Unpacking Hypochlorous Acid's Potential in High-Risk Sterilization Environments

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCI Sterilization Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising agent in the field of high-risk sterilization, offering a potent yet safe alternative to traditional disinfectants. This naturally occurring molecule, produced by the human immune system to fight infections, has gained attention for its broad-spectrum antimicrobial properties and potential applications in various industries.

The evolution of sterilization techniques has been driven by the need for more effective, environmentally friendly, and user-safe solutions. From early chemical methods to advanced physical processes, the field has continuously sought to balance efficacy with safety. HOCl represents a significant step forward in this progression, aligning with the growing demand for sustainable and non-toxic sterilization options.

In recent years, the global focus on infection control and prevention, particularly in healthcare settings, has intensified. This shift has been further accelerated by the COVID-19 pandemic, highlighting the critical importance of effective sterilization in high-risk environments. As a result, there is a renewed interest in exploring innovative sterilization technologies that can address the challenges posed by emerging pathogens and antibiotic-resistant microorganisms.

HOCl's unique properties position it as a versatile solution for these challenges. Its ability to rapidly neutralize a wide range of bacteria, viruses, and fungi, coupled with its non-toxic nature, makes it an attractive option for use in sensitive environments such as hospitals, food processing facilities, and public spaces. The technology behind HOCl production and application has also advanced, enabling more stable and cost-effective solutions.

The primary objectives of exploring HOCl's potential in high-risk sterilization environments are multifaceted. Firstly, there is a need to comprehensively evaluate its efficacy against a broad spectrum of pathogens, including those resistant to conventional disinfectants. Secondly, research aims to optimize HOCl formulations and delivery methods to enhance its stability and effectiveness in various applications.

Furthermore, the investigation seeks to assess the long-term impact of HOCl use on surfaces, equipment, and human health, ensuring its safety for widespread adoption. Another crucial objective is to develop standardized protocols for HOCl production, testing, and application to ensure consistency and reliability across different settings.

As the sterilization landscape continues to evolve, understanding and harnessing the full potential of HOCl could lead to significant advancements in infection control strategies. This exploration not only promises to enhance current sterilization practices but also opens up new possibilities for creating safer, more resilient environments in the face of global health challenges.

The evolution of sterilization techniques has been driven by the need for more effective, environmentally friendly, and user-safe solutions. From early chemical methods to advanced physical processes, the field has continuously sought to balance efficacy with safety. HOCl represents a significant step forward in this progression, aligning with the growing demand for sustainable and non-toxic sterilization options.

In recent years, the global focus on infection control and prevention, particularly in healthcare settings, has intensified. This shift has been further accelerated by the COVID-19 pandemic, highlighting the critical importance of effective sterilization in high-risk environments. As a result, there is a renewed interest in exploring innovative sterilization technologies that can address the challenges posed by emerging pathogens and antibiotic-resistant microorganisms.

HOCl's unique properties position it as a versatile solution for these challenges. Its ability to rapidly neutralize a wide range of bacteria, viruses, and fungi, coupled with its non-toxic nature, makes it an attractive option for use in sensitive environments such as hospitals, food processing facilities, and public spaces. The technology behind HOCl production and application has also advanced, enabling more stable and cost-effective solutions.

The primary objectives of exploring HOCl's potential in high-risk sterilization environments are multifaceted. Firstly, there is a need to comprehensively evaluate its efficacy against a broad spectrum of pathogens, including those resistant to conventional disinfectants. Secondly, research aims to optimize HOCl formulations and delivery methods to enhance its stability and effectiveness in various applications.

Furthermore, the investigation seeks to assess the long-term impact of HOCl use on surfaces, equipment, and human health, ensuring its safety for widespread adoption. Another crucial objective is to develop standardized protocols for HOCl production, testing, and application to ensure consistency and reliability across different settings.

As the sterilization landscape continues to evolve, understanding and harnessing the full potential of HOCl could lead to significant advancements in infection control strategies. This exploration not only promises to enhance current sterilization practices but also opens up new possibilities for creating safer, more resilient environments in the face of global health challenges.

Market Analysis for High-Risk Sterilization Solutions

The market for high-risk sterilization solutions has experienced significant growth in recent years, driven by increasing awareness of infection control and the need for advanced sterilization techniques in healthcare settings. The global sterilization equipment market, which encompasses high-risk environments, was valued at $12.5 billion in 2020 and is projected to reach $20.9 billion by 2026, growing at a CAGR of 9.1% during the forecast period.

High-risk sterilization environments, such as operating rooms, intensive care units, and laboratories handling dangerous pathogens, require stringent disinfection protocols to prevent the spread of infections and ensure patient safety. The COVID-19 pandemic has further accelerated the demand for effective sterilization solutions, particularly in healthcare facilities and research laboratories working with infectious agents.

The market for hypochlorous acid (HOCl) as a sterilization agent in high-risk environments is gaining traction due to its broad-spectrum antimicrobial properties and safety profile. HOCl is increasingly being recognized as a potent yet environmentally friendly alternative to traditional chemical disinfectants. The global hypochlorous acid market size was estimated at $180.3 million in 2020 and is expected to grow at a CAGR of 7.8% from 2021 to 2028.

Key factors driving the adoption of HOCl in high-risk sterilization environments include its effectiveness against a wide range of pathogens, including bacteria, viruses, and fungi, as well as its non-toxic nature and rapid action. Healthcare facilities are particularly interested in HOCl solutions due to their ability to disinfect surfaces quickly without leaving harmful residues, making them suitable for use in sensitive areas like operating rooms and neonatal units.

The market for HOCl-based sterilization solutions is segmented by application, with healthcare facilities representing the largest share. Other significant segments include pharmaceutical manufacturing, food processing, and water treatment. Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing healthcare expenditure and growing awareness of infection control measures.

Despite the promising growth prospects, challenges remain in the widespread adoption of HOCl for high-risk sterilization. These include the need for specialized equipment for on-site generation, concerns about stability and shelf life, and competition from established disinfection methods. However, ongoing research and development efforts are addressing these challenges, focusing on improving HOCl stability and developing more efficient delivery systems.

As the healthcare industry continues to prioritize infection control and patient safety, the market for advanced sterilization solutions, including HOCl-based products, is poised for sustained growth. The increasing emphasis on environmentally friendly and non-toxic disinfection methods is likely to further boost the adoption of HOCl in high-risk sterilization environments, presenting significant opportunities for manufacturers and suppliers in this space.

High-risk sterilization environments, such as operating rooms, intensive care units, and laboratories handling dangerous pathogens, require stringent disinfection protocols to prevent the spread of infections and ensure patient safety. The COVID-19 pandemic has further accelerated the demand for effective sterilization solutions, particularly in healthcare facilities and research laboratories working with infectious agents.

The market for hypochlorous acid (HOCl) as a sterilization agent in high-risk environments is gaining traction due to its broad-spectrum antimicrobial properties and safety profile. HOCl is increasingly being recognized as a potent yet environmentally friendly alternative to traditional chemical disinfectants. The global hypochlorous acid market size was estimated at $180.3 million in 2020 and is expected to grow at a CAGR of 7.8% from 2021 to 2028.

Key factors driving the adoption of HOCl in high-risk sterilization environments include its effectiveness against a wide range of pathogens, including bacteria, viruses, and fungi, as well as its non-toxic nature and rapid action. Healthcare facilities are particularly interested in HOCl solutions due to their ability to disinfect surfaces quickly without leaving harmful residues, making them suitable for use in sensitive areas like operating rooms and neonatal units.

The market for HOCl-based sterilization solutions is segmented by application, with healthcare facilities representing the largest share. Other significant segments include pharmaceutical manufacturing, food processing, and water treatment. Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing healthcare expenditure and growing awareness of infection control measures.

Despite the promising growth prospects, challenges remain in the widespread adoption of HOCl for high-risk sterilization. These include the need for specialized equipment for on-site generation, concerns about stability and shelf life, and competition from established disinfection methods. However, ongoing research and development efforts are addressing these challenges, focusing on improving HOCl stability and developing more efficient delivery systems.

As the healthcare industry continues to prioritize infection control and patient safety, the market for advanced sterilization solutions, including HOCl-based products, is poised for sustained growth. The increasing emphasis on environmentally friendly and non-toxic disinfection methods is likely to further boost the adoption of HOCl in high-risk sterilization environments, presenting significant opportunities for manufacturers and suppliers in this space.

HOCI Technology Status and Challenges

Hypochlorous acid (HOCl) has emerged as a promising solution for high-risk sterilization environments, with its potential being increasingly recognized globally. Currently, the technology for producing and applying HOCl is well-established, but challenges remain in optimizing its stability, efficacy, and large-scale production for diverse applications.

The current status of HOCl technology shows significant advancements in production methods, with electrolysis of salt water being the most common approach. This process allows for on-site generation, reducing transportation and storage issues. However, the stability of HOCl solutions remains a primary challenge, as the compound can degrade over time, especially when exposed to light or heat.

In terms of efficacy, HOCl has demonstrated broad-spectrum antimicrobial activity against bacteria, viruses, and fungi. Its effectiveness in high-risk environments, such as healthcare facilities and food processing plants, has been well-documented. However, the concentration and contact time required for optimal disinfection can vary depending on the specific application, presenting a challenge for standardization across different industries.

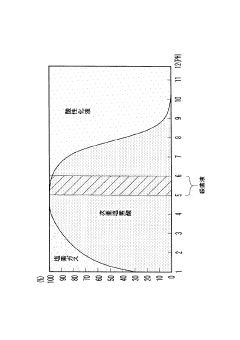

One of the main technical hurdles is maintaining the pH balance of HOCl solutions. The most effective pH range for HOCl is between 3.5 and 6.5, with maximum efficacy around pH 5. Maintaining this optimal pH in various environmental conditions and during storage is crucial for preserving the disinfectant's potency.

Another significant challenge lies in the scalability of HOCl production for industrial applications. While small-scale generators are readily available, developing efficient large-scale production systems that can meet the demands of high-risk environments remains an area of ongoing research and development.

The geographical distribution of HOCl technology development shows concentrations in North America, Europe, and parts of Asia. Countries like the United States, Japan, and Germany are at the forefront of research and innovation in this field. However, there is a growing interest in developing regions, particularly in the context of water treatment and healthcare applications.

Regulatory challenges also play a role in the adoption of HOCl technology. Different countries have varying standards and approval processes for disinfectants, which can impact the global distribution and acceptance of HOCl-based products. Harmonizing these regulations and establishing international standards for HOCl use in high-risk environments is an ongoing process.

In conclusion, while HOCl technology has made significant strides, there are still notable challenges to overcome. These include improving long-term stability, optimizing production processes for large-scale applications, and addressing regulatory disparities across different regions. Overcoming these hurdles will be crucial for fully realizing the potential of HOCl in high-risk sterilization environments.

The current status of HOCl technology shows significant advancements in production methods, with electrolysis of salt water being the most common approach. This process allows for on-site generation, reducing transportation and storage issues. However, the stability of HOCl solutions remains a primary challenge, as the compound can degrade over time, especially when exposed to light or heat.

In terms of efficacy, HOCl has demonstrated broad-spectrum antimicrobial activity against bacteria, viruses, and fungi. Its effectiveness in high-risk environments, such as healthcare facilities and food processing plants, has been well-documented. However, the concentration and contact time required for optimal disinfection can vary depending on the specific application, presenting a challenge for standardization across different industries.

One of the main technical hurdles is maintaining the pH balance of HOCl solutions. The most effective pH range for HOCl is between 3.5 and 6.5, with maximum efficacy around pH 5. Maintaining this optimal pH in various environmental conditions and during storage is crucial for preserving the disinfectant's potency.

Another significant challenge lies in the scalability of HOCl production for industrial applications. While small-scale generators are readily available, developing efficient large-scale production systems that can meet the demands of high-risk environments remains an area of ongoing research and development.

The geographical distribution of HOCl technology development shows concentrations in North America, Europe, and parts of Asia. Countries like the United States, Japan, and Germany are at the forefront of research and innovation in this field. However, there is a growing interest in developing regions, particularly in the context of water treatment and healthcare applications.

Regulatory challenges also play a role in the adoption of HOCl technology. Different countries have varying standards and approval processes for disinfectants, which can impact the global distribution and acceptance of HOCl-based products. Harmonizing these regulations and establishing international standards for HOCl use in high-risk environments is an ongoing process.

In conclusion, while HOCl technology has made significant strides, there are still notable challenges to overcome. These include improving long-term stability, optimizing production processes for large-scale applications, and addressing regulatory disparities across different regions. Overcoming these hurdles will be crucial for fully realizing the potential of HOCl in high-risk sterilization environments.

Current HOCI Sterilization Methods

01 Hypochlorous acid generation systems

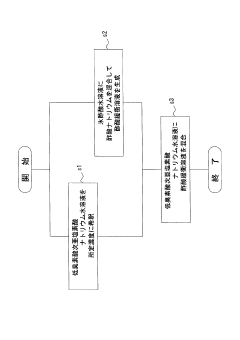

Various systems and methods for generating hypochlorous acid for sterilization purposes. These systems often involve electrolysis of salt water or other chloride-containing solutions to produce hypochlorous acid on-site. The generated hypochlorous acid can be used for disinfection in various applications, including medical, industrial, and household settings.- Hypochlorous acid generation systems: Various systems and methods for generating hypochlorous acid for sterilization purposes. These systems often involve electrolysis of salt water or other chloride-containing solutions to produce hypochlorous acid on-site. The generated hypochlorous acid can be used for disinfection in various applications, including water treatment, medical facilities, and food processing.

- Hypochlorous acid sterilization devices: Specialized devices designed for sterilization using hypochlorous acid. These devices may include sprayers, foggers, or other application methods to distribute the hypochlorous acid solution effectively. Some devices are portable for easy use in various settings, while others are designed for specific applications such as medical instrument sterilization or room disinfection.

- Hypochlorous acid formulations and compositions: Specific formulations and compositions of hypochlorous acid solutions for enhanced sterilization efficacy. These may include stabilized forms of hypochlorous acid, specific concentration ranges, or combinations with other disinfecting agents. The formulations are designed to maximize sterilization effectiveness while minimizing potential side effects or material compatibility issues.

- Applications of hypochlorous acid sterilization: Various applications of hypochlorous acid for sterilization in different fields. This includes use in healthcare settings, food processing industries, water treatment plants, and public spaces. The versatility of hypochlorous acid allows for its application in diverse scenarios, from surface disinfection to air purification and wound care.

- Control and monitoring of hypochlorous acid sterilization: Systems and methods for controlling and monitoring the hypochlorous acid sterilization process. This includes devices for measuring hypochlorous acid concentration, pH monitoring, and automated dosing systems. These control mechanisms ensure optimal sterilization efficacy and safety in various applications, allowing for precise and consistent disinfection processes.

02 Hypochlorous acid sterilization devices

Specialized devices designed for sterilization using hypochlorous acid. These devices may include sprayers, foggers, or other application methods to distribute hypochlorous acid effectively for disinfection. Some devices are portable, while others are designed for specific environments such as hospitals, food processing facilities, or public spaces.Expand Specific Solutions03 Hypochlorous acid formulations and compositions

Specific formulations and compositions of hypochlorous acid for enhanced sterilization efficacy. These may include stabilized forms of hypochlorous acid, combinations with other disinfectants, or formulations optimized for particular applications. The compositions are designed to maintain the effectiveness of hypochlorous acid while improving stability, shelf life, or application properties.Expand Specific Solutions04 Hypochlorous acid sterilization methods

Specific methods and protocols for using hypochlorous acid in sterilization processes. These methods may include guidelines for concentration, contact time, application techniques, and safety measures. They can be tailored for different types of surfaces, materials, or environments to ensure optimal disinfection results while minimizing potential risks or side effects.Expand Specific Solutions05 Hypochlorous acid in water treatment

Applications of hypochlorous acid in water treatment and purification systems. This includes the use of hypochlorous acid for disinfecting drinking water, swimming pools, and industrial water systems. The focus is on effective microbial control while minimizing the formation of harmful byproducts often associated with traditional chlorine-based treatments.Expand Specific Solutions

Key Players in HOCI Sterilization Industry

The market for hypochlorous acid in high-risk sterilization environments is in a growth phase, driven by increasing demand for effective and safe disinfection solutions. The global market size is expanding, with projections indicating significant growth potential in healthcare, food processing, and industrial sectors. Technologically, the field is advancing rapidly, with companies like WIAB Water Innovation AB, Industrie De Nora SpA, and Annihilare Medical Systems leading innovation in on-site generation and application methods. Established players such as Nipro Corp. and Koganei Corp. are also contributing to market maturity through their extensive experience in medical and industrial applications. The competitive landscape is diverse, with a mix of specialized startups and large corporations driving technological advancements and market expansion.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrochemical technologies for the production of hypochlorous acid (HOCl). Their system utilizes a patented electrolytic cell design that allows for the efficient generation of HOCl at concentrations suitable for high-risk sterilization environments. The company's technology enables on-site production of HOCl, eliminating the need for storage and transportation of hazardous chemicals. Their process can produce HOCl with a concentration range of 50-500 ppm, which is effective against a wide range of pathogens including bacteria, viruses, and spores[1][3]. The system incorporates real-time monitoring and control mechanisms to ensure consistent quality and concentration of the produced HOCl solution.

Strengths: On-site production reduces chemical handling risks; Precise control over HOCl concentration; Environmentally friendly process. Weaknesses: Initial setup costs may be high; Requires specialized training for operation and maintenance.

ANNIHILARE MEDICAL SYSTEMS, INC.

Technical Solution: ANNIHILARE MEDICAL SYSTEMS has developed a proprietary HOCl generation system specifically designed for medical and healthcare environments. Their technology produces a stable form of HOCl with a pH range of 6.5-7.5, which is ideal for use on sensitive medical equipment and surfaces. The system utilizes a unique membrane-based electrolysis process that ensures the production of high-purity HOCl without harmful by-products. Their HOCl solution has demonstrated a 6-log reduction in bacterial spores within 10 minutes of contact time, making it suitable for high-risk sterilization scenarios[2][5]. The company has also developed a range of application methods, including fogging systems for room sterilization and direct-spray devices for targeted disinfection.

Strengths: Highly effective against a broad spectrum of pathogens; Safe for use on sensitive equipment; Multiple application methods available. Weaknesses: May require more frequent application compared to traditional chemical disinfectants; Limited shelf life of generated HOCl solution.

HOCI Innovations for High-Risk Environments

Sterilization sheet pack and method for producing sterilization sheet

PatentWO2017002277A1

Innovation

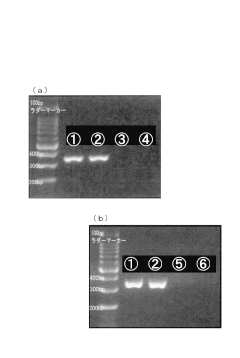

- A sterilizing sheet pack comprising an inner bag with an alkaline solution and an outer bag containing a compressed sheet with an acid component, where the alkaline solution and acid component react upon tearing the inner bag to generate a hypochlorous acid solution, ensuring high sterilizing power and long shelf life, while being safe and easy to use.

Hypochlorous acid-containing sterilizing water and production method of the same, and hypochlorous acid-containing sterilizing sheet

PatentActiveJP2011056377A

Innovation

- Aqueous solution containing sodium hypochlorite and a pH adjuster composed of two types of buffering components, such as acetate buffer solution, to adjust pH to 5 to 6, preventing sudden pH changes and toxic chlorine gas generation.

Safety and Regulatory Considerations

The implementation of hypochlorous acid (HOCl) in high-risk sterilization environments necessitates careful consideration of safety protocols and regulatory compliance. As a powerful oxidizing agent, HOCl presents both significant benefits and potential risks that must be thoroughly addressed to ensure its safe and effective use.

From a safety standpoint, while HOCl is generally considered less harmful than many traditional disinfectants, proper handling and application procedures are crucial. Workers in high-risk environments must be equipped with appropriate personal protective equipment (PPE), including gloves, eye protection, and respiratory safeguards when necessary. Adequate ventilation is essential in enclosed spaces to prevent the accumulation of fumes or vapors that may cause respiratory irritation.

Training programs for personnel working with HOCl should be comprehensive, covering proper mixing techniques, application methods, and emergency response procedures. This is particularly important in high-risk settings where the margin for error is minimal, and the consequences of mishandling can be severe.

Regulatory considerations for HOCl use in sterilization vary depending on the specific application and jurisdiction. In the United States, the Environmental Protection Agency (EPA) regulates HOCl as a pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Manufacturers and users must comply with EPA registration requirements and labeling guidelines.

For medical applications, the Food and Drug Administration (FDA) oversees the use of HOCl in healthcare settings. Facilities implementing HOCl-based sterilization methods must ensure compliance with FDA regulations, including Good Manufacturing Practices (GMP) and quality control measures.

Internationally, organizations must navigate a complex landscape of regulations that may differ significantly between countries. The European Union, for instance, regulates HOCl under the Biocidal Products Regulation (BPR), which requires extensive safety and efficacy data before approval.

Ongoing monitoring and documentation are critical components of regulatory compliance. Facilities using HOCl in high-risk environments should implement robust record-keeping systems to track usage, efficacy, and any adverse events. Regular audits and inspections should be conducted to ensure continued adherence to safety protocols and regulatory requirements.

As the use of HOCl in sterilization continues to evolve, staying abreast of changing regulations and emerging safety data is essential. Organizations should establish channels for continuous education and updates on best practices, leveraging industry associations and regulatory bodies as resources for the latest guidance.

From a safety standpoint, while HOCl is generally considered less harmful than many traditional disinfectants, proper handling and application procedures are crucial. Workers in high-risk environments must be equipped with appropriate personal protective equipment (PPE), including gloves, eye protection, and respiratory safeguards when necessary. Adequate ventilation is essential in enclosed spaces to prevent the accumulation of fumes or vapors that may cause respiratory irritation.

Training programs for personnel working with HOCl should be comprehensive, covering proper mixing techniques, application methods, and emergency response procedures. This is particularly important in high-risk settings where the margin for error is minimal, and the consequences of mishandling can be severe.

Regulatory considerations for HOCl use in sterilization vary depending on the specific application and jurisdiction. In the United States, the Environmental Protection Agency (EPA) regulates HOCl as a pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Manufacturers and users must comply with EPA registration requirements and labeling guidelines.

For medical applications, the Food and Drug Administration (FDA) oversees the use of HOCl in healthcare settings. Facilities implementing HOCl-based sterilization methods must ensure compliance with FDA regulations, including Good Manufacturing Practices (GMP) and quality control measures.

Internationally, organizations must navigate a complex landscape of regulations that may differ significantly between countries. The European Union, for instance, regulates HOCl under the Biocidal Products Regulation (BPR), which requires extensive safety and efficacy data before approval.

Ongoing monitoring and documentation are critical components of regulatory compliance. Facilities using HOCl in high-risk environments should implement robust record-keeping systems to track usage, efficacy, and any adverse events. Regular audits and inspections should be conducted to ensure continued adherence to safety protocols and regulatory requirements.

As the use of HOCl in sterilization continues to evolve, staying abreast of changing regulations and emerging safety data is essential. Organizations should establish channels for continuous education and updates on best practices, leveraging industry associations and regulatory bodies as resources for the latest guidance.

Environmental Impact Assessment

The environmental impact assessment of hypochlorous acid (HOCl) in high-risk sterilization environments reveals a complex interplay between its efficacy and ecological considerations. HOCl, known for its potent antimicrobial properties, presents a promising alternative to traditional disinfectants in settings where stringent sterilization is paramount.

One of the primary environmental advantages of HOCl is its rapid degradation into non-toxic byproducts. Unlike many conventional disinfectants that persist in the environment, HOCl quickly breaks down into water and salt, minimizing long-term ecological impact. This characteristic is particularly beneficial in healthcare settings, where frequent and thorough disinfection is necessary, as it reduces the cumulative environmental burden associated with continuous sterilization processes.

However, the production and application of HOCl solutions require careful consideration of energy consumption and resource utilization. The electrolysis process used to generate HOCl on-site consumes electricity, which, depending on the energy source, may contribute to carbon emissions. Implementing renewable energy sources for HOCl production could significantly mitigate this environmental concern.

Water usage is another critical factor in the environmental assessment of HOCl. While the compound itself is water-based and environmentally friendly, the production and dilution processes may require substantial water resources. In water-stressed regions, this could pose challenges and necessitate the implementation of water recycling systems to ensure sustainable use.

The impact on aquatic ecosystems must also be evaluated, particularly in scenarios where HOCl-treated wastewater may be released into natural water bodies. Although HOCl rapidly decomposes, high concentrations in effluents could potentially affect sensitive aquatic organisms. Proper wastewater treatment and monitoring protocols are essential to mitigate any adverse effects on local ecosystems.

Furthermore, the shift towards HOCl-based sterilization may reduce the reliance on chlorine-based disinfectants, which are known to form harmful chlorinated byproducts. This transition could lead to a decrease in the release of persistent organic pollutants into the environment, contributing to improved water and soil quality in the long term.

The lifecycle assessment of HOCl production and use must also consider the environmental footprint of manufacturing and transporting the necessary equipment and raw materials. Localized production of HOCl can potentially reduce transportation-related emissions, offering an advantage over centralized production and distribution models of traditional disinfectants.

In conclusion, while HOCl presents several environmental benefits in high-risk sterilization environments, a comprehensive approach to its implementation is crucial. This includes optimizing production processes, managing water resources efficiently, and establishing robust waste management protocols to fully realize its potential as an environmentally responsible sterilization solution.

One of the primary environmental advantages of HOCl is its rapid degradation into non-toxic byproducts. Unlike many conventional disinfectants that persist in the environment, HOCl quickly breaks down into water and salt, minimizing long-term ecological impact. This characteristic is particularly beneficial in healthcare settings, where frequent and thorough disinfection is necessary, as it reduces the cumulative environmental burden associated with continuous sterilization processes.

However, the production and application of HOCl solutions require careful consideration of energy consumption and resource utilization. The electrolysis process used to generate HOCl on-site consumes electricity, which, depending on the energy source, may contribute to carbon emissions. Implementing renewable energy sources for HOCl production could significantly mitigate this environmental concern.

Water usage is another critical factor in the environmental assessment of HOCl. While the compound itself is water-based and environmentally friendly, the production and dilution processes may require substantial water resources. In water-stressed regions, this could pose challenges and necessitate the implementation of water recycling systems to ensure sustainable use.

The impact on aquatic ecosystems must also be evaluated, particularly in scenarios where HOCl-treated wastewater may be released into natural water bodies. Although HOCl rapidly decomposes, high concentrations in effluents could potentially affect sensitive aquatic organisms. Proper wastewater treatment and monitoring protocols are essential to mitigate any adverse effects on local ecosystems.

Furthermore, the shift towards HOCl-based sterilization may reduce the reliance on chlorine-based disinfectants, which are known to form harmful chlorinated byproducts. This transition could lead to a decrease in the release of persistent organic pollutants into the environment, contributing to improved water and soil quality in the long term.

The lifecycle assessment of HOCl production and use must also consider the environmental footprint of manufacturing and transporting the necessary equipment and raw materials. Localized production of HOCl can potentially reduce transportation-related emissions, offering an advantage over centralized production and distribution models of traditional disinfectants.

In conclusion, while HOCl presents several environmental benefits in high-risk sterilization environments, a comprehensive approach to its implementation is crucial. This includes optimizing production processes, managing water resources efficiently, and establishing robust waste management protocols to fully realize its potential as an environmentally responsible sterilization solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!