization: Main Player Analysis

The competitive landscape for optimizing check valve flow path design is driven by established leaders and innovative newcomers. The industry aims to improve flow efficiency through efficient fluid control across various applications. Key players like Ford, Bendix, Bosch, and Schlumberger leverage extensive R&D capabilities, while academic institutions like MIT and NTNU contribute cutting-edge research.

Ford Global Technologies LLC

Technical Solution:

Bendix Commercial Vehicle Systems LLC

Technical Solution: Bendix develops advanced check valve designs using CFD simulations to optimize flow paths, reducing turbulence and pressure drops.

Strength: Advanced CFD simulations. Weakness: High development costs.

Check Valve Flow Path Design Optimization: Key Technology Interpretation

Pressure compensation valve

PatentPendingEP4105528A1

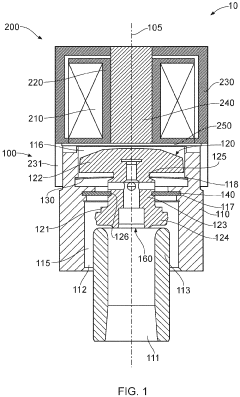

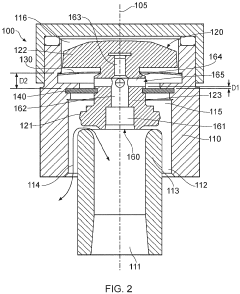

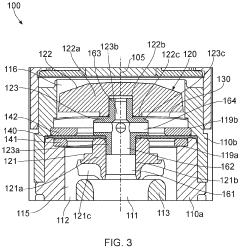

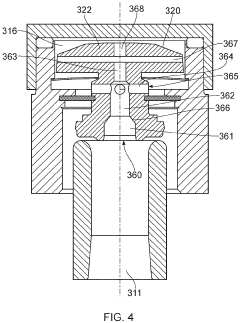

Innovation

- The arrangement of a pressure compensation flow path and the design of the valve body. the valve assembly includes a flexible membrane that forms a seal against the moveable member and the valve body, a biasing member to support and bias the moveable member in an axial direction, and a pressure compensation flow path that allows for fluid communication between a first fluid port and a second fluid port. one innovative aspect of this scheme is the inclusion of at least one opening in the pressure compensation flow path, which extends into the pressure compensation chamber between the armature and the flexible membrane. this design placesthe fluid in the pressure compensation chamber directly, allowing for faster transmission of fluctuations in fluid pressure between the first and second fluid ports.

- The pressure compensation flow path is formed from at least two axial portions with different cross-sectional areas, providing a controlled and optimized flow of fluid.

Check Valve Flow Path Design Optimization Economic Analysis

Check valve flow path optimization is crucial for improving flow efficiency and reducing energy losses. An economic analysis of this technology involves assessing the potential cost savings and return on investment from implementing optimized flow path designs. Key factors to consider include the upfront costs of research, development, and implementation, as well as the long-term operational cost reductions from improved flow efficiency. Additionally, the analysis should evaluate the potential market demand and revenue opportunities for optimized check valve products across various industries. By quantifying the economic benefits and comparing them to the required investments, businesses can make informed decisions about pursuing this technology and allocating resources effectively.

Check Valve Flow Path Design Optimization Policy And Regulatory Impact

The optimization of check valve flow path design aims to enhance flow efficiency by minimizing pressure losses and turbulence. This technology has significant implications for various industries, including oil and gas, chemical processing, and power generation, where check valves are widely employed to prevent backflow. By streamlining the flow path, pressure drops can be reduced, leading to energy savings and improved system performance. The market demand for optimized check valve designs is driven by the need for increased operational efficiency and cost-effectiveness across these sectors. Addressing this challenge requires a multidisciplinary approach, combining expertise in fluid dynamics, computational fluid dynamics (CFD) simulations, and advanced manufacturing techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!