Throttle Body Integration with Active Exhaust Systems

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle-Exhaust Integration Background and Objectives

The integration of throttle bodies with active exhaust systems represents a significant advancement in automotive engineering, aiming to enhance vehicle performance, fuel efficiency, and driving experience. This technological convergence has its roots in the continuous pursuit of optimizing engine output and emissions control.

Historically, throttle bodies and exhaust systems have been developed and optimized separately. Throttle bodies, responsible for regulating air intake into the engine, have evolved from mechanical to electronic control systems. Concurrently, exhaust systems have progressed from simple pipes to complex arrangements incorporating catalytic converters, mufflers, and more recently, active components.

The concept of integrating these two systems emerged from the recognition that coordinated control of air intake and exhaust flow could yield substantial benefits. This integration aligns with the broader trend in automotive engineering towards holistic powertrain management, where various subsystems work in harmony to achieve optimal performance.

The primary objective of this integration is to create a synergistic relationship between air intake and exhaust management. By coordinating the operation of the throttle body with an active exhaust system, engineers aim to achieve several key goals:

1. Enhanced Engine Performance: Precise control over both intake and exhaust can lead to improved power output across different engine speeds and load conditions.

2. Improved Fuel Efficiency: Optimized air-fuel mixture and exhaust flow can contribute to more complete combustion and reduced fuel consumption.

3. Dynamic Sound Management: Active exhaust systems can modulate engine sound, and when integrated with throttle control, can provide a more engaging driving experience without compromising efficiency.

4. Emissions Reduction: Coordinated management of intake and exhaust can potentially lead to more effective emissions control, particularly during transient operating conditions.

5. Adaptive Performance: The integrated system can adjust to various driving modes, environmental conditions, and regulatory requirements, offering a more versatile and compliant powertrain solution.

The technological evolution in this field is driven by advancements in electronic control systems, sensor technology, and materials science. Modern throttle bodies and active exhaust systems are equipped with sophisticated sensors and actuators, enabling real-time adjustments based on a multitude of parameters.

As the automotive industry continues to face stringent emissions regulations and increasing consumer demands for performance and efficiency, the integration of throttle bodies with active exhaust systems represents a promising avenue for innovation. This research aims to explore the current state of this technology, identify challenges, and forecast potential developments that could shape the future of automotive powertrain systems.

Historically, throttle bodies and exhaust systems have been developed and optimized separately. Throttle bodies, responsible for regulating air intake into the engine, have evolved from mechanical to electronic control systems. Concurrently, exhaust systems have progressed from simple pipes to complex arrangements incorporating catalytic converters, mufflers, and more recently, active components.

The concept of integrating these two systems emerged from the recognition that coordinated control of air intake and exhaust flow could yield substantial benefits. This integration aligns with the broader trend in automotive engineering towards holistic powertrain management, where various subsystems work in harmony to achieve optimal performance.

The primary objective of this integration is to create a synergistic relationship between air intake and exhaust management. By coordinating the operation of the throttle body with an active exhaust system, engineers aim to achieve several key goals:

1. Enhanced Engine Performance: Precise control over both intake and exhaust can lead to improved power output across different engine speeds and load conditions.

2. Improved Fuel Efficiency: Optimized air-fuel mixture and exhaust flow can contribute to more complete combustion and reduced fuel consumption.

3. Dynamic Sound Management: Active exhaust systems can modulate engine sound, and when integrated with throttle control, can provide a more engaging driving experience without compromising efficiency.

4. Emissions Reduction: Coordinated management of intake and exhaust can potentially lead to more effective emissions control, particularly during transient operating conditions.

5. Adaptive Performance: The integrated system can adjust to various driving modes, environmental conditions, and regulatory requirements, offering a more versatile and compliant powertrain solution.

The technological evolution in this field is driven by advancements in electronic control systems, sensor technology, and materials science. Modern throttle bodies and active exhaust systems are equipped with sophisticated sensors and actuators, enabling real-time adjustments based on a multitude of parameters.

As the automotive industry continues to face stringent emissions regulations and increasing consumer demands for performance and efficiency, the integration of throttle bodies with active exhaust systems represents a promising avenue for innovation. This research aims to explore the current state of this technology, identify challenges, and forecast potential developments that could shape the future of automotive powertrain systems.

Market Analysis for Integrated Powertrain Systems

The integrated powertrain systems market is experiencing significant growth, driven by the increasing demand for fuel-efficient and high-performance vehicles. This market segment encompasses various components, including throttle bodies and active exhaust systems, which are becoming increasingly interconnected to optimize overall vehicle performance.

The global integrated powertrain systems market is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of advanced technologies in automotive powertrains, stringent emission regulations, and the shift towards electrification.

In the context of throttle body integration with active exhaust systems, the market shows promising potential. Automotive manufacturers are increasingly focusing on enhancing engine performance while meeting stringent emission standards. This has led to a growing interest in sophisticated powertrain solutions that can dynamically adjust engine parameters and exhaust flow characteristics.

The passenger car segment dominates the integrated powertrain systems market, accounting for over 60% of the total market share. This is due to the higher production volume of passenger vehicles and the increasing consumer demand for improved fuel efficiency and performance. However, the commercial vehicle segment is expected to witness faster growth in the coming years, driven by the need for more efficient and environmentally friendly transportation solutions.

Geographically, Asia-Pacific leads the integrated powertrain systems market, followed by Europe and North America. The dominance of the Asia-Pacific region can be attributed to the presence of major automotive manufacturing hubs in countries like China, Japan, and South Korea, as well as the rapid growth of the automotive industry in emerging economies such as India and Southeast Asian nations.

Key market players in the integrated powertrain systems sector include Bosch, Continental AG, Denso Corporation, Magna International, and ZF Friedrichshafen. These companies are investing heavily in research and development to create innovative solutions that integrate various powertrain components, including throttle bodies and active exhaust systems.

The market for integrated throttle body and active exhaust systems is expected to grow as automakers seek to optimize engine performance, reduce emissions, and enhance the overall driving experience. This integration allows for more precise control over engine airflow and exhaust gas management, resulting in improved fuel efficiency, reduced emissions, and enhanced vehicle responsiveness.

The global integrated powertrain systems market is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of advanced technologies in automotive powertrains, stringent emission regulations, and the shift towards electrification.

In the context of throttle body integration with active exhaust systems, the market shows promising potential. Automotive manufacturers are increasingly focusing on enhancing engine performance while meeting stringent emission standards. This has led to a growing interest in sophisticated powertrain solutions that can dynamically adjust engine parameters and exhaust flow characteristics.

The passenger car segment dominates the integrated powertrain systems market, accounting for over 60% of the total market share. This is due to the higher production volume of passenger vehicles and the increasing consumer demand for improved fuel efficiency and performance. However, the commercial vehicle segment is expected to witness faster growth in the coming years, driven by the need for more efficient and environmentally friendly transportation solutions.

Geographically, Asia-Pacific leads the integrated powertrain systems market, followed by Europe and North America. The dominance of the Asia-Pacific region can be attributed to the presence of major automotive manufacturing hubs in countries like China, Japan, and South Korea, as well as the rapid growth of the automotive industry in emerging economies such as India and Southeast Asian nations.

Key market players in the integrated powertrain systems sector include Bosch, Continental AG, Denso Corporation, Magna International, and ZF Friedrichshafen. These companies are investing heavily in research and development to create innovative solutions that integrate various powertrain components, including throttle bodies and active exhaust systems.

The market for integrated throttle body and active exhaust systems is expected to grow as automakers seek to optimize engine performance, reduce emissions, and enhance the overall driving experience. This integration allows for more precise control over engine airflow and exhaust gas management, resulting in improved fuel efficiency, reduced emissions, and enhanced vehicle responsiveness.

Current Challenges in Throttle-Exhaust Synergy

The integration of throttle bodies with active exhaust systems presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving seamless coordination between the throttle body's air intake control and the active exhaust system's backpressure management. This synchronization is crucial for optimizing engine performance, fuel efficiency, and emissions control across various driving conditions.

A major technical hurdle lies in developing sophisticated control algorithms that can simultaneously manage both systems in real-time. These algorithms must account for a multitude of variables, including engine load, speed, temperature, and driver input, while also considering the dynamic nature of exhaust flow and backpressure. The complexity of these calculations increases exponentially when factoring in the need for rapid adjustments to meet stringent emissions standards and performance targets.

Another challenge is the integration of sensors and actuators that can withstand the harsh environment of both intake and exhaust systems. These components must be durable enough to function reliably under extreme temperatures and vibrations while maintaining high precision and quick response times. The development of such robust and accurate sensing technologies is ongoing, with a focus on miniaturization and cost-effectiveness.

The packaging and design of integrated throttle-exhaust systems pose additional difficulties. Engineers must find innovative ways to incorporate active exhaust components within the limited space of modern vehicle architectures, all while ensuring proper thermal management and minimizing weight. This often requires a complete redesign of traditional exhaust layouts and the use of advanced materials that can withstand high temperatures and corrosive exhaust gases.

Furthermore, the calibration of integrated throttle-exhaust systems presents a significant challenge. Fine-tuning the interaction between throttle response and exhaust valve actuation across the entire operating range of an engine requires extensive testing and refinement. This process is further complicated by the need to optimize for various driving modes, such as eco, sport, and comfort settings, each demanding a unique balance of performance, efficiency, and sound characteristics.

Lastly, meeting increasingly stringent noise regulations while maintaining desirable exhaust notes is a delicate balancing act. Active exhaust systems must be capable of providing an engaging auditory experience during performance driving while also offering quiet operation in urban environments. This necessitates the development of advanced sound design techniques and adaptive noise cancellation technologies that can work in harmony with throttle body operations.

A major technical hurdle lies in developing sophisticated control algorithms that can simultaneously manage both systems in real-time. These algorithms must account for a multitude of variables, including engine load, speed, temperature, and driver input, while also considering the dynamic nature of exhaust flow and backpressure. The complexity of these calculations increases exponentially when factoring in the need for rapid adjustments to meet stringent emissions standards and performance targets.

Another challenge is the integration of sensors and actuators that can withstand the harsh environment of both intake and exhaust systems. These components must be durable enough to function reliably under extreme temperatures and vibrations while maintaining high precision and quick response times. The development of such robust and accurate sensing technologies is ongoing, with a focus on miniaturization and cost-effectiveness.

The packaging and design of integrated throttle-exhaust systems pose additional difficulties. Engineers must find innovative ways to incorporate active exhaust components within the limited space of modern vehicle architectures, all while ensuring proper thermal management and minimizing weight. This often requires a complete redesign of traditional exhaust layouts and the use of advanced materials that can withstand high temperatures and corrosive exhaust gases.

Furthermore, the calibration of integrated throttle-exhaust systems presents a significant challenge. Fine-tuning the interaction between throttle response and exhaust valve actuation across the entire operating range of an engine requires extensive testing and refinement. This process is further complicated by the need to optimize for various driving modes, such as eco, sport, and comfort settings, each demanding a unique balance of performance, efficiency, and sound characteristics.

Lastly, meeting increasingly stringent noise regulations while maintaining desirable exhaust notes is a delicate balancing act. Active exhaust systems must be capable of providing an engaging auditory experience during performance driving while also offering quiet operation in urban environments. This necessitates the development of advanced sound design techniques and adaptive noise cancellation technologies that can work in harmony with throttle body operations.

Existing Throttle-Exhaust Integration Solutions

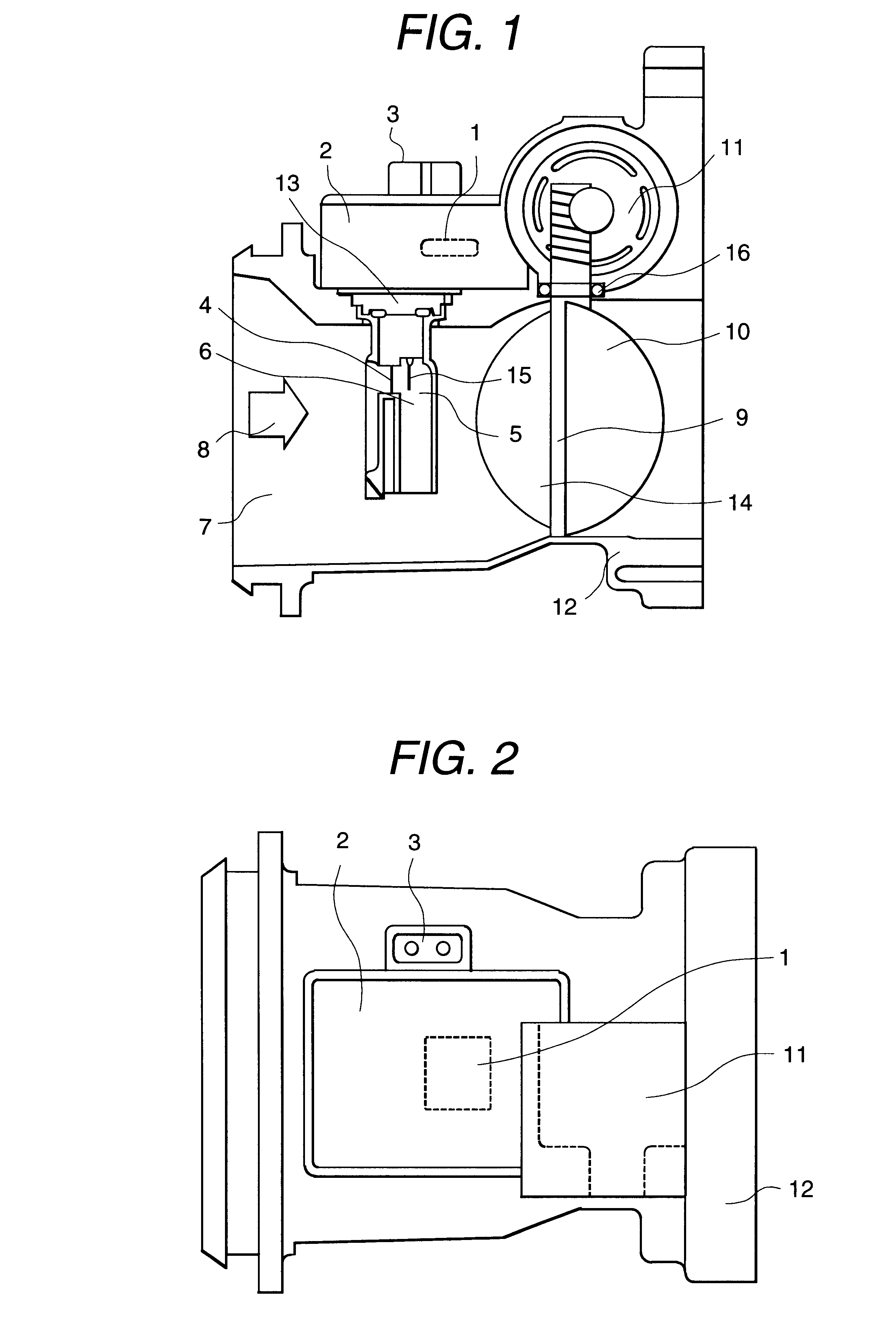

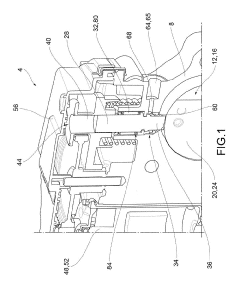

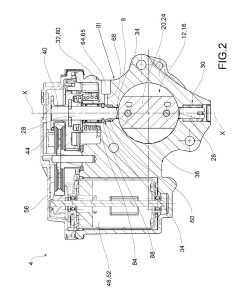

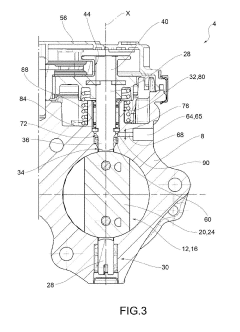

01 Throttle body design and construction

Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Various designs focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.- Throttle body design and construction: Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Various designs focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.

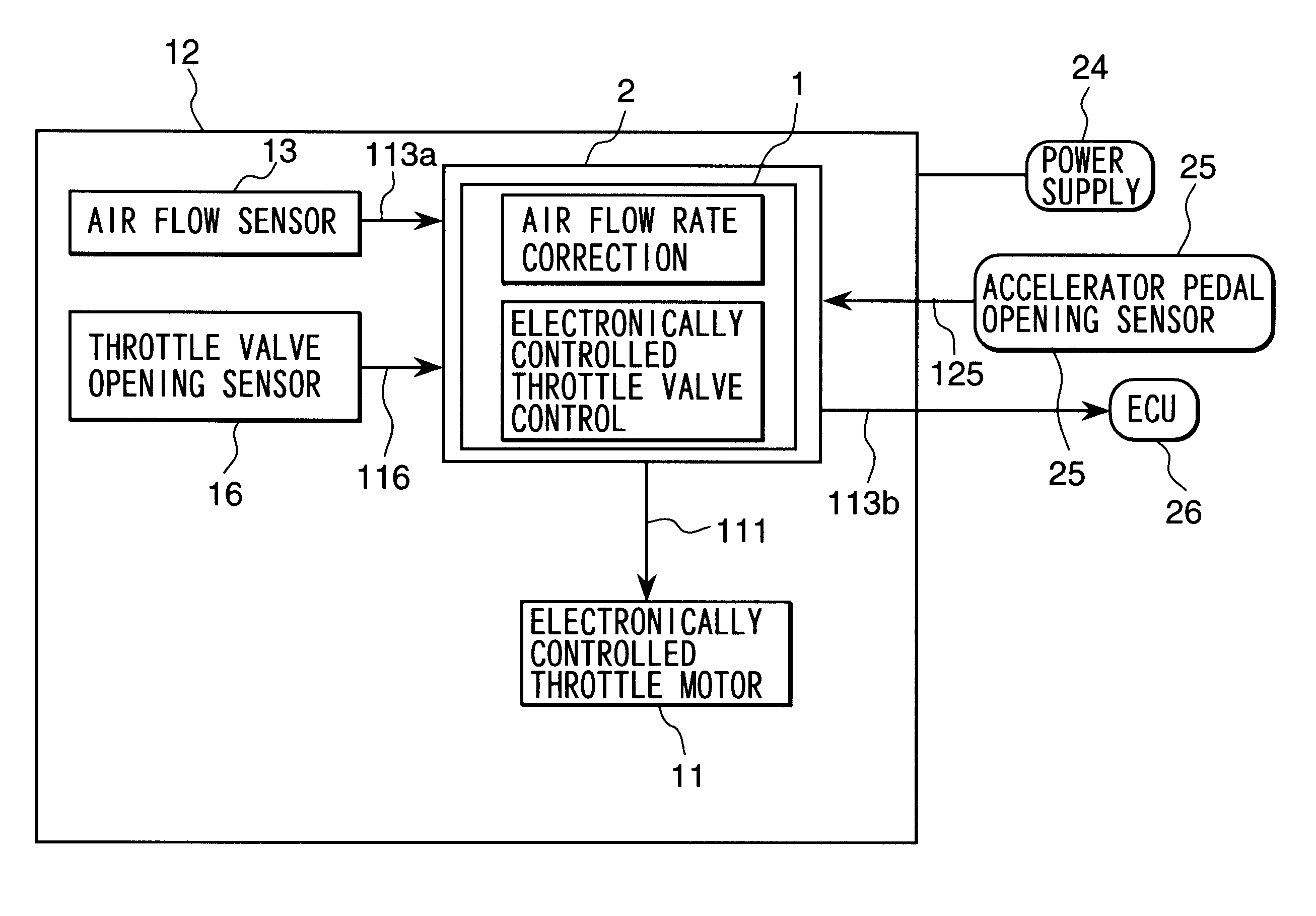

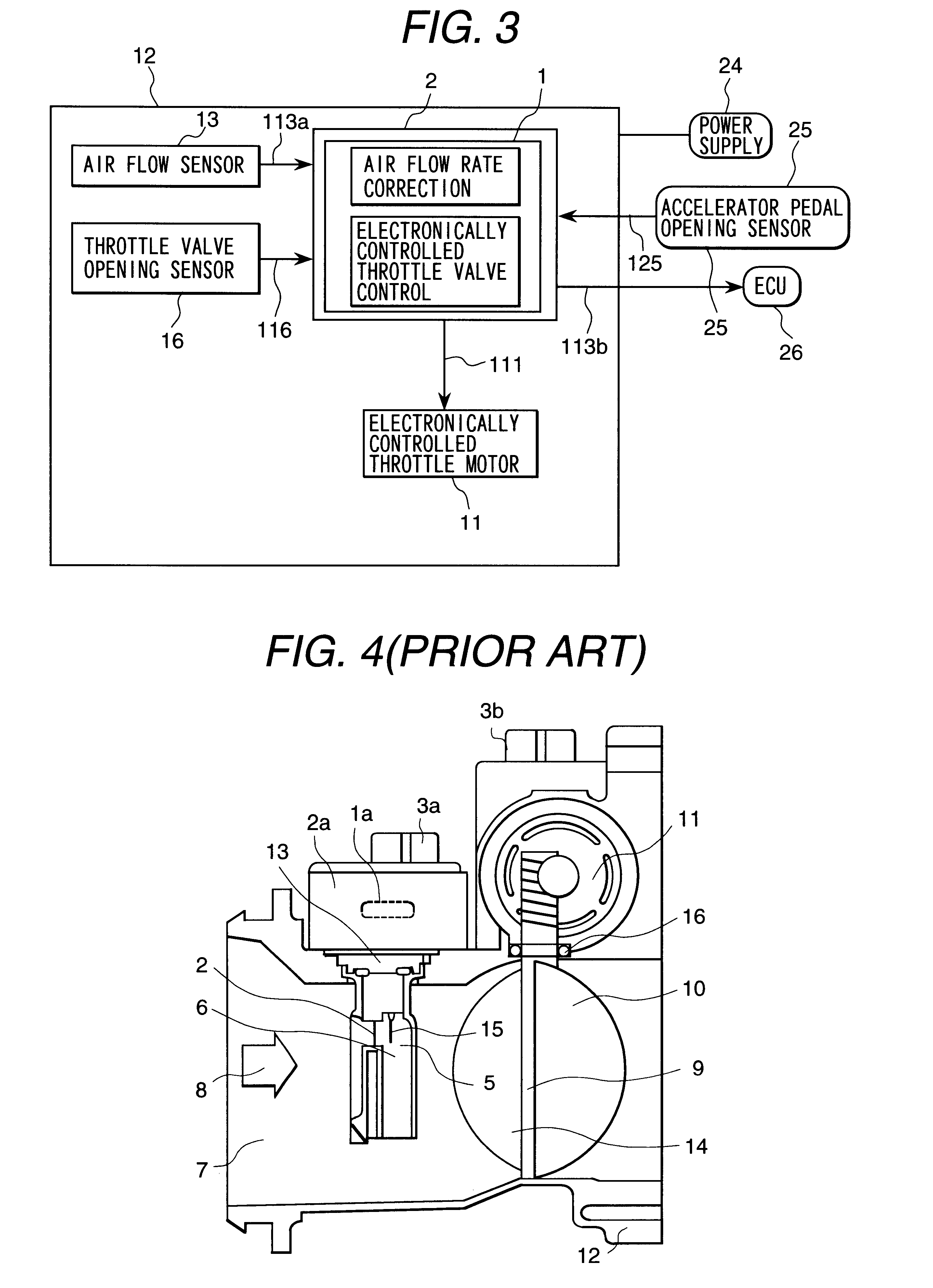

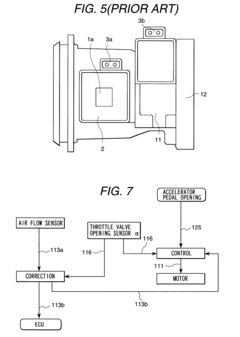

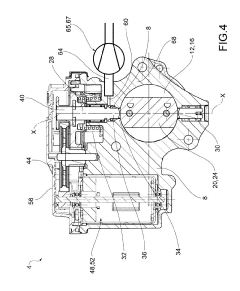

- Electronic throttle control systems: Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on driver input and engine management requirements, improving responsiveness and fuel efficiency.

- Idle air control mechanisms: Throttle bodies may include integrated idle air control mechanisms to regulate engine idle speed. These systems bypass the main throttle plate to provide a controlled amount of air during idle conditions, maintaining stable engine operation and smooth transitions between idle and acceleration.

- Multi-valve throttle bodies: Some throttle body designs incorporate multiple valves or plates to provide more precise control over airflow across different engine operating conditions. This can include primary and secondary throttle plates or separate valves for different cylinders or intake runners, optimizing performance and efficiency.

- Throttle body cleaning and maintenance: Throttle bodies require periodic cleaning and maintenance to prevent carbon buildup and ensure optimal performance. Various designs incorporate features to facilitate cleaning or reduce deposit accumulation, such as special coatings or integrated cleaning ports.

02 Electronic throttle control systems

Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on driver input and engine management requirements, improving responsiveness and fuel efficiency.Expand Specific Solutions03 Idle air control mechanisms

Throttle bodies may include idle air control mechanisms to regulate engine speed during idle conditions. These systems bypass the main throttle plate to provide a controlled amount of air, maintaining stable idle speed and smooth engine operation.Expand Specific Solutions04 Throttle body cleaning and maintenance

Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting performance. Various cleaning methods and maintenance procedures are developed to ensure optimal throttle body operation, including specialized cleaning solutions and tools for removing buildup without damaging sensitive components.Expand Specific Solutions05 Integration with fuel injection systems

Throttle bodies are often integrated with fuel injection systems to optimize air-fuel mixture. This integration can involve positioning fuel injectors near the throttle body or incorporating fuel delivery channels within the throttle body itself, improving atomization and distribution of fuel in the intake air stream.Expand Specific Solutions

Key Players in Automotive Powertrain Industry

The integration of throttle bodies with active exhaust systems is an emerging technology in the automotive industry, currently in its early development stage. The market size for this technology is relatively small but growing, driven by increasing demand for enhanced vehicle performance and customizable driving experiences. The technology's maturity is still evolving, with key players like Holley Group, GM Global Technology Operations, and Ford Global Technologies leading research and development efforts. Companies such as Honda Motor, Continental Automotive Systems, and DENSO Corp are also contributing to advancements in this field. As the technology progresses, we can expect increased competition and innovation from both established automotive manufacturers and specialized aftermarket companies, potentially leading to more sophisticated and integrated systems in the near future.

GM Global Technology Operations LLC

Technical Solution: GM has developed an integrated throttle body and active exhaust system that optimizes engine performance and sound. Their solution uses a variable geometry throttle body that adjusts airflow based on engine load and driver input. This is coupled with an electronically controlled exhaust valve system that modulates exhaust flow and acoustics. The integration allows for real-time coordination between intake and exhaust, improving overall engine efficiency and responsiveness. GM's system also incorporates advanced sensors and control algorithms to fine-tune the throttle and exhaust valve positions for different driving modes, enhancing both performance and fuel economy[1][3].

Strengths: Seamless integration of throttle and exhaust control, improved engine efficiency, and customizable performance modes. Weaknesses: Complexity may lead to higher costs and potential reliability issues in the long term.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered a sophisticated throttle body integration with active exhaust systems, focusing on their high-performance vehicles. Their approach utilizes a drive-by-wire electronic throttle control system that communicates directly with the active exhaust valves. This integration allows for precise control of both intake air and exhaust flow, optimizing engine performance across various RPM ranges. Honda's system also incorporates adaptive learning algorithms that adjust throttle response and exhaust valve timing based on driving conditions and driver behavior. Additionally, they have implemented a unique sound enhancement feature that uses the throttle body and exhaust system in tandem to create a more engaging auditory experience for the driver[2][5].

Strengths: Advanced integration of electronic controls, adaptive performance optimization, and enhanced driver experience. Weaknesses: Potentially higher production costs and increased system complexity.

Core Innovations in Engine Control Systems

Air flow measuring device formed integrally with electronically controlled throttle body

PatentInactiveUS6681742B1

Innovation

- Integration of an air flow meter, pressure gauge, and microcomputer with the electronically controlled throttle body, allowing for accurate air flow rate measurement, correction, and fault diagnosis, reducing errors and enabling self-diagnosis, thereby improving engine control and minimizing harmful emissions.

Throttle body or actuator, in particular for supplying high pressure gas, provided with vent

PatentActiveUS20190264816A1

Innovation

- A throttle body design featuring a main body with a supply duct, a choke valve, and a control shaft with a first gasket to prevent dirt and gas penetration, accompanied by a vent with a non-return device to expel leaked gases outside, preventing backflow and creating a safe sealing mechanism.

Emissions Regulations Impact on Integration

The integration of throttle bodies with active exhaust systems is increasingly influenced by stringent emissions regulations worldwide. These regulations, aimed at reducing vehicle emissions and improving air quality, have a significant impact on the design and functionality of both throttle bodies and exhaust systems.

Emissions standards, such as Euro 6d in Europe and Tier 3 in the United States, set strict limits on pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. To meet these standards, manufacturers must optimize engine performance and exhaust aftertreatment systems, which directly affects the integration of throttle bodies and active exhaust systems.

The throttle body, responsible for controlling airflow into the engine, plays a crucial role in managing emissions. Precise control of air-fuel ratios is essential for minimizing pollutants. As a result, throttle bodies are becoming more sophisticated, incorporating advanced sensors and electronic controls to fine-tune air intake based on real-time emissions data.

Active exhaust systems, which can alter exhaust flow and noise levels, are also being adapted to meet emissions requirements. These systems now incorporate additional components like catalytic converters and particulate filters, which must be carefully integrated with the throttle body's operation to maintain optimal engine performance while reducing emissions.

The integration of these systems requires advanced electronic control units (ECUs) that can simultaneously manage throttle position, exhaust valve actuation, and emissions control devices. This integration allows for dynamic adjustments based on driving conditions, ensuring compliance with emissions standards across various operating modes.

Manufacturers are also exploring innovative solutions, such as variable geometry throttle bodies and adaptive exhaust systems, to enhance the synergy between these components. These technologies allow for greater flexibility in managing airflow and exhaust gases, potentially improving both performance and emissions control.

The impact of emissions regulations extends to the materials used in both throttle bodies and exhaust systems. Heat-resistant and lightweight materials are being developed to withstand higher exhaust temperatures resulting from more efficient combustion processes, while also reducing overall vehicle weight to improve fuel efficiency.

As regulations continue to evolve, the integration of throttle bodies and active exhaust systems will likely become even more complex. Future developments may include predictive emissions control strategies, utilizing artificial intelligence to anticipate and mitigate potential emissions spikes based on driving patterns and environmental conditions.

Emissions standards, such as Euro 6d in Europe and Tier 3 in the United States, set strict limits on pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. To meet these standards, manufacturers must optimize engine performance and exhaust aftertreatment systems, which directly affects the integration of throttle bodies and active exhaust systems.

The throttle body, responsible for controlling airflow into the engine, plays a crucial role in managing emissions. Precise control of air-fuel ratios is essential for minimizing pollutants. As a result, throttle bodies are becoming more sophisticated, incorporating advanced sensors and electronic controls to fine-tune air intake based on real-time emissions data.

Active exhaust systems, which can alter exhaust flow and noise levels, are also being adapted to meet emissions requirements. These systems now incorporate additional components like catalytic converters and particulate filters, which must be carefully integrated with the throttle body's operation to maintain optimal engine performance while reducing emissions.

The integration of these systems requires advanced electronic control units (ECUs) that can simultaneously manage throttle position, exhaust valve actuation, and emissions control devices. This integration allows for dynamic adjustments based on driving conditions, ensuring compliance with emissions standards across various operating modes.

Manufacturers are also exploring innovative solutions, such as variable geometry throttle bodies and adaptive exhaust systems, to enhance the synergy between these components. These technologies allow for greater flexibility in managing airflow and exhaust gases, potentially improving both performance and emissions control.

The impact of emissions regulations extends to the materials used in both throttle bodies and exhaust systems. Heat-resistant and lightweight materials are being developed to withstand higher exhaust temperatures resulting from more efficient combustion processes, while also reducing overall vehicle weight to improve fuel efficiency.

As regulations continue to evolve, the integration of throttle bodies and active exhaust systems will likely become even more complex. Future developments may include predictive emissions control strategies, utilizing artificial intelligence to anticipate and mitigate potential emissions spikes based on driving patterns and environmental conditions.

Performance Testing and Validation Methods

Performance testing and validation methods are crucial components in the research on throttle body integration with active exhaust systems. These methods ensure that the integrated system meets the required performance standards and operates efficiently under various conditions.

One of the primary testing methods involves dynamometer testing, which allows for precise measurement of engine power output and torque across different throttle positions and exhaust configurations. This testing is typically conducted in controlled laboratory environments, enabling researchers to isolate variables and accurately assess the impact of throttle body and exhaust system integration on overall engine performance.

In-vehicle testing is another essential aspect of the validation process. This involves installing the integrated system in actual vehicles and conducting road tests under real-world driving conditions. These tests evaluate factors such as acceleration, fuel efficiency, and overall drivability. Additionally, they help identify any potential issues related to noise, vibration, and harshness (NVH) that may arise from the integration of the throttle body with the active exhaust system.

Emissions testing is a critical component of the validation process, given the increasing focus on environmental regulations. This involves measuring exhaust emissions across various operating conditions to ensure compliance with relevant standards. Advanced emissions testing equipment, such as portable emissions measurement systems (PEMS), can be used to gather real-time data during on-road testing.

Durability and reliability testing are also vital aspects of the validation process. These tests subject the integrated system to prolonged periods of operation under various stress conditions, including extreme temperatures, high-speed operation, and rapid throttle changes. Such testing helps identify potential wear points and ensures the long-term reliability of the integrated system.

Computer simulations and modeling play an increasingly important role in performance testing and validation. Advanced computational fluid dynamics (CFD) software can simulate airflow through the throttle body and exhaust system, allowing researchers to optimize designs before physical prototyping. Similarly, engine control unit (ECU) simulations can help validate the integration of electronic control systems with the physical components.

Acoustic testing is particularly relevant for active exhaust systems integrated with throttle bodies. This involves measuring sound levels and characteristics across different operating conditions to ensure that the system meets both performance and regulatory requirements. Specialized anechoic chambers may be used for precise acoustic measurements.

Finally, thermal management testing is crucial to ensure that the integrated system can maintain optimal operating temperatures across various driving conditions. This involves using thermal imaging cameras and temperature sensors to monitor heat distribution and identify potential hotspots that could affect performance or component longevity.

One of the primary testing methods involves dynamometer testing, which allows for precise measurement of engine power output and torque across different throttle positions and exhaust configurations. This testing is typically conducted in controlled laboratory environments, enabling researchers to isolate variables and accurately assess the impact of throttle body and exhaust system integration on overall engine performance.

In-vehicle testing is another essential aspect of the validation process. This involves installing the integrated system in actual vehicles and conducting road tests under real-world driving conditions. These tests evaluate factors such as acceleration, fuel efficiency, and overall drivability. Additionally, they help identify any potential issues related to noise, vibration, and harshness (NVH) that may arise from the integration of the throttle body with the active exhaust system.

Emissions testing is a critical component of the validation process, given the increasing focus on environmental regulations. This involves measuring exhaust emissions across various operating conditions to ensure compliance with relevant standards. Advanced emissions testing equipment, such as portable emissions measurement systems (PEMS), can be used to gather real-time data during on-road testing.

Durability and reliability testing are also vital aspects of the validation process. These tests subject the integrated system to prolonged periods of operation under various stress conditions, including extreme temperatures, high-speed operation, and rapid throttle changes. Such testing helps identify potential wear points and ensures the long-term reliability of the integrated system.

Computer simulations and modeling play an increasingly important role in performance testing and validation. Advanced computational fluid dynamics (CFD) software can simulate airflow through the throttle body and exhaust system, allowing researchers to optimize designs before physical prototyping. Similarly, engine control unit (ECU) simulations can help validate the integration of electronic control systems with the physical components.

Acoustic testing is particularly relevant for active exhaust systems integrated with throttle bodies. This involves measuring sound levels and characteristics across different operating conditions to ensure that the system meets both performance and regulatory requirements. Specialized anechoic chambers may be used for precise acoustic measurements.

Finally, thermal management testing is crucial to ensure that the integrated system can maintain optimal operating temperatures across various driving conditions. This involves using thermal imaging cameras and temperature sensors to monitor heat distribution and identify potential hotspots that could affect performance or component longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!