Reducing Power Consumption Of Check Valves

NOV 8, 20244 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Reducing Power Consumption Of Check Valves: Technology Background And Goals

The primary objective is to investigate and analyze the current state, challenges, and potential solutions for reducing power consumption in check valves. This technology has significant implications for energy efficiency and sustainability across various industries.

Check valves are essential components in fluid systems, preventing backflow and ensuring proper flow direction. However, their operation can contribute to energy losses and increased power consumption. Addressing this issue is crucial for optimizing system performance and reducing environmental impact.

The analysis will delve into the current technological landscape, identifying key players, existing solutions, and their limitations. It will also explore emerging innovations, such as advanced materials, valve designs, and control mechanisms, that could potentially reduce power consumption while maintaining or enhancing valve functionality. By understanding the market demands, technological trends, and potential breakthroughs, this research aims to provide valuable insights for strategic planning and product development in this field.

The analysis will delve into the current technological landscape, identifying key players, existing solutions, and their limitations. It will also explore emerging innovations, such as advanced materials, valve designs, and control mechanisms, that could potentially reduce power consumption while maintaining or enhancing valve functionality. By understanding the market demands, technological trends, and potential breakthroughs, this research aims to provide valuable insights for strategic planning and product development in this field.

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, power generation, and water treatment. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% from 20XX to 20XX. - Industry Trends

Key trends shaping the check valve market include:- Rising focus on energy efficiency and reducing power consumption

- Increasing adoption of advanced materials for improved durability and performance

- Growing demand for compact and lightweight valve designs

- Application Segments

The major application segments for check valves include:- Oil and gas industry: Used in pipelines, refineries, and offshore platforms

- Power generation: Employed in thermal and nuclear power plants

- Water and wastewater treatment: Essential for controlling fluid flow in treatment systems

- Regional Outlook

The Asia-Pacific region is expected to dominate the check valve market, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold significant market shares due to stringent regulations and the presence of major valve manufacturers.

Reducing Power Consumption Of Check Valves: Technology Status And Challenges

- Valve Design Limitations

Current valve designs have inherent limitations in reducing power consumption, such as friction losses and inefficient flow paths. - Material Constraints

The choice of materials used in valve construction can impact power consumption, with some materials offering better thermal and flow properties. - Control System Inefficiencies

Existing control systems for valve operation may not be optimized for energy efficiency, leading to unnecessary power consumption. - Lack of Real-Time Monitoring

Without real-time monitoring of valve performance and energy usage, it is challenging to identify and address inefficiencies. - Integration Challenges

Integrating energy-efficient valve solutions with existing systems and infrastructure can pose technical and compatibility challenges.

Reducing Power Consumption Of Check Valves: Current Technical Solutions

01 Optimized Valve Design

Check valve designs aim to reduce power consumption through optimized geometry, lightweight materials, and efficient flow paths to minimize flow resistance and pressure drop.- Optimized Check Valve Design: Check valve designs aim to reduce power consumption by minimizing flow resistance and pressure drop through optimized geometry, lightweight materials, and mechanisms to reduce turbulence and friction losses.

- Intelligent Control Systems: Control systems and algorithms optimize check valve operation by adjusting opening/closing timing, monitoring flow conditions, and implementing energy-efficient control strategies to reduce power consumption.

- Low-Friction Materials and Coatings: The use of low-friction materials and coatings in check valve construction reduces frictional losses and improves flow efficiency, leading to lower power consumption.

- Maintenance and Monitoring: Regular maintenance and monitoring of check valves help identify and address issues that may lead to increased power consumption, such as wear, leakage, or improper operation.

- Energy Recovery Integration: Check valves can be integrated with energy recovery systems to capture and reuse energy that would otherwise be dissipated, leading to reduced power consumption.

02 Intelligent Control Systems

Control systems and algorithms regulate check valve operation to ensure optimal power consumption based on flow conditions and system requirements.Expand Specific Solutions03 Low-Friction Materials

Check valve designs incorporate low-friction materials and coatings to reduce frictional losses and minimize power consumption during valve operation.Expand Specific Solutions04 Performance Monitoring

Systems and methods for monitoring and diagnosing check valve performance enable timely maintenance and optimize power consumption through efficient valve operation.Expand Specific Solutions05 Power-Efficient Applications

Check valves are employed in various power-efficient systems, such as hydraulic systems, HVAC systems, and fluid distribution networks, to minimize energy losses and optimize power consumption.Expand Specific Solutions

Reducing Power Consumption Of Check Valves: Main Player Analysis

The competitive landscape for reducing power consumption of check valves is characterized by a mix of established players and emerging innovators. The industry is in a growth phase, driven by increasing demand for energy-efficient solutions. The market size is expanding as sectors like automotive, aerospace, and industrial machinery seek to optimize energy use.

DENSO Corp.

Technical Solution: DENSO Corp. has developed advanced check valve technologies aimed at reducing power consumption through lightweight materials and optimized valve designs.

Strength: Advanced material usage and design optimization. Weakness: High initial development cost.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC focuses on integrating smart control systems with check valves to reduce power consumption through real-time monitoring and adaptive control.

Strength: Real-time monitoring and adaptive control. Weakness: Complexity in system integration.

Reducing Power Consumption Of Check Valves: Key Technology Interpretation

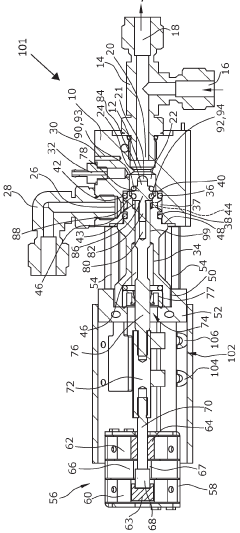

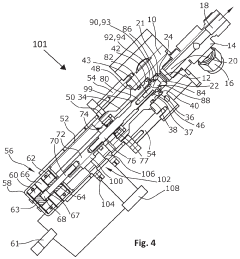

valve device for shutting off and opening a gas flow to an analyzer of a gas measuring system

PatentActiveAT520721A4

Innovation

- Proposing a valve device that reduces power consumption and checks the correct positioning of the valve unit for shutting off and opening a gas flow to an analyzer of a gas measuring system.

- Integrating power consumption reduction and valve positioning verification into a single valve device for gas analyzers.

- ^|Investigate advanced sensor technologies or algorithms for more accurate and energy-efficient valve positioning monitoring.

Check Valve Power Consumption Reduction Economic Analysis

Check valves are essential components in various industrial systems, ensuring efficient and safe fluid flow control. However, their operation can contribute to significant energy consumption, leading to increased operational costs and environmental impact. Reducing power consumption of check valves is a crucial objective for enhancing energy efficiency and sustainability. This economic analysis aims to evaluate the potential cost savings and environmental benefits associated with implementing power-saving strategies for check valves. By examining the economic implications, this analysis can provide valuable insights to support informed decision-making and drive the adoption of energy-efficient solutions in the industry.

Check Valve Power Consumption Reduction Policy And Regulatory Impact

Check valves are essential components in various industrial systems, ensuring proper fluid flow and preventing backflow. However, their operation can contribute to significant power consumption, leading to increased energy costs and environmental impact. Addressing this issue is crucial for improving energy efficiency and sustainability.

The regulatory landscape surrounding power consumption in check valves is evolving rapidly. Governments and industry bodies are implementing stricter regulations and policies to promote energy-efficient practices and reduce carbon footprints. These regulations often mandate specific performance standards, energy labeling, and incentives for adopting energy-saving technologies. Failure to comply can result in penalties or market exclusion.

Assessing the impact of these regulations is vital for businesses operating in this domain. It involves analyzing the potential costs associated with compliance, such as retrofitting existing systems or investing in new technologies. Additionally, it requires evaluating the potential benefits, including cost savings from reduced energy consumption, improved competitiveness, and access to new markets with stringent environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!