Polycarbonate in High-Performance Sports Gear

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in Sports Gear: Evolution and Objectives

Polycarbonate has revolutionized the sports gear industry since its introduction in the 1950s. This versatile thermoplastic polymer, known for its exceptional impact resistance and optical clarity, has become a cornerstone in the development of high-performance sports equipment. The evolution of polycarbonate use in sports gear has been driven by the increasing demand for lighter, stronger, and more durable materials that can enhance athletic performance while ensuring safety.

Initially, polycarbonate found its way into sports eyewear, providing shatter-resistant lenses that offered superior protection compared to traditional glass or acrylic alternatives. As manufacturing techniques advanced, the application of polycarbonate expanded to include protective gear such as helmets, face shields, and body armor for various contact sports. The material's ability to absorb and distribute impact energy made it an ideal choice for these applications, significantly reducing the risk of injury to athletes.

The objectives of incorporating polycarbonate into sports gear have evolved alongside technological advancements and changing consumer expectations. Primary goals include enhancing athlete safety, improving performance through weight reduction, and increasing durability to extend equipment lifespan. Additionally, manufacturers aim to leverage polycarbonate's versatility to create innovative designs that offer better ergonomics and aesthetics.

Recent developments in polycarbonate technology have focused on addressing some of its limitations, such as improving scratch resistance and UV stability. Researchers are exploring nanocomposite formulations and surface treatments to enhance these properties without compromising the material's core strengths. The integration of smart technologies into polycarbonate-based sports gear is another emerging trend, with objectives ranging from real-time impact monitoring to adaptive performance features.

Looking ahead, the future of polycarbonate in sports gear is likely to be shaped by sustainability concerns and the push for more environmentally friendly materials. Objectives in this area include developing bio-based polycarbonates and improving recycling processes to reduce the environmental footprint of sports equipment. Balancing these sustainability goals with the high-performance requirements of modern sports gear presents both a challenge and an opportunity for innovation in the field.

As we continue to push the boundaries of athletic performance, the role of polycarbonate in sports gear is expected to grow. The ongoing research aims to unlock new possibilities, from ultra-lightweight yet highly protective helmets to adaptive body armor that responds to different impact scenarios. These advancements promise to redefine the standards of safety and performance in sports, underscoring the critical importance of continued innovation in polycarbonate technology for high-performance sports gear.

Initially, polycarbonate found its way into sports eyewear, providing shatter-resistant lenses that offered superior protection compared to traditional glass or acrylic alternatives. As manufacturing techniques advanced, the application of polycarbonate expanded to include protective gear such as helmets, face shields, and body armor for various contact sports. The material's ability to absorb and distribute impact energy made it an ideal choice for these applications, significantly reducing the risk of injury to athletes.

The objectives of incorporating polycarbonate into sports gear have evolved alongside technological advancements and changing consumer expectations. Primary goals include enhancing athlete safety, improving performance through weight reduction, and increasing durability to extend equipment lifespan. Additionally, manufacturers aim to leverage polycarbonate's versatility to create innovative designs that offer better ergonomics and aesthetics.

Recent developments in polycarbonate technology have focused on addressing some of its limitations, such as improving scratch resistance and UV stability. Researchers are exploring nanocomposite formulations and surface treatments to enhance these properties without compromising the material's core strengths. The integration of smart technologies into polycarbonate-based sports gear is another emerging trend, with objectives ranging from real-time impact monitoring to adaptive performance features.

Looking ahead, the future of polycarbonate in sports gear is likely to be shaped by sustainability concerns and the push for more environmentally friendly materials. Objectives in this area include developing bio-based polycarbonates and improving recycling processes to reduce the environmental footprint of sports equipment. Balancing these sustainability goals with the high-performance requirements of modern sports gear presents both a challenge and an opportunity for innovation in the field.

As we continue to push the boundaries of athletic performance, the role of polycarbonate in sports gear is expected to grow. The ongoing research aims to unlock new possibilities, from ultra-lightweight yet highly protective helmets to adaptive body armor that responds to different impact scenarios. These advancements promise to redefine the standards of safety and performance in sports, underscoring the critical importance of continued innovation in polycarbonate technology for high-performance sports gear.

Market Demand Analysis for High-Performance Sports Equipment

The market demand for high-performance sports equipment incorporating polycarbonate materials has been steadily increasing in recent years. This growth is driven by several factors, including the rising popularity of extreme sports, increased participation in professional and amateur athletics, and a growing awareness of the importance of safety in sports activities.

Polycarbonate, known for its exceptional impact resistance, lightweight properties, and optical clarity, has become a material of choice for various high-performance sports gear. The global market for polycarbonate in sports equipment is experiencing significant expansion, with a particular focus on protective gear such as helmets, goggles, and shields.

In the cycling industry, polycarbonate-based helmets have seen a surge in demand due to their superior protection capabilities and aerodynamic designs. The market for these helmets has been growing, especially in regions with strict safety regulations and a strong cycling culture.

Similarly, the winter sports sector has witnessed an increased adoption of polycarbonate in ski goggles and protective eyewear. The material's ability to provide clear vision while offering impact resistance has made it highly sought after by both recreational and professional skiers and snowboarders.

The automotive sports segment has also contributed to the rising demand for polycarbonate in high-performance gear. Racing helmets and visors made from polycarbonate blends are preferred for their ability to withstand high-speed impacts while maintaining optical clarity.

Water sports equipment manufacturers have been incorporating polycarbonate into products such as diving masks, snorkels, and protective gear for activities like white-water rafting. The material's resistance to water and chemicals, combined with its durability, has made it an ideal choice for these applications.

The trend towards lightweight yet durable sports equipment has further fueled the demand for polycarbonate-based products. Athletes and sports enthusiasts are increasingly seeking gear that offers maximum protection without compromising on performance or comfort.

Market analysts predict continued growth in the use of polycarbonate in high-performance sports gear. This growth is expected to be driven by ongoing innovations in material science, leading to enhanced polycarbonate formulations with improved properties tailored for specific sports applications.

Polycarbonate, known for its exceptional impact resistance, lightweight properties, and optical clarity, has become a material of choice for various high-performance sports gear. The global market for polycarbonate in sports equipment is experiencing significant expansion, with a particular focus on protective gear such as helmets, goggles, and shields.

In the cycling industry, polycarbonate-based helmets have seen a surge in demand due to their superior protection capabilities and aerodynamic designs. The market for these helmets has been growing, especially in regions with strict safety regulations and a strong cycling culture.

Similarly, the winter sports sector has witnessed an increased adoption of polycarbonate in ski goggles and protective eyewear. The material's ability to provide clear vision while offering impact resistance has made it highly sought after by both recreational and professional skiers and snowboarders.

The automotive sports segment has also contributed to the rising demand for polycarbonate in high-performance gear. Racing helmets and visors made from polycarbonate blends are preferred for their ability to withstand high-speed impacts while maintaining optical clarity.

Water sports equipment manufacturers have been incorporating polycarbonate into products such as diving masks, snorkels, and protective gear for activities like white-water rafting. The material's resistance to water and chemicals, combined with its durability, has made it an ideal choice for these applications.

The trend towards lightweight yet durable sports equipment has further fueled the demand for polycarbonate-based products. Athletes and sports enthusiasts are increasingly seeking gear that offers maximum protection without compromising on performance or comfort.

Market analysts predict continued growth in the use of polycarbonate in high-performance sports gear. This growth is expected to be driven by ongoing innovations in material science, leading to enhanced polycarbonate formulations with improved properties tailored for specific sports applications.

Current State and Challenges of Polycarbonate in Sports Gear

Polycarbonate has emerged as a prominent material in high-performance sports gear, revolutionizing the industry with its unique combination of properties. Currently, polycarbonate is widely used in various sports equipment, including protective gear, eyewear, and structural components. Its popularity stems from its exceptional impact resistance, optical clarity, and lightweight nature, making it ideal for applications where safety and performance are paramount.

In the realm of protective gear, polycarbonate is extensively utilized in helmets for sports such as cycling, skiing, and American football. These helmets benefit from polycarbonate's ability to absorb and distribute impact energy, significantly reducing the risk of head injuries. The material's durability allows for repeated impacts without compromising structural integrity, ensuring long-term protection for athletes.

Eyewear is another area where polycarbonate excels. Sports goggles and sunglasses made from this material offer superior impact resistance compared to traditional glass or other plastics. This is crucial in high-speed or contact sports where eye protection is essential. The optical clarity of polycarbonate also ensures unobstructed vision, a critical factor in athletic performance.

Despite its widespread adoption, polycarbonate faces several challenges in the sports gear industry. One significant issue is its susceptibility to scratching, which can compromise both aesthetics and functionality over time. While scratch-resistant coatings have been developed, finding a balance between scratch resistance and the material's inherent impact strength remains a challenge.

Another hurdle is the material's limited temperature resistance. In extreme weather conditions, polycarbonate can become brittle at low temperatures or soften at high temperatures, potentially affecting its protective properties. This limitation requires careful consideration in the design and application of sports gear for diverse environmental conditions.

The environmental impact of polycarbonate production and disposal is also a growing concern. As sustainability becomes increasingly important in consumer products, the sports gear industry faces pressure to find more eco-friendly alternatives or improve the recyclability of polycarbonate components.

Advancements in material science are addressing some of these challenges. Researchers are exploring nanocomposite formulations to enhance scratch resistance without compromising impact strength. Additionally, efforts are underway to develop bio-based polycarbonates that offer similar performance characteristics with a reduced environmental footprint.

The integration of smart technologies with polycarbonate sports gear presents both opportunities and challenges. While the material's moldability allows for the incorporation of sensors and electronic components, ensuring the durability and reliability of these integrated systems in high-impact environments remains a complex task.

In the realm of protective gear, polycarbonate is extensively utilized in helmets for sports such as cycling, skiing, and American football. These helmets benefit from polycarbonate's ability to absorb and distribute impact energy, significantly reducing the risk of head injuries. The material's durability allows for repeated impacts without compromising structural integrity, ensuring long-term protection for athletes.

Eyewear is another area where polycarbonate excels. Sports goggles and sunglasses made from this material offer superior impact resistance compared to traditional glass or other plastics. This is crucial in high-speed or contact sports where eye protection is essential. The optical clarity of polycarbonate also ensures unobstructed vision, a critical factor in athletic performance.

Despite its widespread adoption, polycarbonate faces several challenges in the sports gear industry. One significant issue is its susceptibility to scratching, which can compromise both aesthetics and functionality over time. While scratch-resistant coatings have been developed, finding a balance between scratch resistance and the material's inherent impact strength remains a challenge.

Another hurdle is the material's limited temperature resistance. In extreme weather conditions, polycarbonate can become brittle at low temperatures or soften at high temperatures, potentially affecting its protective properties. This limitation requires careful consideration in the design and application of sports gear for diverse environmental conditions.

The environmental impact of polycarbonate production and disposal is also a growing concern. As sustainability becomes increasingly important in consumer products, the sports gear industry faces pressure to find more eco-friendly alternatives or improve the recyclability of polycarbonate components.

Advancements in material science are addressing some of these challenges. Researchers are exploring nanocomposite formulations to enhance scratch resistance without compromising impact strength. Additionally, efforts are underway to develop bio-based polycarbonates that offer similar performance characteristics with a reduced environmental footprint.

The integration of smart technologies with polycarbonate sports gear presents both opportunities and challenges. While the material's moldability allows for the incorporation of sensors and electronic components, ensuring the durability and reliability of these integrated systems in high-impact environments remains a complex task.

Existing Polycarbonate Solutions in High-Performance Sports Gear

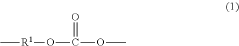

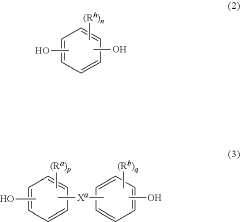

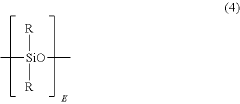

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or materials to achieve improved mechanical, thermal, or electrical properties. These combinations can result in materials with enhanced impact resistance, flame retardancy, or conductivity for various applications.

- Polycarbonate processing and molding techniques: Advancements in processing and molding techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on optimizing production efficiency, reducing defects, and achieving desired shapes and properties in the final products.

- Surface treatment and coating of polycarbonates: Methods for surface treatment and coating of polycarbonate materials to enhance properties such as scratch resistance, UV stability, and adhesion. These techniques can involve chemical modifications, plasma treatments, or application of specialized coatings to improve the durability and functionality of polycarbonate products.

- Recycling and sustainability of polycarbonates: Innovations in recycling processes and sustainable production methods for polycarbonates, including chemical recycling, biodegradable additives, and bio-based alternatives. These approaches aim to reduce environmental impact and improve the lifecycle management of polycarbonate materials.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blends and composites are tailored for various industrial and consumer applications.Expand Specific Solutions03 Polycarbonate processing and manufacturing

Advancements in processing and manufacturing techniques for polycarbonates, including extrusion, injection molding, and film formation. These innovations focus on improving production efficiency, reducing defects, and enhancing the quality of final products. New equipment designs and process parameters are explored to optimize polycarbonate processing.Expand Specific Solutions04 Polycarbonate applications in electronics

Utilization of polycarbonates in electronic devices and components, such as housings, displays, and circuit boards. The focus is on developing polycarbonate formulations with improved heat resistance, dimensional stability, and electrical properties suitable for electronic applications. This includes the use of polycarbonates in emerging technologies like flexible electronics.Expand Specific Solutions05 Sustainable and bio-based polycarbonates

Research into sustainable and bio-based alternatives to traditional polycarbonates, focusing on renewable resources and environmentally friendly production methods. This includes the development of biodegradable polycarbonates and the use of bio-based monomers to reduce reliance on petroleum-based raw materials. The aim is to create more eco-friendly polycarbonate materials without compromising performance.Expand Specific Solutions

Key Players in Polycarbonate Sports Gear Manufacturing

The research on polycarbonate use in high-performance sports gear is in a growth phase, with an expanding market driven by increasing demand for lightweight, durable equipment. The global market size for advanced sports materials is projected to reach several billion dollars by 2025. Technologically, polycarbonate applications are maturing, with companies like SABIC, Covestro, and LG Chem leading innovation. These firms are developing enhanced polycarbonate formulations with improved impact resistance, UV stability, and customizable properties. Collaboration between material suppliers and sports equipment manufacturers, such as Taylor Made Golf and NIKE, is accelerating product development and market adoption.

SABIC Global Technologies BV

Technical Solution: SABIC has developed high-performance polycarbonate blends specifically for sports gear applications. Their LEXAN™ EXL resin technology offers enhanced impact resistance and low-temperature ductility, crucial for protective equipment[1]. The company has also introduced LEXAN™ HP92S resin, which provides excellent flow properties and high impact strength, making it ideal for thin-wall applications in sports helmets and goggles[2]. SABIC's polycarbonate innovations extend to their LEXAN™ LIGHT series, which reduces weight by up to 30% compared to standard polycarbonate while maintaining mechanical properties[3], addressing the demand for lighter yet durable sports equipment.

Strengths: Wide range of specialized polycarbonate blends, industry-leading impact resistance, and weight reduction capabilities. Weaknesses: Potentially higher cost compared to standard polycarbonates, may require specialized processing techniques.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered the use of polycarbonate in high-performance sports gear through its Makrolon® product line. Their advanced polycarbonate grades offer exceptional impact resistance and optical clarity, crucial for protective eyewear and helmets in sports[4]. Covestro has developed Makrolon® 3638, a high-flow polycarbonate specifically designed for thin-wall applications in sports equipment, providing excellent impact strength even at low temperatures[5]. The company has also introduced Makrolon® RE, a more sustainable polycarbonate made with up to 71% bio-circular attributed content, addressing the growing demand for eco-friendly materials in sports gear[6].

Strengths: Excellent impact resistance, optical clarity, and innovative sustainable options. Weaknesses: May have higher production costs, potential limitations in extreme temperature applications.

Core Innovations in Polycarbonate for Sports Applications

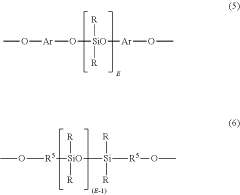

Sports equipment comprising silicone polycarbonate elastomer

PatentInactiveUS20200197755A1

Innovation

- Development of thermoplastic poly(carbonate-siloxane) elastomers with high silicone content, which offer a combination of elastomeric behavior, high traction, and temperature stability, allowing for adjustable properties suitable for various sports equipment and footwear applications.

High heat polycarbonate compositions

PatentInactiveEP3131970A1

Innovation

- Development of high heat polycarbonate-based blend compositions incorporating high heat polycarbonates, polysiloxane-polycarbonate copolymers, and other additives like fillers and antioxidants, which can be directly metallized to form articles with enhanced thermal, mechanical, and rheological properties.

Environmental Impact and Sustainability of Polycarbonate Use

The use of polycarbonate in high-performance sports gear has significant environmental implications that warrant careful consideration. Polycarbonate, a durable and lightweight plastic, offers excellent impact resistance and optical clarity, making it an attractive material for sports equipment. However, its production and disposal pose environmental challenges that need to be addressed for sustainable use.

The manufacturing process of polycarbonate is energy-intensive and relies heavily on fossil fuels, contributing to greenhouse gas emissions. The primary raw material, bisphenol A (BPA), is derived from petroleum and has been associated with potential health and environmental risks. As the demand for high-performance sports gear increases, the environmental footprint of polycarbonate production becomes a growing concern.

Recycling polycarbonate presents both opportunities and challenges. While the material is technically recyclable, the process is complex and often not economically viable. Many recycling facilities lack the specialized equipment needed to handle polycarbonate effectively, leading to a significant portion of used sports gear ending up in landfills or incinerators. This contributes to plastic pollution and the release of harmful chemicals into the environment.

The durability of polycarbonate is a double-edged sword from an environmental perspective. On one hand, its long lifespan reduces the need for frequent replacements, potentially lowering overall resource consumption. On the other hand, this durability means that polycarbonate products persist in the environment for extended periods when discarded improperly.

To address these environmental concerns, several sustainability initiatives are being explored in the sports gear industry. Some manufacturers are investigating bio-based alternatives to traditional polycarbonate, derived from renewable resources such as plant-based materials. These alternatives aim to reduce the carbon footprint of production while maintaining the high-performance characteristics required for sports equipment.

Closed-loop recycling systems are also being developed to improve the recyclability of polycarbonate sports gear. These systems involve collecting used equipment, breaking it down into its chemical components, and reusing these components to create new products. While still in the early stages, this approach shows promise in reducing waste and conserving resources.

Additionally, efforts are being made to improve the energy efficiency of polycarbonate production processes. Advanced manufacturing techniques and the use of renewable energy sources in production facilities can help mitigate the environmental impact of polycarbonate sports gear.

As the sports industry continues to prioritize sustainability, the use of polycarbonate in high-performance gear will likely evolve. Balancing performance requirements with environmental considerations will be crucial in developing the next generation of sports equipment. This may involve a combination of material innovations, improved recycling technologies, and more sustainable production methods to ensure that high-performance sports gear can meet athletic needs without compromising environmental integrity.

The manufacturing process of polycarbonate is energy-intensive and relies heavily on fossil fuels, contributing to greenhouse gas emissions. The primary raw material, bisphenol A (BPA), is derived from petroleum and has been associated with potential health and environmental risks. As the demand for high-performance sports gear increases, the environmental footprint of polycarbonate production becomes a growing concern.

Recycling polycarbonate presents both opportunities and challenges. While the material is technically recyclable, the process is complex and often not economically viable. Many recycling facilities lack the specialized equipment needed to handle polycarbonate effectively, leading to a significant portion of used sports gear ending up in landfills or incinerators. This contributes to plastic pollution and the release of harmful chemicals into the environment.

The durability of polycarbonate is a double-edged sword from an environmental perspective. On one hand, its long lifespan reduces the need for frequent replacements, potentially lowering overall resource consumption. On the other hand, this durability means that polycarbonate products persist in the environment for extended periods when discarded improperly.

To address these environmental concerns, several sustainability initiatives are being explored in the sports gear industry. Some manufacturers are investigating bio-based alternatives to traditional polycarbonate, derived from renewable resources such as plant-based materials. These alternatives aim to reduce the carbon footprint of production while maintaining the high-performance characteristics required for sports equipment.

Closed-loop recycling systems are also being developed to improve the recyclability of polycarbonate sports gear. These systems involve collecting used equipment, breaking it down into its chemical components, and reusing these components to create new products. While still in the early stages, this approach shows promise in reducing waste and conserving resources.

Additionally, efforts are being made to improve the energy efficiency of polycarbonate production processes. Advanced manufacturing techniques and the use of renewable energy sources in production facilities can help mitigate the environmental impact of polycarbonate sports gear.

As the sports industry continues to prioritize sustainability, the use of polycarbonate in high-performance gear will likely evolve. Balancing performance requirements with environmental considerations will be crucial in developing the next generation of sports equipment. This may involve a combination of material innovations, improved recycling technologies, and more sustainable production methods to ensure that high-performance sports gear can meet athletic needs without compromising environmental integrity.

Safety Standards and Regulations for Sports Equipment Materials

Safety standards and regulations play a crucial role in ensuring the quality and reliability of sports equipment materials, particularly in the context of polycarbonate use in high-performance sports gear. These standards are designed to protect athletes from potential injuries and enhance overall performance.

The International Organization for Standardization (ISO) has developed several standards specific to sports equipment materials. ISO 22846 focuses on the safety requirements for helmets used in alpine skiing and snowboarding, while ISO 10256 addresses protective equipment for ice hockey players. These standards outline specific requirements for impact resistance, durability, and overall performance of materials used in sports gear.

In the United States, the American Society for Testing and Materials (ASTM) has established comprehensive guidelines for sports equipment materials. ASTM F1446 sets the standard for athletic helmets, including those made with polycarbonate. This standard specifies testing methods for impact attenuation, retention system strength, and stability, ensuring that helmets provide adequate protection during sports activities.

The European Committee for Standardization (CEN) has also developed standards for sports equipment materials. EN 1077 covers helmets for alpine skiers and snowboarders, while EN 1078 focuses on helmets for pedal cyclists and users of skateboards and roller skates. These standards define requirements for shock absorption, retention system effectiveness, and field of vision, all of which are critical considerations when using polycarbonate in sports gear.

Regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the United States and the European Commission in the EU enforce these standards and regulations. The CPSC has mandatory safety standards for bicycle helmets under 16 CFR Part 1203, which includes specific requirements for materials like polycarbonate used in helmet construction.

Manufacturers of high-performance sports gear must adhere to these standards and regulations when incorporating polycarbonate into their products. Compliance often involves rigorous testing procedures, including impact tests, penetration resistance tests, and environmental exposure tests to ensure the material's performance under various conditions.

As technology and materials science advance, these standards and regulations are periodically reviewed and updated to reflect new findings and improved safety measures. This ongoing process ensures that the use of polycarbonate and other materials in sports equipment continues to meet the highest safety standards, providing athletes with reliable and effective protection during their activities.

The International Organization for Standardization (ISO) has developed several standards specific to sports equipment materials. ISO 22846 focuses on the safety requirements for helmets used in alpine skiing and snowboarding, while ISO 10256 addresses protective equipment for ice hockey players. These standards outline specific requirements for impact resistance, durability, and overall performance of materials used in sports gear.

In the United States, the American Society for Testing and Materials (ASTM) has established comprehensive guidelines for sports equipment materials. ASTM F1446 sets the standard for athletic helmets, including those made with polycarbonate. This standard specifies testing methods for impact attenuation, retention system strength, and stability, ensuring that helmets provide adequate protection during sports activities.

The European Committee for Standardization (CEN) has also developed standards for sports equipment materials. EN 1077 covers helmets for alpine skiers and snowboarders, while EN 1078 focuses on helmets for pedal cyclists and users of skateboards and roller skates. These standards define requirements for shock absorption, retention system effectiveness, and field of vision, all of which are critical considerations when using polycarbonate in sports gear.

Regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the United States and the European Commission in the EU enforce these standards and regulations. The CPSC has mandatory safety standards for bicycle helmets under 16 CFR Part 1203, which includes specific requirements for materials like polycarbonate used in helmet construction.

Manufacturers of high-performance sports gear must adhere to these standards and regulations when incorporating polycarbonate into their products. Compliance often involves rigorous testing procedures, including impact tests, penetration resistance tests, and environmental exposure tests to ensure the material's performance under various conditions.

As technology and materials science advance, these standards and regulations are periodically reviewed and updated to reflect new findings and improved safety measures. This ongoing process ensures that the use of polycarbonate and other materials in sports equipment continues to meet the highest safety standards, providing athletes with reliable and effective protection during their activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!