Reducing Friction In Turbine Engines: Properties And Applications

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background And Goals

## Directory: 技术背景与目标

The primary goal of reducing friction in turbine engines is to enhance efficiency, reliability, and longevity. Turbine engines, crucial in aviation and power generation, face significant energy losses due to friction, impacting fuel consumption and operational costs. Historically, advancements in materials science, lubrication technologies, and surface engineering have driven progress in this field. Current trends focus on developing advanced coatings, nano-lubricants, and novel materials to minimize friction. The objective is to achieve substantial reductions in frictional losses, thereby improving overall engine performance and reducing environmental impact.

Turbine Engine Market Demand Analysis

The turbine engine market is driven by the increasing demand for fuel-efficient and environmentally friendly engines. The aviation industry, in particular, is seeking advanced turbine engines to reduce operational costs and comply with stringent emission regulations.

- Market Growth Drivers: The need for improved fuel efficiency and reduced emissions is a primary driver. Airlines are investing in newer, more efficient engines to lower fuel costs and meet environmental standards.

- Technological Advancements: Innovations in materials and design, such as advanced coatings and lubrication systems, are crucial for reducing friction and enhancing engine performance.

- Industry Trends: The shift towards sustainable aviation fuels (SAFs) and hybrid-electric propulsion systems is influencing the development of turbine engines. These trends necessitate engines that can operate efficiently with alternative fuels and new propulsion technologies.

- Regional Demand: Emerging markets in Asia-Pacific and the Middle East are experiencing rapid growth in air travel, driving demand for new aircraft and, consequently, advanced turbine engines.

- Competitive Landscape: Major players like General Electric, Rolls-Royce, and Pratt & Whitney are leading the market with continuous R&D investments to develop next-generation turbine engines.

Turbine Engine Technology Status And Challenges

### Turbine Engine Technology Status And Challenges

**Current State of Technology**:

- Turbine engines are critical in aviation and power generation, with advancements focusing on efficiency, durability, and environmental impact.

- Modern engines incorporate advanced materials, cooling techniques, and aerodynamic designs to enhance performance.

**Key Challenges**:

- **Friction Reduction**: High friction in turbine components leads to energy loss and wear, necessitating innovative solutions.

- **Material Limitations**: Current materials face challenges in withstanding extreme temperatures and pressures.

- **Environmental Regulations**: Stricter emissions standards require engines to be more efficient and produce fewer pollutants.

**Geographical Distribution**:

- Leading research and development are concentrated in the US, Europe, and Asia, with significant contributions from major aerospace companies and research institutions.

Turbine Engine Current Technical Solutions

01 Use of advanced coatings

Ceramic and diamond-like carbon coatings on turbine components reduce friction and wear, enhancing engine efficiency and lifespan.- Use of advanced coatings: Advanced coatings like ceramics and diamond-like carbon reduce friction and wear on turbine engine components, enhancing efficiency and lifespan.

- Incorporation of lubricating materials: Synthetic oils and greases reduce friction in turbine engines by providing consistent lubrication under high temperatures and pressures.

- Design optimization for reduced friction: Optimizing turbine engine components like bearings and seals using advanced materials and precision techniques minimizes friction.

- Use of advanced materials: Composites and high-performance alloys in turbine engines offer superior strength and low-friction properties, improving performance.

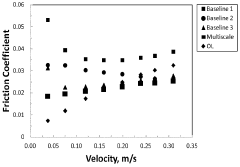

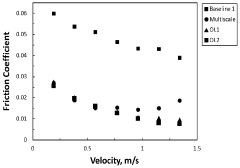

- Implementation of surface treatments: Surface treatments like polishing and texturing create smoother surfaces on turbine components, reducing friction and improving efficiency.

02 Incorporation of lubricating materials

Synthetic oils and greases in turbine engines create a thin film that reduces direct contact and friction between moving parts.Expand Specific Solutions03 Design optimization of engine components

Advanced computational methods optimize turbine components like blades and bearings, reducing friction with smoother surfaces and better aerodynamics.Expand Specific Solutions04 Use of advanced materials

High-performance alloys and composites in turbine engines offer superior strength and durability, reducing friction and wear.Expand Specific Solutions05 Implementation of surface treatments

Polishing and texturing treatments on turbine components enhance surface finish, reducing roughness and friction.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competition landscape for reducing friction in turbine engines includes industry leaders and innovative newcomers. Companies like United Technologies Corp., General Electric Company, and Pratt & Whitney Canada Corp. lead with their experience and resources. Firms such as Applied Nano Surfaces Sweden AB and Safran Aircraft Engines SAS contribute specialized innovations. Technology maturity varies, with some focusing on incremental improvements and others on groundbreaking materials and coatings.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed high-temperature resistant coatings to reduce friction, enhancing engine efficiency and longevity.

Strength: High-temperature resistance. Weakness: High cost of materials.

General Electric Company

Technical Solution: General Electric Company uses ceramic matrix composites and advanced lubricants to reduce friction, improving performance and reducing maintenance costs.

Strength: Advanced material technology. Weakness: Complex manufacturing process.

Turbine Engine Key Technology Interpretation

Friction reduction for engine components

PatentWO2012115972A1

Innovation

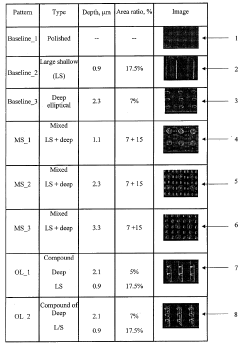

- Texture modifications such as dimples of varying geometries and depths on the surfaces of components.

- Application of a patterned soft mask followed by electrochemical etching to imprint textures onto the component.

- Application of a diamond-like-carbon (DLC) film to the turbine component to reduce friction.

Turbine Engine Friction Reduction Economic Analysis

Reducing friction in turbine engines can significantly enhance efficiency and lower operational costs. Current methods include advanced coatings, lubrication technologies, and material innovations. These solutions aim to minimize wear and tear, improve fuel efficiency, and extend engine lifespan. Economic analysis shows that investing in friction reduction technologies can lead to substantial cost savings in maintenance and fuel consumption, outweighing initial investment costs. The market for such technologies is growing, driven by the demand for more efficient and sustainable energy solutions. Key players are investing heavily in R&D to stay competitive, indicating a promising future for this sector.

Turbine Engine Friction Reduction Environmental Impact

Reducing friction in turbine engines can significantly enhance efficiency and reduce environmental impact. Current research focuses on advanced materials, surface coatings, and lubrication technologies to minimize friction. Innovations in nanotechnology and additive manufacturing are promising, offering potential breakthroughs in creating smoother surfaces and more durable components. These advancements not only improve fuel efficiency but also reduce emissions, contributing to a greener environment. The ongoing development of hybrid and electric propulsion systems further complements these efforts, aiming for a sustainable future in aviation and energy sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!