Advances in Hypochlorous Acid-Based Biocidal Solutions

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Technology Evolution

Hypochlorous acid (HOCl) technology has undergone significant evolution since its discovery in the early 19th century. Initially recognized for its powerful disinfectant properties, HOCl has seen a resurgence of interest in recent decades due to advancements in production methods and a growing demand for safe, effective biocidal solutions.

The early stages of HOCl technology were marked by limited understanding and application. In the 1830s, Antoine Jérôme Balard first isolated hypochlorous acid, but its unstable nature posed challenges for practical use. The technology remained largely dormant until the mid-20th century when its potential in water treatment and disinfection began to be explored more thoroughly.

A significant breakthrough came in the 1970s with the development of electrolyzed water systems. This technology allowed for the on-site generation of HOCl, overcoming stability issues and enabling broader applications. The 1980s and 1990s saw further refinements in production techniques, including membrane electrolysis and advanced chlorine dioxide generation methods, which improved the purity and consistency of HOCl solutions.

The turn of the 21st century marked a new era for HOCl technology. Increased concerns about environmental impact and chemical safety drove research into more sustainable disinfection methods. This period saw the development of stabilized HOCl formulations, extending shelf life and expanding potential applications. Concurrently, advancements in nanotechnology led to the creation of HOCl-based nanoparticles, enhancing penetration and efficacy against biofilms.

In the 2010s, the focus shifted towards optimizing HOCl production for specific applications. Innovations in electrochemical cells and precise pH control mechanisms allowed for the tailoring of HOCl solutions to various industries, including healthcare, agriculture, and food processing. The advent of smart sensors and IoT integration further improved the consistency and efficiency of HOCl generation systems.

Recent years have seen a surge in research on HOCl's mechanisms of action at the molecular level. Studies have elucidated its role in modulating cellular signaling pathways and its potential in wound healing and immune system modulation. This deeper understanding has opened new avenues for HOCl applications in medical treatments and biotechnology.

The COVID-19 pandemic accelerated interest in HOCl technology, spurring innovations in delivery systems such as foggers and electrostatic sprayers. This period also saw increased efforts to standardize HOCl production and testing methods, enhancing its credibility as a safe and effective biocidal solution.

Looking ahead, the evolution of HOCl technology is likely to continue with a focus on sustainability, precision, and integration with other emerging technologies. Ongoing research into novel production methods, such as photocatalytic generation and biologically inspired systems, promises to further expand the potential of this versatile compound in addressing global health and sanitation challenges.

The early stages of HOCl technology were marked by limited understanding and application. In the 1830s, Antoine Jérôme Balard first isolated hypochlorous acid, but its unstable nature posed challenges for practical use. The technology remained largely dormant until the mid-20th century when its potential in water treatment and disinfection began to be explored more thoroughly.

A significant breakthrough came in the 1970s with the development of electrolyzed water systems. This technology allowed for the on-site generation of HOCl, overcoming stability issues and enabling broader applications. The 1980s and 1990s saw further refinements in production techniques, including membrane electrolysis and advanced chlorine dioxide generation methods, which improved the purity and consistency of HOCl solutions.

The turn of the 21st century marked a new era for HOCl technology. Increased concerns about environmental impact and chemical safety drove research into more sustainable disinfection methods. This period saw the development of stabilized HOCl formulations, extending shelf life and expanding potential applications. Concurrently, advancements in nanotechnology led to the creation of HOCl-based nanoparticles, enhancing penetration and efficacy against biofilms.

In the 2010s, the focus shifted towards optimizing HOCl production for specific applications. Innovations in electrochemical cells and precise pH control mechanisms allowed for the tailoring of HOCl solutions to various industries, including healthcare, agriculture, and food processing. The advent of smart sensors and IoT integration further improved the consistency and efficiency of HOCl generation systems.

Recent years have seen a surge in research on HOCl's mechanisms of action at the molecular level. Studies have elucidated its role in modulating cellular signaling pathways and its potential in wound healing and immune system modulation. This deeper understanding has opened new avenues for HOCl applications in medical treatments and biotechnology.

The COVID-19 pandemic accelerated interest in HOCl technology, spurring innovations in delivery systems such as foggers and electrostatic sprayers. This period also saw increased efforts to standardize HOCl production and testing methods, enhancing its credibility as a safe and effective biocidal solution.

Looking ahead, the evolution of HOCl technology is likely to continue with a focus on sustainability, precision, and integration with other emerging technologies. Ongoing research into novel production methods, such as photocatalytic generation and biologically inspired systems, promises to further expand the potential of this versatile compound in addressing global health and sanitation challenges.

Market Demand Analysis

The market demand for hypochlorous acid-based biocidal solutions has been experiencing significant growth in recent years, driven by increasing awareness of hygiene and sanitation across various sectors. The global biocides market, which includes hypochlorous acid-based solutions, is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2028, reaching a market value of $13.9 billion by the end of the forecast period.

The healthcare sector remains a primary driver of demand for hypochlorous acid-based biocidal solutions. Hospitals, clinics, and other medical facilities are increasingly adopting these solutions for disinfection and sterilization purposes due to their efficacy against a wide range of pathogens, including bacteria, viruses, and fungi. The ongoing COVID-19 pandemic has further accelerated this trend, with heightened focus on infection prevention and control measures.

The food and beverage industry represents another significant market for hypochlorous acid-based biocidal solutions. These products are widely used for sanitizing food processing equipment, surfaces, and packaging materials. The growing emphasis on food safety and the need to comply with stringent regulatory standards have boosted the adoption of hypochlorous acid-based solutions in this sector.

Water treatment applications also contribute substantially to the market demand. Hypochlorous acid-based solutions are employed in municipal water treatment plants, swimming pools, and industrial water systems for their powerful disinfection properties. The increasing global focus on access to clean water and improved sanitation facilities is expected to drive further growth in this segment.

The agriculture sector is emerging as a promising market for hypochlorous acid-based biocidal solutions. These products are being used for crop protection, seed treatment, and post-harvest applications. The shift towards sustainable and environmentally friendly agricultural practices is likely to fuel the demand for hypochlorous acid-based solutions as alternatives to traditional chemical pesticides.

Consumer awareness of the importance of household hygiene has led to a rise in demand for hypochlorous acid-based products in the home care segment. These solutions are increasingly being marketed as safe and effective alternatives to conventional household disinfectants, appealing to environmentally conscious consumers.

The Asia-Pacific region is anticipated to witness the highest growth rate in the hypochlorous acid-based biocidal solutions market. Rapid industrialization, urbanization, and improving healthcare infrastructure in countries like China and India are key factors driving this regional growth. North America and Europe continue to be significant markets, with established healthcare systems and stringent regulatory frameworks supporting the adoption of advanced biocidal solutions.

The healthcare sector remains a primary driver of demand for hypochlorous acid-based biocidal solutions. Hospitals, clinics, and other medical facilities are increasingly adopting these solutions for disinfection and sterilization purposes due to their efficacy against a wide range of pathogens, including bacteria, viruses, and fungi. The ongoing COVID-19 pandemic has further accelerated this trend, with heightened focus on infection prevention and control measures.

The food and beverage industry represents another significant market for hypochlorous acid-based biocidal solutions. These products are widely used for sanitizing food processing equipment, surfaces, and packaging materials. The growing emphasis on food safety and the need to comply with stringent regulatory standards have boosted the adoption of hypochlorous acid-based solutions in this sector.

Water treatment applications also contribute substantially to the market demand. Hypochlorous acid-based solutions are employed in municipal water treatment plants, swimming pools, and industrial water systems for their powerful disinfection properties. The increasing global focus on access to clean water and improved sanitation facilities is expected to drive further growth in this segment.

The agriculture sector is emerging as a promising market for hypochlorous acid-based biocidal solutions. These products are being used for crop protection, seed treatment, and post-harvest applications. The shift towards sustainable and environmentally friendly agricultural practices is likely to fuel the demand for hypochlorous acid-based solutions as alternatives to traditional chemical pesticides.

Consumer awareness of the importance of household hygiene has led to a rise in demand for hypochlorous acid-based products in the home care segment. These solutions are increasingly being marketed as safe and effective alternatives to conventional household disinfectants, appealing to environmentally conscious consumers.

The Asia-Pacific region is anticipated to witness the highest growth rate in the hypochlorous acid-based biocidal solutions market. Rapid industrialization, urbanization, and improving healthcare infrastructure in countries like China and India are key factors driving this regional growth. North America and Europe continue to be significant markets, with established healthcare systems and stringent regulatory frameworks supporting the adoption of advanced biocidal solutions.

Technical Challenges

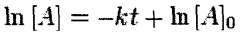

The development of hypochlorous acid-based biocidal solutions faces several technical challenges that researchers and manufacturers must address to enhance their efficacy and broaden their applications. One of the primary obstacles is the stability of hypochlorous acid solutions. These solutions tend to degrade rapidly, losing their antimicrobial potency over time. This instability is particularly pronounced when exposed to light, heat, or organic matter, limiting their shelf life and practical use in various environments.

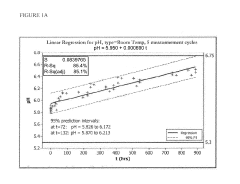

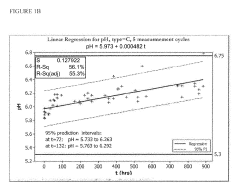

Another significant challenge lies in maintaining the optimal pH range for hypochlorous acid solutions. The biocidal activity of these solutions is highly dependent on pH, with maximum efficacy typically observed between pH 3.5 and 6.5. Developing formulations that can maintain this pH range while remaining stable and safe for use on various surfaces and in different applications is a complex task that requires advanced chemical engineering.

The concentration of hypochlorous acid in biocidal solutions presents another technical hurdle. Higher concentrations generally offer greater antimicrobial efficacy but may also increase the risk of irritation or corrosion. Conversely, lower concentrations may be safer but less effective against certain pathogens. Striking the right balance between efficacy and safety across diverse applications remains an ongoing challenge for researchers and product developers.

The production of hypochlorous acid solutions at scale also poses technical difficulties. Current methods often involve electrolysis of salt water or the use of chemical precursors, both of which can be energy-intensive and may introduce impurities. Developing more efficient, cost-effective, and environmentally friendly production methods is crucial for the widespread adoption of these biocidal solutions.

Compatibility with various materials is another area of concern. While hypochlorous acid is generally considered safe for many surfaces, its potential for corrosion or degradation of certain materials, particularly metals and some plastics, needs to be carefully evaluated and mitigated. This challenge becomes more pronounced in industrial and healthcare settings where a wide range of materials may come into contact with the biocidal solution.

Lastly, the formulation of hypochlorous acid solutions that can effectively penetrate biofilms represents a significant technical challenge. Biofilms, which are communities of microorganisms that adhere to surfaces, can be highly resistant to antimicrobial agents. Developing solutions that can break down or penetrate these protective structures while maintaining their biocidal activity is crucial for expanding the effectiveness of hypochlorous acid-based products in various applications, particularly in medical and industrial settings.

Another significant challenge lies in maintaining the optimal pH range for hypochlorous acid solutions. The biocidal activity of these solutions is highly dependent on pH, with maximum efficacy typically observed between pH 3.5 and 6.5. Developing formulations that can maintain this pH range while remaining stable and safe for use on various surfaces and in different applications is a complex task that requires advanced chemical engineering.

The concentration of hypochlorous acid in biocidal solutions presents another technical hurdle. Higher concentrations generally offer greater antimicrobial efficacy but may also increase the risk of irritation or corrosion. Conversely, lower concentrations may be safer but less effective against certain pathogens. Striking the right balance between efficacy and safety across diverse applications remains an ongoing challenge for researchers and product developers.

The production of hypochlorous acid solutions at scale also poses technical difficulties. Current methods often involve electrolysis of salt water or the use of chemical precursors, both of which can be energy-intensive and may introduce impurities. Developing more efficient, cost-effective, and environmentally friendly production methods is crucial for the widespread adoption of these biocidal solutions.

Compatibility with various materials is another area of concern. While hypochlorous acid is generally considered safe for many surfaces, its potential for corrosion or degradation of certain materials, particularly metals and some plastics, needs to be carefully evaluated and mitigated. This challenge becomes more pronounced in industrial and healthcare settings where a wide range of materials may come into contact with the biocidal solution.

Lastly, the formulation of hypochlorous acid solutions that can effectively penetrate biofilms represents a significant technical challenge. Biofilms, which are communities of microorganisms that adhere to surfaces, can be highly resistant to antimicrobial agents. Developing solutions that can break down or penetrate these protective structures while maintaining their biocidal activity is crucial for expanding the effectiveness of hypochlorous acid-based products in various applications, particularly in medical and industrial settings.

Current HOCL Solutions

01 Composition and preparation of hypochlorous acid solutions

Hypochlorous acid-based biocidal solutions are typically prepared by electrolysis of salt water or through chemical reactions. The composition often includes stabilizers and pH adjusters to maintain the effectiveness of the solution. The concentration of hypochlorous acid and the pH level are critical factors in determining the biocidal efficacy of the solution.- Composition and preparation of hypochlorous acid solutions: Hypochlorous acid-based biocidal solutions are typically prepared by electrolysis of salt water or through chemical reactions. The composition often includes stabilizers and pH adjusters to maintain the effectiveness of the solution. The concentration of hypochlorous acid and the pH level are critical factors in determining the biocidal efficacy of the solution.

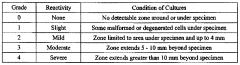

- Biocidal effectiveness against various microorganisms: Hypochlorous acid solutions demonstrate broad-spectrum antimicrobial activity against bacteria, viruses, fungi, and spores. The effectiveness varies depending on the concentration, contact time, and environmental conditions. These solutions are particularly effective in rapid disinfection of surfaces and water treatment applications.

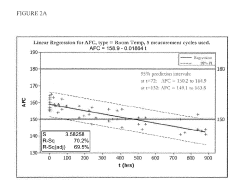

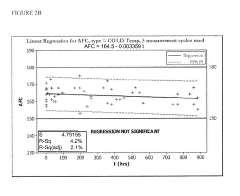

- Stability and shelf life of hypochlorous acid solutions: The stability of hypochlorous acid solutions is a key concern in their formulation and storage. Various methods are employed to enhance stability, including the use of specific packaging materials, addition of stabilizers, and control of storage conditions. Improved stability contributes to maintaining the biocidal effectiveness over extended periods.

- Applications in healthcare and industrial settings: Hypochlorous acid-based biocidal solutions find extensive use in healthcare facilities for disinfection of medical equipment and surfaces. In industrial settings, they are used for water treatment, food processing equipment sanitation, and general surface disinfection. The non-toxic nature and broad-spectrum efficacy make them suitable for various applications requiring high-level disinfection.

- Environmental impact and safety considerations: Hypochlorous acid solutions are generally considered environmentally friendly due to their rapid breakdown into non-toxic components. They pose minimal risk to human health when used as directed, making them suitable for frequent use in various settings. However, proper handling and storage are essential to maintain their effectiveness and safety profile.

02 Biocidal effectiveness against various microorganisms

Hypochlorous acid solutions demonstrate broad-spectrum antimicrobial activity against bacteria, viruses, fungi, and spores. The effectiveness varies depending on the concentration, exposure time, and target microorganism. These solutions are particularly effective in rapidly inactivating pathogens on surfaces and in water treatment applications.Expand Specific Solutions03 Applications in disinfection and sanitization

Hypochlorous acid-based solutions are widely used in various industries for disinfection and sanitization purposes. They are employed in healthcare settings, food processing facilities, water treatment plants, and general surface disinfection. The solutions are particularly valuable in situations requiring rapid and effective microbial control without leaving harmful residues.Expand Specific Solutions04 Stability and shelf life of hypochlorous acid solutions

The stability and shelf life of hypochlorous acid solutions are important considerations for their practical use. Various methods and additives are employed to enhance the stability of these solutions, including pH adjustment, addition of stabilizers, and proper storage conditions. Improved stability ensures maintained biocidal effectiveness over extended periods.Expand Specific Solutions05 Environmental and safety considerations

Hypochlorous acid-based biocidal solutions are generally considered environmentally friendly and safe for human use when properly formulated. They break down into harmless byproducts and do not persist in the environment. However, proper handling and application procedures are necessary to ensure safety and maximize effectiveness while minimizing potential risks.Expand Specific Solutions

Key Industry Players

The hypochlorous acid-based biocidal solutions market is in a growth phase, driven by increasing demand for effective and safe disinfectants. The global market size is expanding, with applications across healthcare, water treatment, and industrial sectors. Technologically, the field is advancing rapidly, with companies like Industrie De Nora SpA and Realm Therapeutics Plc leading innovation in electrochemical production and formulation. Academic institutions such as Louisiana State University are contributing to research, while established players like Schlumberger and emerging firms like Aquaox, Inc. are developing specialized applications. The competitive landscape is diverse, with a mix of large corporations and niche players focusing on specific market segments or technological advancements.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrochemical cell technology for on-site generation of hypochlorous acid (HOCl) solutions. Their system utilizes a membrane-free electrolytic cell design that allows for efficient production of HOCl at concentrations up to 500 ppm [1]. The process involves electrolysis of salt water, producing a stable HOCl solution with a pH range of 5.5-6.5, ideal for maximizing biocidal efficacy [2]. De Nora's technology incorporates real-time monitoring and control systems to ensure consistent HOCl production and quality. The company has also developed specialized electrode coatings that enhance the longevity and efficiency of their electrolytic cells [3].

Strengths: On-site generation eliminates transportation and storage of chemicals; precise control over HOCl concentration and pH; environmentally friendly process using only salt and water. Weaknesses: Requires initial investment in equipment; ongoing maintenance of electrolytic cells; dependent on stable power supply.

WIAB WATER INNOVATION AB

Technical Solution: WIAB WATER INNOVATION AB has pioneered a novel approach to HOCl production using a patented electrolysis process. Their technology, known as ECA (Electrochemical Activation), generates a highly effective HOCl solution with a neutral pH (6.5-7.5) [1]. The system employs a unique cell design that allows for the separation of anodic and cathodic chambers, resulting in a stable HOCl solution without the need for additional pH adjustment [2]. WIAB's innovation lies in their ability to produce HOCl at concentrations up to 1000 ppm while maintaining a neutral pH, which is crucial for both efficacy and material compatibility [3]. The company has also developed smart dosing systems that integrate with their HOCl generators, ensuring optimal application in various industrial and healthcare settings.

Strengths: Produces neutral pH HOCl without additional chemicals; high concentration capabilities; integrated smart dosing systems. Weaknesses: May require specialized training for operation; higher initial cost compared to traditional disinfection methods; limited scalability for very large-scale applications.

HOCL Patents & Research

Stabilized hypohalous acid solutions

PatentActiveUS20190151449A1

Innovation

- A stabilized hypohalous acid solution with a stabilizing amount of dissolved inorganic carbon (DIC) such as bicarbonate or carbonate, maintaining an available free chlorine (AFC) content of 10 to 10,000 ppm and a pH of 4.0 to 7.5, which is prepared by electrolysis of saline and stabilized for at least one month, allowing for longer shelf life and reduced irritation.

METHOD FOR STABILIZING AN ELECTROCHEMICALLY GENERATED SANITIZING SOLUTION HAVING A PREDETERMINED LEVEL OF FREE AVAILABLE CHLORINE AND pH

PatentWO2014179692A1

Innovation

- A stabilized Hypochlorous Acid solution is developed with a stabilizing amount of dissolved ionic compounds (DIC) such as sodium phosphate or polyphosphate, maintaining a pH of 4.0 to 7.5 and FAC content of 10 to 1000 ppm, which is electrochemically generated and formulated as a hydrogel to ensure stability and non-irritating properties.

Regulatory Framework

The regulatory framework surrounding hypochlorous acid-based biocidal solutions is complex and multifaceted, reflecting the diverse applications and potential impacts of these products. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating these solutions under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA requires manufacturers to register their products and provide extensive data on efficacy, safety, and environmental impact before approval for commercial use.

The Food and Drug Administration (FDA) also has oversight in certain applications, particularly when hypochlorous acid solutions are used in food processing or as medical devices. The FDA's regulations focus on ensuring the safety and effectiveness of these products in specific contexts, such as wound care or food contact surfaces.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of hypochlorous acid-based solutions. This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for human health and the environment. Under the BPR, active substances must be approved at the EU level before products containing them can be authorized for use in individual member states.

The regulatory landscape also includes international standards and guidelines, such as those set by the World Health Organization (WHO) and the Codex Alimentarius Commission. These organizations provide recommendations on the safe use of disinfectants and sanitizers, including hypochlorous acid-based products, in various settings like healthcare facilities and food production.

As the technology behind hypochlorous acid solutions advances, regulatory bodies are continually adapting their frameworks to address new formulations and applications. This includes ongoing assessments of the long-term environmental impact and potential for antimicrobial resistance development associated with widespread use of these biocidal solutions.

Manufacturers and researchers in this field must navigate a complex web of regulations that can vary significantly between jurisdictions. This regulatory diversity can present challenges in terms of product development, testing requirements, and market access. However, it also drives innovation as companies strive to develop solutions that meet increasingly stringent safety and efficacy standards across different regulatory regimes.

The evolving nature of regulations in this area underscores the importance of ongoing dialogue between industry stakeholders, regulatory bodies, and scientific experts. This collaboration is essential for ensuring that the regulatory framework keeps pace with technological advancements while maintaining robust protections for public health and the environment.

The Food and Drug Administration (FDA) also has oversight in certain applications, particularly when hypochlorous acid solutions are used in food processing or as medical devices. The FDA's regulations focus on ensuring the safety and effectiveness of these products in specific contexts, such as wound care or food contact surfaces.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of hypochlorous acid-based solutions. This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for human health and the environment. Under the BPR, active substances must be approved at the EU level before products containing them can be authorized for use in individual member states.

The regulatory landscape also includes international standards and guidelines, such as those set by the World Health Organization (WHO) and the Codex Alimentarius Commission. These organizations provide recommendations on the safe use of disinfectants and sanitizers, including hypochlorous acid-based products, in various settings like healthcare facilities and food production.

As the technology behind hypochlorous acid solutions advances, regulatory bodies are continually adapting their frameworks to address new formulations and applications. This includes ongoing assessments of the long-term environmental impact and potential for antimicrobial resistance development associated with widespread use of these biocidal solutions.

Manufacturers and researchers in this field must navigate a complex web of regulations that can vary significantly between jurisdictions. This regulatory diversity can present challenges in terms of product development, testing requirements, and market access. However, it also drives innovation as companies strive to develop solutions that meet increasingly stringent safety and efficacy standards across different regulatory regimes.

The evolving nature of regulations in this area underscores the importance of ongoing dialogue between industry stakeholders, regulatory bodies, and scientific experts. This collaboration is essential for ensuring that the regulatory framework keeps pace with technological advancements while maintaining robust protections for public health and the environment.

Environmental Impact

The environmental impact of hypochlorous acid-based biocidal solutions has become a critical consideration in their development and application. These solutions offer significant advantages over traditional disinfectants due to their high efficacy and low toxicity. However, their widespread use necessitates a thorough examination of their ecological footprint.

One of the primary environmental benefits of hypochlorous acid solutions is their rapid degradation into harmless byproducts. Unlike many conventional disinfectants that persist in the environment, hypochlorous acid quickly breaks down into water and salt. This characteristic significantly reduces the risk of long-term environmental contamination and minimizes the potential for harmful residues to accumulate in ecosystems.

The production process of hypochlorous acid solutions has also seen advancements that contribute to their environmental friendliness. Modern electrolysis techniques allow for on-site generation using only salt, water, and electricity. This approach eliminates the need for transportation and storage of hazardous chemicals, thereby reducing the carbon footprint associated with traditional disinfectant manufacturing and distribution.

However, the environmental impact of hypochlorous acid solutions is not entirely benign. The use of electricity in their production raises questions about energy consumption and associated carbon emissions. While the energy requirements are generally low, the source of electricity plays a crucial role in determining the overall environmental impact. Efforts to integrate renewable energy sources into production processes are ongoing to address this concern.

Another environmental consideration is the potential effect on aquatic ecosystems when hypochlorous acid solutions are released into water bodies. Although the solutions degrade rapidly, high concentrations in localized areas could temporarily disrupt aquatic life. Proper dilution and responsible disposal practices are essential to mitigate these risks.

The packaging and distribution of hypochlorous acid solutions also contribute to their environmental profile. Advances in packaging technology have led to the development of more sustainable options, such as recyclable or biodegradable containers. Additionally, concentrated formulations that can be diluted on-site reduce packaging waste and transportation-related emissions.

Research into the long-term ecological effects of widespread hypochlorous acid use is ongoing. While initial studies suggest minimal environmental impact, continued monitoring and assessment are necessary to ensure that any unforeseen consequences are promptly identified and addressed. This commitment to environmental stewardship is crucial for maintaining the sustainability of hypochlorous acid-based biocidal solutions in various applications.

One of the primary environmental benefits of hypochlorous acid solutions is their rapid degradation into harmless byproducts. Unlike many conventional disinfectants that persist in the environment, hypochlorous acid quickly breaks down into water and salt. This characteristic significantly reduces the risk of long-term environmental contamination and minimizes the potential for harmful residues to accumulate in ecosystems.

The production process of hypochlorous acid solutions has also seen advancements that contribute to their environmental friendliness. Modern electrolysis techniques allow for on-site generation using only salt, water, and electricity. This approach eliminates the need for transportation and storage of hazardous chemicals, thereby reducing the carbon footprint associated with traditional disinfectant manufacturing and distribution.

However, the environmental impact of hypochlorous acid solutions is not entirely benign. The use of electricity in their production raises questions about energy consumption and associated carbon emissions. While the energy requirements are generally low, the source of electricity plays a crucial role in determining the overall environmental impact. Efforts to integrate renewable energy sources into production processes are ongoing to address this concern.

Another environmental consideration is the potential effect on aquatic ecosystems when hypochlorous acid solutions are released into water bodies. Although the solutions degrade rapidly, high concentrations in localized areas could temporarily disrupt aquatic life. Proper dilution and responsible disposal practices are essential to mitigate these risks.

The packaging and distribution of hypochlorous acid solutions also contribute to their environmental profile. Advances in packaging technology have led to the development of more sustainable options, such as recyclable or biodegradable containers. Additionally, concentrated formulations that can be diluted on-site reduce packaging waste and transportation-related emissions.

Research into the long-term ecological effects of widespread hypochlorous acid use is ongoing. While initial studies suggest minimal environmental impact, continued monitoring and assessment are necessary to ensure that any unforeseen consequences are promptly identified and addressed. This commitment to environmental stewardship is crucial for maintaining the sustainability of hypochlorous acid-based biocidal solutions in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!