Additive Manufacturing For Turbine Engines: Innovations And Applications

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive Manufacturing Technology Background And Goals

## Directory: 技术背景与目标

Additive Manufacturing (AM) for turbine engines has evolved significantly over the past few decades. Initially, AM was primarily used for prototyping and small-scale production. However, advancements in materials science and manufacturing techniques have expanded its applications to include the production of complex, high-performance components for turbine engines. The primary goal is to leverage AM to enhance the performance, efficiency, and durability of turbine engines while reducing production costs and lead times. This involves developing new materials and processes that can withstand the extreme conditions within turbine engines, such as high temperatures and pressures. Additionally, AM aims to enable more intricate designs that are not feasible with traditional manufacturing methods, thereby improving overall engine performance and fuel efficiency.

Additive Manufacturing Market Demand Analysis

- Market Potential: Additive manufacturing (AM) for turbine engines shows significant market potential due to its ability to produce complex geometries, reduce material waste, and enhance performance. The aerospace and energy sectors are primary drivers, seeking efficiency and cost reduction.

- Industry Demand: The demand for AM in turbine engines is driven by the need for lightweight, high-performance components. This technology enables rapid prototyping and customization, meeting the industry's stringent requirements for precision and durability.

- Growth Trends: The AM market for turbine engines is expected to grow substantially, with advancements in materials and processes. The increasing adoption of AM by major aerospace and energy companies highlights its strategic importance.

- Competitive Landscape: Key players in the AM market for turbine engines include GE Aviation, Siemens, and Rolls-Royce. These companies are investing heavily in R&D to enhance AM capabilities and maintain a competitive edge.

- Regulatory and Certification: The adoption of AM in turbine engines is influenced by stringent regulatory standards and certification processes. Meeting these requirements is crucial for market acceptance and widespread implementation.

- Challenges and Opportunities: While AM offers numerous benefits, challenges such as high initial costs, material limitations, and the need for skilled labor persist. However, ongoing research and technological advancements present opportunities for overcoming these barriers.

Additive Manufacturing Technology Status And Challenges

### 技术现状与挑战

**Current State of Technology**:

Additive manufacturing (AM) for turbine engines has advanced significantly, enabling complex geometries and lightweight structures. Key materials include superalloys and ceramics, essential for high-temperature performance.

**Challenges**:

- Material Properties: Ensuring consistent material properties, such as strength and heat resistance, remains a challenge.

- Quality Control: Achieving uniformity and precision in AM-produced parts is critical for reliability.

- Cost and Scalability: High production costs and scalability issues hinder widespread adoption.

- Regulatory Compliance: Meeting stringent aerospace standards and certifications is complex and time-consuming.

Additive Manufacturing Current Technical Solutions

01 Use of Additive Manufacturing for Turbine Blade Fabrication

Additive manufacturing techniques, such as selective laser melting and electron beam melting, are used to fabricate turbine blades. These methods allow for the production of complex geometries and internal cooling channels that are difficult to achieve with traditional manufacturing methods.- Use of additive manufacturing for turbine blade production: Additive manufacturing techniques, such as selective laser melting and electron beam melting, are used to produce turbine blades with complex geometries and improved performance. These techniques allow for the creation of lightweight and durable blades that can withstand high temperatures and stresses.

- Integration of cooling channels in turbine components: Additive manufacturing enables the integration of intricate cooling channels within turbine components, enhancing their thermal management and efficiency. These cooling channels help to maintain optimal operating temperatures and extend the lifespan of the components.

- Repair and refurbishment of turbine parts using additive manufacturing: Additive manufacturing is employed to repair and refurbish worn or damaged turbine parts. This process involves adding material to the affected areas, restoring the parts to their original specifications and extending their service life.

- Development of high-performance alloys for additive manufacturing: Research and development efforts focus on creating high-performance alloys specifically designed for additive manufacturing processes. These alloys offer superior mechanical properties, corrosion resistance, and thermal stability, making them ideal for use in turbine engines.

- Optimization of additive manufacturing processes for turbine components: Efforts are made to optimize additive manufacturing processes, such as adjusting printing parameters and post-processing techniques, to improve the quality and performance of turbine components. This optimization ensures that the final products meet stringent industry standards.

02 Material Optimization in Additive Manufacturing

Advanced materials, including superalloys and ceramic matrix composites, are optimized for use in additive manufacturing processes to enhance the performance and durability of turbine engines. These materials offer high-temperature resistance and improved mechanical properties.Expand Specific Solutions03 Integration of Sensors and Monitoring Systems

Additive manufacturing enables the integration of sensors and monitoring systems directly into turbine engine components. This allows for real-time monitoring of engine performance and early detection of potential issues, improving maintenance and operational efficiency.Expand Specific Solutions04 Repair and Refurbishment of Turbine Components

Additive manufacturing is used for the repair and refurbishment of turbine engine components. Techniques such as laser cladding and directed energy deposition can restore worn or damaged parts, extending the life of the components and reducing maintenance costs.Expand Specific Solutions05 Design Optimization and Weight Reduction

Additive manufacturing allows for the optimization of turbine engine designs, leading to significant weight reduction and improved fuel efficiency. Complex lattice structures and topology optimization can be employed to achieve lightweight yet strong components.Expand Specific Solutions

Additive Manufacturing Main Player Analysis

The competitive landscape for additive manufacturing in turbine engines includes established aerospace giants and specialized technology firms. The industry is growing, driven by efficiency and performance improvements. Companies like General Electric Company, Siemens AG, and Rolls-Royce Plc lead with advanced capabilities and significant R&D investments. Other notable players include Safran Aircraft Engines SAS and United Technologies Corp.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines SAS uses advanced 3D printing to produce complex engine components, enhancing performance and reducing weight. Their technology focuses on high-temperature materials suitable for turbine environments.

Strength: Advanced material usage. Weakness: High production cost.

United Technologies Corp.

Technical Solution: United Technologies Corp. invests in laser sintering and electron beam melting to create intricate parts, improving engine efficiency and durability. Their approach reduces lead times and material waste.

Strength: Efficient production process. Weakness: Limited material options.

Additive Manufacturing Key Technology Interpretation

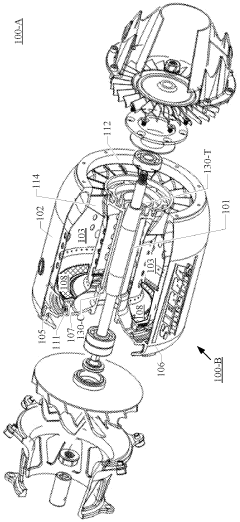

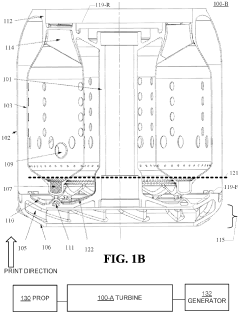

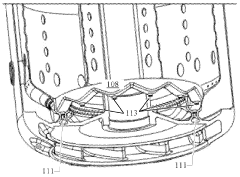

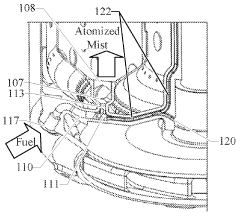

Additively manufactured gas turbine fuel injector ring and UNI-body turbine engine

PatentWO2024010565A1

Innovation

- The use of additive manufacturing (am) technology for the manufacturing of a unibodied micro turbine engine.

- The design of the unibodied micro turbine engine to take advantage of the benefits of geometries that are not possible via casting, or traditional subtractive machining operations.

- The consideration of the machine limitations found on existing laser powder bed am equipment, and the design of the unibodied micro turbine engine to work around these limitations.

Additive Manufacturing For Turbine Engines Material Analysis

Additive manufacturing (AM) for turbine engines involves using 3D printing technologies to produce complex engine components. This method offers significant advantages, including reduced material waste, enhanced design flexibility, and the ability to create intricate geometries that are difficult or impossible with traditional manufacturing. Key materials used in AM for turbine engines include high-temperature alloys, ceramics, and composite materials, each selected for their ability to withstand extreme conditions. Current challenges include ensuring material consistency, achieving desired mechanical properties, and scaling production. Future innovations may focus on improving material performance, process efficiency, and integrating AM into mainstream turbine engine manufacturing.

Additive Manufacturing For Turbine Engines Regulatory Impact

Additive Manufacturing (AM) for turbine engines significantly impacts regulatory frameworks. AM introduces new materials and complex geometries, necessitating updated certification processes. Regulatory bodies must adapt to ensure safety and reliability, addressing challenges like material consistency and structural integrity. The evolving nature of AM technologies requires continuous collaboration between manufacturers and regulators to establish standardized testing and validation protocols. This dynamic interaction aims to streamline certification while maintaining rigorous safety standards, ultimately fostering innovation and enhancing the performance and efficiency of turbine engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!