Smart Actuation And Control For Check Valves

Check Valves Technology Background And Goals

Additionally, the report will clearly define the expected technological goals and capabilities that smart actuation and control systems for check valves aim to achieve. This will serve as a benchmark for evaluating the current state of the art and identifying areas that require further research and development efforts.

Check Valves Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, power generation, and water treatment. Factors such as infrastructure development, urbanization, and the need for efficient fluid control systems contribute to market expansion. - Industry Trends

Key trends shaping the check valve market include:- Increasing adoption of advanced materials like stainless steel and alloys for improved durability and corrosion resistance

- Rising demand for compact and lightweight valve designs to optimize space utilization

- Growing emphasis on energy-efficient and low-maintenance valve solutions

- Adoption of smart valve technologies with remote monitoring and control capabilities

- Application Sectors

Major application sectors driving the demand for check valves include:- Oil and gas industry: Used in pipelines, refineries, and offshore platforms

- Chemical processing: Essential for controlling fluid flow in chemical plants

- Power generation: Employed in steam and cooling water systems

- Water and wastewater treatment: Crucial for preventing backflow and maintaining system integrity

Check Valves Technology Status And Challenges

- Valve Actuation Mechanisms Various actuation mechanisms are employed to control check valve operation, including pneumatic, hydraulic, electric, and manual actuation. Each method has its advantages and limitations in terms of response time, precision, and reliability.

- Control Systems Integration Integrating check valves with advanced control systems enables real-time monitoring, remote operation, and predictive maintenance. However, challenges arise in ensuring seamless communication and compatibility between different components.

- Materials and Design Optimization Optimizing valve materials and design is crucial for improved durability, reduced wear, and enhanced performance. Challenges include selecting suitable materials for harsh environments and minimizing pressure losses.

- Condition Monitoring and Diagnostics Implementing condition monitoring and diagnostic techniques can help detect valve failures early and prevent costly downtime. Challenges involve developing reliable sensors and data analysis algorithms.

Check Valves Current Technical Solutions

01 Solenoid or Motor Actuation

Patents describe using solenoids or motors to actuate check valves, enabling precise control and automation based on various parameters or conditions.- Solenoid or Motor Actuation: Patents describe using solenoids or motors to actuate check valves, enabling precise control and automation based on various parameters or conditions.

- Electronic Circuit Control: Patents disclose using electronic circuits and controllers to monitor and control check valve operation, adjusting valve position based on sensor inputs.

- Wireless Communication Control: Patents describe using wireless technologies like Bluetooth or Wi-Fi for remote control and monitoring of check valves, enabling smart actuation from a distance.

- Sensor Integration for Monitoring: Patents discuss integrating sensors like pressure, flow, or position sensors with check valves for monitoring performance and making intelligent control decisions.

- Intelligent Algorithms for Control: Patents describe using intelligent algorithms like machine learning or fuzzy logic for optimizing check valve control based on various input parameters and conditions.

02 Electronic Circuit Control

Patents disclose using electronic circuits and control systems to monitor and control check valve operation, enabling smart and automated control based on sensor inputs.Expand Specific Solutions03 Integrated Sensors

Patents describe check valves with integrated sensors for detecting parameters like pressure, flow rate, or valve position, enabling smart control and monitoring.Expand Specific Solutions04 Wireless Communication Control

Patents discuss using wireless communication technologies for remote control and monitoring of check valves, enabling smart and centralized control from a single location.Expand Specific Solutions05 Self-Diagnostic Capabilities

Patents cover check valves with built-in self-diagnostic capabilities for detecting and reporting issues or malfunctions, enabling smart maintenance and troubleshooting.Expand Specific Solutions

Check Valves Main Player Analysis

SAMSON AG

Eaton Corp.

Check Valves Key Technology Interpretation

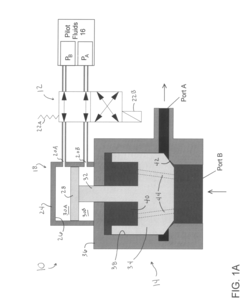

- The check valve assembly includes a movable member that can be controlled to enable bidirectional flow, allowing the valve to selectively check flow in either direction.

- The pilot valve assembly uses a pilot piston and stem to mechanically couple to and control the movable member of the check valve assembly.

- The valve system enables the displacement output of a pump/motor to be controlled by selectively operating individual check valve assemblies bidirectionally.

Environmental Impact

The integration of smart actuation and control technologies into check valves presents both opportunities and challenges in terms of environmental impact. On one hand, intelligent valve systems can contribute to more efficient fluid management, reducing energy consumption and minimizing waste. However, the manufacturing processes and materials involved may have environmental implications that need to be carefully considered.

One of the primary environmental benefits of smart check valves lies in their ability to optimize fluid flow and prevent backflow more effectively than traditional valves. This can lead to significant energy savings in various industrial processes, such as water distribution systems, chemical processing plants, and power generation facilities. By minimizing unnecessary pumping and reducing leakage, smart valves can help conserve resources and lower the overall carbon footprint of these operations.

Additionally, the real-time monitoring and predictive maintenance capabilities of smart check valves can extend their lifespan and reduce the need for frequent replacements. This not only translates into cost savings but also minimizes the environmental impact associated with the production and disposal of valve components.

However, the production of smart valves may involve the use of specialized materials and electronic components, which could have environmental implications during their manufacturing and disposal phases. Careful consideration should be given to the sourcing of raw materials, energy consumption during production, and the implementation of sustainable practices throughout the supply chain.

Furthermore, the integration of electronic components and sensors into check valves may raise concerns about electronic waste and the potential for hazardous materials to be released into the environment if not properly handled during disposal or recycling processes.

To mitigate these potential environmental impacts, manufacturers of smart check valves should prioritize eco-friendly design principles, such as using recyclable materials, minimizing the use of hazardous substances, and implementing closed-loop manufacturing processes. Additionally, proper end-of-life management strategies, including responsible recycling and disposal practices, should be established to ensure the responsible handling of electronic components and valve materials.

Overall, while smart check valves offer significant potential for environmental benefits through improved efficiency and resource conservation, their environmental impact should be carefully evaluated throughout their entire life cycle. Collaboration between manufacturers, regulators, and end-users is crucial to ensure that the adoption of these advanced valve technologies aligns with sustainable practices and minimizes any negative environmental consequences.

Policy And Regulatory Impact

The regulatory landscape for smart valves is a complex and evolving area, with various standards and guidelines governing their design, manufacturing, and deployment across different industries and regions. Ensuring compliance with these regulations is crucial for manufacturers and end-users to mitigate risks, maintain safety, and foster innovation.

At the international level, organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established standards for valve design, performance, and testing. These standards provide a framework for ensuring consistent quality, reliability, and interoperability of smart valves across different applications and markets.

In the United States, the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) have developed comprehensive codes and standards for valves used in various industries, including oil and gas, power generation, and chemical processing. These standards cover aspects such as material selection, design calculations, testing procedures, and maintenance requirements.

The European Union has implemented directives like the Pressure Equipment Directive (PED) and the Machinery Directive, which establish essential safety requirements for pressure equipment, including valves, and ensure the free movement of these products within the European market. Compliance with these directives is mandatory for manufacturers seeking to sell their products in the EU.

In addition to these overarching regulations, specific industries may have their own guidelines and best practices for smart valve implementation. For instance, the pharmaceutical industry adheres to Good Manufacturing Practices (GMP) and other regulatory requirements set by agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

As smart valve technology continues to evolve, regulatory bodies are actively working to update existing standards and develop new guidelines to address emerging challenges and opportunities. Collaboration between industry stakeholders, regulatory agencies, and standardization organizations is crucial to ensure a harmonized and effective regulatory framework that promotes innovation while maintaining safety and reliability.