Hypochlorous Acid: Transitioning from Traditional to High-Tech Applications

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Tech Evolution

Hypochlorous acid (HOCl) has undergone a remarkable transformation from its traditional applications to cutting-edge technological uses. Initially discovered in the early 19th century, HOCl was primarily utilized as a disinfectant and sanitizer in various industries. Its powerful antimicrobial properties made it a staple in water treatment, food processing, and healthcare settings.

The evolution of HOCl technology can be traced through several key phases. In the early stages, the focus was on understanding its chemical properties and optimizing production methods. This led to the development of more stable and concentrated forms of HOCl, expanding its potential applications.

A significant milestone in HOCl's technological evolution came with the advent of electrolyzed water systems in the late 20th century. These systems allowed for on-site generation of HOCl, revolutionizing its use in industrial and commercial settings. This innovation addressed the challenges of storage and transportation associated with traditional chlorine-based disinfectants.

The 21st century has seen a surge in research and development efforts to harness the full potential of HOCl. Advanced production techniques, such as membrane electrolysis and plasma-activated water systems, have emerged, enabling the creation of highly pure and stable HOCl solutions. These advancements have paved the way for new applications in fields like agriculture, wound care, and environmental remediation.

In recent years, nanotechnology has played a crucial role in enhancing HOCl's efficacy and expanding its applications. The development of nanocarriers and encapsulation techniques has improved the stability and targeted delivery of HOCl, opening up possibilities in areas such as drug delivery and advanced materials.

The integration of HOCl technology with smart systems and Internet of Things (IoT) devices represents the latest frontier in its evolution. Automated disinfection systems, real-time monitoring of HOCl levels, and data-driven optimization of application processes are becoming increasingly common in various industries.

As environmental concerns and the demand for sustainable solutions grow, HOCl has gained renewed interest as an eco-friendly alternative to traditional chemical disinfectants. Research into green production methods and the exploration of HOCl's role in circular economy models are shaping its future trajectory.

The ongoing COVID-19 pandemic has further accelerated the development and adoption of HOCl-based technologies, particularly in the realm of surface and air disinfection. This has led to innovations in misting systems, electrostatic sprayers, and other advanced application methods, solidifying HOCl's position as a key player in modern hygiene and infection control strategies.

The evolution of HOCl technology can be traced through several key phases. In the early stages, the focus was on understanding its chemical properties and optimizing production methods. This led to the development of more stable and concentrated forms of HOCl, expanding its potential applications.

A significant milestone in HOCl's technological evolution came with the advent of electrolyzed water systems in the late 20th century. These systems allowed for on-site generation of HOCl, revolutionizing its use in industrial and commercial settings. This innovation addressed the challenges of storage and transportation associated with traditional chlorine-based disinfectants.

The 21st century has seen a surge in research and development efforts to harness the full potential of HOCl. Advanced production techniques, such as membrane electrolysis and plasma-activated water systems, have emerged, enabling the creation of highly pure and stable HOCl solutions. These advancements have paved the way for new applications in fields like agriculture, wound care, and environmental remediation.

In recent years, nanotechnology has played a crucial role in enhancing HOCl's efficacy and expanding its applications. The development of nanocarriers and encapsulation techniques has improved the stability and targeted delivery of HOCl, opening up possibilities in areas such as drug delivery and advanced materials.

The integration of HOCl technology with smart systems and Internet of Things (IoT) devices represents the latest frontier in its evolution. Automated disinfection systems, real-time monitoring of HOCl levels, and data-driven optimization of application processes are becoming increasingly common in various industries.

As environmental concerns and the demand for sustainable solutions grow, HOCl has gained renewed interest as an eco-friendly alternative to traditional chemical disinfectants. Research into green production methods and the exploration of HOCl's role in circular economy models are shaping its future trajectory.

The ongoing COVID-19 pandemic has further accelerated the development and adoption of HOCl-based technologies, particularly in the realm of surface and air disinfection. This has led to innovations in misting systems, electrostatic sprayers, and other advanced application methods, solidifying HOCl's position as a key player in modern hygiene and infection control strategies.

Market Demand Analysis

The market demand for hypochlorous acid (HOCl) has been experiencing significant growth, driven by its versatile applications across various industries. Traditionally used as a disinfectant and sanitizer, HOCl is now transitioning into high-tech applications, expanding its market potential.

In the healthcare sector, HOCl has gained traction as an effective and safe antimicrobial agent. Hospitals, clinics, and dental practices are increasingly adopting HOCl-based solutions for surface disinfection and wound care. The ongoing global health concerns have further accelerated the demand for reliable disinfectants, positioning HOCl as a preferred choice due to its non-toxic nature and broad-spectrum efficacy.

The food and beverage industry represents another significant market for HOCl. As consumers become more health-conscious and demand cleaner labels, food manufacturers are turning to HOCl as a natural preservative and sanitizer. Its ability to extend shelf life without leaving harmful residues aligns well with the clean-label trend, driving adoption in food processing and packaging applications.

Agriculture and horticulture sectors are also contributing to the growing demand for HOCl. Farmers and growers are utilizing HOCl-based solutions for crop protection, seed treatment, and hydroponic systems. The eco-friendly profile of HOCl makes it an attractive alternative to traditional chemical pesticides, addressing the increasing regulatory pressure and consumer preference for sustainable farming practices.

The personal care and cosmetics industry is emerging as a promising market for HOCl. Skincare products incorporating HOCl are gaining popularity due to their antimicrobial properties and potential benefits in treating various skin conditions. This trend is expected to continue as consumers seek gentler, yet effective skincare solutions.

In the water treatment sector, HOCl is finding applications in both industrial and residential settings. Its effectiveness in water purification, coupled with its environmentally friendly nature, is driving adoption in municipal water treatment plants, swimming pools, and household water filtration systems.

The transition of HOCl into high-tech applications is opening new market opportunities. In the electronics industry, HOCl is being explored for cleaning and sterilizing sensitive components. The semiconductor manufacturing process, which requires ultra-clean environments, is a potential growth area for HOCl-based solutions.

As research continues to uncover new applications for HOCl, the market is expected to expand further. The development of stable formulations and advanced delivery systems is likely to enhance the versatility of HOCl, potentially leading to its integration into smart devices and IoT-enabled sanitization systems.

In the healthcare sector, HOCl has gained traction as an effective and safe antimicrobial agent. Hospitals, clinics, and dental practices are increasingly adopting HOCl-based solutions for surface disinfection and wound care. The ongoing global health concerns have further accelerated the demand for reliable disinfectants, positioning HOCl as a preferred choice due to its non-toxic nature and broad-spectrum efficacy.

The food and beverage industry represents another significant market for HOCl. As consumers become more health-conscious and demand cleaner labels, food manufacturers are turning to HOCl as a natural preservative and sanitizer. Its ability to extend shelf life without leaving harmful residues aligns well with the clean-label trend, driving adoption in food processing and packaging applications.

Agriculture and horticulture sectors are also contributing to the growing demand for HOCl. Farmers and growers are utilizing HOCl-based solutions for crop protection, seed treatment, and hydroponic systems. The eco-friendly profile of HOCl makes it an attractive alternative to traditional chemical pesticides, addressing the increasing regulatory pressure and consumer preference for sustainable farming practices.

The personal care and cosmetics industry is emerging as a promising market for HOCl. Skincare products incorporating HOCl are gaining popularity due to their antimicrobial properties and potential benefits in treating various skin conditions. This trend is expected to continue as consumers seek gentler, yet effective skincare solutions.

In the water treatment sector, HOCl is finding applications in both industrial and residential settings. Its effectiveness in water purification, coupled with its environmentally friendly nature, is driving adoption in municipal water treatment plants, swimming pools, and household water filtration systems.

The transition of HOCl into high-tech applications is opening new market opportunities. In the electronics industry, HOCl is being explored for cleaning and sterilizing sensitive components. The semiconductor manufacturing process, which requires ultra-clean environments, is a potential growth area for HOCl-based solutions.

As research continues to uncover new applications for HOCl, the market is expected to expand further. The development of stable formulations and advanced delivery systems is likely to enhance the versatility of HOCl, potentially leading to its integration into smart devices and IoT-enabled sanitization systems.

Current Tech Challenges

The transition of hypochlorous acid (HOCl) from traditional to high-tech applications faces several significant challenges. One of the primary obstacles is the stability of HOCl solutions. Due to its reactive nature, HOCl tends to degrade rapidly, limiting its shelf life and effectiveness in various applications. This instability poses difficulties in storage, transportation, and long-term use, particularly in commercial and industrial settings.

Another major challenge lies in the production and scalability of HOCl solutions. Traditional methods of generating HOCl often involve complex processes or require specialized equipment, making large-scale production costly and inefficient. The need for more cost-effective and streamlined production methods is crucial for wider adoption in high-tech applications.

The concentration control of HOCl solutions presents another technical hurdle. Maintaining precise and consistent concentrations is essential for many advanced applications, especially in healthcare and sanitization. However, achieving this level of control can be challenging due to the compound's reactive nature and sensitivity to environmental factors.

Compatibility issues with various materials and surfaces also pose significant challenges. HOCl's corrosive properties can limit its use with certain metals and materials, necessitating the development of compatible storage and application systems. This is particularly crucial in sectors like medical devices and advanced manufacturing, where material integrity is paramount.

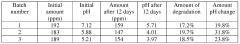

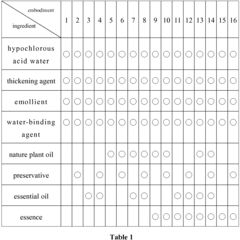

The lack of standardized testing and quality control methods for HOCl solutions is another obstacle. Without uniform standards, it becomes difficult to ensure consistency and efficacy across different production batches and applications. This challenge is particularly evident in regulatory compliance for high-tech and medical applications.

Furthermore, there is a need for advanced delivery systems that can maintain the stability and effectiveness of HOCl during application. Current methods may not be suitable for all high-tech applications, especially those requiring precise, controlled delivery or integration with other technologies.

Lastly, the perception and understanding of HOCl's potential in high-tech applications remain limited. Despite its proven effectiveness in traditional uses, there is a knowledge gap in recognizing and leveraging its capabilities in advanced technological contexts. Overcoming this challenge requires extensive research, education, and demonstration of HOCl's versatility and benefits in new application areas.

Another major challenge lies in the production and scalability of HOCl solutions. Traditional methods of generating HOCl often involve complex processes or require specialized equipment, making large-scale production costly and inefficient. The need for more cost-effective and streamlined production methods is crucial for wider adoption in high-tech applications.

The concentration control of HOCl solutions presents another technical hurdle. Maintaining precise and consistent concentrations is essential for many advanced applications, especially in healthcare and sanitization. However, achieving this level of control can be challenging due to the compound's reactive nature and sensitivity to environmental factors.

Compatibility issues with various materials and surfaces also pose significant challenges. HOCl's corrosive properties can limit its use with certain metals and materials, necessitating the development of compatible storage and application systems. This is particularly crucial in sectors like medical devices and advanced manufacturing, where material integrity is paramount.

The lack of standardized testing and quality control methods for HOCl solutions is another obstacle. Without uniform standards, it becomes difficult to ensure consistency and efficacy across different production batches and applications. This challenge is particularly evident in regulatory compliance for high-tech and medical applications.

Furthermore, there is a need for advanced delivery systems that can maintain the stability and effectiveness of HOCl during application. Current methods may not be suitable for all high-tech applications, especially those requiring precise, controlled delivery or integration with other technologies.

Lastly, the perception and understanding of HOCl's potential in high-tech applications remain limited. Despite its proven effectiveness in traditional uses, there is a knowledge gap in recognizing and leveraging its capabilities in advanced technological contexts. Overcoming this challenge requires extensive research, education, and demonstration of HOCl's versatility and benefits in new application areas.

Existing HOCL Solutions

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization and formulation of hypochlorous acid solutions: Techniques for stabilizing hypochlorous acid solutions are crucial for maintaining their efficacy over time. This includes pH control, addition of stabilizing agents, and specialized packaging to prevent degradation. Formulation strategies aim to enhance shelf life and preserve the active properties of hypochlorous acid.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its natural occurrence in the human immune system and low cytotoxicity make it suitable for these sensitive applications.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation, water treatment, and various industrial processes. Its strong oxidizing properties and eco-friendly nature make it suitable for cleaning, decontamination, and odor control in industrial settings and public spaces.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields such as healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, including bacteria, viruses, and fungi, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

To enhance the shelf life and maintain the efficacy of hypochlorous acid solutions, various stabilization techniques are employed. These may include pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation and maintain the active chlorine content.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid finds applications in medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its gentle yet effective nature makes it suitable for use on sensitive tissues while providing antimicrobial benefits.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in various environmental and industrial applications, such as water treatment, agriculture, and surface disinfection. Its eco-friendly nature and ability to break down into harmless byproducts make it an attractive option for sustainable practices.Expand Specific Solutions

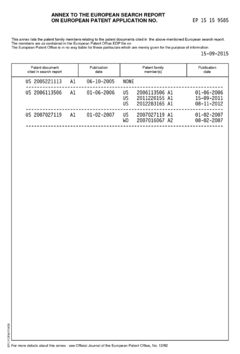

Key Industry Players

The hypochlorous acid market is transitioning from traditional to high-tech applications, indicating an industry in the growth phase. The market is expanding as companies like WIAB WATER INNOVATION AB and Guangzhou Taidaoan Medical Technology Co., Ltd. explore innovative uses. Technological maturity varies, with established players like Industrie De Nora SpA and SANYO Electric Co., Ltd. driving advancements. Research institutions such as Zhejiang Sci-Tech University and Hunan University of Science & Technology contribute to the field's development. The involvement of diverse companies, from specialized firms like Aquaox, Inc. to conglomerates like BASF Corp., suggests a competitive landscape with significant growth potential and ongoing technological evolution.

WIAB WATER INNOVATION AB

Technical Solution: WIAB WATER INNOVATION AB has developed an innovative electrolysis-based system for on-site production of hypochlorous acid (HOCl). Their technology utilizes a patented membrane cell design that allows for the efficient generation of HOCl with precise control over concentration and pH. The system employs advanced electrodes and a specialized electrolyte solution to optimize the production process. WIAB's approach enables the creation of stable HOCl solutions with extended shelf life, addressing one of the key challenges in HOCl applications[1]. The company has also integrated IoT capabilities for remote monitoring and control of HOCl production units, enhancing operational efficiency and quality control[2].

Strengths: On-site production reduces transportation costs and environmental impact. IoT integration allows for precise control and monitoring. Weaknesses: May require initial investment in equipment and training for end-users.

FUJIFILM Corp.

Technical Solution: FUJIFILM Corp. has applied its expertise in materials science and nanotechnology to develop innovative HOCl-based solutions. The company has created a proprietary HOCl formulation that exhibits enhanced stability and efficacy, particularly for medical and healthcare applications. FUJIFILM's technology incorporates advanced nanoparticle carriers that protect HOCl molecules and enable targeted delivery to specific surfaces or pathogens[9]. This approach has resulted in HOCl products with prolonged antimicrobial activity and improved performance in challenging environments. The company has also developed novel spray and misting systems for HOCl application, utilizing their expertise in fine particle technology to achieve optimal coverage and penetration[10]. FUJIFILM's research extends to exploring the potential of HOCl in advanced wound care, leveraging their imaging technologies to study the interactions between HOCl and biological tissues at the molecular level.

Strengths: Advanced materials science and nanotechnology expertise. Specialized HOCl formulations for medical applications. Weaknesses: May face regulatory challenges in introducing new HOCl-based medical products to the market.

Core HOCL Innovations

Mixing device

PatentWO2013121295A2

Innovation

- A mixing device that produces fluidic vortices within a chamber with strategically placed apertures to stabilize hypochlorous acid by controlling proton concentration and pH through the use of buffering agents like acetic acid, allowing for its production and storage for extended periods without the need for onsite generation.

Semi-fluidic composition for lubricating, moisture retaining, disinfecting, sterilizing and method using the same

PatentInactiveEP2937101A1

Innovation

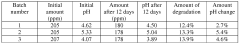

- A semi-fluid composition combining hypochlorous acid with a thickening agent, emollient, and water-binding agent to create a stable, slow-release hydrogel or viscous substance that adheres well to surfaces and provides extended-spectrum disinfection and sterilization, while also lubricating and retaining moisture, using ingredients like agar powder, glyceryl caprylate, and glycerin.

Regulatory Framework

The regulatory framework surrounding hypochlorous acid (HOCl) is complex and multifaceted, reflecting its diverse applications across various industries. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl as a pesticide and disinfectant. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), HOCl-based products must be registered with the EPA before they can be sold or distributed. This process involves rigorous testing to ensure safety and efficacy.

The Food and Drug Administration (FDA) also has oversight of HOCl, particularly in food-related applications and medical devices. For food contact surfaces, HOCl is generally recognized as safe (GRAS) when used according to good manufacturing practices. In medical applications, HOCl-based products may be regulated as medical devices, requiring premarket approval or clearance depending on their intended use and risk classification.

Internationally, regulatory approaches to HOCl vary. The European Union, through the European Chemicals Agency (ECHA), regulates HOCl under the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. This framework requires manufacturers and importers to register substances and provide safety data. Additionally, the Biocidal Products Regulation (BPR) governs the use of HOCl in disinfectants and other biocidal applications within the EU.

As HOCl transitions into high-tech applications, new regulatory challenges emerge. In the field of advanced materials and nanotechnology, regulatory bodies are still developing frameworks to address potential risks. The EPA's Toxic Substances Control Act (TSCA) may come into play for novel HOCl-based materials, requiring manufacturers to submit premanufacture notices for new chemical substances.

Occupational safety regulations also apply to the production and use of HOCl. In the United States, the Occupational Safety and Health Administration (OSHA) sets exposure limits and safety standards for workers handling HOCl and related compounds. Similar agencies in other countries, such as the Health and Safety Executive (HSE) in the UK, provide guidelines for safe handling and use in industrial settings.

As the applications of HOCl expand into emerging fields like 3D printing, smart materials, and biomedical engineering, regulatory bodies are likely to adapt existing frameworks or develop new ones to address specific concerns. This evolving regulatory landscape presents both challenges and opportunities for innovators and manufacturers working with HOCl, necessitating ongoing engagement with regulatory agencies and proactive compliance strategies.

The Food and Drug Administration (FDA) also has oversight of HOCl, particularly in food-related applications and medical devices. For food contact surfaces, HOCl is generally recognized as safe (GRAS) when used according to good manufacturing practices. In medical applications, HOCl-based products may be regulated as medical devices, requiring premarket approval or clearance depending on their intended use and risk classification.

Internationally, regulatory approaches to HOCl vary. The European Union, through the European Chemicals Agency (ECHA), regulates HOCl under the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. This framework requires manufacturers and importers to register substances and provide safety data. Additionally, the Biocidal Products Regulation (BPR) governs the use of HOCl in disinfectants and other biocidal applications within the EU.

As HOCl transitions into high-tech applications, new regulatory challenges emerge. In the field of advanced materials and nanotechnology, regulatory bodies are still developing frameworks to address potential risks. The EPA's Toxic Substances Control Act (TSCA) may come into play for novel HOCl-based materials, requiring manufacturers to submit premanufacture notices for new chemical substances.

Occupational safety regulations also apply to the production and use of HOCl. In the United States, the Occupational Safety and Health Administration (OSHA) sets exposure limits and safety standards for workers handling HOCl and related compounds. Similar agencies in other countries, such as the Health and Safety Executive (HSE) in the UK, provide guidelines for safe handling and use in industrial settings.

As the applications of HOCl expand into emerging fields like 3D printing, smart materials, and biomedical engineering, regulatory bodies are likely to adapt existing frameworks or develop new ones to address specific concerns. This evolving regulatory landscape presents both challenges and opportunities for innovators and manufacturers working with HOCl, necessitating ongoing engagement with regulatory agencies and proactive compliance strategies.

Environmental Impact

The environmental impact of hypochlorous acid (HOCl) is a critical consideration as its applications expand from traditional to high-tech sectors. HOCl is generally regarded as an environmentally friendly alternative to many conventional disinfectants and sanitizers due to its natural occurrence and rapid breakdown into harmless components.

In aqueous environments, HOCl quickly decomposes into water, oxygen, and sodium chloride, leaving no harmful residues. This characteristic makes it particularly attractive for water treatment applications, where it can effectively disinfect without introducing persistent chemicals into ecosystems. The use of HOCl in water treatment systems has shown promising results in reducing the environmental footprint compared to traditional chlorine-based methods.

The production of HOCl through electrolysis of salt water is an energy-efficient process that minimizes the need for transportation and storage of hazardous chemicals. This on-site generation capability further reduces the carbon footprint associated with its use. Additionally, the low concentration required for effective disinfection means less chemical input overall, contributing to a reduced environmental impact.

In agricultural applications, HOCl has demonstrated potential in replacing more harmful pesticides and fungicides. Its use in crop protection and post-harvest treatment can lead to decreased chemical runoff into soil and water systems, supporting more sustainable farming practices. The biodegradability of HOCl ensures that it does not accumulate in the environment or enter the food chain, unlike some persistent organic pollutants used in agriculture.

The transition to HOCl in industrial cleaning and sanitation processes also offers environmental benefits. Its non-toxic nature reduces the risk of chemical spills and associated environmental damage. Furthermore, the elimination of harsh chemicals in cleaning protocols can improve air quality in indoor environments, benefiting both human health and the surrounding ecosystem.

However, it is important to note that while HOCl itself has a favorable environmental profile, the broader environmental impact of its production and application must be considered. The energy consumption and potential emissions associated with large-scale electrolysis systems, as well as the sourcing of raw materials, should be evaluated in a comprehensive life cycle assessment.

As HOCl technology advances, ongoing research is focused on optimizing production methods to further reduce energy consumption and enhance its environmental benefits. The development of more efficient electrolysis systems and the integration of renewable energy sources in HOCl production are key areas of investigation that promise to further improve its environmental credentials.

In aqueous environments, HOCl quickly decomposes into water, oxygen, and sodium chloride, leaving no harmful residues. This characteristic makes it particularly attractive for water treatment applications, where it can effectively disinfect without introducing persistent chemicals into ecosystems. The use of HOCl in water treatment systems has shown promising results in reducing the environmental footprint compared to traditional chlorine-based methods.

The production of HOCl through electrolysis of salt water is an energy-efficient process that minimizes the need for transportation and storage of hazardous chemicals. This on-site generation capability further reduces the carbon footprint associated with its use. Additionally, the low concentration required for effective disinfection means less chemical input overall, contributing to a reduced environmental impact.

In agricultural applications, HOCl has demonstrated potential in replacing more harmful pesticides and fungicides. Its use in crop protection and post-harvest treatment can lead to decreased chemical runoff into soil and water systems, supporting more sustainable farming practices. The biodegradability of HOCl ensures that it does not accumulate in the environment or enter the food chain, unlike some persistent organic pollutants used in agriculture.

The transition to HOCl in industrial cleaning and sanitation processes also offers environmental benefits. Its non-toxic nature reduces the risk of chemical spills and associated environmental damage. Furthermore, the elimination of harsh chemicals in cleaning protocols can improve air quality in indoor environments, benefiting both human health and the surrounding ecosystem.

However, it is important to note that while HOCl itself has a favorable environmental profile, the broader environmental impact of its production and application must be considered. The energy consumption and potential emissions associated with large-scale electrolysis systems, as well as the sourcing of raw materials, should be evaluated in a comprehensive life cycle assessment.

As HOCl technology advances, ongoing research is focused on optimizing production methods to further reduce energy consumption and enhance its environmental benefits. The development of more efficient electrolysis systems and the integration of renewable energy sources in HOCl production are key areas of investigation that promise to further improve its environmental credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!