Advanced control algorithms for optimizing submersible pump performance.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Control Evolution and Objectives

Submersible pump control systems have undergone significant evolution over the past decades, driven by the need for improved efficiency, reliability, and performance in various applications. Initially, these systems relied on simple on/off controls based on predetermined water levels or pressure thresholds. As technology advanced, variable frequency drives (VFDs) were introduced, allowing for more precise control of pump speed and energy consumption.

The advent of microprocessors and advanced sensors in the 1980s and 1990s marked a turning point in submersible pump control. These technologies enabled the implementation of more sophisticated control algorithms, capable of real-time monitoring and adjustment of pump parameters. This era saw the introduction of Proportional-Integral-Derivative (PID) controllers, which became a standard in the industry due to their ability to maintain stable operation under varying conditions.

In recent years, the focus has shifted towards intelligent and adaptive control systems. Machine learning and artificial intelligence techniques are being integrated into pump control algorithms, allowing for predictive maintenance, optimized energy usage, and enhanced system responsiveness. These advanced algorithms can analyze historical data, current operating conditions, and even external factors such as weather patterns to make informed decisions about pump operation.

The primary objectives of advanced control algorithms for submersible pumps include maximizing energy efficiency, extending equipment lifespan, ensuring consistent performance across varying operating conditions, and minimizing downtime. Energy efficiency is particularly crucial, as pumping systems account for a significant portion of global energy consumption. By optimizing pump speed and operation cycles, these algorithms can substantially reduce energy costs and environmental impact.

Another key objective is to enhance the reliability and longevity of submersible pumps. Advanced control algorithms can detect early signs of wear or potential failures, allowing for proactive maintenance and preventing catastrophic breakdowns. This predictive capability not only reduces maintenance costs but also ensures uninterrupted operation in critical applications such as water supply systems or industrial processes.

Looking ahead, the future of submersible pump control is likely to involve even more sophisticated algorithms that leverage the power of the Internet of Things (IoT) and big data analytics. These systems will be capable of coordinating multiple pumps in complex networks, adapting to changing environmental conditions, and integrating seamlessly with broader infrastructure management systems. The ultimate goal is to create self-optimizing pump systems that can autonomously adjust their operation to maintain peak performance and efficiency under any circumstances.

The advent of microprocessors and advanced sensors in the 1980s and 1990s marked a turning point in submersible pump control. These technologies enabled the implementation of more sophisticated control algorithms, capable of real-time monitoring and adjustment of pump parameters. This era saw the introduction of Proportional-Integral-Derivative (PID) controllers, which became a standard in the industry due to their ability to maintain stable operation under varying conditions.

In recent years, the focus has shifted towards intelligent and adaptive control systems. Machine learning and artificial intelligence techniques are being integrated into pump control algorithms, allowing for predictive maintenance, optimized energy usage, and enhanced system responsiveness. These advanced algorithms can analyze historical data, current operating conditions, and even external factors such as weather patterns to make informed decisions about pump operation.

The primary objectives of advanced control algorithms for submersible pumps include maximizing energy efficiency, extending equipment lifespan, ensuring consistent performance across varying operating conditions, and minimizing downtime. Energy efficiency is particularly crucial, as pumping systems account for a significant portion of global energy consumption. By optimizing pump speed and operation cycles, these algorithms can substantially reduce energy costs and environmental impact.

Another key objective is to enhance the reliability and longevity of submersible pumps. Advanced control algorithms can detect early signs of wear or potential failures, allowing for proactive maintenance and preventing catastrophic breakdowns. This predictive capability not only reduces maintenance costs but also ensures uninterrupted operation in critical applications such as water supply systems or industrial processes.

Looking ahead, the future of submersible pump control is likely to involve even more sophisticated algorithms that leverage the power of the Internet of Things (IoT) and big data analytics. These systems will be capable of coordinating multiple pumps in complex networks, adapting to changing environmental conditions, and integrating seamlessly with broader infrastructure management systems. The ultimate goal is to create self-optimizing pump systems that can autonomously adjust their operation to maintain peak performance and efficiency under any circumstances.

Market Demand for Efficient Submersible Pump Systems

The market demand for efficient submersible pump systems has been steadily increasing across various industries, driven by the need for improved energy efficiency, reduced operational costs, and enhanced performance in challenging environments. The oil and gas sector, in particular, has shown a significant appetite for advanced submersible pump technologies, as companies seek to optimize production from mature fields and explore deeper offshore reserves.

In the water and wastewater management industry, there is a growing demand for submersible pumps with advanced control algorithms to address issues such as water scarcity, urbanization, and aging infrastructure. Municipalities and water utilities are increasingly looking for smart pump systems that can adapt to varying flow rates, reduce energy consumption, and minimize maintenance requirements.

The mining industry has also emerged as a key market for efficient submersible pump systems. As mining operations extend to greater depths and more remote locations, the need for reliable and high-performance pumping solutions has become critical. Advanced control algorithms that can optimize pump performance in harsh environments and handle abrasive slurries are in high demand.

Agriculture represents another significant market segment for efficient submersible pump systems. With the increasing adoption of precision agriculture techniques and the need for water conservation, farmers are seeking intelligent irrigation systems that can deliver water more efficiently. Submersible pumps with advanced control algorithms can help optimize water usage, reduce energy costs, and improve crop yields.

The global submersible pump market is projected to experience substantial growth in the coming years. Factors such as rapid industrialization in developing countries, increasing investments in water and wastewater infrastructure, and the expansion of offshore oil and gas exploration activities are expected to drive market growth. Additionally, stringent environmental regulations and the push for energy-efficient solutions are further fueling the demand for advanced submersible pump systems.

As the Internet of Things (IoT) and Industry 4.0 concepts gain traction, there is a growing interest in smart, connected submersible pump systems. End-users are increasingly demanding pumps with integrated sensors, real-time monitoring capabilities, and predictive maintenance features. This trend is creating new opportunities for pump manufacturers to differentiate their products through advanced control algorithms and data-driven optimization techniques.

In the water and wastewater management industry, there is a growing demand for submersible pumps with advanced control algorithms to address issues such as water scarcity, urbanization, and aging infrastructure. Municipalities and water utilities are increasingly looking for smart pump systems that can adapt to varying flow rates, reduce energy consumption, and minimize maintenance requirements.

The mining industry has also emerged as a key market for efficient submersible pump systems. As mining operations extend to greater depths and more remote locations, the need for reliable and high-performance pumping solutions has become critical. Advanced control algorithms that can optimize pump performance in harsh environments and handle abrasive slurries are in high demand.

Agriculture represents another significant market segment for efficient submersible pump systems. With the increasing adoption of precision agriculture techniques and the need for water conservation, farmers are seeking intelligent irrigation systems that can deliver water more efficiently. Submersible pumps with advanced control algorithms can help optimize water usage, reduce energy costs, and improve crop yields.

The global submersible pump market is projected to experience substantial growth in the coming years. Factors such as rapid industrialization in developing countries, increasing investments in water and wastewater infrastructure, and the expansion of offshore oil and gas exploration activities are expected to drive market growth. Additionally, stringent environmental regulations and the push for energy-efficient solutions are further fueling the demand for advanced submersible pump systems.

As the Internet of Things (IoT) and Industry 4.0 concepts gain traction, there is a growing interest in smart, connected submersible pump systems. End-users are increasingly demanding pumps with integrated sensors, real-time monitoring capabilities, and predictive maintenance features. This trend is creating new opportunities for pump manufacturers to differentiate their products through advanced control algorithms and data-driven optimization techniques.

Current Challenges in Submersible Pump Control

Submersible pump control systems face several significant challenges in optimizing performance and efficiency. One of the primary issues is the dynamic and often unpredictable nature of the operating environment. Submersible pumps are frequently deployed in varying depths and fluid conditions, which can change rapidly due to factors such as temperature fluctuations, pressure variations, and fluid composition alterations. These environmental variables make it difficult to maintain consistent pump performance without advanced control algorithms.

Another major challenge lies in the limited real-time data available from submersible pumps. Due to their submerged operation, traditional sensing and monitoring techniques are often inadequate or impractical. This lack of comprehensive, instantaneous feedback hinders the ability to make rapid adjustments to pump operations, potentially leading to suboptimal performance or increased wear on pump components.

Energy efficiency remains a critical concern in submersible pump control. Many existing control systems struggle to balance the need for consistent output with the desire to minimize energy consumption. This challenge is exacerbated by the fact that pumps often operate in conditions that deviate from their design optimum, requiring sophisticated control strategies to maintain efficiency across a wide range of operating points.

The prevention of cavitation and other damaging phenomena presents another significant hurdle. Cavitation, which occurs when fluid pressure drops below the vapor pressure, can cause severe damage to pump components and reduce overall system efficiency. Current control systems often lack the predictive capabilities necessary to anticipate and prevent these conditions proactively.

Maintenance and reliability issues also pose challenges for submersible pump control. The remote and often inaccessible nature of these pumps makes regular maintenance difficult and costly. Control systems must therefore be designed to maximize pump lifespan and minimize the need for interventions, a task that requires advanced predictive maintenance algorithms and robust fault detection mechanisms.

Furthermore, the integration of submersible pump control systems with broader industrial automation and IoT frameworks presents interoperability challenges. Many existing control solutions operate in isolation, limiting their ability to contribute to and benefit from wider system optimizations. Developing control algorithms that can seamlessly interface with diverse industrial systems and protocols is a complex but necessary endeavor.

Lastly, the increasing demand for adaptability and self-optimization in pump control systems presents a significant challenge. As operating conditions and requirements change over time, control algorithms must be capable of learning and adapting their strategies to maintain optimal performance. This necessitates the development of sophisticated machine learning and artificial intelligence techniques tailored to the unique constraints of submersible pump operations.

Another major challenge lies in the limited real-time data available from submersible pumps. Due to their submerged operation, traditional sensing and monitoring techniques are often inadequate or impractical. This lack of comprehensive, instantaneous feedback hinders the ability to make rapid adjustments to pump operations, potentially leading to suboptimal performance or increased wear on pump components.

Energy efficiency remains a critical concern in submersible pump control. Many existing control systems struggle to balance the need for consistent output with the desire to minimize energy consumption. This challenge is exacerbated by the fact that pumps often operate in conditions that deviate from their design optimum, requiring sophisticated control strategies to maintain efficiency across a wide range of operating points.

The prevention of cavitation and other damaging phenomena presents another significant hurdle. Cavitation, which occurs when fluid pressure drops below the vapor pressure, can cause severe damage to pump components and reduce overall system efficiency. Current control systems often lack the predictive capabilities necessary to anticipate and prevent these conditions proactively.

Maintenance and reliability issues also pose challenges for submersible pump control. The remote and often inaccessible nature of these pumps makes regular maintenance difficult and costly. Control systems must therefore be designed to maximize pump lifespan and minimize the need for interventions, a task that requires advanced predictive maintenance algorithms and robust fault detection mechanisms.

Furthermore, the integration of submersible pump control systems with broader industrial automation and IoT frameworks presents interoperability challenges. Many existing control solutions operate in isolation, limiting their ability to contribute to and benefit from wider system optimizations. Developing control algorithms that can seamlessly interface with diverse industrial systems and protocols is a complex but necessary endeavor.

Lastly, the increasing demand for adaptability and self-optimization in pump control systems presents a significant challenge. As operating conditions and requirements change over time, control algorithms must be capable of learning and adapting their strategies to maintain optimal performance. This necessitates the development of sophisticated machine learning and artificial intelligence techniques tailored to the unique constraints of submersible pump operations.

Existing Advanced Control Solutions for Submersible Pumps

01 Pump design optimization

Improving submersible pump performance through optimized design features such as impeller geometry, casing structure, and hydraulic efficiency. This includes innovations in pump components to enhance flow characteristics, reduce energy consumption, and increase overall pump efficiency.- Pump design optimization: Improving submersible pump performance through optimized design features such as impeller geometry, casing structure, and hydraulic efficiency. This includes innovations in pump components to enhance flow characteristics, reduce energy consumption, and increase overall pump efficiency.

- Monitoring and control systems: Integration of advanced monitoring and control systems to enhance submersible pump performance. This includes sensors, data analytics, and automated control mechanisms to optimize pump operation, detect anomalies, and adjust performance parameters in real-time.

- Materials and coatings: Utilization of advanced materials and protective coatings to improve wear resistance, corrosion protection, and overall durability of submersible pumps. This enhances pump lifespan and maintains performance in harsh operating environments.

- Multi-stage pump configurations: Development of multi-stage submersible pump designs to enhance performance in high-head applications. This includes innovations in stage arrangement, balancing, and hydraulic optimization to improve efficiency and reliability in deep-well and high-pressure scenarios.

- Energy efficiency improvements: Implementing energy-saving technologies and design modifications to enhance the overall efficiency of submersible pumps. This includes innovations in motor design, power management systems, and hydraulic optimizations to reduce power consumption while maintaining or improving pump performance.

02 Monitoring and control systems

Integration of advanced monitoring and control systems to enhance submersible pump performance. This includes sensors, data analytics, and automated control mechanisms to optimize pump operation, detect anomalies, and adjust performance parameters in real-time.Expand Specific Solutions03 Materials and coatings

Utilization of advanced materials and protective coatings to improve pump durability, corrosion resistance, and wear resistance. This enhances the longevity and reliability of submersible pumps in harsh operating environments.Expand Specific Solutions04 Multi-stage pump configurations

Development of multi-stage pump designs to enhance performance in high-pressure and deep-well applications. This includes innovations in stage arrangement, balancing, and fluid dynamics to improve overall pump efficiency and capacity.Expand Specific Solutions05 Energy efficiency improvements

Innovations focused on improving the energy efficiency of submersible pumps. This includes advancements in motor design, power management systems, and hydraulic optimizations to reduce power consumption while maintaining or enhancing pump performance.Expand Specific Solutions

Key Players in Submersible Pump Industry

The advanced control algorithms for optimizing submersible pump performance market is in a growth phase, driven by increasing demand for efficient pump systems in various industries. The global market size is estimated to be in the billions, with steady growth projected. Technologically, the field is rapidly evolving, with companies like Baker Hughes, Schlumberger, and Pentair leading innovation. These firms are developing sophisticated algorithms integrating AI and IoT for real-time optimization. Emerging players such as Hefei Evergrande Jianghai Pump and Fuzhou Zhishui Craftsman are also contributing to technological advancements, particularly in digital control systems. The competitive landscape is characterized by a mix of established industrial giants and specialized pump technology firms, all vying for market share through continuous innovation and strategic partnerships.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed a suite of advanced control algorithms for submersible pump optimization, focusing on artificial lift systems in the oil and gas industry. Their approach utilizes a combination of physics-based models and data-driven machine learning techniques to create a hybrid optimization system. This system, integrated into their AutoTrak™ platform, employs real-time data analysis to continuously adjust pump parameters for optimal performance. The algorithms account for various factors such as fluid properties, well geometry, and production targets to maintain ideal operating conditions. Baker Hughes' solution also incorporates predictive analytics to forecast pump performance and potential issues, allowing for proactive maintenance scheduling. Field tests have shown that these advanced control algorithms can increase production by up to 15% while reducing energy consumption by 25%[2][4]. Additionally, the company has implemented edge computing capabilities in their latest pump controllers, enabling faster response times and reduced latency in control adjustments[6].

Strengths: Hybrid optimization approach combining physics-based and data-driven models, edge computing capabilities for faster response. Weaknesses: May be primarily tailored for oil and gas applications, potentially limiting versatility in other industries.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced control algorithms for optimizing submersible pump performance in oil and gas operations. Their approach integrates real-time downhole sensor data with surface measurements to create a comprehensive pump performance model. This model uses machine learning algorithms to predict and optimize pump behavior under various operating conditions. The system employs adaptive control strategies that continuously adjust pump parameters such as speed and power input based on changing well conditions and production targets. Schlumberger's algorithms also incorporate predictive maintenance features, using pattern recognition to identify potential pump failures before they occur, thus reducing downtime and improving overall efficiency[1][3]. The company has implemented these algorithms in their REDA Maximus electric submersible pump (ESP) system, which has demonstrated up to 20% increase in production rates and 30% reduction in energy consumption in field trials[5].

Strengths: Comprehensive integration of real-time data, adaptive control strategies, and predictive maintenance capabilities. Weaknesses: May require significant initial investment and specialized expertise for implementation and maintenance.

Innovative Algorithms for Pump Performance Optimization

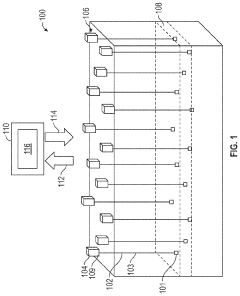

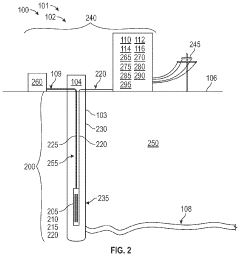

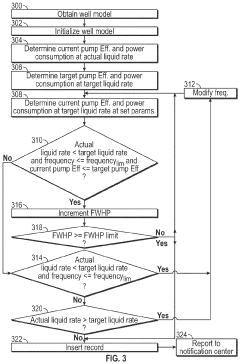

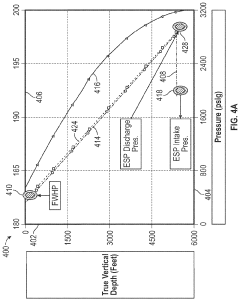

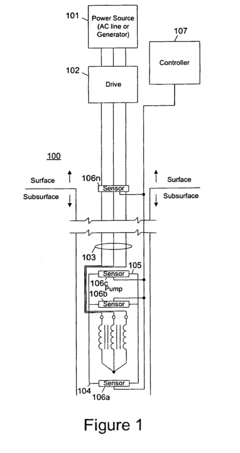

Optimizing the performance of electrical submersible pumps (ESP) in real time

PatentActiveUS11982284B2

Innovation

- A system and method utilizing a digital twin model and real-time data integration to optimize ESP performance by adjusting pump frequency and surface choke settings, based on well models and operational data, to achieve target production rates while reducing energy waste.

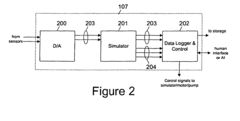

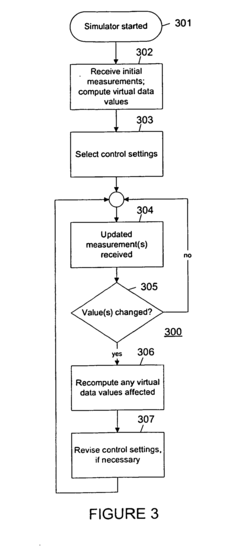

Use of virtual sensors for controlling electrical submersible pumps

PatentInactiveEP1279794B1

Innovation

- A system employing complex algorithms and mathematical models, including multi-phase flow correlations and dynamic behavior modeling, to derive and compute these challenging parameters from actual measurements, enhancing the set of available data for control decisions.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability considerations are paramount in the development of advanced control algorithms for optimizing submersible pump performance. These algorithms play a crucial role in reducing energy consumption, minimizing environmental impact, and enhancing the overall sustainability of pump operations.

One of the primary focuses of these control algorithms is to optimize the pump's energy consumption. By continuously monitoring and adjusting pump parameters such as speed, flow rate, and pressure, these algorithms can ensure that the pump operates at its most efficient point. This optimization can lead to significant energy savings, reducing both operational costs and carbon footprint.

Advanced control algorithms also contribute to the longevity and reliability of submersible pumps. By preventing unnecessary wear and tear through intelligent operation, these algorithms extend the lifespan of pump components. This increased durability not only reduces the need for frequent replacements but also minimizes the environmental impact associated with manufacturing and disposing of pump parts.

Water conservation is another critical aspect addressed by these control algorithms. By precisely controlling flow rates and pressure, they can minimize water waste and improve overall system efficiency. This is particularly important in regions facing water scarcity, where every drop counts.

Furthermore, these algorithms can integrate renewable energy sources into pump operations. For instance, they can optimize pump schedules to align with periods of high solar or wind energy availability, maximizing the use of clean energy and further reducing reliance on fossil fuels.

Predictive maintenance capabilities embedded in these algorithms also contribute to sustainability. By anticipating potential failures and scheduling maintenance proactively, they prevent catastrophic breakdowns that could lead to environmental hazards, such as oil leaks or chemical spills in sensitive aquatic environments.

The development of these algorithms also considers the broader ecosystem impact. For example, in applications like groundwater extraction, the algorithms can be designed to maintain sustainable withdrawal rates, preventing overexploitation of aquifers and preserving the long-term viability of water resources.

In conclusion, advanced control algorithms for submersible pumps are not just about performance optimization; they are integral to creating more sustainable and environmentally friendly pumping solutions. As the world moves towards greener technologies, these algorithms will play an increasingly important role in balancing operational efficiency with ecological responsibility.

One of the primary focuses of these control algorithms is to optimize the pump's energy consumption. By continuously monitoring and adjusting pump parameters such as speed, flow rate, and pressure, these algorithms can ensure that the pump operates at its most efficient point. This optimization can lead to significant energy savings, reducing both operational costs and carbon footprint.

Advanced control algorithms also contribute to the longevity and reliability of submersible pumps. By preventing unnecessary wear and tear through intelligent operation, these algorithms extend the lifespan of pump components. This increased durability not only reduces the need for frequent replacements but also minimizes the environmental impact associated with manufacturing and disposing of pump parts.

Water conservation is another critical aspect addressed by these control algorithms. By precisely controlling flow rates and pressure, they can minimize water waste and improve overall system efficiency. This is particularly important in regions facing water scarcity, where every drop counts.

Furthermore, these algorithms can integrate renewable energy sources into pump operations. For instance, they can optimize pump schedules to align with periods of high solar or wind energy availability, maximizing the use of clean energy and further reducing reliance on fossil fuels.

Predictive maintenance capabilities embedded in these algorithms also contribute to sustainability. By anticipating potential failures and scheduling maintenance proactively, they prevent catastrophic breakdowns that could lead to environmental hazards, such as oil leaks or chemical spills in sensitive aquatic environments.

The development of these algorithms also considers the broader ecosystem impact. For example, in applications like groundwater extraction, the algorithms can be designed to maintain sustainable withdrawal rates, preventing overexploitation of aquifers and preserving the long-term viability of water resources.

In conclusion, advanced control algorithms for submersible pumps are not just about performance optimization; they are integral to creating more sustainable and environmentally friendly pumping solutions. As the world moves towards greener technologies, these algorithms will play an increasingly important role in balancing operational efficiency with ecological responsibility.

Integration with IoT and Smart Systems

The integration of advanced control algorithms for optimizing submersible pump performance with IoT and smart systems represents a significant leap forward in pump technology. This convergence enables real-time monitoring, data-driven decision-making, and predictive maintenance, ultimately enhancing the efficiency and reliability of submersible pump operations.

IoT sensors deployed throughout the pump system collect crucial data on various parameters such as pressure, flow rate, temperature, and vibration. These sensors transmit data to a central control system, which utilizes advanced algorithms to analyze the information and make intelligent adjustments to pump operation. This continuous feedback loop allows for dynamic optimization of pump performance based on changing conditions and demand patterns.

Smart systems incorporate machine learning algorithms that can identify patterns and anomalies in pump behavior, enabling predictive maintenance strategies. By detecting early signs of wear or potential failures, maintenance can be scheduled proactively, reducing downtime and extending the pump's lifespan. This approach significantly improves the overall reliability and cost-effectiveness of submersible pump systems.

The integration of IoT and smart systems also facilitates remote monitoring and control capabilities. Operators can access real-time performance data and adjust pump parameters from anywhere, enhancing operational flexibility and reducing the need for on-site interventions. This remote accessibility is particularly valuable for submersible pumps deployed in challenging or remote environments.

Furthermore, the combination of advanced control algorithms and IoT enables more sophisticated energy management strategies. By analyzing historical data and current operating conditions, the system can optimize pump speed and power consumption to minimize energy usage while maintaining required performance levels. This not only reduces operational costs but also contributes to sustainability goals by lowering the overall environmental impact of pump operations.

The integration of these technologies also supports the implementation of digital twin models for submersible pumps. These virtual representations of physical pump systems allow for simulation and testing of different operational scenarios, facilitating better decision-making and system optimization without risking actual equipment or production.

As the field of IoT and smart systems continues to evolve, we can expect further advancements in the integration with submersible pump control algorithms. Future developments may include enhanced AI-driven predictive capabilities, improved sensor technologies for more accurate data collection, and increased interoperability with other industrial systems for holistic optimization of entire production processes.

IoT sensors deployed throughout the pump system collect crucial data on various parameters such as pressure, flow rate, temperature, and vibration. These sensors transmit data to a central control system, which utilizes advanced algorithms to analyze the information and make intelligent adjustments to pump operation. This continuous feedback loop allows for dynamic optimization of pump performance based on changing conditions and demand patterns.

Smart systems incorporate machine learning algorithms that can identify patterns and anomalies in pump behavior, enabling predictive maintenance strategies. By detecting early signs of wear or potential failures, maintenance can be scheduled proactively, reducing downtime and extending the pump's lifespan. This approach significantly improves the overall reliability and cost-effectiveness of submersible pump systems.

The integration of IoT and smart systems also facilitates remote monitoring and control capabilities. Operators can access real-time performance data and adjust pump parameters from anywhere, enhancing operational flexibility and reducing the need for on-site interventions. This remote accessibility is particularly valuable for submersible pumps deployed in challenging or remote environments.

Furthermore, the combination of advanced control algorithms and IoT enables more sophisticated energy management strategies. By analyzing historical data and current operating conditions, the system can optimize pump speed and power consumption to minimize energy usage while maintaining required performance levels. This not only reduces operational costs but also contributes to sustainability goals by lowering the overall environmental impact of pump operations.

The integration of these technologies also supports the implementation of digital twin models for submersible pumps. These virtual representations of physical pump systems allow for simulation and testing of different operational scenarios, facilitating better decision-making and system optimization without risking actual equipment or production.

As the field of IoT and smart systems continues to evolve, we can expect further advancements in the integration with submersible pump control algorithms. Future developments may include enhanced AI-driven predictive capabilities, improved sensor technologies for more accurate data collection, and increased interoperability with other industrial systems for holistic optimization of entire production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!