Role of submersible pumps in streamlining agriculture logistics.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Evolution in Agriculture

The evolution of submersible pumps in agriculture represents a significant technological advancement that has revolutionized irrigation practices and water management in the agricultural sector. Initially developed for industrial applications, submersible pumps found their way into agriculture in the mid-20th century, offering farmers a more efficient and reliable method of water extraction and distribution.

In the early stages of their agricultural adoption, submersible pumps were primarily used for deep well irrigation. These early models were often large, heavy, and required significant power to operate. However, they provided a crucial advantage over surface pumps by being able to operate at greater depths and with higher efficiency, making them ideal for areas with low water tables or in regions prone to drought.

As technology progressed, submersible pumps became more compact, energy-efficient, and versatile. The introduction of corrosion-resistant materials and improved sealing techniques in the 1970s and 1980s extended the lifespan of these pumps, making them more cost-effective for farmers. This period also saw the development of variable speed drives, allowing for better control over water flow and pressure, which was particularly beneficial for precision irrigation systems.

The 1990s and early 2000s marked a significant leap in submersible pump technology with the integration of electronic controls and monitoring systems. These advancements enabled farmers to remotely manage their irrigation systems, optimize water usage, and detect potential issues before they escalated into major problems. The incorporation of sensors and data analytics further enhanced the efficiency of water distribution, contributing to more sustainable farming practices.

In recent years, the focus has shifted towards developing submersible pumps that are not only highly efficient but also environmentally friendly. Solar-powered submersible pumps have gained popularity, especially in remote areas or regions with unreliable electricity supply. These eco-friendly alternatives have made irrigation possible in previously challenging locations, expanding agricultural possibilities and improving food security.

The latest innovations in submersible pump technology for agriculture include smart pumps with IoT capabilities. These advanced systems can integrate with broader farm management platforms, providing real-time data on soil moisture, weather conditions, and crop health to optimize irrigation schedules. This level of automation and precision has significantly contributed to water conservation efforts and increased crop yields.

As we look to the future, the evolution of submersible pumps in agriculture continues to focus on sustainability, energy efficiency, and integration with smart farming technologies. Research is ongoing into materials that can further improve pump durability and efficiency, as well as designs that can operate effectively in increasingly challenging environmental conditions. The role of submersible pumps in agriculture has thus expanded from mere water extraction to becoming a crucial component in the broader context of precision agriculture and sustainable water management.

In the early stages of their agricultural adoption, submersible pumps were primarily used for deep well irrigation. These early models were often large, heavy, and required significant power to operate. However, they provided a crucial advantage over surface pumps by being able to operate at greater depths and with higher efficiency, making them ideal for areas with low water tables or in regions prone to drought.

As technology progressed, submersible pumps became more compact, energy-efficient, and versatile. The introduction of corrosion-resistant materials and improved sealing techniques in the 1970s and 1980s extended the lifespan of these pumps, making them more cost-effective for farmers. This period also saw the development of variable speed drives, allowing for better control over water flow and pressure, which was particularly beneficial for precision irrigation systems.

The 1990s and early 2000s marked a significant leap in submersible pump technology with the integration of electronic controls and monitoring systems. These advancements enabled farmers to remotely manage their irrigation systems, optimize water usage, and detect potential issues before they escalated into major problems. The incorporation of sensors and data analytics further enhanced the efficiency of water distribution, contributing to more sustainable farming practices.

In recent years, the focus has shifted towards developing submersible pumps that are not only highly efficient but also environmentally friendly. Solar-powered submersible pumps have gained popularity, especially in remote areas or regions with unreliable electricity supply. These eco-friendly alternatives have made irrigation possible in previously challenging locations, expanding agricultural possibilities and improving food security.

The latest innovations in submersible pump technology for agriculture include smart pumps with IoT capabilities. These advanced systems can integrate with broader farm management platforms, providing real-time data on soil moisture, weather conditions, and crop health to optimize irrigation schedules. This level of automation and precision has significantly contributed to water conservation efforts and increased crop yields.

As we look to the future, the evolution of submersible pumps in agriculture continues to focus on sustainability, energy efficiency, and integration with smart farming technologies. Research is ongoing into materials that can further improve pump durability and efficiency, as well as designs that can operate effectively in increasingly challenging environmental conditions. The role of submersible pumps in agriculture has thus expanded from mere water extraction to becoming a crucial component in the broader context of precision agriculture and sustainable water management.

Agricultural Logistics Market Analysis

The agricultural logistics market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for efficient food supply chains and the adoption of advanced technologies. The global agricultural logistics market was valued at approximately $130 billion in 2020 and is projected to reach $190 billion by 2025, growing at a CAGR of around 8% during the forecast period.

One of the key factors contributing to this growth is the rising global population and the subsequent increase in food demand. As the world's population is expected to reach 9.7 billion by 2050, there is a pressing need for more efficient agricultural production and distribution systems. This has led to a surge in investments in agricultural logistics infrastructure and technologies, including submersible pumps, which play a crucial role in irrigation and water management.

The market is also being shaped by changing consumer preferences and the growing demand for fresh, high-quality produce. This trend has led to the development of more sophisticated cold chain logistics and storage solutions, which are essential for maintaining the quality and shelf life of perishable agricultural products. Submersible pumps are integral to these systems, as they help maintain optimal temperature and humidity levels in storage facilities and during transportation.

Geographically, Asia-Pacific is the largest and fastest-growing market for agricultural logistics, driven by the rapid urbanization and increasing disposable incomes in countries like China and India. North America and Europe follow closely, with well-established agricultural sectors and advanced logistics networks. The adoption of submersible pumps in these regions is particularly high, as farmers and logistics providers seek to optimize water usage and improve overall operational efficiency.

The market is characterized by the presence of both large multinational corporations and numerous small and medium-sized enterprises. Key players in the agricultural logistics market include companies like DHL, FedEx, and UPS, which offer specialized services for the transportation of agricultural products. Additionally, there are numerous regional and local players that cater to specific market segments or geographical areas.

The role of submersible pumps in streamlining agricultural logistics is becoming increasingly important as the industry faces challenges such as water scarcity and the need for sustainable farming practices. These pumps are essential for efficient irrigation systems, which are crucial for maintaining crop yields and quality. By enabling precise water management, submersible pumps contribute to reduced water waste and improved crop productivity, ultimately enhancing the efficiency of the entire agricultural supply chain.

One of the key factors contributing to this growth is the rising global population and the subsequent increase in food demand. As the world's population is expected to reach 9.7 billion by 2050, there is a pressing need for more efficient agricultural production and distribution systems. This has led to a surge in investments in agricultural logistics infrastructure and technologies, including submersible pumps, which play a crucial role in irrigation and water management.

The market is also being shaped by changing consumer preferences and the growing demand for fresh, high-quality produce. This trend has led to the development of more sophisticated cold chain logistics and storage solutions, which are essential for maintaining the quality and shelf life of perishable agricultural products. Submersible pumps are integral to these systems, as they help maintain optimal temperature and humidity levels in storage facilities and during transportation.

Geographically, Asia-Pacific is the largest and fastest-growing market for agricultural logistics, driven by the rapid urbanization and increasing disposable incomes in countries like China and India. North America and Europe follow closely, with well-established agricultural sectors and advanced logistics networks. The adoption of submersible pumps in these regions is particularly high, as farmers and logistics providers seek to optimize water usage and improve overall operational efficiency.

The market is characterized by the presence of both large multinational corporations and numerous small and medium-sized enterprises. Key players in the agricultural logistics market include companies like DHL, FedEx, and UPS, which offer specialized services for the transportation of agricultural products. Additionally, there are numerous regional and local players that cater to specific market segments or geographical areas.

The role of submersible pumps in streamlining agricultural logistics is becoming increasingly important as the industry faces challenges such as water scarcity and the need for sustainable farming practices. These pumps are essential for efficient irrigation systems, which are crucial for maintaining crop yields and quality. By enabling precise water management, submersible pumps contribute to reduced water waste and improved crop productivity, ultimately enhancing the efficiency of the entire agricultural supply chain.

Challenges in Pump Technology

Despite the significant advancements in submersible pump technology for agricultural applications, several challenges persist in the development and implementation of these systems. One of the primary obstacles is the need for improved energy efficiency. As agriculture logistics increasingly rely on submersible pumps for irrigation and water management, the energy consumption of these devices becomes a critical factor. Engineers are constantly striving to develop pumps that can deliver higher flow rates and pressure while consuming less power, a balance that remains difficult to achieve.

Durability and reliability present another set of challenges in pump technology. Submersible pumps operate in harsh environments, often exposed to abrasive particles, corrosive chemicals, and varying water qualities. These conditions can lead to accelerated wear and tear, reducing the pump's lifespan and increasing maintenance requirements. Developing materials and designs that can withstand these conditions without compromising performance or significantly increasing costs is an ongoing challenge for manufacturers.

The integration of smart technologies into submersible pumps poses both opportunities and challenges. While the incorporation of sensors, IoT connectivity, and automated control systems can greatly enhance pump efficiency and monitoring capabilities, it also introduces complexity and potential points of failure. Ensuring the reliability of these smart components in wet and often remote environments remains a significant technical hurdle.

Scalability is another challenge facing pump technology in agricultural logistics. As farms vary greatly in size and water requirements, developing pump systems that can efficiently scale from small operations to large industrial farms without sacrificing performance or economic viability is crucial. This often requires innovative design approaches and modular systems that can be easily adapted to different agricultural settings.

Environmental concerns also drive challenges in pump technology development. There is an increasing demand for pumps that minimize their impact on aquatic ecosystems, particularly in terms of fish safety and habitat preservation. Designing pumps that can effectively move water without harming aquatic life requires careful consideration of factors such as impeller design, screening mechanisms, and operational speeds.

Lastly, the challenge of cost-effectiveness remains paramount. While advanced technologies can improve pump performance and efficiency, they often come at a higher initial cost. Striking a balance between technological advancement and affordability is crucial for widespread adoption in the agricultural sector, particularly in developing regions where resources may be limited. This necessitates innovative approaches to manufacturing, materials selection, and design optimization to deliver high-performance pumps at competitive price points.

Durability and reliability present another set of challenges in pump technology. Submersible pumps operate in harsh environments, often exposed to abrasive particles, corrosive chemicals, and varying water qualities. These conditions can lead to accelerated wear and tear, reducing the pump's lifespan and increasing maintenance requirements. Developing materials and designs that can withstand these conditions without compromising performance or significantly increasing costs is an ongoing challenge for manufacturers.

The integration of smart technologies into submersible pumps poses both opportunities and challenges. While the incorporation of sensors, IoT connectivity, and automated control systems can greatly enhance pump efficiency and monitoring capabilities, it also introduces complexity and potential points of failure. Ensuring the reliability of these smart components in wet and often remote environments remains a significant technical hurdle.

Scalability is another challenge facing pump technology in agricultural logistics. As farms vary greatly in size and water requirements, developing pump systems that can efficiently scale from small operations to large industrial farms without sacrificing performance or economic viability is crucial. This often requires innovative design approaches and modular systems that can be easily adapted to different agricultural settings.

Environmental concerns also drive challenges in pump technology development. There is an increasing demand for pumps that minimize their impact on aquatic ecosystems, particularly in terms of fish safety and habitat preservation. Designing pumps that can effectively move water without harming aquatic life requires careful consideration of factors such as impeller design, screening mechanisms, and operational speeds.

Lastly, the challenge of cost-effectiveness remains paramount. While advanced technologies can improve pump performance and efficiency, they often come at a higher initial cost. Striking a balance between technological advancement and affordability is crucial for widespread adoption in the agricultural sector, particularly in developing regions where resources may be limited. This necessitates innovative approaches to manufacturing, materials selection, and design optimization to deliver high-performance pumps at competitive price points.

Current Submersible Pump Solutions

01 Design improvements for submersible pumps

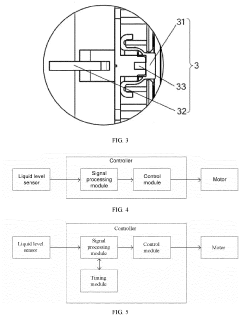

Various design improvements have been made to enhance the performance and efficiency of submersible pumps. These include modifications to the pump structure, impeller design, and motor configuration to optimize fluid flow, increase durability, and improve overall pump efficiency in submerged conditions.- Design and construction of submersible pumps: This category focuses on the structural aspects and design innovations of submersible pumps. It includes improvements in pump housing, impeller design, and overall construction to enhance efficiency and durability in submerged environments. These advancements aim to optimize pump performance, increase lifespan, and improve reliability in various applications.

- Control systems for submersible pumps: This point covers the development of advanced control systems for submersible pumps. It includes innovations in monitoring, automation, and remote operation capabilities. These systems aim to improve pump efficiency, prevent failures, and enable real-time adjustments based on operating conditions, enhancing overall performance and reducing maintenance needs.

- Energy efficiency in submersible pumps: This category addresses improvements in the energy efficiency of submersible pumps. It includes innovations in motor design, power management, and hydraulic efficiency. These advancements aim to reduce power consumption, optimize performance, and minimize operational costs while maintaining or improving pump output.

- Specialized submersible pumps for specific applications: This point focuses on submersible pumps designed for specific industries or applications. It includes pumps tailored for oil and gas extraction, wastewater treatment, mining, and other specialized uses. These pumps feature unique designs and materials to handle specific fluids, pressures, and environmental conditions encountered in their respective applications.

- Maintenance and reliability of submersible pumps: This category covers innovations aimed at improving the maintenance and reliability of submersible pumps. It includes advancements in materials, sealing technologies, and diagnostic systems. These developments focus on extending pump lifespan, reducing downtime, and simplifying maintenance procedures to ensure consistent performance in challenging submerged environments.

02 Control systems for submersible pumps

Advanced control systems have been developed for submersible pumps to enhance their operation and monitoring capabilities. These systems may include sensors, data analysis tools, and remote monitoring features to optimize pump performance, detect faults, and enable predictive maintenance.Expand Specific Solutions03 Energy-efficient submersible pump technologies

Innovations in submersible pump technology focus on improving energy efficiency. This includes the development of high-efficiency motors, variable speed drives, and optimized hydraulic designs to reduce power consumption while maintaining or improving pump performance in underwater applications.Expand Specific Solutions04 Materials and coatings for submersible pumps

Advancements in materials science and coating technologies have led to the development of corrosion-resistant and wear-resistant materials for submersible pumps. These innovations help extend the lifespan of pumps operating in harsh underwater environments and improve their overall reliability.Expand Specific Solutions05 Specialized submersible pumps for specific applications

Customized submersible pump designs have been created for specific industries and applications. These may include pumps for deep-sea exploration, wastewater treatment, oil and gas extraction, or mining operations, each with unique features tailored to their operating environments and requirements.Expand Specific Solutions

Key Submersible Pump Manufacturers

The submersible pump market in agriculture logistics is in a growth phase, driven by increasing demand for efficient water management and irrigation systems. The global market size is projected to expand significantly in the coming years, with a compound annual growth rate expected to be in the double digits. Technologically, submersible pumps are relatively mature, but ongoing innovations focus on improving energy efficiency, durability, and smart control features. Key players in this space include Baker Hughes Co., Schlumberger Technologies, Inc., and Halliburton Energy Services, Inc., who are leveraging their expertise in fluid handling technologies to develop advanced submersible pump solutions for agricultural applications. Emerging companies like Anhui Sanlian Pump Industry Co. Ltd. and Fujian Sea Knight Pump Co., Ltd. are also making strides in this sector, particularly in the Asian market.

Anhui Sanlian Pump Industry Co. Ltd.

Technical Solution: Anhui Sanlian Pump Industry Co. Ltd. has developed advanced submersible pumps specifically designed for agricultural logistics. Their pumps utilize high-efficiency motors and impeller designs to maximize water flow while minimizing energy consumption. The company's pumps incorporate smart control systems that allow for remote monitoring and adjustment of pump performance based on real-time field conditions[1]. These pumps are equipped with anti-clogging mechanisms to handle debris and sediment commonly found in agricultural water sources, ensuring consistent operation in challenging environments[2]. Anhui Sanlian's pumps also feature corrosion-resistant materials to withstand exposure to fertilizers and other agricultural chemicals, prolonging the pump's lifespan and reducing maintenance requirements[3].

Strengths: High efficiency, smart control capabilities, and durability in agricultural settings. Weaknesses: May have a higher initial cost compared to traditional pumps, and potential complexity in setup and maintenance of smart features.

Fujian Sea Knight Pump Co., Ltd.

Technical Solution: Fujian Sea Knight Pump Co., Ltd. has developed a range of submersible pumps tailored for agricultural logistics applications. Their pumps feature a unique hydraulic design that optimizes flow rates and pressure for various agricultural needs, from irrigation to water transfer in processing facilities[4]. The company has implemented advanced materials technology, using composite materials that offer superior wear resistance and chemical compatibility with agricultural fluids[5]. Sea Knight's pumps are equipped with variable frequency drives, allowing for precise control of pump speed and power consumption, which is crucial for adapting to changing water demands in agricultural operations[6]. Additionally, their pumps incorporate self-diagnostic systems that can predict maintenance needs, reducing downtime and improving overall system reliability in agricultural logistics chains.

Strengths: Versatile performance, energy efficiency, and predictive maintenance capabilities. Weaknesses: Potentially higher cost due to advanced features, and may require specialized training for optimal use and maintenance.

Innovative Pump Designs

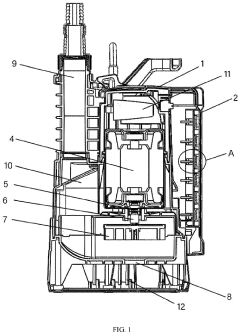

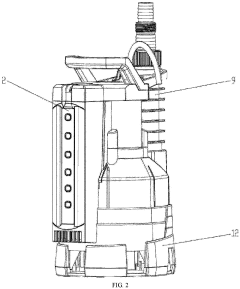

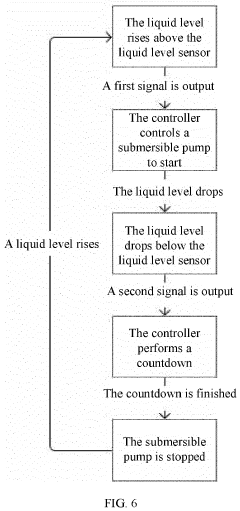

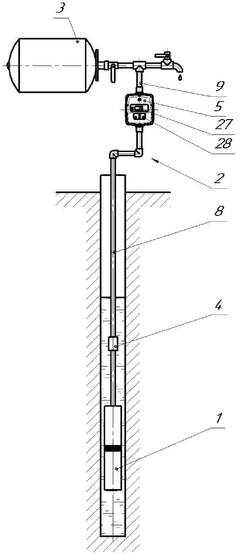

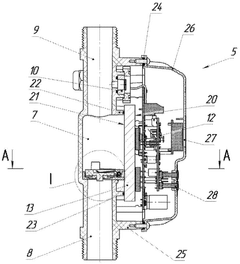

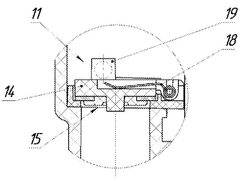

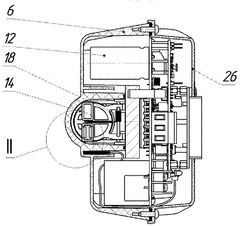

Submersible pump and automatic liquid level control method

PatentActiveEP4328452A1

Innovation

- A submersible pump with adjustable liquid level sensors, indicator lights, and a controller module that includes a signal processing and timing module, allowing for manual switching and automatic control of the pump based on detected liquid levels, preventing idling and adapting to different environments.

Autonomous water supply system with automatic control of a submersible pump

PatentWO2025083674A1

Innovation

- The system incorporates a frequency converter mounted on a plate heat sink in the flow chamber, and a dry-run protection sensor in the form of a curtain with a permanent magnet and Hall sensor, optimizing the electronic control unit and enhancing heat dissipation and dry-run detection.

Environmental Impact Assessment

The implementation of submersible pumps in agricultural logistics has significant environmental implications that warrant careful consideration. These pumps, while enhancing efficiency in water management and irrigation systems, can potentially impact local ecosystems and natural resources.

One of the primary environmental concerns is the effect on groundwater levels. Submersible pumps, capable of extracting water from deep aquifers, may lead to over-extraction if not properly regulated. This can result in the depletion of groundwater resources, affecting not only agricultural operations but also surrounding ecosystems and communities that rely on the same water sources.

The energy consumption of submersible pumps is another critical factor in their environmental impact assessment. While these pumps are generally more energy-efficient than surface pumps, their continuous operation in large-scale agricultural settings can contribute to increased electricity demand. This, in turn, may lead to higher carbon emissions if the energy source is not renewable, potentially exacerbating climate change issues.

Soil erosion and land degradation are additional environmental concerns associated with the use of submersible pumps in agriculture. Improper irrigation practices facilitated by these pumps can lead to soil salinization, waterlogging, and erosion, particularly in areas with poor drainage or susceptible soil types. These effects can have long-term consequences on soil fertility and agricultural productivity.

However, submersible pumps also offer potential environmental benefits when used judiciously. They can contribute to more efficient water use in agriculture, reducing overall water consumption and minimizing waste. This is particularly important in water-scarce regions where conservation is crucial. Additionally, by enabling precise irrigation scheduling, these pumps can help reduce runoff and the associated pollution of surface water bodies with agricultural chemicals.

The impact on local biodiversity should also be considered. While submersible pumps themselves may not directly affect wildlife, changes in water availability and land use patterns resulting from their implementation can influence habitat quality and species distribution. Proper environmental management plans should be developed to mitigate any negative effects on local flora and fauna.

In conclusion, the environmental impact of submersible pumps in agricultural logistics is multifaceted. While they offer potential benefits in terms of water and energy efficiency, their implementation must be carefully managed to avoid negative consequences such as groundwater depletion, soil degradation, and ecosystem disruption. Sustainable use of these pumps requires a balanced approach that considers both agricultural productivity and environmental conservation.

One of the primary environmental concerns is the effect on groundwater levels. Submersible pumps, capable of extracting water from deep aquifers, may lead to over-extraction if not properly regulated. This can result in the depletion of groundwater resources, affecting not only agricultural operations but also surrounding ecosystems and communities that rely on the same water sources.

The energy consumption of submersible pumps is another critical factor in their environmental impact assessment. While these pumps are generally more energy-efficient than surface pumps, their continuous operation in large-scale agricultural settings can contribute to increased electricity demand. This, in turn, may lead to higher carbon emissions if the energy source is not renewable, potentially exacerbating climate change issues.

Soil erosion and land degradation are additional environmental concerns associated with the use of submersible pumps in agriculture. Improper irrigation practices facilitated by these pumps can lead to soil salinization, waterlogging, and erosion, particularly in areas with poor drainage or susceptible soil types. These effects can have long-term consequences on soil fertility and agricultural productivity.

However, submersible pumps also offer potential environmental benefits when used judiciously. They can contribute to more efficient water use in agriculture, reducing overall water consumption and minimizing waste. This is particularly important in water-scarce regions where conservation is crucial. Additionally, by enabling precise irrigation scheduling, these pumps can help reduce runoff and the associated pollution of surface water bodies with agricultural chemicals.

The impact on local biodiversity should also be considered. While submersible pumps themselves may not directly affect wildlife, changes in water availability and land use patterns resulting from their implementation can influence habitat quality and species distribution. Proper environmental management plans should be developed to mitigate any negative effects on local flora and fauna.

In conclusion, the environmental impact of submersible pumps in agricultural logistics is multifaceted. While they offer potential benefits in terms of water and energy efficiency, their implementation must be carefully managed to avoid negative consequences such as groundwater depletion, soil degradation, and ecosystem disruption. Sustainable use of these pumps requires a balanced approach that considers both agricultural productivity and environmental conservation.

Cost-Benefit Analysis

The implementation of submersible pumps in agriculture logistics presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for submersible pumps can be substantial, including the purchase of the pump itself, installation expenses, and necessary infrastructure modifications. These upfront costs may pose a significant barrier for smaller agricultural operations or those with limited capital.

However, the long-term benefits of submersible pumps often outweigh the initial expenditure. Operational costs tend to be lower compared to traditional surface pumps, primarily due to improved energy efficiency. Submersible pumps typically consume less electricity, resulting in reduced energy bills over time. Additionally, their underwater placement minimizes the need for priming and reduces the risk of cavitation, leading to lower maintenance costs and extended equipment lifespan.

In terms of productivity, submersible pumps offer significant advantages. Their ability to operate at greater depths and handle higher flow rates enables more efficient water extraction and distribution. This increased efficiency can lead to improved crop yields and the potential for expanding cultivated areas, ultimately boosting overall agricultural output and revenue.

The reliability of submersible pumps also contributes to their cost-effectiveness. Their design makes them less susceptible to environmental factors such as flooding or extreme weather conditions, reducing downtime and associated losses. This reliability is particularly crucial in agriculture, where timely irrigation can make a substantial difference in crop quality and yield.

From a logistics perspective, submersible pumps streamline water management processes. Their compact design and underwater placement free up valuable surface space, allowing for more efficient land use and easier movement of machinery and personnel. This spatial efficiency can lead to improved overall farm logistics and potentially reduce labor costs associated with water management tasks.

Environmental considerations also factor into the cost-benefit analysis. Submersible pumps generally have a smaller environmental footprint compared to surface pumps. They produce less noise pollution and have a reduced risk of oil or fuel leaks contaminating water sources. These environmental benefits can translate into tangible cost savings by helping farms comply with environmental regulations and potentially qualify for eco-friendly incentives or certifications.

In conclusion, while the initial investment in submersible pumps may be substantial, the long-term benefits in terms of operational efficiency, reliability, and environmental sustainability often result in a favorable cost-benefit ratio for agricultural operations. The decision to implement submersible pumps should be based on a comprehensive analysis of specific farm conditions, water requirements, and long-term agricultural goals.

However, the long-term benefits of submersible pumps often outweigh the initial expenditure. Operational costs tend to be lower compared to traditional surface pumps, primarily due to improved energy efficiency. Submersible pumps typically consume less electricity, resulting in reduced energy bills over time. Additionally, their underwater placement minimizes the need for priming and reduces the risk of cavitation, leading to lower maintenance costs and extended equipment lifespan.

In terms of productivity, submersible pumps offer significant advantages. Their ability to operate at greater depths and handle higher flow rates enables more efficient water extraction and distribution. This increased efficiency can lead to improved crop yields and the potential for expanding cultivated areas, ultimately boosting overall agricultural output and revenue.

The reliability of submersible pumps also contributes to their cost-effectiveness. Their design makes them less susceptible to environmental factors such as flooding or extreme weather conditions, reducing downtime and associated losses. This reliability is particularly crucial in agriculture, where timely irrigation can make a substantial difference in crop quality and yield.

From a logistics perspective, submersible pumps streamline water management processes. Their compact design and underwater placement free up valuable surface space, allowing for more efficient land use and easier movement of machinery and personnel. This spatial efficiency can lead to improved overall farm logistics and potentially reduce labor costs associated with water management tasks.

Environmental considerations also factor into the cost-benefit analysis. Submersible pumps generally have a smaller environmental footprint compared to surface pumps. They produce less noise pollution and have a reduced risk of oil or fuel leaks contaminating water sources. These environmental benefits can translate into tangible cost savings by helping farms comply with environmental regulations and potentially qualify for eco-friendly incentives or certifications.

In conclusion, while the initial investment in submersible pumps may be substantial, the long-term benefits in terms of operational efficiency, reliability, and environmental sustainability often result in a favorable cost-benefit ratio for agricultural operations. The decision to implement submersible pumps should be based on a comprehensive analysis of specific farm conditions, water requirements, and long-term agricultural goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!