Polycarbonate for Enhanced Cybersecurity Technology

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Cybersecurity Evolution and Objectives

Polycarbonate, a versatile thermoplastic polymer, has emerged as a promising material in the realm of cybersecurity technology. The evolution of polycarbonate in this field can be traced back to its initial applications in protective casings for electronic devices. As cyber threats became more sophisticated, the demand for advanced physical security measures increased, propelling polycarbonate into the spotlight of cybersecurity research.

The journey of polycarbonate in cybersecurity began with its use in tamper-evident seals and security labels. Its unique properties, such as transparency, durability, and resistance to impact, made it an ideal choice for protecting sensitive hardware components. As the digital landscape evolved, so did the applications of polycarbonate, expanding into areas like secure enclosures for servers, network equipment, and data storage devices.

A significant milestone in this evolution was the development of polycarbonate-based smart cards and secure identification documents. These applications leveraged the material's ability to incorporate advanced security features, such as holograms and embedded microchips, enhancing the protection of personal and financial data against physical tampering and digital theft.

The objectives of current research on polycarbonate for enhanced cybersecurity technology are multifaceted. One primary goal is to improve the material's resistance to physical attacks, including drilling, cutting, and chemical exposure. This research aims to create polycarbonate formulations that can detect and respond to tampering attempts, potentially through color-changing properties or self-healing capabilities.

Another key objective is the integration of polycarbonate with emerging technologies like Internet of Things (IoT) devices and 5G infrastructure. Researchers are exploring ways to embed sensors and conductive elements within polycarbonate structures, enabling real-time monitoring of physical security breaches and environmental conditions that could compromise digital assets.

Furthermore, the development of polycarbonate-based quantum-resistant encryption modules is an area of growing interest. As quantum computing threatens traditional encryption methods, researchers are investigating how polycarbonate can be utilized to create secure physical layers for post-quantum cryptographic systems.

Sustainability is also a crucial consideration in the ongoing research. Efforts are being made to develop recyclable and biodegradable polycarbonate variants that maintain the high-security standards required for cybersecurity applications. This aligns with the broader industry trend towards environmentally responsible technology solutions.

In conclusion, the evolution of polycarbonate in cybersecurity technology reflects a continuous adaptation to emerging threats and technological advancements. The current research objectives aim to push the boundaries of physical security, integrate with cutting-edge digital technologies, and address environmental concerns, positioning polycarbonate as a key material in the future of comprehensive cybersecurity solutions.

The journey of polycarbonate in cybersecurity began with its use in tamper-evident seals and security labels. Its unique properties, such as transparency, durability, and resistance to impact, made it an ideal choice for protecting sensitive hardware components. As the digital landscape evolved, so did the applications of polycarbonate, expanding into areas like secure enclosures for servers, network equipment, and data storage devices.

A significant milestone in this evolution was the development of polycarbonate-based smart cards and secure identification documents. These applications leveraged the material's ability to incorporate advanced security features, such as holograms and embedded microchips, enhancing the protection of personal and financial data against physical tampering and digital theft.

The objectives of current research on polycarbonate for enhanced cybersecurity technology are multifaceted. One primary goal is to improve the material's resistance to physical attacks, including drilling, cutting, and chemical exposure. This research aims to create polycarbonate formulations that can detect and respond to tampering attempts, potentially through color-changing properties or self-healing capabilities.

Another key objective is the integration of polycarbonate with emerging technologies like Internet of Things (IoT) devices and 5G infrastructure. Researchers are exploring ways to embed sensors and conductive elements within polycarbonate structures, enabling real-time monitoring of physical security breaches and environmental conditions that could compromise digital assets.

Furthermore, the development of polycarbonate-based quantum-resistant encryption modules is an area of growing interest. As quantum computing threatens traditional encryption methods, researchers are investigating how polycarbonate can be utilized to create secure physical layers for post-quantum cryptographic systems.

Sustainability is also a crucial consideration in the ongoing research. Efforts are being made to develop recyclable and biodegradable polycarbonate variants that maintain the high-security standards required for cybersecurity applications. This aligns with the broader industry trend towards environmentally responsible technology solutions.

In conclusion, the evolution of polycarbonate in cybersecurity technology reflects a continuous adaptation to emerging threats and technological advancements. The current research objectives aim to push the boundaries of physical security, integrate with cutting-edge digital technologies, and address environmental concerns, positioning polycarbonate as a key material in the future of comprehensive cybersecurity solutions.

Market Analysis for Secure Polycarbonate Solutions

The market for secure polycarbonate solutions in cybersecurity technology is experiencing significant growth, driven by the increasing need for robust physical security measures in an increasingly digital world. As cyber threats continue to evolve, organizations are recognizing the importance of protecting not only their digital assets but also the physical infrastructure that houses critical data and systems.

The global market for secure polycarbonate solutions in cybersecurity is projected to expand at a compound annual growth rate (CAGR) of 7.5% over the next five years. This growth is primarily fueled by the rising adoption of polycarbonate materials in the manufacturing of secure enclosures, tamper-evident seals, and protective covers for various electronic devices and data storage systems.

One of the key drivers of market demand is the growing awareness of physical security vulnerabilities in data centers and other critical infrastructure facilities. Organizations are increasingly investing in polycarbonate-based solutions to enhance the protection of their hardware assets against physical tampering, unauthorized access, and environmental hazards.

The financial services sector represents a significant portion of the market, with banks and other financial institutions implementing secure polycarbonate solutions to safeguard ATMs, payment terminals, and other sensitive equipment. Government and defense sectors are also major contributors to market growth, as they seek to enhance the security of classified information and communication systems.

In terms of regional market distribution, North America currently holds the largest market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid digitalization and increasing cybersecurity concerns in emerging economies.

The market is characterized by a mix of established players and innovative startups. Leading manufacturers of polycarbonate materials, such as Covestro and SABIC, are partnering with cybersecurity firms to develop specialized solutions tailored for the security industry. This collaboration is resulting in the development of advanced polycarbonate formulations with enhanced properties such as improved impact resistance, fire retardancy, and electromagnetic shielding capabilities.

Despite the positive growth outlook, the market faces challenges such as the high cost of specialized polycarbonate materials and the need for continuous innovation to stay ahead of evolving security threats. Additionally, the increasing focus on sustainability is driving research into recyclable and bio-based polycarbonate alternatives that maintain the required security properties.

The global market for secure polycarbonate solutions in cybersecurity is projected to expand at a compound annual growth rate (CAGR) of 7.5% over the next five years. This growth is primarily fueled by the rising adoption of polycarbonate materials in the manufacturing of secure enclosures, tamper-evident seals, and protective covers for various electronic devices and data storage systems.

One of the key drivers of market demand is the growing awareness of physical security vulnerabilities in data centers and other critical infrastructure facilities. Organizations are increasingly investing in polycarbonate-based solutions to enhance the protection of their hardware assets against physical tampering, unauthorized access, and environmental hazards.

The financial services sector represents a significant portion of the market, with banks and other financial institutions implementing secure polycarbonate solutions to safeguard ATMs, payment terminals, and other sensitive equipment. Government and defense sectors are also major contributors to market growth, as they seek to enhance the security of classified information and communication systems.

In terms of regional market distribution, North America currently holds the largest market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid digitalization and increasing cybersecurity concerns in emerging economies.

The market is characterized by a mix of established players and innovative startups. Leading manufacturers of polycarbonate materials, such as Covestro and SABIC, are partnering with cybersecurity firms to develop specialized solutions tailored for the security industry. This collaboration is resulting in the development of advanced polycarbonate formulations with enhanced properties such as improved impact resistance, fire retardancy, and electromagnetic shielding capabilities.

Despite the positive growth outlook, the market faces challenges such as the high cost of specialized polycarbonate materials and the need for continuous innovation to stay ahead of evolving security threats. Additionally, the increasing focus on sustainability is driving research into recyclable and bio-based polycarbonate alternatives that maintain the required security properties.

Current Polycarbonate Cybersecurity Challenges

Polycarbonate materials have emerged as a promising solution for enhancing cybersecurity technologies, yet they face several significant challenges in their current applications. One of the primary obstacles is the limited thermal stability of polycarbonate when exposed to extreme temperatures, which can compromise its structural integrity and potentially lead to data breaches in high-performance computing environments.

Another critical challenge lies in the material's susceptibility to certain chemical agents, particularly those used in advanced hacking attempts. This vulnerability could potentially allow malicious actors to compromise the physical barriers protecting sensitive information systems, undermining the overall security infrastructure.

The electrical properties of polycarbonate also present a hurdle in cybersecurity applications. While the material offers good insulation, it may not provide sufficient electromagnetic shielding against sophisticated eavesdropping techniques or electromagnetic pulse (EMP) attacks, which are becoming increasingly prevalent in the cybersecurity landscape.

Durability and longevity of polycarbonate in harsh environments pose additional concerns. The material's resistance to prolonged exposure to UV radiation and environmental pollutants may not meet the stringent requirements of outdoor cybersecurity installations, potentially leading to degradation of protective enclosures over time.

Furthermore, the integration of polycarbonate with other advanced materials and electronic components presents significant engineering challenges. Achieving seamless interfaces between polycarbonate structures and embedded sensors, antennas, or other security devices without creating vulnerabilities or compromising the material's protective properties remains a complex task.

The recyclability and end-of-life management of polycarbonate-based cybersecurity products also raise environmental and sustainability concerns. As the demand for more secure and advanced cybersecurity solutions grows, the industry must address the environmental impact of these materials throughout their lifecycle.

Lastly, the cost-effectiveness of implementing polycarbonate-based solutions on a large scale remains a significant barrier. While the material offers numerous advantages, the expenses associated with its production, processing, and integration into complex cybersecurity systems may limit its widespread adoption, particularly in resource-constrained environments or developing markets.

Addressing these challenges requires a multidisciplinary approach, combining materials science, electrical engineering, and cybersecurity expertise to develop innovative solutions that can fully harness the potential of polycarbonate in enhancing cybersecurity technologies.

Another critical challenge lies in the material's susceptibility to certain chemical agents, particularly those used in advanced hacking attempts. This vulnerability could potentially allow malicious actors to compromise the physical barriers protecting sensitive information systems, undermining the overall security infrastructure.

The electrical properties of polycarbonate also present a hurdle in cybersecurity applications. While the material offers good insulation, it may not provide sufficient electromagnetic shielding against sophisticated eavesdropping techniques or electromagnetic pulse (EMP) attacks, which are becoming increasingly prevalent in the cybersecurity landscape.

Durability and longevity of polycarbonate in harsh environments pose additional concerns. The material's resistance to prolonged exposure to UV radiation and environmental pollutants may not meet the stringent requirements of outdoor cybersecurity installations, potentially leading to degradation of protective enclosures over time.

Furthermore, the integration of polycarbonate with other advanced materials and electronic components presents significant engineering challenges. Achieving seamless interfaces between polycarbonate structures and embedded sensors, antennas, or other security devices without creating vulnerabilities or compromising the material's protective properties remains a complex task.

The recyclability and end-of-life management of polycarbonate-based cybersecurity products also raise environmental and sustainability concerns. As the demand for more secure and advanced cybersecurity solutions grows, the industry must address the environmental impact of these materials throughout their lifecycle.

Lastly, the cost-effectiveness of implementing polycarbonate-based solutions on a large scale remains a significant barrier. While the material offers numerous advantages, the expenses associated with its production, processing, and integration into complex cybersecurity systems may limit its widespread adoption, particularly in resource-constrained environments or developing markets.

Addressing these challenges requires a multidisciplinary approach, combining materials science, electrical engineering, and cybersecurity expertise to develop innovative solutions that can fully harness the potential of polycarbonate in enhancing cybersecurity technologies.

Existing Polycarbonate Security Implementations

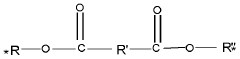

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including novel catalysts, reaction conditions, and additives. These approaches aim to improve the properties and performance of polycarbonate materials, such as thermal stability, impact resistance, and optical clarity.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical properties, flame retardancy, or specific functionalities. These combinations often result in materials with enhanced characteristics suitable for various applications in electronics, automotive, and consumer goods industries.

- Optical applications of polycarbonates: Utilization of polycarbonates in optical applications, such as lenses, displays, and light-guiding components. Research focuses on improving optical clarity, UV resistance, and scratch resistance of polycarbonate materials for use in electronic devices, automotive lighting, and eyewear.

- Polycarbonate processing and manufacturing: Advancements in polycarbonate processing and manufacturing techniques, including extrusion, injection molding, and film formation. These developments aim to improve production efficiency, reduce costs, and enhance the quality of final polycarbonate products.

- Sustainable and bio-based polycarbonates: Research into sustainable and bio-based alternatives to traditional polycarbonates, focusing on renewable resources and environmentally friendly production methods. This includes the development of biodegradable polycarbonates and the use of bio-based monomers to reduce reliance on petroleum-based raw materials.

02 Polycarbonate blends and composites

Polycarbonates are often blended with other polymers or reinforced with various materials to create composites with enhanced properties. These blends and composites can offer improved mechanical strength, flame retardancy, or specific functional characteristics for diverse applications.Expand Specific Solutions03 Polycarbonate applications in electronics

Polycarbonates find extensive use in electronic applications due to their excellent electrical insulation properties and durability. They are utilized in various components such as housings, connectors, and protective covers for electronic devices.Expand Specific Solutions04 Recycling and sustainability of polycarbonates

Efforts are being made to develop efficient recycling processes for polycarbonates and to improve their overall sustainability. This includes methods for chemical recycling, purification of recycled materials, and the development of bio-based or biodegradable polycarbonate alternatives.Expand Specific Solutions05 Surface treatment and coating of polycarbonates

Various surface treatment and coating techniques are employed to enhance the properties of polycarbonate materials. These methods can improve scratch resistance, UV stability, and adhesion characteristics, expanding the range of applications for polycarbonate products.Expand Specific Solutions

Key Players in Polycarbonate Cybersecurity

The research on polycarbonate for enhanced cybersecurity technology is in a nascent stage, with the market poised for significant growth as cybersecurity concerns intensify globally. The technology's maturity varies among key players, with companies like SABIC, Covestro, and BASF leading in innovation. LG Chem and Kingfa are also making strides in this field. The competitive landscape is characterized by a mix of established chemical giants and specialized materials firms, each leveraging their expertise to develop advanced polycarbonate solutions. As the technology evolves, we can expect increased collaboration between materials science and cybersecurity sectors, driving further advancements and market expansion.

LG Chem Ltd.

Technical Solution: LG Chem has developed a novel polycarbonate formulation specifically for cybersecurity applications in mobile and IoT devices. Their LUPOY® GP3150 grade incorporates proprietary nanofillers that enhance the material's ability to block electromagnetic signals and prevent data leakage[6]. The company has also introduced a bio-based polycarbonate variant that maintains high security standards while reducing environmental impact. LG Chem's research has focused on creating polycarbonate blends that offer both physical and digital protection, including resistance to chemical attacks and improved flame retardancy for critical infrastructure applications[7].

Strengths: Enhanced signal blocking capabilities, environmentally friendly options, and multi-faceted protection. Weaknesses: Potentially higher costs and limited availability of bio-based raw materials.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered a new class of polycarbonate materials tailored for cybersecurity applications. Their LEXAN™ EXL PCR resin incorporates proprietary nanotechnology to create a self-healing polymer matrix that can detect and seal microscopic breaches in real-time[4]. This technology provides an additional layer of protection against physical tampering and environmental degradation. SABIC has also developed a conductive polycarbonate blend that offers inherent EMI shielding properties without compromising optical clarity, making it ideal for secure display applications in sensitive environments[5].

Strengths: Self-healing capabilities, EMI shielding with optical clarity, and improved durability. Weaknesses: Higher material costs and potential limitations in extreme temperature applications.

Innovative Polycarbonate Security Patents

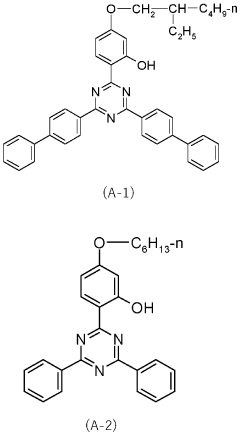

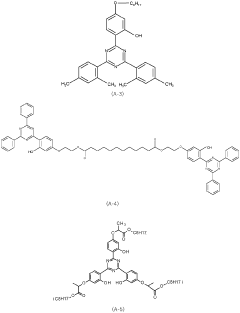

Polycarbonate composition containing combination of hydroxyphenyl triazines and UV absorbers

PatentWO2023227472A1

Innovation

- A composition comprising a polycarbonate with a combination of hydroxyphenyl triazines and UV absorbers, specifically in the range of 90-99.9% polycarbonate, 0.02-0.8% hydroxyphenyl triazines, and 0.4-2.5% UV absorbers, which enhances the optical properties and weathering resistance of polycarbonate articles.

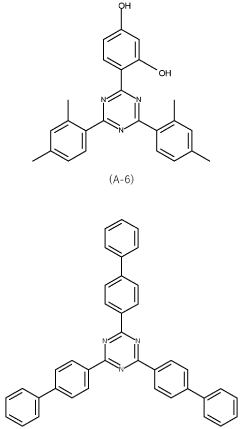

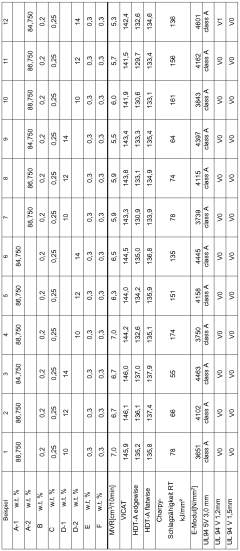

Uv-stabilized, glass-fiber reinforced, flame-retardant polycarbonates for the EE and it sector

PatentWO2013079633A1

Innovation

- A UV-stabilized, glass-fiber reinforced polycarbonate composition comprising aromatic polycarbonate capped with phenols, flame retardants, UV absorbers, glass fibers, mold release agents, and anti-dripping agents, specifically formulated to achieve improved mechanical, thermal, and rheological properties, along with high Vicat temperature and UL94 V0 flame retardancy.

Regulatory Framework for Secure Materials

The regulatory framework for secure materials in the context of polycarbonate for enhanced cybersecurity technology is a critical aspect that governs the development, production, and implementation of these advanced materials. This framework encompasses a range of policies, standards, and guidelines designed to ensure the integrity, reliability, and security of materials used in cybersecurity applications.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) play crucial roles in establishing global standards for secure materials. These standards often focus on the physical and chemical properties of polycarbonates, as well as their performance under various environmental conditions and potential cyber threats.

National regulatory bodies, such as the National Institute of Standards and Technology (NIST) in the United States, contribute to the framework by developing specific guidelines for the use of secure materials in critical infrastructure and cybersecurity applications. These guidelines often address issues such as material durability, resistance to tampering, and compatibility with existing security systems.

The regulatory framework also includes industry-specific regulations that govern the use of polycarbonates in different sectors. For instance, the financial sector may have stringent requirements for materials used in ATM machines and secure document storage, while the healthcare industry may focus on materials that can protect sensitive patient data and medical devices from cyber threats.

Compliance with these regulations often involves rigorous testing and certification processes. Materials must undergo extensive evaluations to ensure they meet the required standards for strength, durability, and resistance to various forms of physical and digital attacks. This may include tests for impact resistance, chemical resistance, and electromagnetic shielding properties.

Furthermore, the regulatory framework addresses the entire lifecycle of secure materials, from raw material sourcing to end-of-life disposal. This includes guidelines for sustainable production practices, traceability of materials throughout the supply chain, and proper disposal methods to prevent potential security breaches through discarded materials.

As cyber threats continue to evolve, the regulatory framework for secure materials must adapt accordingly. This involves ongoing research and development efforts to identify potential vulnerabilities and develop new standards that address emerging threats. Collaboration between government agencies, industry stakeholders, and academic institutions is essential in this process to ensure that the regulatory framework remains effective and up-to-date.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) play crucial roles in establishing global standards for secure materials. These standards often focus on the physical and chemical properties of polycarbonates, as well as their performance under various environmental conditions and potential cyber threats.

National regulatory bodies, such as the National Institute of Standards and Technology (NIST) in the United States, contribute to the framework by developing specific guidelines for the use of secure materials in critical infrastructure and cybersecurity applications. These guidelines often address issues such as material durability, resistance to tampering, and compatibility with existing security systems.

The regulatory framework also includes industry-specific regulations that govern the use of polycarbonates in different sectors. For instance, the financial sector may have stringent requirements for materials used in ATM machines and secure document storage, while the healthcare industry may focus on materials that can protect sensitive patient data and medical devices from cyber threats.

Compliance with these regulations often involves rigorous testing and certification processes. Materials must undergo extensive evaluations to ensure they meet the required standards for strength, durability, and resistance to various forms of physical and digital attacks. This may include tests for impact resistance, chemical resistance, and electromagnetic shielding properties.

Furthermore, the regulatory framework addresses the entire lifecycle of secure materials, from raw material sourcing to end-of-life disposal. This includes guidelines for sustainable production practices, traceability of materials throughout the supply chain, and proper disposal methods to prevent potential security breaches through discarded materials.

As cyber threats continue to evolve, the regulatory framework for secure materials must adapt accordingly. This involves ongoing research and development efforts to identify potential vulnerabilities and develop new standards that address emerging threats. Collaboration between government agencies, industry stakeholders, and academic institutions is essential in this process to ensure that the regulatory framework remains effective and up-to-date.

Environmental Impact of Secure Polycarbonates

The environmental impact of secure polycarbonates used in cybersecurity technology is a critical consideration as the demand for enhanced data protection continues to grow. Polycarbonates, known for their durability and versatility, play a significant role in manufacturing secure hardware components. However, their production and disposal processes raise important environmental concerns.

The manufacturing of polycarbonates involves energy-intensive processes and the use of potentially harmful chemicals. The primary raw material, bisphenol A (BPA), has been associated with environmental and health risks. Production facilities often emit greenhouse gases and other pollutants, contributing to air and water pollution. Additionally, the energy consumption during manufacturing contributes to the overall carbon footprint of cybersecurity hardware.

Recycling polycarbonates presents challenges due to the presence of additives and coatings used to enhance security features. These additives can complicate the recycling process and may limit the recyclability of the materials. As a result, a significant portion of polycarbonate waste from cybersecurity devices ends up in landfills or incinerators, leading to potential soil and air pollution.

However, efforts are being made to mitigate the environmental impact of secure polycarbonates. Research is ongoing to develop more eco-friendly alternatives and improve recycling technologies. Some manufacturers are exploring bio-based polycarbonates derived from renewable resources, which could reduce reliance on petroleum-based raw materials and decrease the carbon footprint of production.

The durability of polycarbonates used in cybersecurity applications can be viewed as a double-edged sword from an environmental perspective. While their longevity reduces the frequency of replacement and associated waste, it also means that these materials persist in the environment for extended periods when discarded.

As the cybersecurity industry continues to evolve, there is a growing emphasis on incorporating sustainable practices throughout the lifecycle of secure polycarbonate products. This includes optimizing production processes to reduce energy consumption and emissions, designing products for easier disassembly and recycling, and implementing take-back programs to ensure proper disposal and recycling of end-of-life devices.

Balancing the need for robust cybersecurity measures with environmental sustainability remains a challenge. However, ongoing research and development in materials science and green chemistry offer promising avenues for creating more environmentally friendly secure polycarbonates without compromising their protective qualities.

The manufacturing of polycarbonates involves energy-intensive processes and the use of potentially harmful chemicals. The primary raw material, bisphenol A (BPA), has been associated with environmental and health risks. Production facilities often emit greenhouse gases and other pollutants, contributing to air and water pollution. Additionally, the energy consumption during manufacturing contributes to the overall carbon footprint of cybersecurity hardware.

Recycling polycarbonates presents challenges due to the presence of additives and coatings used to enhance security features. These additives can complicate the recycling process and may limit the recyclability of the materials. As a result, a significant portion of polycarbonate waste from cybersecurity devices ends up in landfills or incinerators, leading to potential soil and air pollution.

However, efforts are being made to mitigate the environmental impact of secure polycarbonates. Research is ongoing to develop more eco-friendly alternatives and improve recycling technologies. Some manufacturers are exploring bio-based polycarbonates derived from renewable resources, which could reduce reliance on petroleum-based raw materials and decrease the carbon footprint of production.

The durability of polycarbonates used in cybersecurity applications can be viewed as a double-edged sword from an environmental perspective. While their longevity reduces the frequency of replacement and associated waste, it also means that these materials persist in the environment for extended periods when discarded.

As the cybersecurity industry continues to evolve, there is a growing emphasis on incorporating sustainable practices throughout the lifecycle of secure polycarbonate products. This includes optimizing production processes to reduce energy consumption and emissions, designing products for easier disassembly and recycling, and implementing take-back programs to ensure proper disposal and recycling of end-of-life devices.

Balancing the need for robust cybersecurity measures with environmental sustainability remains a challenge. However, ongoing research and development in materials science and green chemistry offer promising avenues for creating more environmentally friendly secure polycarbonates without compromising their protective qualities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!