Hastelloy is a family of corrosion-resistant metal alloys primarily composed of nickel, with varying amounts of molybdenum, iron, cobalt, and chromium. Originally developed by Haynes International, Hastelloy is widely used in extreme environments where other materials fail—particularly in aerospace, chemical processing, marine, and energy industries.

As industries face increasing demands for durability, environmental safety, and operational efficiency, Hastelloy stands out due to its resistance to oxidation, pitting, and high-temperature degradation. From nuclear reactors to clean energy systems, it continues to evolve as a foundational material for high-stakes engineering.

This article explores Hastelloy’s key properties, its diverse application domains, comparative benefits and limitations, emerging innovations, and what the future holds for this high-performance alloy through PatSnap Eureka AI Agent.

Material Composition & Key Properties

Hastelloy is not a single alloy, but a group of superalloys (notably Hastelloy C-22, C-276, X, and N). Common compositional traits include:

- Nickel (Ni): High corrosion and oxidation resistance

- Molybdenum (Mo): Enhances resistance to pitting and crevice corrosion

- Chromium (Cr): Improves oxidation and acid resistance

- Iron (Fe), Cobalt (Co): Improves strength and workability

Key Properties:

- Outstanding resistance to hydrochloric, sulfuric, and phosphoric acids

- Retains strength and shape at temperatures up to 1100°C

- Excellent weldability and fabrication versatility

- Low thermal expansion and high stress tolerance

- Superior fatigue resistance under cyclical loading

Common forms include tubes, plates, wires, bars, and custom-formed components.

Application Domains

⚗️ Chemical Processing & Industrial Systems

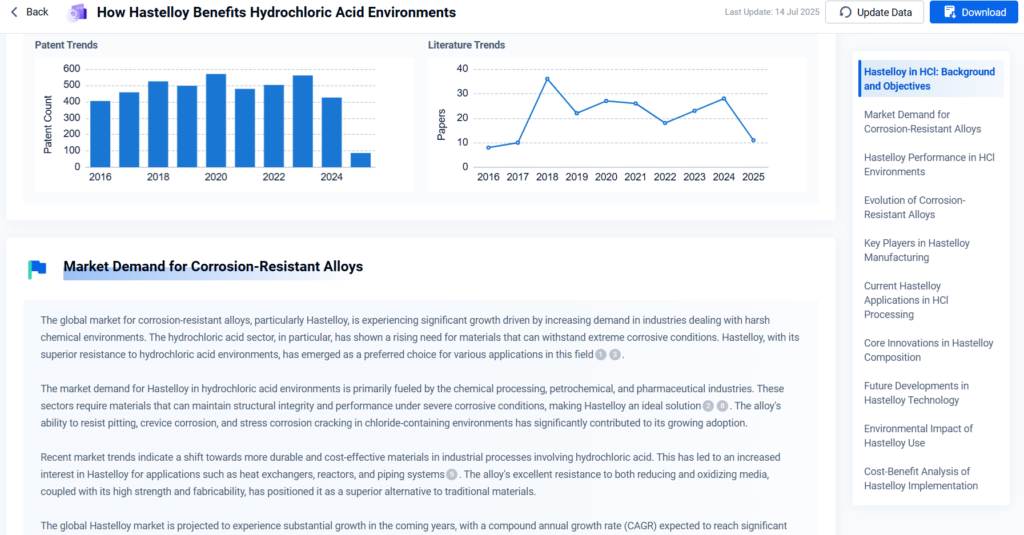

Hastelloy is critical in systems that handle aggressive chemicals, high pressures, and rapid temperature swings.

- Material Role: Resistant to acid corrosion, pressure containment, and chemical reaction stability

- Research Focus: Reducing maintenance cost in plants, enhancing safety in hydrochloric acid environments, and improving process efficiency

- Related Reports:

- How Hastelloy Benefits Hydrochloric Acid Environments?

- Hastelloy Optimization: Techniques for Chemical Resistance

- How Hastelloy Alloy Reduces Maintenance Costs in Plants?

- Hastelloy’s Role in Modern Power Distribution Networks

- Hastelloy Solutions for Reducing Corrosive Wear

- Hastelloy Application Innovations for Industrial Progress

- Hastelloy Technologies for Industrial Emission Management

✈ Aerospace & Thermal-Resistant Components

Lightweight and resilient under extreme heat, Hastelloy is ideal for aerospace components, turbine engines, and thermal shielding.

- Material Role: High strength-to-weight ratio and oxidation resistance

- Research Focus: Applications in aerospace thermal control, space exploration equipment, and heat exchangers

- Related Reports:

- Hastelloy Alloy Advances in Aerospace Componentry

- Hastelloy’s Deployment in Spacecraft Thermal Control

- Enhancing Safety with Hastelloy’s High-Heat Resistance

- Hastelloy Applications in Geothermal Energy Solutions

- Hastelloy Developments for Advanced Heat Exchangers

- Hastelloy Advances in Aerospace Thermal Management

- Hastelloy Alloy Development in High-Reliability Systems

🌊 Energy, Oil & Gas, and Nuclear Applications

Hastelloy ensures performance in corrosive fluids, radioactive environments, and geothermal operations.

- Material Role: Extends component lifespan and enhances safety

- Research Focus: Sustainability in geothermal systems, nuclear reactor safety, and emissions reduction

- Related Reports:

- Hastelloy Innovations in Nuclear Reactor Safety

- Modern Uses of Hastelloy in Energy Production

- Hastelloy in Oil and Gas: Solutions for Harsh Environments

- Hastelloy’s Role in Sustainable Energy Infrastructure Design

- Hastelloy Solutions in Low-Carbon Emission Applications

- Hastelloy Trends in Global Marine Applications

🏗 Sustainable Infrastructure & Environmental Systems

As urban development embraces green engineering, Hastelloy contributes to corrosion-resistant and long-life structures.

- Material Role: Durable in polluted or coastal conditions; aids emission control

- Research Focus: Architectural sustainability, emission control innovations, and water treatment

- Related Reports:

- Hastelloy’s Contribution to Sustainable Infrastructure Projects

- Hastelloy’s Impact on Emission Reduction Technologies

- Hastelloy’s Application in Modern Water Treatment Facilities

- Hastelloy’s Role in Environmental Monitoring Systems

- Hastelloy Strategies for Sustainable Waste Management

- Hastelloy for Tackling Industrial Safety Challenges

- Hastelloy Applications in Environmental Preservation Strategies

⚙️ Advanced Manufacturing & Material Innovation

From precision instruments to additive manufacturing, Hastelloy adapts to modern fabrication needs.

- Material Role: Enhances performance, reliability, and material lifespan

- Research Focus: Smart design integration, fabrication techniques, and industrial automation

- Related Reports:

- How to Optimize Hastelloy Welding Processes?

- Hastelloy’s Integration in Digital Manufacturing Processes

- Hastelloy Innovations in Advanced Drainage Systems

- Hastelloy Technology Improvements for Reducing Manufacturing Costs

- Hastelloy Optimization Techniques in Modern Applications

- Hastelloy Systems for Improving Industrial Sustainability

- Advancements in Hastelloy Alloy Fabrication Techniques

Comparative Advantages & Limitations

Advantages:

- ✓ Exceptional resistance to oxidizing and reducing agents

- ✓ High thermal and mechanical stability

- ✓ Long lifecycle in extreme conditions

- ✓ Versatile fabrication and weldability

Limitations:

- Higher material cost compared to standard stainless steel

- Requires specialized handling and fabrication expertise

- Susceptible to chloride stress corrosion in certain environments if improperly alloyed

Compared with stainless steel or Inconel, Hastelloy excels in extreme chemical and high-temperature applications but may not be cost-effective for general-purpose use.

Future Outlook & Research Frontiers

Hastelloy will continue to be central to innovation in high-risk, high-performance industries.

Emerging Trends:

- AI-designed Hastelloy components for thermal performance

- Eco-friendly alloying processes for green production

- 3D-printable Hastelloy for customized aerospace parts

- Integration in hydrogen economy infrastructure

- Enhanced recycling and reuse strategies for alloy sustainability

These innovations aim to reduce environmental impact, improve cost-efficiency, and unlock new frontiers in safety and performance.

Conclusion

Hastelloy stands at the intersection of resilience, adaptability, and industrial utility. Its unmatched corrosion and heat resistance make it indispensable in aerospace, energy, and chemical sectors. As material demands intensify, Hastelloy’s performance advantages and continuous innovation ensure it will remain a material of choice for next-gen engineering challenges.

Accelerate Innovation with PatSnap Eureka AI Agent

Want to stay ahead in materials innovation?

PatSnap Eureka AI Agent empowers researchers and engineers to:

- Analyze Hastelloy patent landscapes

- Benchmark corrosion-resistant alloys

- Discover hidden innovation trends

👉 Request a free demo today and revolutionize your materials strategy.