Polycarbonate for Next-Generation Energy Solutions

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in Energy: Background and Objectives

Polycarbonate, a versatile thermoplastic polymer, has been a cornerstone in various industries since its discovery in the 1950s. Its unique combination of properties, including high impact resistance, optical clarity, and thermal stability, has made it an invaluable material in applications ranging from automotive to electronics. In recent years, the focus on sustainable and efficient energy solutions has brought polycarbonate to the forefront of energy-related research and development.

The evolution of polycarbonate in the energy sector has been marked by continuous improvements in its chemical and physical properties. Initially used primarily for its durability and insulation properties, polycarbonate has now emerged as a potential game-changer in next-generation energy solutions. This shift is driven by the global push towards renewable energy sources and the need for more efficient energy storage and transmission systems.

The primary objective of researching polycarbonate for next-generation energy solutions is to harness its unique properties to address critical challenges in the energy sector. These challenges include improving the efficiency of solar panels, enhancing the performance of batteries and fuel cells, and developing more durable and lightweight components for wind turbines and other renewable energy infrastructure.

One of the key areas of focus is the application of polycarbonate in photovoltaic systems. Researchers are exploring ways to utilize polycarbonate's optical properties and durability to create more efficient and longer-lasting solar panels. This includes developing new formulations of polycarbonate that can withstand harsh environmental conditions while maintaining optimal light transmission.

In the field of energy storage, polycarbonate is being investigated for its potential in improving battery technology. The polymer's properties make it an attractive option for battery casings and separators, potentially leading to safer and more efficient energy storage solutions. Additionally, research is underway to explore polycarbonate's role in advanced fuel cell technologies, where its chemical resistance and thermal stability could prove invaluable.

The development of polycarbonate for energy applications also aligns with the broader trend of sustainable materials in the energy sector. As the world moves towards a circular economy, there is a growing emphasis on developing recyclable and biodegradable versions of polycarbonate, ensuring that these next-generation energy solutions are not only efficient but also environmentally friendly.

As we delve deeper into the research on polycarbonate for next-generation energy solutions, it becomes clear that this material has the potential to revolutionize multiple aspects of the energy sector. From enhancing the performance of renewable energy technologies to improving energy storage and transmission systems, polycarbonate stands at the cusp of playing a pivotal role in shaping the future of sustainable energy.

The evolution of polycarbonate in the energy sector has been marked by continuous improvements in its chemical and physical properties. Initially used primarily for its durability and insulation properties, polycarbonate has now emerged as a potential game-changer in next-generation energy solutions. This shift is driven by the global push towards renewable energy sources and the need for more efficient energy storage and transmission systems.

The primary objective of researching polycarbonate for next-generation energy solutions is to harness its unique properties to address critical challenges in the energy sector. These challenges include improving the efficiency of solar panels, enhancing the performance of batteries and fuel cells, and developing more durable and lightweight components for wind turbines and other renewable energy infrastructure.

One of the key areas of focus is the application of polycarbonate in photovoltaic systems. Researchers are exploring ways to utilize polycarbonate's optical properties and durability to create more efficient and longer-lasting solar panels. This includes developing new formulations of polycarbonate that can withstand harsh environmental conditions while maintaining optimal light transmission.

In the field of energy storage, polycarbonate is being investigated for its potential in improving battery technology. The polymer's properties make it an attractive option for battery casings and separators, potentially leading to safer and more efficient energy storage solutions. Additionally, research is underway to explore polycarbonate's role in advanced fuel cell technologies, where its chemical resistance and thermal stability could prove invaluable.

The development of polycarbonate for energy applications also aligns with the broader trend of sustainable materials in the energy sector. As the world moves towards a circular economy, there is a growing emphasis on developing recyclable and biodegradable versions of polycarbonate, ensuring that these next-generation energy solutions are not only efficient but also environmentally friendly.

As we delve deeper into the research on polycarbonate for next-generation energy solutions, it becomes clear that this material has the potential to revolutionize multiple aspects of the energy sector. From enhancing the performance of renewable energy technologies to improving energy storage and transmission systems, polycarbonate stands at the cusp of playing a pivotal role in shaping the future of sustainable energy.

Market Analysis for PC-Based Energy Solutions

The market for polycarbonate-based energy solutions is experiencing significant growth, driven by the increasing demand for sustainable and efficient energy technologies. As the world transitions towards cleaner energy sources, polycarbonate materials are finding new applications in various sectors of the energy industry. The versatility, durability, and thermal properties of polycarbonate make it an attractive option for next-generation energy solutions.

In the solar energy sector, polycarbonate is gaining traction as a lightweight and cost-effective alternative to traditional glass panels. The market for polycarbonate solar panels is expected to expand rapidly, particularly in regions with extreme weather conditions where durability is crucial. Additionally, the automotive industry is increasingly adopting polycarbonate-based components for electric vehicles, including battery casings and thermal management systems, contributing to the overall market growth.

The energy storage sector presents another significant opportunity for polycarbonate-based solutions. As the demand for grid-scale and residential energy storage systems rises, polycarbonate materials are being utilized in battery casings and structural components due to their excellent insulation properties and fire resistance. This trend is likely to continue as countries invest heavily in renewable energy infrastructure and smart grid technologies.

In the wind energy sector, polycarbonate is finding applications in turbine blade coatings and nacelle components, offering improved durability and weather resistance. The market for these specialized polycarbonate products is expected to grow in tandem with the expansion of offshore and onshore wind farms globally.

The building and construction industry is also contributing to the market growth of polycarbonate-based energy solutions. Energy-efficient building materials, such as polycarbonate roofing and wall systems, are gaining popularity due to their thermal insulation properties and ability to reduce energy consumption in buildings.

Geographically, Asia-Pacific is emerging as a key market for polycarbonate-based energy solutions, driven by rapid industrialization, urbanization, and government initiatives promoting clean energy adoption. North America and Europe continue to be significant markets, with a focus on innovation and high-performance applications in the energy sector.

Despite the positive outlook, the market faces challenges such as fluctuating raw material prices and competition from alternative materials. However, ongoing research and development efforts are focused on enhancing the performance and sustainability of polycarbonate-based energy solutions, which is expected to open up new market opportunities and drive long-term growth in this sector.

In the solar energy sector, polycarbonate is gaining traction as a lightweight and cost-effective alternative to traditional glass panels. The market for polycarbonate solar panels is expected to expand rapidly, particularly in regions with extreme weather conditions where durability is crucial. Additionally, the automotive industry is increasingly adopting polycarbonate-based components for electric vehicles, including battery casings and thermal management systems, contributing to the overall market growth.

The energy storage sector presents another significant opportunity for polycarbonate-based solutions. As the demand for grid-scale and residential energy storage systems rises, polycarbonate materials are being utilized in battery casings and structural components due to their excellent insulation properties and fire resistance. This trend is likely to continue as countries invest heavily in renewable energy infrastructure and smart grid technologies.

In the wind energy sector, polycarbonate is finding applications in turbine blade coatings and nacelle components, offering improved durability and weather resistance. The market for these specialized polycarbonate products is expected to grow in tandem with the expansion of offshore and onshore wind farms globally.

The building and construction industry is also contributing to the market growth of polycarbonate-based energy solutions. Energy-efficient building materials, such as polycarbonate roofing and wall systems, are gaining popularity due to their thermal insulation properties and ability to reduce energy consumption in buildings.

Geographically, Asia-Pacific is emerging as a key market for polycarbonate-based energy solutions, driven by rapid industrialization, urbanization, and government initiatives promoting clean energy adoption. North America and Europe continue to be significant markets, with a focus on innovation and high-performance applications in the energy sector.

Despite the positive outlook, the market faces challenges such as fluctuating raw material prices and competition from alternative materials. However, ongoing research and development efforts are focused on enhancing the performance and sustainability of polycarbonate-based energy solutions, which is expected to open up new market opportunities and drive long-term growth in this sector.

Current PC Technology and Challenges in Energy Sector

Polycarbonate (PC) has emerged as a promising material in the energy sector, particularly for next-generation energy solutions. Currently, PC is widely used in various energy-related applications due to its unique combination of properties, including high impact strength, optical clarity, and thermal stability. In the solar energy industry, PC is utilized for manufacturing photovoltaic module components, such as backsheets and junction boxes, enhancing the durability and efficiency of solar panels.

The automotive sector has also embraced PC technology for lightweight vehicle components and battery casings in electric vehicles, contributing to improved energy efficiency and range. Additionally, PC finds applications in wind turbine components, energy-efficient lighting systems, and smart grid infrastructure, showcasing its versatility in the energy sector.

Despite its widespread use, PC technology faces several challenges in meeting the evolving demands of the energy industry. One significant hurdle is improving the material's long-term weatherability and UV resistance, particularly for outdoor applications in solar and wind energy systems. Enhancing these properties without compromising other desirable characteristics remains a complex task for researchers and manufacturers.

Another challenge lies in developing PC formulations with improved flame retardancy and thermal management capabilities, crucial for safe and efficient energy storage solutions. As the demand for high-performance batteries grows, PC materials must evolve to meet stringent safety standards while maintaining their lightweight and durable nature.

The energy sector also requires PC materials with enhanced chemical resistance to withstand exposure to various electrolytes, fuels, and other aggressive substances encountered in energy production and storage systems. Developing PC grades that can maintain their structural integrity and performance under these harsh conditions is an ongoing area of research and development.

Furthermore, as sustainability becomes increasingly important, the industry faces the challenge of improving the recyclability and biodegradability of PC materials without sacrificing their performance characteristics. This includes developing more efficient recycling processes and exploring bio-based alternatives to traditional petroleum-derived PC.

Lastly, the energy sector demands continuous innovation in PC processing technologies to enable the production of complex geometries and multi-material components. Advancements in injection molding, 3D printing, and other manufacturing techniques are necessary to fully leverage the potential of PC in next-generation energy solutions.

The automotive sector has also embraced PC technology for lightweight vehicle components and battery casings in electric vehicles, contributing to improved energy efficiency and range. Additionally, PC finds applications in wind turbine components, energy-efficient lighting systems, and smart grid infrastructure, showcasing its versatility in the energy sector.

Despite its widespread use, PC technology faces several challenges in meeting the evolving demands of the energy industry. One significant hurdle is improving the material's long-term weatherability and UV resistance, particularly for outdoor applications in solar and wind energy systems. Enhancing these properties without compromising other desirable characteristics remains a complex task for researchers and manufacturers.

Another challenge lies in developing PC formulations with improved flame retardancy and thermal management capabilities, crucial for safe and efficient energy storage solutions. As the demand for high-performance batteries grows, PC materials must evolve to meet stringent safety standards while maintaining their lightweight and durable nature.

The energy sector also requires PC materials with enhanced chemical resistance to withstand exposure to various electrolytes, fuels, and other aggressive substances encountered in energy production and storage systems. Developing PC grades that can maintain their structural integrity and performance under these harsh conditions is an ongoing area of research and development.

Furthermore, as sustainability becomes increasingly important, the industry faces the challenge of improving the recyclability and biodegradability of PC materials without sacrificing their performance characteristics. This includes developing more efficient recycling processes and exploring bio-based alternatives to traditional petroleum-derived PC.

Lastly, the energy sector demands continuous innovation in PC processing technologies to enable the production of complex geometries and multi-material components. Advancements in injection molding, 3D printing, and other manufacturing techniques are necessary to fully leverage the potential of PC in next-generation energy solutions.

Existing PC-Based Energy Solutions

01 Polycarbonate synthesis and modification

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blends and composites are tailored for various industrial and consumer applications.

- Polycarbonate processing and manufacturing techniques: Advancements in processing and manufacturing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on improving production efficiency, reducing defects, and enhancing the quality of final products. Innovations in equipment design and process parameters are key aspects of this area.

- Polycarbonate applications in electronics and optics: Utilization of polycarbonates in electronic and optical applications, such as display screens, lenses, and data storage devices. The focus is on developing polycarbonate formulations with enhanced optical clarity, scratch resistance, and dimensional stability to meet the demanding requirements of these high-tech applications.

- Sustainable and bio-based polycarbonates: Research into sustainable and bio-based alternatives to traditional polycarbonates, focusing on renewable resources and environmentally friendly production methods. This includes the development of bio-based monomers, green catalysts, and recycling technologies to reduce the environmental impact of polycarbonate production and use.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These combinations can result in materials with enhanced impact resistance, flame retardancy, or conductivity, expanding the application range of polycarbonates.Expand Specific Solutions03 Polycarbonate processing and molding techniques

Advancements in processing and molding techniques for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and achieving desired shapes and properties in the final products.Expand Specific Solutions04 Polycarbonate surface treatments and coatings

Methods for modifying the surface properties of polycarbonates through treatments or coatings. These techniques can enhance scratch resistance, UV stability, anti-fogging properties, or adhesion to other materials, thereby expanding the use of polycarbonates in various applications.Expand Specific Solutions05 Polycarbonate applications in electronics and optics

Specialized formulations and manufacturing processes for polycarbonates used in electronic and optical applications. This includes the development of high-performance polycarbonates for use in display screens, lenses, data storage devices, and other high-tech components requiring specific optical or electrical properties.Expand Specific Solutions

Key Players in PC Energy Innovation

The research on polycarbonate for next-generation energy solutions is in a dynamic phase, with significant market potential and technological advancements. The industry is transitioning from early-stage development to more mature applications, driven by the growing demand for sustainable energy solutions. Major players like LG Chem, Covestro, and SABIC are leading the charge, leveraging their expertise in polymer science and chemical engineering. The market size is expanding rapidly, fueled by increasing investments in renewable energy and energy storage technologies. While the technology is progressing, it's not yet fully mature, with companies like Wanhua Chemical and Kingfa Sci. & Tech. actively pursuing innovations to enhance performance and reduce costs.

LG Chem Ltd.

Technical Solution: LG Chem has made significant strides in polycarbonate research for energy applications, particularly in battery technologies. Their LUPOY® PC series includes grades specifically designed for battery module housings, offering high impact strength and flame retardancy (UL94 V-0 at 0.8mm)[13]. LG Chem has developed polycarbonate/ABS blends with improved chemical resistance for use in fuel cell systems[14]. Their research also extends to polycarbonate-based separator materials for lithium-ion batteries, potentially enhancing safety and performance[15]. LG Chem's integration of nanotechnology into polycarbonate formulations has resulted in materials with improved barrier properties, crucial for protecting sensitive energy components.

Strengths: Strong synergy between polycarbonate research and battery technology expertise, innovative approaches to material design. Weaknesses: May face challenges in scaling up some advanced technologies for mass production.

Covestro Deutschland AG

Technical Solution: Covestro has developed high-performance polycarbonate blends specifically for next-generation energy solutions. Their Makrolon® RE series incorporates up to 71% post-consumer recycled content, reducing carbon footprint by up to 50% compared to fossil-based polycarbonates[1]. For energy storage applications, they've engineered flame-retardant grades that meet UL94 V-0 standards at just 0.8mm thickness, ensuring safety in battery casings[2]. Covestro's polycarbonate composites also offer enhanced thermal management properties, crucial for maintaining optimal operating temperatures in energy systems[3].

Strengths: Sustainable materials with high recycled content, excellent flame retardancy, and superior thermal management. Weaknesses: Potentially higher cost compared to traditional polycarbonates, may require specialized processing techniques.

Breakthrough PC Technologies for Energy Storage

Eco-friendly synthesis of biodegradable polycarbonate from co2 and epoxide

PatentPendingIN202321017490A

Innovation

- The synthesis of biodegradable polycarbonate from carbon dioxide (CO2) and epoxide using a metal-organic framework (MOF) catalyst, which initiates a polymerization reaction that produces polycarbonates that can break down naturally, reducing waste and pollution.

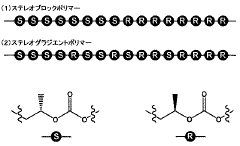

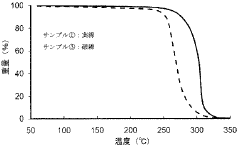

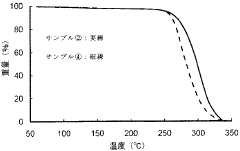

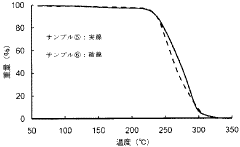

POLYCARBONATE EXCELLENT IN HEAT STABILITY AND METHOD FOR MANUFACTURING THE SAME

PatentInactiveJPWO2012102101A1

Innovation

- A polycarbonate with a repeating unit of an optical isomer containing asymmetric carbon is produced by dissolving a chain polycarbonate in a solvent that does not dissolve it, allowing for regions with different absolute configurations to precipitate, enhancing thermal stability.

Environmental Impact of PC in Energy Solutions

The environmental impact of polycarbonate (PC) in energy solutions is a critical consideration as the world moves towards more sustainable and efficient energy systems. PC's versatility and unique properties make it a valuable material in various energy applications, but its production and disposal processes raise environmental concerns.

PC manufacturing requires significant energy input and relies on fossil fuel-derived raw materials, contributing to greenhouse gas emissions. The production process also involves potentially harmful chemicals, such as bisphenol A (BPA), which can have adverse effects on ecosystems if not properly managed. However, advancements in production technologies have led to more energy-efficient and cleaner manufacturing processes, reducing the overall environmental footprint.

In terms of energy solutions, PC's durability and longevity contribute to the extended lifespan of energy-related products, reducing the need for frequent replacements and associated waste. This is particularly evident in solar panel applications, where PC is used as a protective layer, enhancing the panels' efficiency and lifespan. The material's lightweight nature also reduces transportation-related emissions and energy consumption during installation and maintenance of energy infrastructure.

PC's recyclability is a significant factor in its environmental impact. While the material is technically recyclable, the process can be complex and energy-intensive. The presence of additives and coatings in some PC products can complicate recycling efforts. However, recent innovations in recycling technologies have improved the efficiency and feasibility of PC recycling, potentially reducing its end-of-life environmental impact.

In the context of energy storage solutions, PC's use in battery casings and components contributes to the development of more efficient and longer-lasting energy storage systems. This indirectly supports the integration of renewable energy sources into the grid, potentially offsetting the environmental impact of PC production through reduced reliance on fossil fuels.

The material's thermal and electrical insulation properties also play a role in improving energy efficiency in various applications, from building materials to electronic components. By enhancing insulation and reducing energy loss, PC contributes to overall energy conservation efforts.

However, the persistence of PC in the environment, particularly when improperly disposed of, remains a concern. While not as problematic as some other plastics, PC can still contribute to microplastic pollution in aquatic ecosystems. Ongoing research into biodegradable alternatives and improved end-of-life management strategies aims to address these issues.

As the energy sector continues to evolve, the environmental impact of PC in energy solutions will likely be further scrutinized. Balancing its beneficial properties with environmental considerations will be crucial in determining its role in next-generation energy technologies.

PC manufacturing requires significant energy input and relies on fossil fuel-derived raw materials, contributing to greenhouse gas emissions. The production process also involves potentially harmful chemicals, such as bisphenol A (BPA), which can have adverse effects on ecosystems if not properly managed. However, advancements in production technologies have led to more energy-efficient and cleaner manufacturing processes, reducing the overall environmental footprint.

In terms of energy solutions, PC's durability and longevity contribute to the extended lifespan of energy-related products, reducing the need for frequent replacements and associated waste. This is particularly evident in solar panel applications, where PC is used as a protective layer, enhancing the panels' efficiency and lifespan. The material's lightweight nature also reduces transportation-related emissions and energy consumption during installation and maintenance of energy infrastructure.

PC's recyclability is a significant factor in its environmental impact. While the material is technically recyclable, the process can be complex and energy-intensive. The presence of additives and coatings in some PC products can complicate recycling efforts. However, recent innovations in recycling technologies have improved the efficiency and feasibility of PC recycling, potentially reducing its end-of-life environmental impact.

In the context of energy storage solutions, PC's use in battery casings and components contributes to the development of more efficient and longer-lasting energy storage systems. This indirectly supports the integration of renewable energy sources into the grid, potentially offsetting the environmental impact of PC production through reduced reliance on fossil fuels.

The material's thermal and electrical insulation properties also play a role in improving energy efficiency in various applications, from building materials to electronic components. By enhancing insulation and reducing energy loss, PC contributes to overall energy conservation efforts.

However, the persistence of PC in the environment, particularly when improperly disposed of, remains a concern. While not as problematic as some other plastics, PC can still contribute to microplastic pollution in aquatic ecosystems. Ongoing research into biodegradable alternatives and improved end-of-life management strategies aims to address these issues.

As the energy sector continues to evolve, the environmental impact of PC in energy solutions will likely be further scrutinized. Balancing its beneficial properties with environmental considerations will be crucial in determining its role in next-generation energy technologies.

Regulatory Framework for PC in Energy Industry

The regulatory framework for polycarbonate (PC) in the energy industry is a complex and evolving landscape that significantly impacts the development and implementation of next-generation energy solutions. As PC gains prominence in various energy applications, governments and regulatory bodies worldwide are adapting their policies to ensure safety, environmental protection, and sustainable development.

In the United States, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) play crucial roles in shaping the regulatory environment for PC in energy applications. The EPA's Toxic Substances Control Act (TSCA) regulates the production, use, and disposal of chemical substances, including PC. The DOE, through its Office of Energy Efficiency and Renewable Energy, sets standards for energy-efficient products and technologies that may incorporate PC components.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the use of PC in energy-related products. This comprehensive framework requires manufacturers and importers to register chemical substances, including those used in PC production, and assess their potential risks to human health and the environment.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both impact the use of PC in energy applications. These regulations focus on ensuring the safe use of chemicals and promoting sustainable development in the energy sector.

International standards organizations, such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), have developed specific standards for PC materials used in energy applications. These standards address issues such as thermal stability, electrical insulation properties, and fire resistance, which are critical for PC components in energy systems.

The regulatory landscape also encompasses specific energy sector regulations. For instance, in the solar energy industry, PC materials used in photovoltaic modules must comply with IEC 61215 and IEC 61730 standards, which ensure the long-term reliability and safety of solar panels. Similarly, in the wind energy sector, PC components must meet the requirements set by standards like IEC 61400 for wind turbines.

As the energy industry continues to evolve, regulatory frameworks are adapting to address emerging challenges. For example, the growing focus on circular economy principles has led to new regulations promoting the recyclability and reusability of PC materials in energy applications. The European Union's Circular Economy Action Plan and similar initiatives in other regions are driving the development of more sustainable PC-based energy solutions.

In the United States, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) play crucial roles in shaping the regulatory environment for PC in energy applications. The EPA's Toxic Substances Control Act (TSCA) regulates the production, use, and disposal of chemical substances, including PC. The DOE, through its Office of Energy Efficiency and Renewable Energy, sets standards for energy-efficient products and technologies that may incorporate PC components.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the use of PC in energy-related products. This comprehensive framework requires manufacturers and importers to register chemical substances, including those used in PC production, and assess their potential risks to human health and the environment.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both impact the use of PC in energy applications. These regulations focus on ensuring the safe use of chemicals and promoting sustainable development in the energy sector.

International standards organizations, such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), have developed specific standards for PC materials used in energy applications. These standards address issues such as thermal stability, electrical insulation properties, and fire resistance, which are critical for PC components in energy systems.

The regulatory landscape also encompasses specific energy sector regulations. For instance, in the solar energy industry, PC materials used in photovoltaic modules must comply with IEC 61215 and IEC 61730 standards, which ensure the long-term reliability and safety of solar panels. Similarly, in the wind energy sector, PC components must meet the requirements set by standards like IEC 61400 for wind turbines.

As the energy industry continues to evolve, regulatory frameworks are adapting to address emerging challenges. For example, the growing focus on circular economy principles has led to new regulations promoting the recyclability and reusability of PC materials in energy applications. The European Union's Circular Economy Action Plan and similar initiatives in other regions are driving the development of more sustainable PC-based energy solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!