How submersible pumps support environmental remediation projects.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Tech Evolution and Goals

Submersible pumps have played a crucial role in environmental remediation projects since their inception in the early 20th century. The technology has evolved significantly, driven by the growing need for efficient and reliable pumping solutions in challenging environments. Initially designed for dewatering applications in mining and construction, submersible pumps have since found extensive use in groundwater remediation, wastewater treatment, and contaminated site cleanup.

The evolution of submersible pump technology has been marked by several key milestones. In the 1960s and 1970s, the introduction of corrosion-resistant materials and improved sealing techniques enabled pumps to handle a wider range of contaminants and operate in more aggressive environments. The 1980s and 1990s saw advancements in motor efficiency and control systems, leading to more energy-efficient and precise pumping operations.

Recent technological developments have focused on enhancing the pumps' ability to handle complex environmental remediation tasks. Integration of smart sensors and real-time monitoring systems has improved the pumps' performance and reliability in contaminated groundwater extraction. Additionally, the development of variable frequency drives has allowed for more flexible operation, adapting to changing site conditions and remediation requirements.

The current goals for submersible pump technology in environmental remediation projects are multifaceted. One primary objective is to increase energy efficiency, reducing the overall environmental impact of remediation operations. This involves optimizing pump designs, improving motor efficiency, and developing more sophisticated control algorithms.

Another key goal is to enhance the pumps' ability to handle a diverse range of contaminants and challenging site conditions. This includes developing new materials and coatings resistant to chemical degradation, as well as improving the pumps' ability to handle solids and abrasive particles without compromising performance or lifespan.

Miniaturization and modularization of submersible pumps are also important objectives, allowing for easier installation and maintenance in confined spaces and complex geological formations. This trend is particularly relevant for in-situ remediation techniques, where precise control over groundwater flow and contaminant extraction is critical.

Furthermore, the integration of advanced monitoring and control technologies is a significant focus. The aim is to create "smart" submersible pumps capable of self-diagnosis, predictive maintenance, and adaptive operation based on real-time environmental data. This not only improves the efficiency of remediation projects but also reduces downtime and maintenance costs.

The evolution of submersible pump technology has been marked by several key milestones. In the 1960s and 1970s, the introduction of corrosion-resistant materials and improved sealing techniques enabled pumps to handle a wider range of contaminants and operate in more aggressive environments. The 1980s and 1990s saw advancements in motor efficiency and control systems, leading to more energy-efficient and precise pumping operations.

Recent technological developments have focused on enhancing the pumps' ability to handle complex environmental remediation tasks. Integration of smart sensors and real-time monitoring systems has improved the pumps' performance and reliability in contaminated groundwater extraction. Additionally, the development of variable frequency drives has allowed for more flexible operation, adapting to changing site conditions and remediation requirements.

The current goals for submersible pump technology in environmental remediation projects are multifaceted. One primary objective is to increase energy efficiency, reducing the overall environmental impact of remediation operations. This involves optimizing pump designs, improving motor efficiency, and developing more sophisticated control algorithms.

Another key goal is to enhance the pumps' ability to handle a diverse range of contaminants and challenging site conditions. This includes developing new materials and coatings resistant to chemical degradation, as well as improving the pumps' ability to handle solids and abrasive particles without compromising performance or lifespan.

Miniaturization and modularization of submersible pumps are also important objectives, allowing for easier installation and maintenance in confined spaces and complex geological formations. This trend is particularly relevant for in-situ remediation techniques, where precise control over groundwater flow and contaminant extraction is critical.

Furthermore, the integration of advanced monitoring and control technologies is a significant focus. The aim is to create "smart" submersible pumps capable of self-diagnosis, predictive maintenance, and adaptive operation based on real-time environmental data. This not only improves the efficiency of remediation projects but also reduces downtime and maintenance costs.

Environmental Remediation Market Analysis

The environmental remediation market has been experiencing significant growth in recent years, driven by increasing awareness of environmental issues, stricter regulations, and the need to address legacy contamination. This market encompasses a wide range of activities aimed at cleaning up polluted sites, including soil, groundwater, and surface water remediation.

The global environmental remediation market was valued at approximately $85 billion in 2020 and is projected to reach $142 billion by 2027, growing at a CAGR of around 7.5% during the forecast period. This growth is primarily attributed to the rising number of environmental cleanup projects, government initiatives, and increasing investments in sustainable development.

Key factors driving market growth include the growing industrialization and urbanization, which have led to increased pollution and contamination of natural resources. Additionally, the implementation of stringent environmental regulations by governments worldwide has compelled industries to adopt remediation technologies and practices.

The market is segmented based on technology, including soil remediation, groundwater remediation, and surface water remediation. Soil remediation currently holds the largest market share due to the widespread contamination of soil from industrial activities, agricultural practices, and improper waste disposal.

Geographically, North America dominates the environmental remediation market, followed by Europe and Asia-Pacific. The United States, in particular, has a mature market due to its well-established regulatory framework and numerous Superfund sites requiring cleanup.

Submersible pumps play a crucial role in environmental remediation projects, particularly in groundwater and surface water remediation. These pumps are widely used for extracting contaminated water from wells, trenches, and other water bodies for treatment. The demand for submersible pumps in this market is expected to grow steadily, driven by their efficiency, reliability, and ability to handle various types of contaminants.

Key players in the environmental remediation market include Clean Harbors, AECOM, Golder Associates, and Jacobs Engineering Group. These companies offer a range of services, including site assessment, remediation design, and implementation of cleanup technologies.

Emerging trends in the market include the adoption of in-situ remediation techniques, which are more cost-effective and less disruptive than traditional ex-situ methods. Additionally, there is a growing focus on sustainable remediation practices that minimize environmental impact and energy consumption during the cleanup process.

The global environmental remediation market was valued at approximately $85 billion in 2020 and is projected to reach $142 billion by 2027, growing at a CAGR of around 7.5% during the forecast period. This growth is primarily attributed to the rising number of environmental cleanup projects, government initiatives, and increasing investments in sustainable development.

Key factors driving market growth include the growing industrialization and urbanization, which have led to increased pollution and contamination of natural resources. Additionally, the implementation of stringent environmental regulations by governments worldwide has compelled industries to adopt remediation technologies and practices.

The market is segmented based on technology, including soil remediation, groundwater remediation, and surface water remediation. Soil remediation currently holds the largest market share due to the widespread contamination of soil from industrial activities, agricultural practices, and improper waste disposal.

Geographically, North America dominates the environmental remediation market, followed by Europe and Asia-Pacific. The United States, in particular, has a mature market due to its well-established regulatory framework and numerous Superfund sites requiring cleanup.

Submersible pumps play a crucial role in environmental remediation projects, particularly in groundwater and surface water remediation. These pumps are widely used for extracting contaminated water from wells, trenches, and other water bodies for treatment. The demand for submersible pumps in this market is expected to grow steadily, driven by their efficiency, reliability, and ability to handle various types of contaminants.

Key players in the environmental remediation market include Clean Harbors, AECOM, Golder Associates, and Jacobs Engineering Group. These companies offer a range of services, including site assessment, remediation design, and implementation of cleanup technologies.

Emerging trends in the market include the adoption of in-situ remediation techniques, which are more cost-effective and less disruptive than traditional ex-situ methods. Additionally, there is a growing focus on sustainable remediation practices that minimize environmental impact and energy consumption during the cleanup process.

Current Challenges in Pump-Based Remediation

Pump-based remediation technologies face several significant challenges in environmental cleanup projects. One of the primary issues is the heterogeneity of contaminated sites, which can greatly affect pump efficiency and effectiveness. Soil and aquifer characteristics vary widely, from highly permeable sandy soils to less permeable clay formations. This variability makes it difficult to design a one-size-fits-all pumping system, often requiring site-specific customization and potentially multiple pump types to address different zones within a single site.

Another challenge is the phenomenon of contaminant rebound. After initial pumping efforts, contaminant concentrations may decrease, but once pumping stops or slows, concentrations can increase again due to slow desorption from soil particles or diffusion from less permeable zones. This necessitates long-term pumping operations, increasing project duration and costs.

The presence of non-aqueous phase liquids (NAPLs) poses a particular challenge for pump-based remediation. These contaminants, such as oil or industrial solvents, do not mix well with water and can form separate phases in the subsurface. Conventional pumping methods may be ineffective in removing NAPLs, requiring specialized pumping techniques or additional treatment technologies.

Energy consumption and sustainability are growing concerns in pump-based remediation. Long-term pumping operations can be energy-intensive, leading to high operational costs and potentially significant carbon footprints. This challenge is driving the need for more energy-efficient pump designs and the integration of renewable energy sources to power remediation systems.

Clogging and fouling of pumps and associated equipment present ongoing maintenance challenges. Mineral precipitation, biological growth, and suspended solids can accumulate in pumps, well screens, and treatment systems, reducing efficiency and potentially causing system failures. Regular maintenance and innovative anti-fouling technologies are necessary to address this issue.

The management of extracted groundwater also poses challenges. Pumped water often requires treatment before discharge or reinjection, adding complexity and cost to remediation projects. In some cases, the volume of water extracted can be substantial, necessitating careful water management strategies to avoid impacts on local water resources or overwhelm treatment facilities.

Lastly, there is the challenge of achieving regulatory cleanup standards within reasonable timeframes and budgets. Pump-based remediation can be a slow process, particularly for addressing low-level residual contamination. Balancing the need for thorough cleanup with project timelines and cost constraints often requires innovative approaches and careful optimization of pumping strategies.

Another challenge is the phenomenon of contaminant rebound. After initial pumping efforts, contaminant concentrations may decrease, but once pumping stops or slows, concentrations can increase again due to slow desorption from soil particles or diffusion from less permeable zones. This necessitates long-term pumping operations, increasing project duration and costs.

The presence of non-aqueous phase liquids (NAPLs) poses a particular challenge for pump-based remediation. These contaminants, such as oil or industrial solvents, do not mix well with water and can form separate phases in the subsurface. Conventional pumping methods may be ineffective in removing NAPLs, requiring specialized pumping techniques or additional treatment technologies.

Energy consumption and sustainability are growing concerns in pump-based remediation. Long-term pumping operations can be energy-intensive, leading to high operational costs and potentially significant carbon footprints. This challenge is driving the need for more energy-efficient pump designs and the integration of renewable energy sources to power remediation systems.

Clogging and fouling of pumps and associated equipment present ongoing maintenance challenges. Mineral precipitation, biological growth, and suspended solids can accumulate in pumps, well screens, and treatment systems, reducing efficiency and potentially causing system failures. Regular maintenance and innovative anti-fouling technologies are necessary to address this issue.

The management of extracted groundwater also poses challenges. Pumped water often requires treatment before discharge or reinjection, adding complexity and cost to remediation projects. In some cases, the volume of water extracted can be substantial, necessitating careful water management strategies to avoid impacts on local water resources or overwhelm treatment facilities.

Lastly, there is the challenge of achieving regulatory cleanup standards within reasonable timeframes and budgets. Pump-based remediation can be a slow process, particularly for addressing low-level residual contamination. Balancing the need for thorough cleanup with project timelines and cost constraints often requires innovative approaches and careful optimization of pumping strategies.

Existing Submersible Pump Solutions

01 Design and construction of submersible pumps

Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor closely coupled to the pump body. The design focuses on efficient operation underwater, including features for heat dissipation, pressure equalization, and protection against liquid ingress.- Design improvements for submersible pumps: Various design improvements have been made to enhance the performance and efficiency of submersible pumps. These include modifications to the pump housing, impeller design, and motor configuration to optimize fluid flow, increase durability, and improve overall pump efficiency in submerged conditions.

- Control systems for submersible pumps: Advanced control systems have been developed for submersible pumps to enhance their operation and monitoring capabilities. These systems may include sensors, data analysis algorithms, and remote monitoring features to optimize pump performance, detect faults, and enable predictive maintenance.

- Energy-efficient submersible pump technologies: Innovations in submersible pump technology have focused on improving energy efficiency. This includes the development of variable speed drives, high-efficiency motors, and optimized hydraulic designs to reduce power consumption while maintaining or improving pump performance in underwater applications.

- Materials and coatings for submersible pumps: Advancements in materials science and coating technologies have led to the development of more durable and corrosion-resistant submersible pumps. These innovations help extend the lifespan of pumps operating in harsh underwater environments and improve their overall reliability.

- Specialized submersible pumps for specific applications: Customized submersible pump designs have been created for specific industries and applications. These may include pumps for deep-sea exploration, wastewater treatment, oil and gas extraction, or mining operations, each with unique features tailored to their operating environments and requirements.

02 Control systems for submersible pumps

Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring various parameters such as pressure, flow rate, and temperature. They can adjust pump operation based on real-time data, improving efficiency and preventing damage.Expand Specific Solutions03 Energy efficiency improvements in submersible pumps

Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, improved impeller designs, and the use of variable frequency drives. These advancements aim to reduce power consumption while maintaining or improving pump performance.Expand Specific Solutions04 Materials and coatings for submersible pumps

The selection of materials and coatings plays a crucial role in the durability and performance of submersible pumps. Corrosion-resistant alloys, wear-resistant coatings, and advanced polymers are used to extend the life of pump components and improve their resistance to harsh underwater environments.Expand Specific Solutions05 Application-specific submersible pump designs

Submersible pumps are tailored for specific applications such as wastewater treatment, oil and gas extraction, and deep-sea operations. These specialized designs incorporate features to handle particular fluid properties, operating depths, and environmental conditions unique to each application.Expand Specific Solutions

Key Players in Environmental Pump Industry

The environmental remediation industry utilizing submersible pumps is in a growth phase, driven by increasing environmental regulations and awareness. The global market for environmental remediation technologies is projected to reach $82.7 billion by 2025. Technologically, submersible pumps for remediation are relatively mature, with ongoing innovations in efficiency and durability. Key players like Schlumberger, Baker Hughes, and Flowserve are leading in this space, offering advanced pump solutions. Emerging companies such as Grundfos and Ebara are also making significant contributions, particularly in energy-efficient and specialized remediation pump technologies. The competitive landscape is characterized by a mix of established oilfield service companies and specialized pump manufacturers, each leveraging their unique expertise to address environmental challenges.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced submersible pump systems specifically designed for environmental remediation projects. Their technology incorporates intelligent monitoring and control systems that optimize pump performance based on real-time data. The company's submersible pumps utilize corrosion-resistant materials and specialized impeller designs to handle contaminated groundwater and other challenging fluids encountered in remediation efforts. Schlumberger's pumps are equipped with variable frequency drives, allowing for precise flow control and energy efficiency[1]. Additionally, they have implemented remote monitoring capabilities, enabling operators to adjust pump parameters and troubleshoot issues from off-site locations, reducing downtime and improving overall project efficiency[3].

Strengths: Advanced monitoring and control systems, corrosion-resistant materials, energy efficiency, remote operation capabilities. Weaknesses: Higher initial cost compared to standard pumps, may require specialized training for operation and maintenance.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed a range of submersible pumps tailored for environmental remediation applications. Their pumps feature innovative hydraulic designs that enhance efficiency and reliability when handling contaminated fluids. The company's technology incorporates advanced materials such as duplex stainless steel and specialized coatings to resist corrosion and abrasion in harsh environments[2]. Baker Hughes' pumps are equipped with smart sensors that provide real-time performance data, allowing for predictive maintenance and optimized operation. They have also implemented modular designs that facilitate easy installation and servicing in challenging remediation sites[4]. Furthermore, Baker Hughes offers customized solutions that can be adapted to specific project requirements, such as handling high solids content or volatile organic compounds (VOCs)[5].

Strengths: Innovative hydraulic designs, corrosion-resistant materials, smart sensor technology, modular and customizable solutions. Weaknesses: May have higher upfront costs, potential complexity in maintenance for advanced features.

Innovative Pump Designs for Remediation

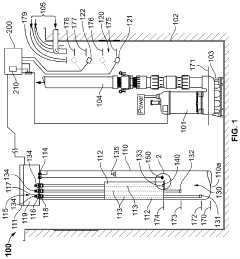

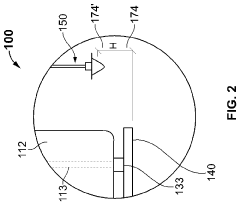

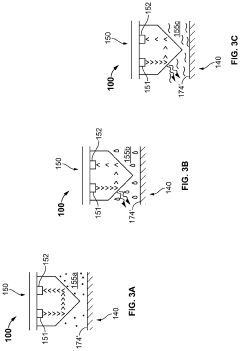

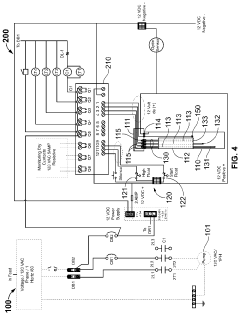

Submersible pump contaminant detection system

PatentPendingUS20230340952A1

Innovation

- A system comprising a stilling tube with integrated sensors, including conductivity and optical sensors, that calms turbulence and accurately detects hydrocarbon layers as thin as 1/16 inches, using a programmable logic controller and capacitive sensors to distinguish between media based on physical properties, ensuring precise contaminant detection and control.

Apparatus for purifying aqueous phases containing finely powdered waste or pollutant phases

PatentWO1994013380A1

Innovation

- A compact, user-friendly device equipped with a ceramic tubular membrane filter module and a submersible pump that can be placed directly in a container, allowing for in-situ separation of oil and water phases with minimal infrastructure requirements, enabling efficient treatment and discharge of pollutant-laden waste water into sewage systems.

Regulatory Framework for Remediation Equipment

The regulatory framework for remediation equipment, including submersible pumps used in environmental remediation projects, is complex and multifaceted. It encompasses various levels of governance, from international agreements to local regulations, all aimed at ensuring the safe and effective use of equipment in environmental cleanup efforts.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and best practices for environmental remediation. These guidelines often influence national policies and regulations, creating a baseline for equipment standards and operational procedures.

In the United States, the Environmental Protection Agency (EPA) plays a central role in establishing and enforcing regulations for remediation equipment. The EPA's Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund, sets forth stringent requirements for equipment used in hazardous waste site cleanup. This includes specifications for submersible pumps, such as materials compatibility, performance standards, and safety features.

The Occupational Safety and Health Administration (OSHA) also contributes to the regulatory framework by mandating safety standards for workers operating remediation equipment. These regulations cover aspects such as personal protective equipment, training requirements, and operational safety protocols for submersible pumps and other remediation tools.

State-level environmental agencies often have additional regulations that complement federal standards. These may include specific permitting requirements, discharge limits, and monitoring protocols for remediation equipment. Local authorities may also impose zoning restrictions or noise ordinances that affect the deployment and operation of submersible pumps in remediation projects.

Equipment manufacturers must adhere to various industry standards and certifications. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines for the design, construction, and testing of submersible pumps and other remediation equipment. Compliance with these standards is often a prerequisite for regulatory approval and market acceptance.

The regulatory landscape also addresses the environmental impact of the equipment itself. This includes regulations on energy efficiency, emissions, and the use of environmentally friendly materials in pump construction. As sustainability becomes increasingly important, regulations are evolving to promote the development and use of more eco-friendly remediation technologies.

Continuous monitoring and reporting requirements form another critical aspect of the regulatory framework. Operators must regularly assess and document the performance of submersible pumps and other equipment, ensuring compliance with environmental standards and remediation goals. This data-driven approach allows regulatory bodies to evaluate the effectiveness of remediation efforts and adjust policies as needed.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and best practices for environmental remediation. These guidelines often influence national policies and regulations, creating a baseline for equipment standards and operational procedures.

In the United States, the Environmental Protection Agency (EPA) plays a central role in establishing and enforcing regulations for remediation equipment. The EPA's Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund, sets forth stringent requirements for equipment used in hazardous waste site cleanup. This includes specifications for submersible pumps, such as materials compatibility, performance standards, and safety features.

The Occupational Safety and Health Administration (OSHA) also contributes to the regulatory framework by mandating safety standards for workers operating remediation equipment. These regulations cover aspects such as personal protective equipment, training requirements, and operational safety protocols for submersible pumps and other remediation tools.

State-level environmental agencies often have additional regulations that complement federal standards. These may include specific permitting requirements, discharge limits, and monitoring protocols for remediation equipment. Local authorities may also impose zoning restrictions or noise ordinances that affect the deployment and operation of submersible pumps in remediation projects.

Equipment manufacturers must adhere to various industry standards and certifications. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines for the design, construction, and testing of submersible pumps and other remediation equipment. Compliance with these standards is often a prerequisite for regulatory approval and market acceptance.

The regulatory landscape also addresses the environmental impact of the equipment itself. This includes regulations on energy efficiency, emissions, and the use of environmentally friendly materials in pump construction. As sustainability becomes increasingly important, regulations are evolving to promote the development and use of more eco-friendly remediation technologies.

Continuous monitoring and reporting requirements form another critical aspect of the regulatory framework. Operators must regularly assess and document the performance of submersible pumps and other equipment, ensuring compliance with environmental standards and remediation goals. This data-driven approach allows regulatory bodies to evaluate the effectiveness of remediation efforts and adjust policies as needed.

Sustainability Impact of Pump Technologies

Submersible pumps play a crucial role in supporting environmental remediation projects, offering significant sustainability benefits compared to traditional pump technologies. These pumps are designed to operate underwater, making them ideal for applications in contaminated groundwater treatment, wastewater management, and soil remediation.

One of the primary sustainability advantages of submersible pumps is their energy efficiency. By being submerged directly in the fluid they are pumping, these devices minimize energy losses associated with suction lift and long discharge lines. This results in reduced power consumption and lower carbon emissions over the lifecycle of remediation projects. Additionally, submersible pumps often require smaller motors to achieve the same flow rates as surface-mounted pumps, further enhancing their energy efficiency.

The compact design of submersible pumps contributes to their sustainability impact by reducing the physical footprint of remediation systems. This minimizes site disturbance and allows for more flexible installation options, particularly in urban or environmentally sensitive areas. The reduced surface infrastructure also translates to less material usage in pump housings and support structures, lowering the overall environmental impact of pump manufacturing and installation.

Submersible pumps demonstrate superior durability and longevity in harsh environmental conditions, which is particularly relevant in remediation projects dealing with corrosive or abrasive fluids. This extended operational lifespan reduces the frequency of pump replacements, minimizing waste generation and the need for resource-intensive manufacturing of replacement units. Furthermore, the sealed nature of submersible pumps prevents contamination of the pumped fluid, ensuring more effective treatment processes and reducing the risk of secondary environmental impacts.

In terms of noise pollution, submersible pumps offer a significant advantage over surface-mounted alternatives. The underwater operation naturally dampens sound, resulting in quieter remediation sites. This is particularly beneficial in urban areas or ecologically sensitive locations where noise reduction is a priority for minimizing disturbance to local communities and wildlife.

The versatility of submersible pumps allows for their application across various remediation techniques, including pump-and-treat systems, air sparging, and in-situ chemical oxidation. This adaptability enables more efficient and targeted remediation strategies, potentially reducing the overall duration and resource intensity of environmental cleanup projects. By facilitating more effective contaminant removal and treatment, submersible pumps contribute to faster site restoration and reduced long-term environmental impacts.

One of the primary sustainability advantages of submersible pumps is their energy efficiency. By being submerged directly in the fluid they are pumping, these devices minimize energy losses associated with suction lift and long discharge lines. This results in reduced power consumption and lower carbon emissions over the lifecycle of remediation projects. Additionally, submersible pumps often require smaller motors to achieve the same flow rates as surface-mounted pumps, further enhancing their energy efficiency.

The compact design of submersible pumps contributes to their sustainability impact by reducing the physical footprint of remediation systems. This minimizes site disturbance and allows for more flexible installation options, particularly in urban or environmentally sensitive areas. The reduced surface infrastructure also translates to less material usage in pump housings and support structures, lowering the overall environmental impact of pump manufacturing and installation.

Submersible pumps demonstrate superior durability and longevity in harsh environmental conditions, which is particularly relevant in remediation projects dealing with corrosive or abrasive fluids. This extended operational lifespan reduces the frequency of pump replacements, minimizing waste generation and the need for resource-intensive manufacturing of replacement units. Furthermore, the sealed nature of submersible pumps prevents contamination of the pumped fluid, ensuring more effective treatment processes and reducing the risk of secondary environmental impacts.

In terms of noise pollution, submersible pumps offer a significant advantage over surface-mounted alternatives. The underwater operation naturally dampens sound, resulting in quieter remediation sites. This is particularly beneficial in urban areas or ecologically sensitive locations where noise reduction is a priority for minimizing disturbance to local communities and wildlife.

The versatility of submersible pumps allows for their application across various remediation techniques, including pump-and-treat systems, air sparging, and in-situ chemical oxidation. This adaptability enables more efficient and targeted remediation strategies, potentially reducing the overall duration and resource intensity of environmental cleanup projects. By facilitating more effective contaminant removal and treatment, submersible pumps contribute to faster site restoration and reduced long-term environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!