Propyne's Function as a Renewable Feedstock for Polymers

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne as Polymer Feedstock: Background and Objectives

Propyne, also known as methylacetylene, has emerged as a promising renewable feedstock for polymer production, offering a sustainable alternative to traditional petroleum-based resources. This research focuses on exploring propyne's potential in the polymer industry, aiming to address the growing demand for environmentally friendly materials and reduce reliance on fossil fuels.

The development of propyne as a polymer feedstock is rooted in the broader context of green chemistry and sustainable materials science. As global concerns about climate change and resource depletion intensify, there is an increasing push towards renewable and biodegradable polymers. Propyne, with its simple three-carbon structure and high reactivity, presents unique opportunities for polymer synthesis and modification.

Historically, propyne has been primarily viewed as a byproduct of petroleum refining and ethylene production. However, recent advancements in bioengineering and renewable resource utilization have opened new avenues for its sustainable production. Researchers are now exploring methods to generate propyne from biomass and other renewable sources, aligning with the principles of circular economy and waste valorization.

The technical evolution of propyne utilization in polymer science has seen significant progress over the past decades. Early studies focused on its potential as a comonomer in various polymerization processes. More recent research has expanded to investigate propyne's role in the synthesis of novel polymer structures, functionalization of existing polymers, and development of high-performance materials with unique properties.

The primary objectives of this research are multifaceted. Firstly, it aims to comprehensively assess the current state of propyne-based polymer technology, identifying key achievements and remaining challenges. Secondly, the study seeks to explore innovative approaches for incorporating propyne into polymer synthesis, with a focus on enhancing material properties and expanding application possibilities.

Furthermore, this research endeavors to evaluate the economic and environmental implications of transitioning to propyne-based polymer production. This includes analyzing the potential for reducing carbon footprints, improving energy efficiency, and creating new value chains in the chemical industry. The study also aims to identify potential barriers to widespread adoption and propose strategies to overcome these obstacles.

Lastly, the research objectives encompass the exploration of propyne's synergies with other emerging technologies in materials science, such as catalysis, nanotechnology, and additive manufacturing. By investigating these intersections, the study aims to uncover novel applications and push the boundaries of polymer science towards more sustainable and advanced materials.

The development of propyne as a polymer feedstock is rooted in the broader context of green chemistry and sustainable materials science. As global concerns about climate change and resource depletion intensify, there is an increasing push towards renewable and biodegradable polymers. Propyne, with its simple three-carbon structure and high reactivity, presents unique opportunities for polymer synthesis and modification.

Historically, propyne has been primarily viewed as a byproduct of petroleum refining and ethylene production. However, recent advancements in bioengineering and renewable resource utilization have opened new avenues for its sustainable production. Researchers are now exploring methods to generate propyne from biomass and other renewable sources, aligning with the principles of circular economy and waste valorization.

The technical evolution of propyne utilization in polymer science has seen significant progress over the past decades. Early studies focused on its potential as a comonomer in various polymerization processes. More recent research has expanded to investigate propyne's role in the synthesis of novel polymer structures, functionalization of existing polymers, and development of high-performance materials with unique properties.

The primary objectives of this research are multifaceted. Firstly, it aims to comprehensively assess the current state of propyne-based polymer technology, identifying key achievements and remaining challenges. Secondly, the study seeks to explore innovative approaches for incorporating propyne into polymer synthesis, with a focus on enhancing material properties and expanding application possibilities.

Furthermore, this research endeavors to evaluate the economic and environmental implications of transitioning to propyne-based polymer production. This includes analyzing the potential for reducing carbon footprints, improving energy efficiency, and creating new value chains in the chemical industry. The study also aims to identify potential barriers to widespread adoption and propose strategies to overcome these obstacles.

Lastly, the research objectives encompass the exploration of propyne's synergies with other emerging technologies in materials science, such as catalysis, nanotechnology, and additive manufacturing. By investigating these intersections, the study aims to uncover novel applications and push the boundaries of polymer science towards more sustainable and advanced materials.

Market Analysis for Renewable Polymer Feedstocks

The market for renewable polymer feedstocks has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to traditional petroleum-based polymers. Propyne, also known as methylacetylene, is emerging as a promising renewable feedstock for polymer production, offering unique properties and potential advantages over conventional sources.

The global market for bio-based polymers is projected to expand rapidly, with some estimates suggesting a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is fueled by consumer demand for eco-friendly products, stringent environmental regulations, and corporate sustainability initiatives. As industries seek to reduce their carbon footprint, the demand for renewable feedstocks like propyne is expected to rise substantially.

Propyne's potential as a renewable feedstock for polymers is particularly attractive in sectors such as packaging, automotive, and construction. The packaging industry, in particular, is showing keen interest in sustainable materials due to increasing pressure to reduce plastic waste. Propyne-based polymers could offer biodegradable or recyclable alternatives to traditional plastics, addressing both environmental concerns and market demands.

The automotive sector is another key market for renewable polymer feedstocks. As automakers strive to reduce vehicle weight and improve fuel efficiency, there is a growing need for lightweight, durable materials derived from sustainable sources. Propyne-based polymers could potentially meet these requirements, offering opportunities for innovation in automotive components and interiors.

In the construction industry, the push for green building materials is creating new opportunities for renewable polymer feedstocks. Propyne-derived polymers could be used in insulation, sealants, and other building materials, contributing to improved energy efficiency and reduced environmental impact of buildings.

However, the market for propyne as a renewable feedstock faces several challenges. The availability and cost of propyne production from renewable sources remain significant hurdles. Currently, most propyne is produced as a byproduct of petroleum refining, and developing economically viable methods for its renewable production is crucial for market expansion.

Competition from other renewable feedstocks, such as bio-based ethylene and propylene, also impacts the market potential of propyne. These more established renewable feedstocks have already gained traction in the polymer industry, and propyne will need to demonstrate clear advantages to carve out its market share.

Despite these challenges, the potential for propyne in the renewable polymer feedstock market remains promising. As research and development efforts continue to improve production methods and explore new applications, propyne could play a significant role in the transition towards more sustainable polymer production.

The global market for bio-based polymers is projected to expand rapidly, with some estimates suggesting a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is fueled by consumer demand for eco-friendly products, stringent environmental regulations, and corporate sustainability initiatives. As industries seek to reduce their carbon footprint, the demand for renewable feedstocks like propyne is expected to rise substantially.

Propyne's potential as a renewable feedstock for polymers is particularly attractive in sectors such as packaging, automotive, and construction. The packaging industry, in particular, is showing keen interest in sustainable materials due to increasing pressure to reduce plastic waste. Propyne-based polymers could offer biodegradable or recyclable alternatives to traditional plastics, addressing both environmental concerns and market demands.

The automotive sector is another key market for renewable polymer feedstocks. As automakers strive to reduce vehicle weight and improve fuel efficiency, there is a growing need for lightweight, durable materials derived from sustainable sources. Propyne-based polymers could potentially meet these requirements, offering opportunities for innovation in automotive components and interiors.

In the construction industry, the push for green building materials is creating new opportunities for renewable polymer feedstocks. Propyne-derived polymers could be used in insulation, sealants, and other building materials, contributing to improved energy efficiency and reduced environmental impact of buildings.

However, the market for propyne as a renewable feedstock faces several challenges. The availability and cost of propyne production from renewable sources remain significant hurdles. Currently, most propyne is produced as a byproduct of petroleum refining, and developing economically viable methods for its renewable production is crucial for market expansion.

Competition from other renewable feedstocks, such as bio-based ethylene and propylene, also impacts the market potential of propyne. These more established renewable feedstocks have already gained traction in the polymer industry, and propyne will need to demonstrate clear advantages to carve out its market share.

Despite these challenges, the potential for propyne in the renewable polymer feedstock market remains promising. As research and development efforts continue to improve production methods and explore new applications, propyne could play a significant role in the transition towards more sustainable polymer production.

Current Challenges in Propyne-based Polymer Production

The production of propyne-based polymers faces several significant challenges that hinder its widespread adoption as a renewable feedstock. One of the primary obstacles is the limited availability of propyne as a raw material. Although propyne can be derived from renewable sources, such as biomass or waste streams, the current production methods are not sufficiently efficient or cost-effective to meet industrial demands.

Another major challenge lies in the polymerization process itself. Propyne's high reactivity can lead to uncontrolled polymerization, resulting in polymers with inconsistent properties and molecular weights. This lack of control over the polymerization reaction makes it difficult to produce polymers with specific desired characteristics, which is crucial for various applications.

The catalysts used in propyne polymerization also present significant hurdles. Many existing catalysts are either too expensive for large-scale production or lack the selectivity required to produce high-quality polymers. Developing more efficient and selective catalysts that can operate under milder conditions remains a key area of research.

Furthermore, the purification of propyne-based polymers poses technical difficulties. The presence of unreacted monomers, oligomers, and other byproducts can significantly affect the final product's properties. Developing effective purification techniques that can be scaled up for industrial production is essential for producing high-quality propyne-based polymers.

Environmental concerns also play a role in the challenges faced by propyne-based polymer production. While propyne itself can be derived from renewable sources, the overall production process may still have a significant environmental impact. Addressing issues such as energy consumption, waste generation, and potential emissions is crucial for ensuring the sustainability of propyne-based polymer production.

Lastly, the integration of propyne-based polymers into existing manufacturing processes and supply chains presents logistical challenges. Many industries have established infrastructure and processes optimized for conventional petroleum-based polymers. Adapting these systems to accommodate propyne-based alternatives requires significant investment and technical expertise, which can be a barrier to adoption.

Overcoming these challenges requires a multidisciplinary approach, combining advances in chemistry, materials science, and engineering. Continued research and development efforts are needed to improve propyne production methods, develop more efficient catalysts, enhance polymerization control, and optimize purification techniques. Additionally, addressing the environmental and logistical aspects of propyne-based polymer production will be crucial for its successful implementation as a renewable feedstock for the polymer industry.

Another major challenge lies in the polymerization process itself. Propyne's high reactivity can lead to uncontrolled polymerization, resulting in polymers with inconsistent properties and molecular weights. This lack of control over the polymerization reaction makes it difficult to produce polymers with specific desired characteristics, which is crucial for various applications.

The catalysts used in propyne polymerization also present significant hurdles. Many existing catalysts are either too expensive for large-scale production or lack the selectivity required to produce high-quality polymers. Developing more efficient and selective catalysts that can operate under milder conditions remains a key area of research.

Furthermore, the purification of propyne-based polymers poses technical difficulties. The presence of unreacted monomers, oligomers, and other byproducts can significantly affect the final product's properties. Developing effective purification techniques that can be scaled up for industrial production is essential for producing high-quality propyne-based polymers.

Environmental concerns also play a role in the challenges faced by propyne-based polymer production. While propyne itself can be derived from renewable sources, the overall production process may still have a significant environmental impact. Addressing issues such as energy consumption, waste generation, and potential emissions is crucial for ensuring the sustainability of propyne-based polymer production.

Lastly, the integration of propyne-based polymers into existing manufacturing processes and supply chains presents logistical challenges. Many industries have established infrastructure and processes optimized for conventional petroleum-based polymers. Adapting these systems to accommodate propyne-based alternatives requires significant investment and technical expertise, which can be a barrier to adoption.

Overcoming these challenges requires a multidisciplinary approach, combining advances in chemistry, materials science, and engineering. Continued research and development efforts are needed to improve propyne production methods, develop more efficient catalysts, enhance polymerization control, and optimize purification techniques. Additionally, addressing the environmental and logistical aspects of propyne-based polymer production will be crucial for its successful implementation as a renewable feedstock for the polymer industry.

Existing Propyne-to-Polymer Conversion Methods

01 Synthesis and production of propyne

Various methods and processes for synthesizing and producing propyne are described. These include catalytic processes, thermal cracking, and other chemical reactions to obtain propyne from different starting materials.- Synthesis and production of propyne: Various methods for synthesizing and producing propyne are described, including catalytic processes, thermal cracking, and chemical reactions. These techniques aim to improve yield, efficiency, and purity of propyne production for industrial applications.

- Propyne as a raw material in chemical processes: Propyne serves as an important raw material in various chemical processes, including the production of polymers, resins, and other organic compounds. Its reactivity and structure make it valuable for synthesizing more complex molecules in industrial applications.

- Purification and separation of propyne: Methods and systems for purifying and separating propyne from mixtures are discussed. These processes involve techniques such as distillation, adsorption, and membrane separation to obtain high-purity propyne for use in various applications.

- Propyne in fuel compositions: The use of propyne in fuel compositions is explored, including its potential as an additive or component in various fuel blends. Research focuses on improving combustion efficiency, reducing emissions, and enhancing overall fuel performance.

- Safety and handling of propyne: Due to its flammable and potentially explosive nature, safety measures and proper handling techniques for propyne are crucial. Patents describe methods for storage, transportation, and use of propyne in industrial settings to minimize risks and ensure safe operations.

02 Purification and separation of propyne

Techniques for purifying and separating propyne from other gases or mixtures are outlined. These methods may involve distillation, adsorption, or membrane separation to obtain high-purity propyne.Expand Specific Solutions03 Applications of propyne in chemical synthesis

Propyne is used as a starting material or intermediate in various chemical syntheses. It can be employed in the production of polymers, pharmaceuticals, and other organic compounds through reactions such as cycloadditions or hydrogenations.Expand Specific Solutions04 Storage and handling of propyne

Methods and equipment for safely storing and handling propyne are described. This includes specialized containers, pressure vessels, and safety measures to prevent accidents due to the flammable nature of propyne.Expand Specific Solutions05 Detection and analysis of propyne

Techniques for detecting and analyzing propyne in various environments or mixtures are presented. These may include spectroscopic methods, gas chromatography, or other analytical techniques to identify and quantify propyne.Expand Specific Solutions

Key Players in Propyne-based Polymer Research

The research on propyne's function as a renewable feedstock for polymers is in an early developmental stage, with the market still emerging. The global push for sustainable materials is driving interest, but commercial applications remain limited. Key players include academic institutions like Huazhong University of Science & Technology and Sichuan University, as well as chemical companies like Arkema and Kingfa Sci. & Tech. These organizations are exploring propyne's potential through laboratory-scale studies and pilot projects. The technology is still maturing, with challenges in scalability and cost-effectiveness to be addressed before widespread industrial adoption. Collaboration between academia and industry will be crucial for advancing this promising but nascent field.

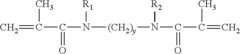

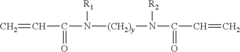

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has developed a novel approach for utilizing propyne as a renewable feedstock for polymer production. Their research focuses on the catalytic conversion of propyne into high-value polymers through controlled polymerization processes. The institute has successfully synthesized a range of propyne-based polymers with diverse properties, including thermoplastics and elastomers[1]. Their method involves using advanced metal-organic catalysts to achieve precise control over the polymer structure and molecular weight distribution[2]. Additionally, they have explored the incorporation of propyne-derived monomers into copolymers, enhancing the sustainability and performance of existing polymer systems[3].

Strengths: Cutting-edge catalytic technology, diverse polymer product range, and integration with existing polymer systems. Weaknesses: Potential scalability challenges and competition from established petrochemical-based polymers.

Arkema France SA

Technical Solution: Arkema France SA has made significant strides in utilizing propyne as a renewable feedstock for polymer production. Their approach focuses on developing bio-based propyne through innovative fermentation processes, ensuring a sustainable source of this valuable monomer[4]. Arkema has successfully integrated propyne-derived monomers into their existing polymer production lines, particularly in the synthesis of high-performance acrylics and specialty polymers[5]. The company has also developed proprietary catalysts that enable efficient polymerization of propyne and its derivatives, resulting in polymers with enhanced thermal and mechanical properties[6]. Furthermore, Arkema has invested in pilot-scale facilities to demonstrate the feasibility of large-scale propyne-based polymer production, addressing key challenges in process optimization and product quality control[7].

Strengths: Integrated approach from monomer production to polymer synthesis, established market presence, and scalable production capabilities. Weaknesses: Dependence on bio-based propyne production efficiency and potential regulatory hurdles for novel materials.

Innovative Propyne Polymerization Techniques

Renewable polymers from post-consumer pet depolymerized feedstock

PatentPendingUS20250154333A1

Innovation

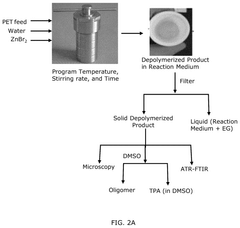

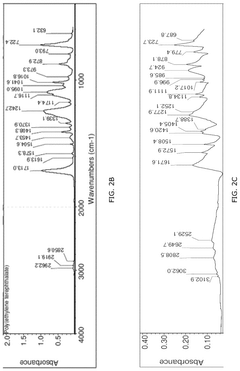

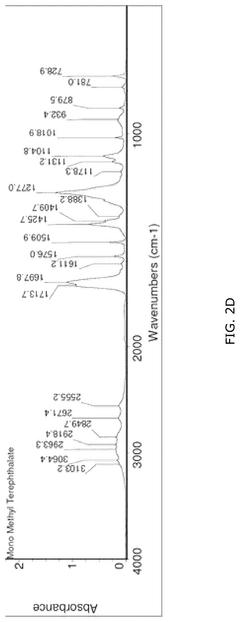

- A depolymerization process that uses an aqueous metal salt solution, specifically with ZnBr2 or ZnI2, to break down PET into depolymerized-polyester oligomers, which can be further modified to produce renewable PET and various commercial polymers, operating at milder temperatures and using simpler catalyst separation techniques.

Method for the fracture stimulation of a subterranean formation having a wellbore by using impact-modified thermoset polymer nanocomposite particles as proppants

PatentInactiveUS20130333889A1

Innovation

- The method involves manufacturing ultralightweight thermoset polymer nanocomposite particles with a terpolymer matrix of styrene, ethylinylbenzene, and divinylbenzene, using carbon black as a nanofiller, and incorporating an impact modifier to enhance crosslinking and heat resistance, followed by suspension polymerization and post-polymerization heat treatment to achieve optimal properties.

Environmental Impact of Propyne as a Renewable Resource

The environmental impact of propyne as a renewable resource is a critical consideration in its potential use as a feedstock for polymers. Propyne, also known as methylacetylene, offers several advantages from an environmental perspective when compared to traditional fossil-based feedstocks.

One of the primary benefits of using propyne as a renewable resource is its potential to reduce greenhouse gas emissions. As a byproduct of biomass processing, propyne can be derived from renewable sources such as agricultural waste or dedicated energy crops. This renewable origin significantly lowers the carbon footprint associated with polymer production, as it reduces reliance on fossil fuels and promotes a more circular economy.

The production of propyne from renewable sources also contributes to the conservation of non-renewable resources. By utilizing biomass-derived propyne, the polymer industry can decrease its dependence on petroleum-based feedstocks, helping to preserve finite fossil fuel reserves for other essential applications.

Furthermore, the use of propyne as a renewable feedstock aligns with the principles of green chemistry. Its production from biomass often involves less energy-intensive processes compared to the extraction and refining of fossil fuels. This can lead to reduced energy consumption and lower overall environmental impact throughout the polymer production lifecycle.

Propyne's potential as a platform molecule for various polymer syntheses also offers opportunities for the development of more environmentally friendly materials. Polymers derived from propyne may exhibit enhanced biodegradability or recyclability, addressing concerns related to plastic waste accumulation in the environment.

However, it is important to consider potential challenges and limitations associated with propyne's environmental impact. The large-scale production of propyne from renewable sources may require significant land use for biomass cultivation, potentially competing with food production or natural habitats. Additionally, the environmental benefits of propyne-based polymers must be evaluated on a case-by-case basis, considering factors such as production efficiency, product lifespan, and end-of-life disposal options.

To fully assess the environmental impact of propyne as a renewable resource, comprehensive life cycle assessments (LCAs) are necessary. These studies should compare propyne-based polymers with their fossil-derived counterparts, taking into account factors such as water usage, land use changes, and potential emissions throughout the entire production and use cycle.

In conclusion, while propyne shows promise as an environmentally friendly renewable feedstock for polymers, its overall impact must be carefully evaluated. Continued research and development efforts are needed to optimize production processes, improve efficiency, and maximize the environmental benefits of propyne-based materials in the context of sustainable polymer production.

One of the primary benefits of using propyne as a renewable resource is its potential to reduce greenhouse gas emissions. As a byproduct of biomass processing, propyne can be derived from renewable sources such as agricultural waste or dedicated energy crops. This renewable origin significantly lowers the carbon footprint associated with polymer production, as it reduces reliance on fossil fuels and promotes a more circular economy.

The production of propyne from renewable sources also contributes to the conservation of non-renewable resources. By utilizing biomass-derived propyne, the polymer industry can decrease its dependence on petroleum-based feedstocks, helping to preserve finite fossil fuel reserves for other essential applications.

Furthermore, the use of propyne as a renewable feedstock aligns with the principles of green chemistry. Its production from biomass often involves less energy-intensive processes compared to the extraction and refining of fossil fuels. This can lead to reduced energy consumption and lower overall environmental impact throughout the polymer production lifecycle.

Propyne's potential as a platform molecule for various polymer syntheses also offers opportunities for the development of more environmentally friendly materials. Polymers derived from propyne may exhibit enhanced biodegradability or recyclability, addressing concerns related to plastic waste accumulation in the environment.

However, it is important to consider potential challenges and limitations associated with propyne's environmental impact. The large-scale production of propyne from renewable sources may require significant land use for biomass cultivation, potentially competing with food production or natural habitats. Additionally, the environmental benefits of propyne-based polymers must be evaluated on a case-by-case basis, considering factors such as production efficiency, product lifespan, and end-of-life disposal options.

To fully assess the environmental impact of propyne as a renewable resource, comprehensive life cycle assessments (LCAs) are necessary. These studies should compare propyne-based polymers with their fossil-derived counterparts, taking into account factors such as water usage, land use changes, and potential emissions throughout the entire production and use cycle.

In conclusion, while propyne shows promise as an environmentally friendly renewable feedstock for polymers, its overall impact must be carefully evaluated. Continued research and development efforts are needed to optimize production processes, improve efficiency, and maximize the environmental benefits of propyne-based materials in the context of sustainable polymer production.

Economic Feasibility of Propyne-based Polymers

The economic feasibility of propyne-based polymers is a critical factor in determining their potential for widespread adoption in the market. As a renewable feedstock, propyne offers several advantages that could contribute to its economic viability in polymer production.

One of the primary economic benefits of propyne-based polymers is their potential for cost reduction in raw material sourcing. Propyne can be derived from renewable sources such as biomass or captured carbon dioxide, potentially offering a more stable and sustainable supply chain compared to traditional petroleum-based feedstocks. This could lead to reduced price volatility and long-term cost savings for manufacturers.

The production processes for propyne-based polymers may also offer economic advantages. Many of these processes can be integrated into existing petrochemical infrastructure, minimizing the need for extensive capital investments. Additionally, the high reactivity of propyne often allows for more efficient polymerization reactions, potentially reducing energy consumption and processing times.

Market demand for sustainable materials is growing rapidly, driven by consumer preferences and regulatory pressures. Propyne-based polymers, with their renewable origins, could command premium prices in certain sectors, particularly in packaging, automotive, and consumer goods industries. This price premium could offset any additional production costs and improve overall profitability.

However, the economic feasibility of propyne-based polymers also faces several challenges. The current scale of propyne production from renewable sources is limited, which could lead to higher costs until production volumes increase. Additionally, the development of new catalysts and process technologies specific to propyne-based polymers may require significant upfront investment in research and development.

Competing technologies, such as other bio-based polymers or advanced recycling methods, could impact the market potential of propyne-based materials. The economic viability will depend on how propyne-based polymers perform in terms of cost, properties, and sustainability metrics compared to these alternatives.

Government policies and incentives will play a crucial role in the economic feasibility of propyne-based polymers. Carbon pricing mechanisms, tax incentives for renewable materials, and regulations promoting the use of sustainable products could significantly improve the competitive position of these materials in the market.

In conclusion, while propyne-based polymers show promise from an economic perspective, their feasibility will depend on continued technological advancements, scaling of production, and favorable market conditions. Ongoing research and development efforts, coupled with strategic partnerships across the value chain, will be essential in realizing the full economic potential of these innovative materials.

One of the primary economic benefits of propyne-based polymers is their potential for cost reduction in raw material sourcing. Propyne can be derived from renewable sources such as biomass or captured carbon dioxide, potentially offering a more stable and sustainable supply chain compared to traditional petroleum-based feedstocks. This could lead to reduced price volatility and long-term cost savings for manufacturers.

The production processes for propyne-based polymers may also offer economic advantages. Many of these processes can be integrated into existing petrochemical infrastructure, minimizing the need for extensive capital investments. Additionally, the high reactivity of propyne often allows for more efficient polymerization reactions, potentially reducing energy consumption and processing times.

Market demand for sustainable materials is growing rapidly, driven by consumer preferences and regulatory pressures. Propyne-based polymers, with their renewable origins, could command premium prices in certain sectors, particularly in packaging, automotive, and consumer goods industries. This price premium could offset any additional production costs and improve overall profitability.

However, the economic feasibility of propyne-based polymers also faces several challenges. The current scale of propyne production from renewable sources is limited, which could lead to higher costs until production volumes increase. Additionally, the development of new catalysts and process technologies specific to propyne-based polymers may require significant upfront investment in research and development.

Competing technologies, such as other bio-based polymers or advanced recycling methods, could impact the market potential of propyne-based materials. The economic viability will depend on how propyne-based polymers perform in terms of cost, properties, and sustainability metrics compared to these alternatives.

Government policies and incentives will play a crucial role in the economic feasibility of propyne-based polymers. Carbon pricing mechanisms, tax incentives for renewable materials, and regulations promoting the use of sustainable products could significantly improve the competitive position of these materials in the market.

In conclusion, while propyne-based polymers show promise from an economic perspective, their feasibility will depend on continued technological advancements, scaling of production, and favorable market conditions. Ongoing research and development efforts, coupled with strategic partnerships across the value chain, will be essential in realizing the full economic potential of these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!