How to Drive Precision with Hypochlorous Acid Microdispersing Systems?

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Microdispersing Background and Objectives

Hypochlorous acid (HOCl) microdispersing systems have emerged as a promising technology in various industries, particularly in disinfection and sanitization applications. The development of these systems can be traced back to the early 2000s when researchers began exploring more efficient ways to harness the antimicrobial properties of HOCl. This technology has since evolved, driven by the growing demand for effective, safe, and environmentally friendly disinfection solutions.

The primary objective of HOCl microdispersing systems is to achieve precise and uniform distribution of hypochlorous acid particles, typically in the range of 1-5 microns. This level of precision allows for optimal surface coverage and penetration, enhancing the overall efficacy of the disinfection process. By controlling factors such as particle size, concentration, and dispersion patterns, these systems aim to maximize the antimicrobial effects of HOCl while minimizing waste and potential environmental impact.

Recent advancements in HOCl microdispersing technology have been largely influenced by the global health crises and the increasing focus on hygiene in various sectors. The COVID-19 pandemic, in particular, has accelerated research and development efforts in this field, pushing for more innovative and efficient disinfection methods. As a result, the technology has seen rapid improvements in areas such as electrostatic spraying, ultrasonic nebulization, and advanced nozzle designs.

The evolution of HOCl microdispersing systems is closely tied to developments in related fields, including fluid dynamics, materials science, and electronic control systems. Researchers and engineers are continuously working to optimize the generation, storage, and delivery of HOCl solutions, addressing challenges such as stability, corrosion resistance, and precise dosage control. These efforts are crucial in expanding the application range of HOCl microdispersing systems beyond traditional disinfection scenarios.

Looking ahead, the technological goals for HOCl microdispersing systems include further miniaturization, increased energy efficiency, and enhanced automation. There is a growing interest in developing smart, IoT-enabled systems that can adapt to different environmental conditions and disinfection requirements in real-time. Additionally, researchers are exploring ways to integrate HOCl microdispersing technology with other disinfection methods, such as UV light or ozone treatment, to create more comprehensive and effective sanitization solutions.

As the technology continues to mature, there is an increasing focus on standardization and regulatory compliance. This includes developing precise measurement and control mechanisms to ensure consistent HOCl concentration and dispersion across various applications. The ultimate aim is to establish HOCl microdispersing systems as a reliable, scalable, and sustainable solution for a wide range of disinfection needs, from healthcare facilities to food processing plants and public transportation systems.

The primary objective of HOCl microdispersing systems is to achieve precise and uniform distribution of hypochlorous acid particles, typically in the range of 1-5 microns. This level of precision allows for optimal surface coverage and penetration, enhancing the overall efficacy of the disinfection process. By controlling factors such as particle size, concentration, and dispersion patterns, these systems aim to maximize the antimicrobial effects of HOCl while minimizing waste and potential environmental impact.

Recent advancements in HOCl microdispersing technology have been largely influenced by the global health crises and the increasing focus on hygiene in various sectors. The COVID-19 pandemic, in particular, has accelerated research and development efforts in this field, pushing for more innovative and efficient disinfection methods. As a result, the technology has seen rapid improvements in areas such as electrostatic spraying, ultrasonic nebulization, and advanced nozzle designs.

The evolution of HOCl microdispersing systems is closely tied to developments in related fields, including fluid dynamics, materials science, and electronic control systems. Researchers and engineers are continuously working to optimize the generation, storage, and delivery of HOCl solutions, addressing challenges such as stability, corrosion resistance, and precise dosage control. These efforts are crucial in expanding the application range of HOCl microdispersing systems beyond traditional disinfection scenarios.

Looking ahead, the technological goals for HOCl microdispersing systems include further miniaturization, increased energy efficiency, and enhanced automation. There is a growing interest in developing smart, IoT-enabled systems that can adapt to different environmental conditions and disinfection requirements in real-time. Additionally, researchers are exploring ways to integrate HOCl microdispersing technology with other disinfection methods, such as UV light or ozone treatment, to create more comprehensive and effective sanitization solutions.

As the technology continues to mature, there is an increasing focus on standardization and regulatory compliance. This includes developing precise measurement and control mechanisms to ensure consistent HOCl concentration and dispersion across various applications. The ultimate aim is to establish HOCl microdispersing systems as a reliable, scalable, and sustainable solution for a wide range of disinfection needs, from healthcare facilities to food processing plants and public transportation systems.

Market Analysis for HOCl Precision Applications

The market for hypochlorous acid (HOCl) precision applications is experiencing significant growth, driven by increasing demand across various industries. HOCl's unique properties as a powerful yet safe disinfectant have positioned it as a versatile solution for precision cleaning and sanitization needs.

In the healthcare sector, HOCl microdispersing systems are gaining traction for wound care, surgical site preparation, and medical device sterilization. The ability to precisely control HOCl concentration and dispersion allows for targeted application, reducing the risk of infection while minimizing tissue damage. This precision has led to a growing adoption in hospitals, clinics, and long-term care facilities.

The food and beverage industry represents another key market for HOCl precision applications. With stringent food safety regulations and consumer demand for clean-label products, HOCl microdispersing systems offer an effective solution for sanitizing food contact surfaces, processing equipment, and even fresh produce. The precise application ensures thorough disinfection without leaving harmful residues or affecting product taste.

In the agriculture sector, HOCl precision systems are being utilized for crop protection and hydroponic applications. The ability to deliver controlled amounts of HOCl through irrigation systems or as a foliar spray helps combat plant pathogens while minimizing chemical usage. This aligns with the growing trend towards sustainable and organic farming practices.

The water treatment industry is also adopting HOCl precision technologies for applications such as cooling towers, swimming pools, and municipal water systems. The precise control of HOCl concentration allows for effective disinfection while minimizing the formation of harmful byproducts often associated with traditional chlorine-based treatments.

Market analysis indicates that the global HOCl market is expected to grow at a compound annual growth rate (CAGR) of over 7% in the coming years. The precision application segment is anticipated to be a key driver of this growth, with increasing investments in research and development to enhance microdispersing technologies.

Geographically, North America and Europe currently lead the market for HOCl precision applications, owing to stringent regulations and high adoption rates in healthcare and food industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing awareness of HOCl benefits and rising demand for safe disinfection solutions in developing countries.

As the technology continues to evolve, new opportunities are emerging in sectors such as aerospace, electronics manufacturing, and personal care products. The development of more advanced microdispersing systems, coupled with increasing awareness of HOCl's benefits, is expected to further expand the market potential for precision applications in the coming years.

In the healthcare sector, HOCl microdispersing systems are gaining traction for wound care, surgical site preparation, and medical device sterilization. The ability to precisely control HOCl concentration and dispersion allows for targeted application, reducing the risk of infection while minimizing tissue damage. This precision has led to a growing adoption in hospitals, clinics, and long-term care facilities.

The food and beverage industry represents another key market for HOCl precision applications. With stringent food safety regulations and consumer demand for clean-label products, HOCl microdispersing systems offer an effective solution for sanitizing food contact surfaces, processing equipment, and even fresh produce. The precise application ensures thorough disinfection without leaving harmful residues or affecting product taste.

In the agriculture sector, HOCl precision systems are being utilized for crop protection and hydroponic applications. The ability to deliver controlled amounts of HOCl through irrigation systems or as a foliar spray helps combat plant pathogens while minimizing chemical usage. This aligns with the growing trend towards sustainable and organic farming practices.

The water treatment industry is also adopting HOCl precision technologies for applications such as cooling towers, swimming pools, and municipal water systems. The precise control of HOCl concentration allows for effective disinfection while minimizing the formation of harmful byproducts often associated with traditional chlorine-based treatments.

Market analysis indicates that the global HOCl market is expected to grow at a compound annual growth rate (CAGR) of over 7% in the coming years. The precision application segment is anticipated to be a key driver of this growth, with increasing investments in research and development to enhance microdispersing technologies.

Geographically, North America and Europe currently lead the market for HOCl precision applications, owing to stringent regulations and high adoption rates in healthcare and food industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing awareness of HOCl benefits and rising demand for safe disinfection solutions in developing countries.

As the technology continues to evolve, new opportunities are emerging in sectors such as aerospace, electronics manufacturing, and personal care products. The development of more advanced microdispersing systems, coupled with increasing awareness of HOCl's benefits, is expected to further expand the market potential for precision applications in the coming years.

Current Challenges in HOCl Microdispersing Systems

Despite the promising potential of Hypochlorous Acid (HOCl) microdispersing systems, several challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is maintaining the stability of HOCl solutions over extended periods. HOCl is known to degrade rapidly, especially when exposed to light, heat, or organic matter, which can significantly reduce its efficacy in various applications.

Another critical challenge lies in achieving consistent and precise microdispersion of HOCl. The size and uniformity of droplets produced by microdispersing systems greatly influence the effectiveness of HOCl in disinfection and other applications. Current systems often struggle to maintain uniform droplet size distribution, leading to variations in coverage and efficacy.

The pH control of HOCl solutions presents an additional hurdle. The antimicrobial activity of HOCl is highly dependent on pH, with optimal effectiveness typically occurring in a narrow range between pH 5 and 6.5. Maintaining this precise pH level during storage and application can be challenging, especially in diverse environmental conditions.

Scalability and cost-effectiveness of HOCl production and microdispersing systems pose significant challenges for widespread industrial adoption. Current methods of HOCl generation, such as electrolysis of salt water, can be energy-intensive and may not be easily scalable for large-scale applications.

Material compatibility is another concern in HOCl microdispersing systems. The corrosive nature of HOCl can lead to degradation of equipment components, affecting system longevity and performance. Developing materials and coatings that can withstand prolonged exposure to HOCl without compromising system integrity remains a challenge.

Regulatory hurdles and lack of standardization in HOCl production and application methods further complicate the widespread adoption of these systems. The absence of clear guidelines and quality standards can lead to inconsistencies in product efficacy and safety across different manufacturers and applications.

Lastly, there is a need for more comprehensive research on the long-term environmental impact of widespread HOCl use. While HOCl is generally considered environmentally friendly due to its rapid breakdown into harmless byproducts, the potential ecological effects of large-scale, continuous application in various settings require further investigation to ensure sustainable implementation.

Another critical challenge lies in achieving consistent and precise microdispersion of HOCl. The size and uniformity of droplets produced by microdispersing systems greatly influence the effectiveness of HOCl in disinfection and other applications. Current systems often struggle to maintain uniform droplet size distribution, leading to variations in coverage and efficacy.

The pH control of HOCl solutions presents an additional hurdle. The antimicrobial activity of HOCl is highly dependent on pH, with optimal effectiveness typically occurring in a narrow range between pH 5 and 6.5. Maintaining this precise pH level during storage and application can be challenging, especially in diverse environmental conditions.

Scalability and cost-effectiveness of HOCl production and microdispersing systems pose significant challenges for widespread industrial adoption. Current methods of HOCl generation, such as electrolysis of salt water, can be energy-intensive and may not be easily scalable for large-scale applications.

Material compatibility is another concern in HOCl microdispersing systems. The corrosive nature of HOCl can lead to degradation of equipment components, affecting system longevity and performance. Developing materials and coatings that can withstand prolonged exposure to HOCl without compromising system integrity remains a challenge.

Regulatory hurdles and lack of standardization in HOCl production and application methods further complicate the widespread adoption of these systems. The absence of clear guidelines and quality standards can lead to inconsistencies in product efficacy and safety across different manufacturers and applications.

Lastly, there is a need for more comprehensive research on the long-term environmental impact of widespread HOCl use. While HOCl is generally considered environmentally friendly due to its rapid breakdown into harmless byproducts, the potential ecological effects of large-scale, continuous application in various settings require further investigation to ensure sustainable implementation.

Existing HOCl Microdispersing Solutions

01 Microdispersion systems for hypochlorous acid

Advanced microdispersion systems are developed to enhance the stability and effectiveness of hypochlorous acid solutions. These systems utilize specialized equipment and techniques to create fine, uniform droplets of hypochlorous acid, improving its distribution and contact with target surfaces or microorganisms.- Microdispersion systems for hypochlorous acid: Advanced microdispersion systems are developed to enhance the stability and efficacy of hypochlorous acid solutions. These systems utilize specialized equipment and techniques to create fine, uniform droplets of hypochlorous acid, improving its distribution and interaction with target surfaces or microorganisms. The microdispersion process helps maintain the acid's potency and extends its shelf life.

- Precision control in hypochlorous acid generation: Methods and apparatus are developed for precise control of hypochlorous acid generation. These innovations focus on accurately regulating factors such as electrolysis parameters, reactant concentrations, and environmental conditions to produce hypochlorous acid with consistent quality and concentration. Advanced sensors and feedback systems are often incorporated to maintain precision throughout the production process.

- Stabilization techniques for hypochlorous acid solutions: Various stabilization techniques are employed to prolong the shelf life and maintain the efficacy of hypochlorous acid solutions. These may include the use of specific additives, pH adjustments, or packaging innovations that minimize degradation and preserve the acid's antimicrobial properties. The goal is to create stable formulations suitable for long-term storage and various applications.

- Application methods for precise hypochlorous acid delivery: Innovative application methods are developed to ensure precise delivery of hypochlorous acid to target areas. These may include specialized spraying systems, fogging devices, or other dispensing mechanisms designed to optimize coverage and minimize waste. The focus is on achieving uniform distribution and controlled dosage for various disinfection and treatment applications.

- Integration of hypochlorous acid systems with IoT and smart technologies: Advanced hypochlorous acid systems are being integrated with Internet of Things (IoT) and smart technologies to enhance monitoring, control, and optimization. These innovations allow for remote management, real-time data analysis, and automated adjustments to ensure consistent performance and efficiency in various applications, from water treatment to medical disinfection.

02 Precision control in hypochlorous acid generation

Innovative methods and devices are designed to achieve precise control over the generation of hypochlorous acid. This includes accurate regulation of electrolysis parameters, reactant concentrations, and environmental conditions to produce hypochlorous acid with consistent quality and desired properties.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

Various stabilization techniques are employed to extend the shelf life and maintain the efficacy of hypochlorous acid solutions. These may include the use of specific additives, pH adjustments, or packaging innovations to prevent degradation and ensure long-term stability of the microdispersed hypochlorous acid.Expand Specific Solutions04 Application-specific formulations of hypochlorous acid

Tailored formulations of hypochlorous acid are developed for specific applications, such as medical disinfection, water treatment, or agricultural use. These formulations optimize the concentration, pH, and additional components to enhance the performance of hypochlorous acid in targeted scenarios.Expand Specific Solutions05 Monitoring and quality control systems

Advanced monitoring and quality control systems are implemented to ensure the precision and consistency of hypochlorous acid microdispersing processes. These systems may incorporate real-time sensors, data analytics, and automated adjustments to maintain optimal production parameters and product quality.Expand Specific Solutions

Key Players in HOCl Microdispersing Industry

The hypochlorous acid microdispersing systems market is in a growth phase, driven by increasing demand for efficient disinfection solutions across various industries. The global market size is expanding, with a projected CAGR of 7-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Industrie De Nora SpA and Holtec International leading innovation in electrochemical and microdispersion technologies. Academic institutions such as Hunan University of Science & Technology and Zhejiang Sci-Tech University are contributing to research and development. The competitive landscape is diverse, including established players like Nipro Corp. and emerging specialists like PCT Ltd., indicating a maturing but still dynamic market with opportunities for technological differentiation and market expansion.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed a sophisticated Hypochlorous Acid (HOCl) microdispersing system based on their extensive experience in electrochemistry and water treatment. Their system utilizes advanced Dimensionally Stable Anodes (DSA®) technology, which provides superior electrode performance and longevity in the electrolytic production of HOCl[1]. De Nora's system incorporates a modular design that allows for scalability, making it suitable for both small-scale and large-scale applications. The electrolytic cells are equipped with precision flow controllers and pH sensors to ensure consistent HOCl production with concentrations typically ranging from 100 to 1000 ppm[2]. The company's microdispersing technology employs high-pressure atomization nozzles that generate HOCl mist particles with an average size of 1-3 microns, enabling excellent surface penetration and disinfection efficacy[3].

Strengths: Scalable modular design suitable for various application sizes; high-quality electrode technology ensures consistent HOCl production. Weaknesses: May have higher upfront costs due to advanced technology; requires specialized knowledge for system operation and maintenance.

WIAB WATER INNOVATION AB

Technical Solution: WIAB WATER INNOVATION AB has developed an innovative Hypochlorous Acid (HOCl) microdispersing system that focuses on sustainability and efficiency. Their system utilizes a patented electrolysis process that optimizes energy consumption while producing high-quality HOCl solutions. WIAB's technology incorporates advanced membrane separation techniques to ensure the purity of the generated HOCl, with typical concentrations ranging from 200 to 600 ppm[1]. The system features intelligent control algorithms that continuously monitor and adjust key parameters such as pH, oxidation-reduction potential (ORP), and conductivity to maintain optimal HOCl production conditions[2]. WIAB's microdispersing technology employs ultrasonic nebulizers to generate HOCl mist particles with an average size of 2-4 microns, providing excellent surface coverage and penetration[3]. The company has also developed a proprietary stabilization process that extends the shelf life of the produced HOCl solution up to 60 days when stored under appropriate conditions[4].

Strengths: Energy-efficient production process; extended shelf life of HOCl solution. Weaknesses: May require specialized training for system operation; initial setup costs could be higher than conventional disinfection methods.

Core Innovations in HOCl Precision Dispersing

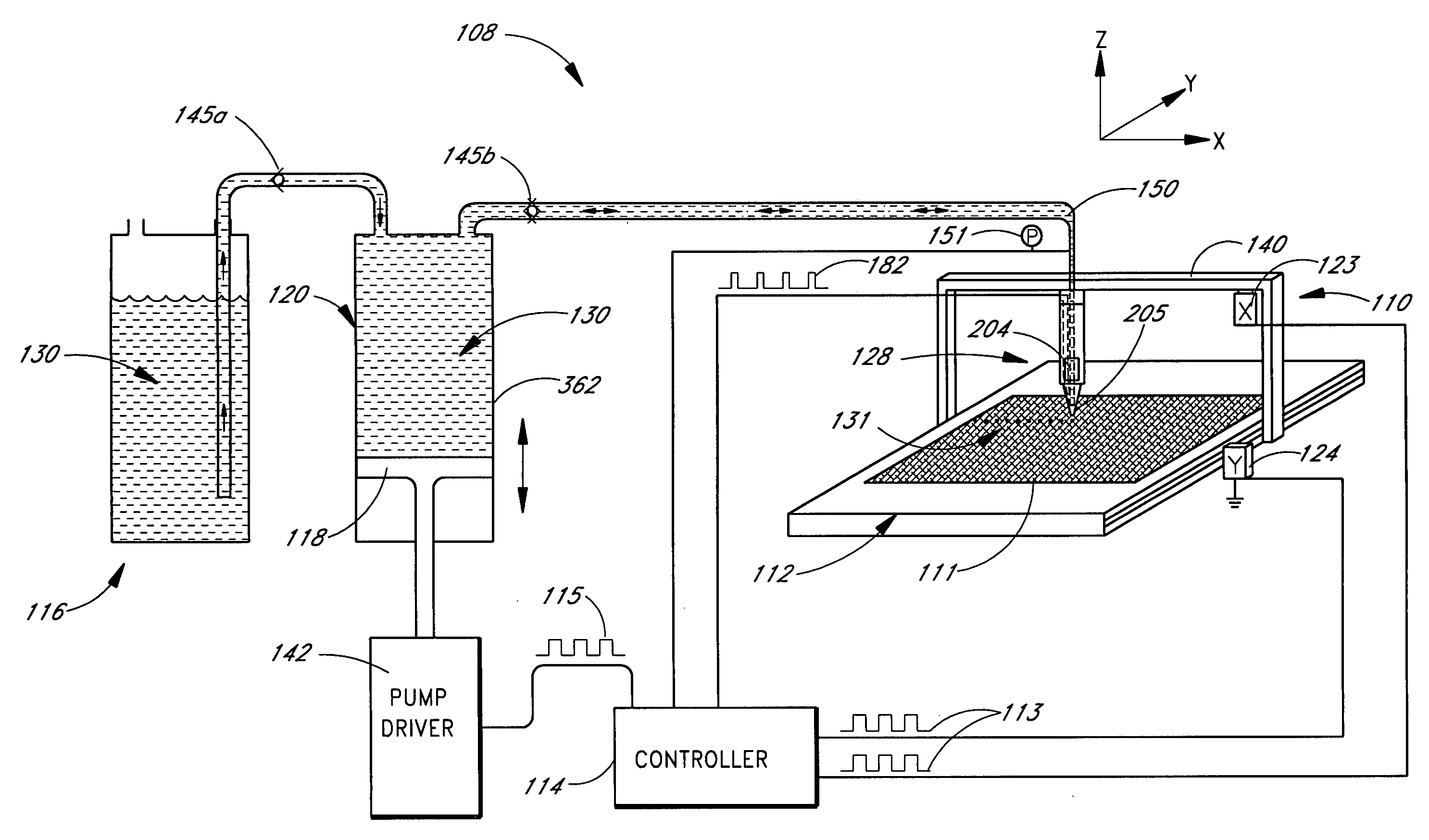

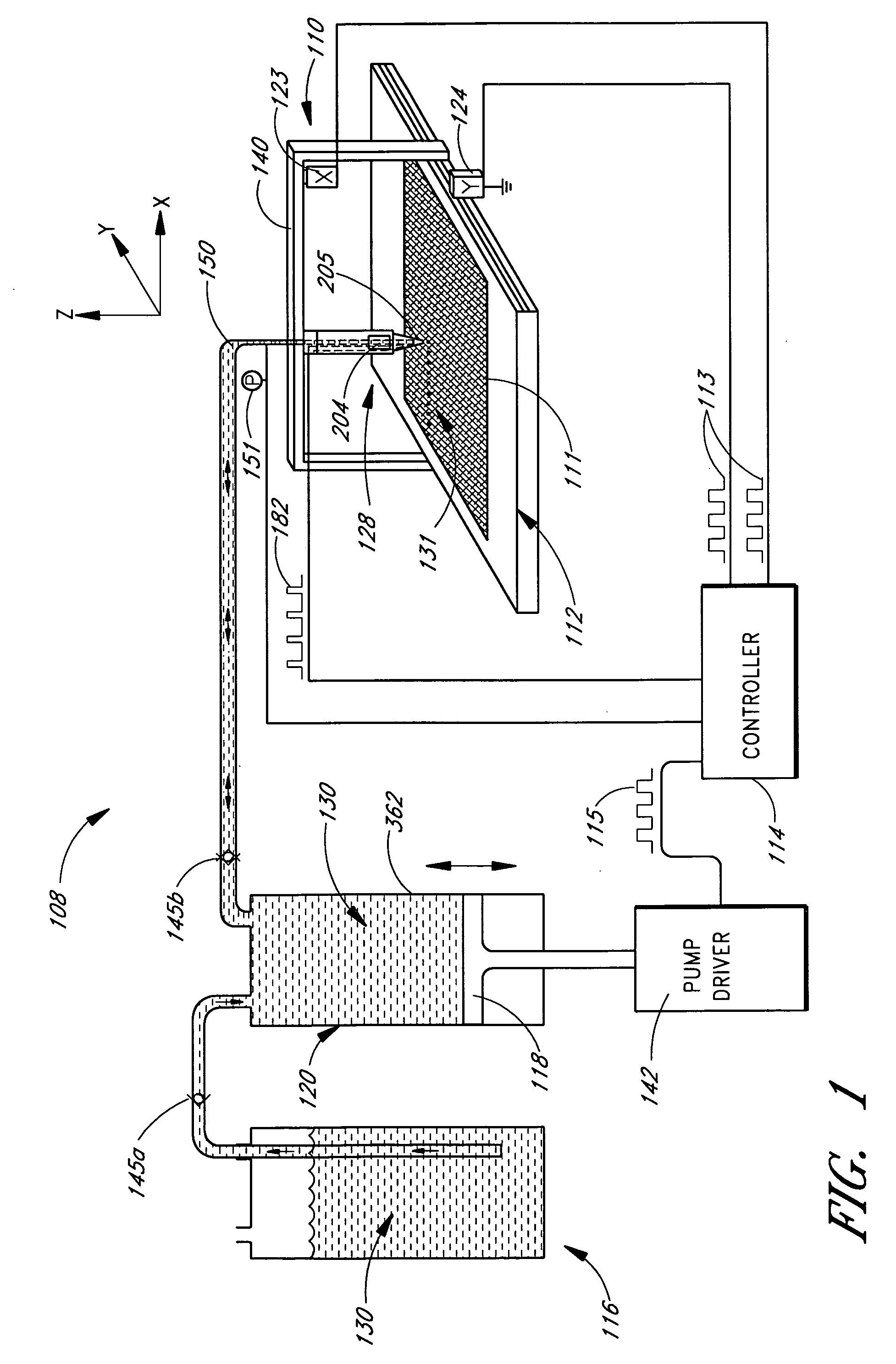

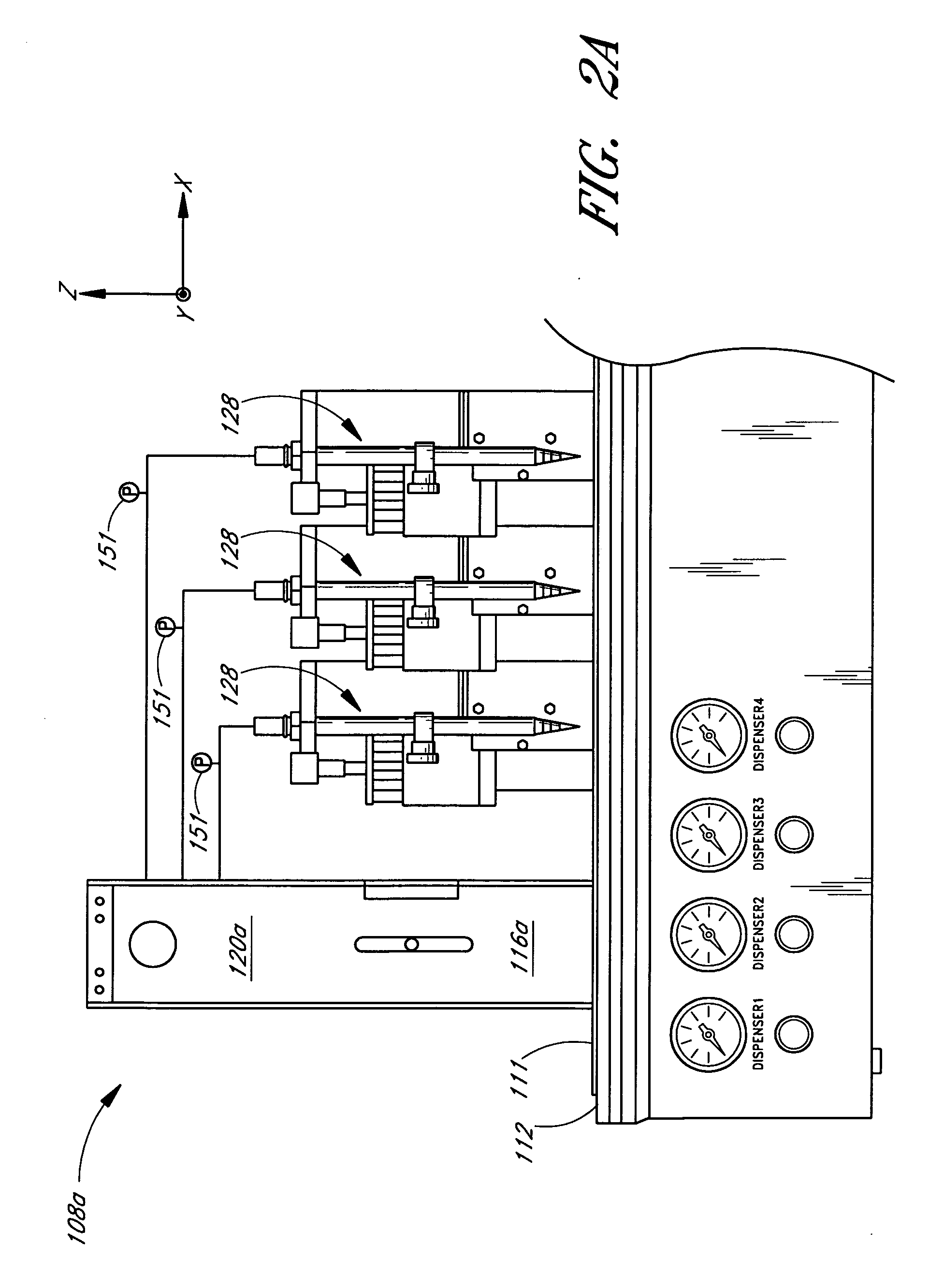

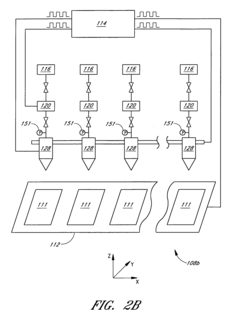

Method for high throughput drop dispensing of specific patterns

PatentInactiveUS20060211132A1

Innovation

- A high-speed precision dispensing system that uses a positive displacement pump in combination with a solenoid valve dispenser, controlled by a user-defined text file, to dispense microfluidic and sub-microfluidic quantities of reagents in specific patterns onto or into a target substrate, allowing for a wide dynamic range of dispense volumes and complex combinatorial patterns.

Safety and Regulatory Considerations for HOCl Systems

The implementation of hypochlorous acid (HOCl) microdispersing systems requires careful consideration of safety and regulatory aspects to ensure compliance and protect users and the environment. These systems must adhere to strict guidelines set by various regulatory bodies, including the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) in the United States, as well as similar agencies in other countries.

One of the primary safety considerations for HOCl systems is the potential for chemical exposure. While HOCl is generally considered safe when used as directed, prolonged exposure or high concentrations can cause irritation to the eyes, skin, and respiratory system. Manufacturers must provide clear safety instructions and appropriate personal protective equipment (PPE) recommendations for operators and maintenance personnel.

The storage and handling of HOCl solutions also require attention to safety protocols. Although HOCl is less corrosive than many other disinfectants, proper containment and storage conditions are essential to maintain its stability and prevent accidental spills or leaks. Facilities using HOCl microdispersing systems should implement proper chemical management practices, including secondary containment and spill response procedures.

From a regulatory standpoint, HOCl systems used for disinfection purposes must meet efficacy standards set by regulatory agencies. This includes demonstrating the ability to achieve specified log reductions of target pathogens within required contact times. Manufacturers must conduct thorough testing and provide documentation to support their efficacy claims.

Environmental considerations are also crucial in the regulatory landscape for HOCl systems. The EPA regulates the discharge of chemicals into the environment, and users of HOCl systems must ensure that any wastewater or residual solution is properly treated or disposed of in accordance with local and federal regulations. This may involve neutralization processes or specific disposal protocols.

In the context of precision applications, such as in healthcare or food processing environments, additional regulatory requirements may apply. For instance, in medical settings, HOCl systems may need to comply with standards set by healthcare accreditation organizations. In food processing, compliance with food safety regulations and Good Manufacturing Practices (GMP) is essential.

Manufacturers of HOCl microdispersing systems must also consider product labeling and documentation requirements. Clear and accurate labeling of the system components, including safety warnings and usage instructions, is mandatory. Additionally, maintaining detailed records of system performance, maintenance, and any adverse events is crucial for regulatory compliance and product liability purposes.

As the technology evolves and new applications for HOCl microdispersing systems emerge, ongoing regulatory monitoring and adaptation will be necessary. Companies developing and implementing these systems should establish robust regulatory affairs departments or partnerships to stay abreast of changing requirements and ensure continued compliance across various markets and applications.

One of the primary safety considerations for HOCl systems is the potential for chemical exposure. While HOCl is generally considered safe when used as directed, prolonged exposure or high concentrations can cause irritation to the eyes, skin, and respiratory system. Manufacturers must provide clear safety instructions and appropriate personal protective equipment (PPE) recommendations for operators and maintenance personnel.

The storage and handling of HOCl solutions also require attention to safety protocols. Although HOCl is less corrosive than many other disinfectants, proper containment and storage conditions are essential to maintain its stability and prevent accidental spills or leaks. Facilities using HOCl microdispersing systems should implement proper chemical management practices, including secondary containment and spill response procedures.

From a regulatory standpoint, HOCl systems used for disinfection purposes must meet efficacy standards set by regulatory agencies. This includes demonstrating the ability to achieve specified log reductions of target pathogens within required contact times. Manufacturers must conduct thorough testing and provide documentation to support their efficacy claims.

Environmental considerations are also crucial in the regulatory landscape for HOCl systems. The EPA regulates the discharge of chemicals into the environment, and users of HOCl systems must ensure that any wastewater or residual solution is properly treated or disposed of in accordance with local and federal regulations. This may involve neutralization processes or specific disposal protocols.

In the context of precision applications, such as in healthcare or food processing environments, additional regulatory requirements may apply. For instance, in medical settings, HOCl systems may need to comply with standards set by healthcare accreditation organizations. In food processing, compliance with food safety regulations and Good Manufacturing Practices (GMP) is essential.

Manufacturers of HOCl microdispersing systems must also consider product labeling and documentation requirements. Clear and accurate labeling of the system components, including safety warnings and usage instructions, is mandatory. Additionally, maintaining detailed records of system performance, maintenance, and any adverse events is crucial for regulatory compliance and product liability purposes.

As the technology evolves and new applications for HOCl microdispersing systems emerge, ongoing regulatory monitoring and adaptation will be necessary. Companies developing and implementing these systems should establish robust regulatory affairs departments or partnerships to stay abreast of changing requirements and ensure continued compliance across various markets and applications.

Environmental Impact of HOCl Microdispersing

The environmental impact of hypochlorous acid (HOCl) microdispersing systems is a critical consideration in their implementation and widespread adoption. These systems offer significant advantages in terms of precision and efficiency, but their ecological footprint must be carefully evaluated.

HOCl is a powerful oxidizing agent that naturally decomposes into harmless byproducts, primarily salt and water. This characteristic makes it an environmentally friendly alternative to many traditional disinfectants and sanitizers. When used in microdispersing systems, the environmental benefits are further amplified due to the precise application and reduced waste.

The production of HOCl through electrolysis of salt water requires minimal energy input, resulting in a low carbon footprint compared to the manufacture of conventional chemical disinfectants. Additionally, the on-site generation capability of many HOCl systems eliminates the need for transportation and storage of hazardous chemicals, further reducing the overall environmental impact.

Microdispersing technology allows for the creation of ultra-fine HOCl droplets, typically in the range of 1-5 microns. This fine mist ensures optimal surface coverage and penetration, leading to more effective disinfection with less solution. As a result, water consumption is significantly reduced compared to traditional spraying or wiping methods.

The degradation of HOCl in the environment is rapid and does not leave harmful residues. Unlike many chemical disinfectants that can persist in water systems and potentially harm aquatic life, HOCl quickly breaks down into non-toxic components. This characteristic minimizes the risk of environmental contamination and protects ecosystems from the adverse effects often associated with chemical runoff.

However, it is essential to consider the potential impact of increased salt concentrations in wastewater resulting from HOCl production and use. While the quantities are generally small, proper management and dilution practices should be implemented to prevent localized salinity issues in sensitive aquatic environments.

The use of HOCl microdispersing systems also contributes to a reduction in plastic waste. Many traditional disinfectant products come in single-use plastic containers, whereas HOCl can be generated on-site in reusable vessels, significantly decreasing plastic consumption and associated environmental burdens.

In conclusion, HOCl microdispersing systems present a promising solution for environmentally conscious disinfection practices. Their low environmental impact, coupled with high efficacy, positions them as a sustainable alternative in various applications, from healthcare to food processing and beyond. As research continues and technology advances, the environmental benefits of these systems are likely to increase further, solidifying their role in eco-friendly sanitization strategies.

HOCl is a powerful oxidizing agent that naturally decomposes into harmless byproducts, primarily salt and water. This characteristic makes it an environmentally friendly alternative to many traditional disinfectants and sanitizers. When used in microdispersing systems, the environmental benefits are further amplified due to the precise application and reduced waste.

The production of HOCl through electrolysis of salt water requires minimal energy input, resulting in a low carbon footprint compared to the manufacture of conventional chemical disinfectants. Additionally, the on-site generation capability of many HOCl systems eliminates the need for transportation and storage of hazardous chemicals, further reducing the overall environmental impact.

Microdispersing technology allows for the creation of ultra-fine HOCl droplets, typically in the range of 1-5 microns. This fine mist ensures optimal surface coverage and penetration, leading to more effective disinfection with less solution. As a result, water consumption is significantly reduced compared to traditional spraying or wiping methods.

The degradation of HOCl in the environment is rapid and does not leave harmful residues. Unlike many chemical disinfectants that can persist in water systems and potentially harm aquatic life, HOCl quickly breaks down into non-toxic components. This characteristic minimizes the risk of environmental contamination and protects ecosystems from the adverse effects often associated with chemical runoff.

However, it is essential to consider the potential impact of increased salt concentrations in wastewater resulting from HOCl production and use. While the quantities are generally small, proper management and dilution practices should be implemented to prevent localized salinity issues in sensitive aquatic environments.

The use of HOCl microdispersing systems also contributes to a reduction in plastic waste. Many traditional disinfectant products come in single-use plastic containers, whereas HOCl can be generated on-site in reusable vessels, significantly decreasing plastic consumption and associated environmental burdens.

In conclusion, HOCl microdispersing systems present a promising solution for environmentally conscious disinfection practices. Their low environmental impact, coupled with high efficacy, positions them as a sustainable alternative in various applications, from healthcare to food processing and beyond. As research continues and technology advances, the environmental benefits of these systems are likely to increase further, solidifying their role in eco-friendly sanitization strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!