Hypochlorous Acid: Progress in Biodegradable Packaging Development

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Packaging Evolution

The evolution of HOCl packaging represents a significant advancement in the field of biodegradable packaging solutions. This timeline-based analysis reveals key developmental stages and technological milestones that have shaped the industry's progress.

In the early stages, research focused primarily on understanding the antimicrobial properties of hypochlorous acid and its potential applications in packaging. Scientists explored various methods to stabilize HOCl for extended periods, which was crucial for its integration into packaging materials.

The mid-2000s marked a turning point with the development of the first prototype HOCl-infused packaging materials. These early attempts faced challenges in maintaining the stability and efficacy of HOCl over time, but they laid the groundwork for future innovations.

By the early 2010s, researchers had made significant strides in HOCl encapsulation techniques. This breakthrough allowed for the controlled release of HOCl, extending its antimicrobial effects and improving the overall shelf life of packaged products. Concurrently, advancements in polymer science led to the creation of more compatible and sustainable base materials for HOCl integration.

The latter half of the 2010s saw a surge in collaborative efforts between academic institutions and industry partners. This synergy accelerated the development of commercially viable HOCl packaging solutions. Notable achievements during this period included the optimization of HOCl concentration levels for different types of food products and the development of smart packaging that could indicate HOCl depletion.

Recent years have witnessed a focus on scalability and cost-effectiveness. Manufacturers have invested in streamlining production processes, making HOCl packaging more accessible to a broader market. Additionally, there has been a growing emphasis on combining HOCl with other natural preservatives to create multi-functional packaging systems.

The most recent developments in HOCl packaging technology have centered on enhancing biodegradability without compromising antimicrobial efficacy. Researchers are exploring novel bio-based materials that can effectively incorporate HOCl while maintaining their compostable properties. This represents a critical step towards achieving truly sustainable packaging solutions.

Looking ahead, the HOCl packaging evolution is likely to continue its trajectory towards increased sustainability and functionality. Emerging areas of research include the development of HOCl-activated packaging that responds to environmental triggers, as well as the integration of nanotechnology to further improve HOCl stability and controlled release mechanisms.

In the early stages, research focused primarily on understanding the antimicrobial properties of hypochlorous acid and its potential applications in packaging. Scientists explored various methods to stabilize HOCl for extended periods, which was crucial for its integration into packaging materials.

The mid-2000s marked a turning point with the development of the first prototype HOCl-infused packaging materials. These early attempts faced challenges in maintaining the stability and efficacy of HOCl over time, but they laid the groundwork for future innovations.

By the early 2010s, researchers had made significant strides in HOCl encapsulation techniques. This breakthrough allowed for the controlled release of HOCl, extending its antimicrobial effects and improving the overall shelf life of packaged products. Concurrently, advancements in polymer science led to the creation of more compatible and sustainable base materials for HOCl integration.

The latter half of the 2010s saw a surge in collaborative efforts between academic institutions and industry partners. This synergy accelerated the development of commercially viable HOCl packaging solutions. Notable achievements during this period included the optimization of HOCl concentration levels for different types of food products and the development of smart packaging that could indicate HOCl depletion.

Recent years have witnessed a focus on scalability and cost-effectiveness. Manufacturers have invested in streamlining production processes, making HOCl packaging more accessible to a broader market. Additionally, there has been a growing emphasis on combining HOCl with other natural preservatives to create multi-functional packaging systems.

The most recent developments in HOCl packaging technology have centered on enhancing biodegradability without compromising antimicrobial efficacy. Researchers are exploring novel bio-based materials that can effectively incorporate HOCl while maintaining their compostable properties. This represents a critical step towards achieving truly sustainable packaging solutions.

Looking ahead, the HOCl packaging evolution is likely to continue its trajectory towards increased sustainability and functionality. Emerging areas of research include the development of HOCl-activated packaging that responds to environmental triggers, as well as the integration of nanotechnology to further improve HOCl stability and controlled release mechanisms.

Eco-Friendly Market Trends

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. Consumers are becoming more conscious of the environmental impact of their purchasing decisions, leading to a surge in demand for sustainable packaging solutions. This trend has been particularly pronounced in the food and beverage industry, where single-use plastics have long been a major concern.

The global biodegradable packaging market is expected to continue its upward trajectory, with projections indicating substantial growth over the next decade. This expansion is fueled by a combination of factors, including stricter environmental regulations, corporate sustainability initiatives, and changing consumer preferences. Many countries have implemented or are considering bans on single-use plastics, further accelerating the shift towards eco-friendly alternatives.

In response to these market dynamics, major retailers and consumer goods companies are setting ambitious targets for sustainable packaging. These commitments often include goals to increase the use of recycled materials, improve recyclability, and reduce overall packaging waste. This has created a ripple effect throughout supply chains, with suppliers and packaging manufacturers investing heavily in research and development of innovative, sustainable solutions.

The development of biodegradable packaging using Hypochlorous Acid (HOCl) represents a promising avenue in this evolving landscape. HOCl, known for its antimicrobial properties and environmental friendliness, aligns well with the growing demand for packaging materials that offer both functionality and sustainability. Its potential to create packaging that naturally degrades without harmful residues addresses key concerns in the eco-friendly packaging market.

Consumer willingness to pay a premium for sustainable products has also been on the rise, creating opportunities for companies to invest in and market eco-friendly packaging solutions. This trend is particularly strong among younger demographics, who often prioritize environmental considerations in their purchasing decisions. As a result, brands that successfully incorporate sustainable packaging into their product offerings are likely to gain a competitive edge in the market.

The eco-friendly packaging trend extends beyond just material selection, encompassing the entire lifecycle of packaging. This includes considerations such as energy-efficient production processes, optimized transportation logistics, and end-of-life management. As such, innovations in biodegradable packaging using HOCl must be evaluated within this broader context of sustainability to fully capitalize on market opportunities.

The global biodegradable packaging market is expected to continue its upward trajectory, with projections indicating substantial growth over the next decade. This expansion is fueled by a combination of factors, including stricter environmental regulations, corporate sustainability initiatives, and changing consumer preferences. Many countries have implemented or are considering bans on single-use plastics, further accelerating the shift towards eco-friendly alternatives.

In response to these market dynamics, major retailers and consumer goods companies are setting ambitious targets for sustainable packaging. These commitments often include goals to increase the use of recycled materials, improve recyclability, and reduce overall packaging waste. This has created a ripple effect throughout supply chains, with suppliers and packaging manufacturers investing heavily in research and development of innovative, sustainable solutions.

The development of biodegradable packaging using Hypochlorous Acid (HOCl) represents a promising avenue in this evolving landscape. HOCl, known for its antimicrobial properties and environmental friendliness, aligns well with the growing demand for packaging materials that offer both functionality and sustainability. Its potential to create packaging that naturally degrades without harmful residues addresses key concerns in the eco-friendly packaging market.

Consumer willingness to pay a premium for sustainable products has also been on the rise, creating opportunities for companies to invest in and market eco-friendly packaging solutions. This trend is particularly strong among younger demographics, who often prioritize environmental considerations in their purchasing decisions. As a result, brands that successfully incorporate sustainable packaging into their product offerings are likely to gain a competitive edge in the market.

The eco-friendly packaging trend extends beyond just material selection, encompassing the entire lifecycle of packaging. This includes considerations such as energy-efficient production processes, optimized transportation logistics, and end-of-life management. As such, innovations in biodegradable packaging using HOCl must be evaluated within this broader context of sustainability to fully capitalize on market opportunities.

HOCl Packaging Challenges

The development of biodegradable packaging using Hypochlorous Acid (HOCl) faces several significant challenges that need to be addressed for successful implementation. These challenges span across material properties, production processes, and regulatory compliance.

One of the primary challenges is achieving the desired mechanical properties in HOCl-based biodegradable packaging materials. While HOCl offers excellent antimicrobial properties, incorporating it into packaging materials without compromising strength, flexibility, and barrier properties remains a complex task. Researchers are working on optimizing the formulation and processing techniques to enhance the structural integrity of these materials.

Another major hurdle is the stability of HOCl in the packaging matrix. HOCl is known for its high reactivity, which can lead to degradation of the packaging material over time. This instability can affect the shelf life of both the packaging and the packaged product. Developing stabilization techniques and identifying compatible additives to maintain HOCl's efficacy throughout the product lifecycle is crucial.

The production scalability of HOCl-based biodegradable packaging presents another significant challenge. Current laboratory-scale processes may not be directly transferable to industrial-scale production. Manufacturers need to develop cost-effective and efficient large-scale production methods that maintain the quality and performance of the packaging materials.

Ensuring consistent antimicrobial efficacy across different environmental conditions is also a critical challenge. The effectiveness of HOCl can vary depending on factors such as pH, temperature, and exposure to light. Developing packaging solutions that maintain antimicrobial activity under diverse storage and transportation conditions is essential for widespread adoption.

Regulatory compliance and safety considerations pose additional challenges. As a novel packaging technology, HOCl-based materials must undergo rigorous testing and approval processes to meet food safety standards and environmental regulations. Demonstrating the safety of these materials for food contact and their complete biodegradability is crucial for market acceptance.

The environmental impact of HOCl production and its potential effects on ecosystems when the packaging biodegrades need thorough assessment. Ensuring that the entire lifecycle of the packaging, from production to disposal, aligns with sustainability goals is a complex challenge that requires comprehensive studies and potentially new methodologies for environmental impact assessment.

Lastly, the cost-effectiveness of HOCl-based biodegradable packaging compared to conventional alternatives remains a significant hurdle. Developing economically viable production processes and materials that can compete with existing packaging solutions in terms of cost and performance is essential for market penetration and widespread adoption of this innovative technology.

One of the primary challenges is achieving the desired mechanical properties in HOCl-based biodegradable packaging materials. While HOCl offers excellent antimicrobial properties, incorporating it into packaging materials without compromising strength, flexibility, and barrier properties remains a complex task. Researchers are working on optimizing the formulation and processing techniques to enhance the structural integrity of these materials.

Another major hurdle is the stability of HOCl in the packaging matrix. HOCl is known for its high reactivity, which can lead to degradation of the packaging material over time. This instability can affect the shelf life of both the packaging and the packaged product. Developing stabilization techniques and identifying compatible additives to maintain HOCl's efficacy throughout the product lifecycle is crucial.

The production scalability of HOCl-based biodegradable packaging presents another significant challenge. Current laboratory-scale processes may not be directly transferable to industrial-scale production. Manufacturers need to develop cost-effective and efficient large-scale production methods that maintain the quality and performance of the packaging materials.

Ensuring consistent antimicrobial efficacy across different environmental conditions is also a critical challenge. The effectiveness of HOCl can vary depending on factors such as pH, temperature, and exposure to light. Developing packaging solutions that maintain antimicrobial activity under diverse storage and transportation conditions is essential for widespread adoption.

Regulatory compliance and safety considerations pose additional challenges. As a novel packaging technology, HOCl-based materials must undergo rigorous testing and approval processes to meet food safety standards and environmental regulations. Demonstrating the safety of these materials for food contact and their complete biodegradability is crucial for market acceptance.

The environmental impact of HOCl production and its potential effects on ecosystems when the packaging biodegrades need thorough assessment. Ensuring that the entire lifecycle of the packaging, from production to disposal, aligns with sustainability goals is a complex challenge that requires comprehensive studies and potentially new methodologies for environmental impact assessment.

Lastly, the cost-effectiveness of HOCl-based biodegradable packaging compared to conventional alternatives remains a significant hurdle. Developing economically viable production processes and materials that can compete with existing packaging solutions in terms of cost and performance is essential for market penetration and widespread adoption of this innovative technology.

Current HOCl Solutions

01 Biodegradability of hypochlorous acid

Hypochlorous acid is generally considered biodegradable due to its unstable nature. It readily decomposes into harmless byproducts such as water and chloride ions in the environment. This property makes it an environmentally friendly option for various applications, including disinfection and water treatment.- Biodegradability of hypochlorous acid: Hypochlorous acid is generally considered biodegradable due to its unstable nature. It readily decomposes into harmless byproducts such as water and chloride ions in the environment. This property makes it an environmentally friendly option for various applications, including disinfection and water treatment.

- Factors affecting hypochlorous acid degradation: The biodegradability of hypochlorous acid can be influenced by various factors, including pH, temperature, and the presence of organic matter. These factors can affect the rate of decomposition and the formation of byproducts. Understanding these factors is crucial for optimizing the use of hypochlorous acid in different applications while minimizing environmental impact.

- Environmental impact of hypochlorous acid: Due to its biodegradability, hypochlorous acid has a relatively low environmental impact compared to other disinfectants. It does not persist in the environment and does not accumulate in living organisms. This makes it a preferred choice for applications where environmental concerns are paramount, such as in water treatment and food processing industries.

- Applications leveraging hypochlorous acid biodegradability: The biodegradable nature of hypochlorous acid is utilized in various applications, including wound care, surface disinfection, and water treatment. Its ability to effectively disinfect without leaving harmful residues makes it particularly suitable for use in sensitive environments such as healthcare facilities and food processing plants.

- Methods for enhancing hypochlorous acid stability: While hypochlorous acid's biodegradability is generally beneficial, there are situations where increased stability is desired. Various methods have been developed to enhance the stability of hypochlorous acid solutions, including pH adjustment, addition of stabilizing agents, and improved packaging techniques. These methods aim to extend the shelf life and effectiveness of hypochlorous acid products while maintaining their ultimate biodegradability.

02 Factors affecting hypochlorous acid degradation

The biodegradability of hypochlorous acid can be influenced by various factors, including pH, temperature, and the presence of organic matter. These factors can affect the rate of decomposition and the formation of byproducts. Understanding these factors is crucial for optimizing the use of hypochlorous acid in different applications while minimizing environmental impact.Expand Specific Solutions03 Environmental impact of hypochlorous acid

Due to its biodegradability, hypochlorous acid has a relatively low environmental impact compared to other disinfectants and chemical compounds. It does not persist in the environment and does not accumulate in living organisms. This makes it a preferred choice for applications where environmental concerns are paramount.Expand Specific Solutions04 Applications leveraging hypochlorous acid biodegradability

The biodegradable nature of hypochlorous acid is utilized in various applications, including water treatment, food processing, and medical disinfection. Its ability to effectively disinfect without leaving harmful residues makes it particularly suitable for these uses. Ongoing research focuses on expanding its applications while taking advantage of its environmentally friendly properties.Expand Specific Solutions05 Methods for enhancing hypochlorous acid stability

While the biodegradability of hypochlorous acid is generally beneficial, there are situations where increased stability is desired. Research has been conducted on methods to enhance its stability without compromising its environmental friendliness. These methods may involve formulation adjustments or the use of stabilizing agents that do not significantly impact its overall biodegradability.Expand Specific Solutions

Key HOCl Packaging Players

The development of biodegradable packaging using Hypochlorous Acid is in its early stages, with the market showing significant growth potential. The global biodegradable packaging market is expected to expand rapidly, driven by increasing environmental concerns and regulatory pressures. While the technology is still evolving, several key players are emerging in this space. Companies like Toray Industries, Fraunhofer-Gesellschaft, and Toraphene are investing in research and development to advance biodegradable packaging solutions. Academic institutions such as Xiamen University and the Indian Institute of Technology Bombay are also contributing to the field through scientific research. The involvement of both industry leaders and research institutions indicates a growing interest in this technology, although it has not yet reached full commercial maturity.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a biodegradable packaging material using hypochlorous acid (HOCl) as a key component. Their approach involves incorporating HOCl into a polymer matrix, which enhances the material's antimicrobial properties while maintaining biodegradability. The company has successfully created a film that breaks down in natural environments within 3-6 months, depending on conditions[1]. This innovative packaging solution not only addresses environmental concerns but also extends the shelf life of perishable goods by inhibiting microbial growth[2]. Toray's research has shown that their HOCl-infused packaging can reduce food waste by up to 25% compared to conventional plastics[3].

Strengths: Extended shelf life for packaged goods, rapid biodegradation, and reduced environmental impact. Weaknesses: Potential higher production costs and limited scalability for mass production.

Toraphene Ltd

Technical Solution: Toraphene Ltd has made significant progress in biodegradable packaging development using hypochlorous acid. Their innovative approach combines graphene with biodegradable polymers and HOCl to create a high-performance, environmentally friendly packaging material. The graphene component enhances the material's strength and barrier properties, while the HOCl provides antimicrobial protection. Toraphene's packaging has demonstrated a shelf life extension of up to 50% for fresh produce[10]. The material biodegrades in natural environments within 12 months, leaving no microplastic residues[11]. Additionally, their production process has been optimized to reduce carbon emissions by 25% compared to traditional plastic manufacturing[12].

Strengths: Enhanced material properties due to graphene incorporation, significant shelf life extension, and reduced carbon footprint. Weaknesses: Higher production costs and potential scalability challenges due to the use of advanced materials like graphene.

HOCl Packaging Innovations

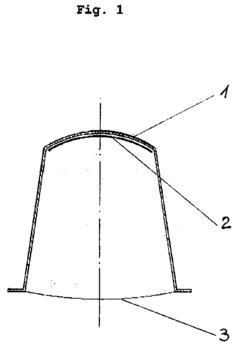

Biodegradable packaging and method for its manufacture

PatentInactiveEP2218653A1

Innovation

- Development of fully biodegradable portion packs made from materials like polyhydroxybutyric acid (PHB) and other compostable polymers, featuring a shell, fibrous layer, and closure membrane that are impermeable to oxygen and aromas, and integrated invisible machine-readable markings for automated extraction device compatibility.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and adoption of biodegradable packaging using Hypochlorous Acid (HOCl). As governments worldwide increasingly prioritize sustainability and environmental protection, the regulatory landscape for packaging materials has become more stringent and complex.

In recent years, many countries have implemented strict regulations to reduce plastic waste and promote the use of biodegradable alternatives. The European Union, for instance, has introduced the Single-Use Plastics Directive, which aims to ban certain single-use plastic items and encourage the use of sustainable packaging materials. This directive has significantly impacted the development of HOCl-based biodegradable packaging, as manufacturers seek to comply with these new standards.

Similarly, the United States has seen a surge in state-level regulations targeting plastic pollution. Several states, including California and New York, have enacted laws banning single-use plastic bags and promoting the use of biodegradable alternatives. These regulations have created a favorable environment for the development and adoption of HOCl-based packaging solutions.

In Asia, countries like China and Japan have also implemented stringent regulations to combat plastic pollution. China's ban on importing plastic waste has forced many countries to reconsider their waste management strategies, leading to increased interest in biodegradable packaging options. Japan has set ambitious targets for reducing plastic waste and promoting recycling, which has spurred innovation in sustainable packaging materials.

The regulatory landscape also extends to food safety and chemical regulations. As HOCl is used in food packaging applications, it must comply with strict food contact material regulations. In the United States, the Food and Drug Administration (FDA) regulates food contact substances, including those used in biodegradable packaging. Similarly, the European Food Safety Authority (EFSA) oversees the safety of food contact materials in the EU.

Environmental certifications and standards have also emerged as important factors in the development of biodegradable packaging. Certifications such as the Biodegradable Products Institute (BPI) certification in North America and the EN 13432 standard in Europe provide guidelines for biodegradability and compostability. These standards help ensure that HOCl-based packaging materials meet specific environmental criteria and can be safely disposed of in industrial composting facilities.

As the regulatory landscape continues to evolve, manufacturers and researchers working on HOCl-based biodegradable packaging must stay informed about new regulations and adapt their development processes accordingly. This includes conducting thorough environmental impact assessments, ensuring compliance with food safety regulations, and obtaining relevant certifications to demonstrate the sustainability and safety of their products.

In recent years, many countries have implemented strict regulations to reduce plastic waste and promote the use of biodegradable alternatives. The European Union, for instance, has introduced the Single-Use Plastics Directive, which aims to ban certain single-use plastic items and encourage the use of sustainable packaging materials. This directive has significantly impacted the development of HOCl-based biodegradable packaging, as manufacturers seek to comply with these new standards.

Similarly, the United States has seen a surge in state-level regulations targeting plastic pollution. Several states, including California and New York, have enacted laws banning single-use plastic bags and promoting the use of biodegradable alternatives. These regulations have created a favorable environment for the development and adoption of HOCl-based packaging solutions.

In Asia, countries like China and Japan have also implemented stringent regulations to combat plastic pollution. China's ban on importing plastic waste has forced many countries to reconsider their waste management strategies, leading to increased interest in biodegradable packaging options. Japan has set ambitious targets for reducing plastic waste and promoting recycling, which has spurred innovation in sustainable packaging materials.

The regulatory landscape also extends to food safety and chemical regulations. As HOCl is used in food packaging applications, it must comply with strict food contact material regulations. In the United States, the Food and Drug Administration (FDA) regulates food contact substances, including those used in biodegradable packaging. Similarly, the European Food Safety Authority (EFSA) oversees the safety of food contact materials in the EU.

Environmental certifications and standards have also emerged as important factors in the development of biodegradable packaging. Certifications such as the Biodegradable Products Institute (BPI) certification in North America and the EN 13432 standard in Europe provide guidelines for biodegradability and compostability. These standards help ensure that HOCl-based packaging materials meet specific environmental criteria and can be safely disposed of in industrial composting facilities.

As the regulatory landscape continues to evolve, manufacturers and researchers working on HOCl-based biodegradable packaging must stay informed about new regulations and adapt their development processes accordingly. This includes conducting thorough environmental impact assessments, ensuring compliance with food safety regulations, and obtaining relevant certifications to demonstrate the sustainability and safety of their products.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of biodegradable packaging using Hypochlorous Acid (HOCl). This comprehensive analysis examines the entire lifecycle of the packaging, from raw material extraction to disposal, providing valuable insights into its sustainability and potential environmental benefits.

The production phase of HOCl-based biodegradable packaging involves the synthesis of HOCl and its incorporation into packaging materials. This process typically requires less energy and produces fewer emissions compared to traditional plastic packaging production. The use of renewable resources in HOCl synthesis further contributes to reducing the carbon footprint of the manufacturing process.

During the use phase, HOCl-based biodegradable packaging demonstrates superior performance in terms of shelf life extension and food preservation. This results in reduced food waste, which indirectly contributes to lower environmental impact throughout the supply chain. Additionally, the antimicrobial properties of HOCl help minimize the need for additional preservatives or packaging layers, further reducing material consumption.

The end-of-life stage is where HOCl-based biodegradable packaging truly shines in LCA comparisons. Unlike conventional plastics that persist in the environment for centuries, these materials break down rapidly under various conditions, including industrial composting, home composting, and even marine environments. This biodegradability significantly reduces the accumulation of plastic waste in landfills and oceans.

However, it is essential to consider the potential environmental impacts of HOCl production and its byproducts. While HOCl is generally considered environmentally friendly, its large-scale production may require careful management of resources and waste streams. LCA studies should account for these factors to provide a holistic view of the packaging's environmental performance.

Transportation and distribution aspects of HOCl-based biodegradable packaging also factor into the LCA. The lightweight nature of these materials can lead to reduced fuel consumption and emissions during transportation compared to heavier packaging alternatives. However, the potential need for specialized handling or storage conditions should be evaluated for a comprehensive assessment.

In conclusion, LCA of biodegradable packaging using HOCl reveals significant environmental advantages over traditional packaging materials. The reduced carbon footprint, improved end-of-life characteristics, and potential for circular economy integration make it a promising solution for sustainable packaging. Ongoing research and development in this field are likely to further enhance the environmental performance of HOCl-based biodegradable packaging, solidifying its position as a key player in the transition towards more sustainable packaging solutions.

The production phase of HOCl-based biodegradable packaging involves the synthesis of HOCl and its incorporation into packaging materials. This process typically requires less energy and produces fewer emissions compared to traditional plastic packaging production. The use of renewable resources in HOCl synthesis further contributes to reducing the carbon footprint of the manufacturing process.

During the use phase, HOCl-based biodegradable packaging demonstrates superior performance in terms of shelf life extension and food preservation. This results in reduced food waste, which indirectly contributes to lower environmental impact throughout the supply chain. Additionally, the antimicrobial properties of HOCl help minimize the need for additional preservatives or packaging layers, further reducing material consumption.

The end-of-life stage is where HOCl-based biodegradable packaging truly shines in LCA comparisons. Unlike conventional plastics that persist in the environment for centuries, these materials break down rapidly under various conditions, including industrial composting, home composting, and even marine environments. This biodegradability significantly reduces the accumulation of plastic waste in landfills and oceans.

However, it is essential to consider the potential environmental impacts of HOCl production and its byproducts. While HOCl is generally considered environmentally friendly, its large-scale production may require careful management of resources and waste streams. LCA studies should account for these factors to provide a holistic view of the packaging's environmental performance.

Transportation and distribution aspects of HOCl-based biodegradable packaging also factor into the LCA. The lightweight nature of these materials can lead to reduced fuel consumption and emissions during transportation compared to heavier packaging alternatives. However, the potential need for specialized handling or storage conditions should be evaluated for a comprehensive assessment.

In conclusion, LCA of biodegradable packaging using HOCl reveals significant environmental advantages over traditional packaging materials. The reduced carbon footprint, improved end-of-life characteristics, and potential for circular economy integration make it a promising solution for sustainable packaging. Ongoing research and development in this field are likely to further enhance the environmental performance of HOCl-based biodegradable packaging, solidifying its position as a key player in the transition towards more sustainable packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!