How to Ensure Effective Hypochlorous Acid Dosage Control in Applications?

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Dosage Control Background and Objectives

Hypochlorous acid (HOCl) has emerged as a powerful and versatile disinfectant, gaining prominence in various applications due to its effectiveness against a wide range of pathogens. The control of HOCl dosage is crucial for ensuring optimal performance and safety across diverse sectors, including water treatment, healthcare, food processing, and agriculture. This technical research report aims to explore the background and objectives of HOCl dosage control, providing a comprehensive overview of its evolution and current goals.

The development of HOCl as a disinfectant dates back to the early 20th century, with its use in water treatment becoming widespread by the mid-1900s. However, the precise control of HOCl dosage remained a challenge due to limitations in measurement and delivery technologies. Over the past few decades, advancements in sensors, automation, and understanding of HOCl chemistry have significantly improved dosage control capabilities.

The primary objective of effective HOCl dosage control is to maintain an optimal concentration that maximizes disinfection efficacy while minimizing potential adverse effects. This balance is critical as insufficient dosage may lead to inadequate pathogen inactivation, while excessive dosage can result in unwanted chemical reactions, equipment corrosion, or potential health risks.

In recent years, the COVID-19 pandemic has heightened interest in HOCl as a safe and effective disinfectant, further emphasizing the need for precise dosage control. This has led to increased research and development efforts focused on improving HOCl generation, measurement, and delivery systems across various applications.

The technical evolution of HOCl dosage control has been driven by several key factors. These include the development of more accurate and reliable sensors for real-time monitoring of HOCl concentrations, advancements in automation and control systems for precise dosing, and improved understanding of HOCl stability and reactivity under different environmental conditions.

Current objectives in HOCl dosage control research and development include:

1. Enhancing the accuracy and reliability of HOCl measurement techniques, particularly in complex matrices and challenging environments.

2. Developing intelligent dosing systems that can adapt to varying water quality parameters and disinfection demands in real-time.

3. Optimizing HOCl generation methods to produce consistent concentrations with minimal by-products.

4. Improving the stability of HOCl solutions to extend shelf life and maintain efficacy over longer periods.

5. Integrating HOCl dosage control systems with broader water management and disinfection protocols to ensure comprehensive pathogen control.

As the applications of HOCl continue to expand, the importance of effective dosage control becomes increasingly critical. This research aims to explore current technologies, challenges, and potential innovations in HOCl dosage control, providing insights to guide future developments in this vital area of disinfection technology.

The development of HOCl as a disinfectant dates back to the early 20th century, with its use in water treatment becoming widespread by the mid-1900s. However, the precise control of HOCl dosage remained a challenge due to limitations in measurement and delivery technologies. Over the past few decades, advancements in sensors, automation, and understanding of HOCl chemistry have significantly improved dosage control capabilities.

The primary objective of effective HOCl dosage control is to maintain an optimal concentration that maximizes disinfection efficacy while minimizing potential adverse effects. This balance is critical as insufficient dosage may lead to inadequate pathogen inactivation, while excessive dosage can result in unwanted chemical reactions, equipment corrosion, or potential health risks.

In recent years, the COVID-19 pandemic has heightened interest in HOCl as a safe and effective disinfectant, further emphasizing the need for precise dosage control. This has led to increased research and development efforts focused on improving HOCl generation, measurement, and delivery systems across various applications.

The technical evolution of HOCl dosage control has been driven by several key factors. These include the development of more accurate and reliable sensors for real-time monitoring of HOCl concentrations, advancements in automation and control systems for precise dosing, and improved understanding of HOCl stability and reactivity under different environmental conditions.

Current objectives in HOCl dosage control research and development include:

1. Enhancing the accuracy and reliability of HOCl measurement techniques, particularly in complex matrices and challenging environments.

2. Developing intelligent dosing systems that can adapt to varying water quality parameters and disinfection demands in real-time.

3. Optimizing HOCl generation methods to produce consistent concentrations with minimal by-products.

4. Improving the stability of HOCl solutions to extend shelf life and maintain efficacy over longer periods.

5. Integrating HOCl dosage control systems with broader water management and disinfection protocols to ensure comprehensive pathogen control.

As the applications of HOCl continue to expand, the importance of effective dosage control becomes increasingly critical. This research aims to explore current technologies, challenges, and potential innovations in HOCl dosage control, providing insights to guide future developments in this vital area of disinfection technology.

Market Analysis for HOCl Applications

The market for hypochlorous acid (HOCl) applications has been experiencing significant growth in recent years, driven by increasing awareness of its effectiveness as a disinfectant and sanitizer. HOCl's broad-spectrum antimicrobial properties, combined with its safety profile and eco-friendly nature, have positioned it as a versatile solution across various industries.

In the healthcare sector, HOCl has gained traction for wound care, surface disinfection, and sterilization of medical equipment. The ongoing global focus on infection control, particularly in hospital settings, has further boosted demand. The food and beverage industry has also embraced HOCl for sanitizing food contact surfaces and produce washing, aligning with consumer preferences for chemical-free food safety solutions.

Water treatment represents another substantial market for HOCl applications. Municipal water suppliers and industrial facilities are increasingly adopting HOCl systems for water disinfection due to their effectiveness against a wide range of pathogens and reduced formation of harmful disinfection by-products compared to traditional chlorine-based methods.

The agriculture sector has shown growing interest in HOCl for crop protection and livestock management. Its use in hydroponics and aquaculture for pathogen control without harmful residues has opened new market opportunities. Additionally, the personal care industry has begun incorporating HOCl into products such as skin care formulations and oral care solutions, capitalizing on its gentle yet effective antimicrobial properties.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in HOCl applications, driven by rapid industrialization, increasing healthcare expenditure, and stringent regulations on food safety and water quality. North America and Europe continue to be significant markets, with established applications across various sectors and ongoing research into new use cases.

The COVID-19 pandemic has further accelerated market growth, with heightened focus on disinfection and sanitization across all industries. This has led to increased adoption of HOCl-based solutions in public spaces, transportation, and hospitality sectors. As the market expands, there is a growing need for advanced dosage control systems to ensure optimal efficacy and cost-effectiveness of HOCl applications across diverse settings.

In the healthcare sector, HOCl has gained traction for wound care, surface disinfection, and sterilization of medical equipment. The ongoing global focus on infection control, particularly in hospital settings, has further boosted demand. The food and beverage industry has also embraced HOCl for sanitizing food contact surfaces and produce washing, aligning with consumer preferences for chemical-free food safety solutions.

Water treatment represents another substantial market for HOCl applications. Municipal water suppliers and industrial facilities are increasingly adopting HOCl systems for water disinfection due to their effectiveness against a wide range of pathogens and reduced formation of harmful disinfection by-products compared to traditional chlorine-based methods.

The agriculture sector has shown growing interest in HOCl for crop protection and livestock management. Its use in hydroponics and aquaculture for pathogen control without harmful residues has opened new market opportunities. Additionally, the personal care industry has begun incorporating HOCl into products such as skin care formulations and oral care solutions, capitalizing on its gentle yet effective antimicrobial properties.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in HOCl applications, driven by rapid industrialization, increasing healthcare expenditure, and stringent regulations on food safety and water quality. North America and Europe continue to be significant markets, with established applications across various sectors and ongoing research into new use cases.

The COVID-19 pandemic has further accelerated market growth, with heightened focus on disinfection and sanitization across all industries. This has led to increased adoption of HOCl-based solutions in public spaces, transportation, and hospitality sectors. As the market expands, there is a growing need for advanced dosage control systems to ensure optimal efficacy and cost-effectiveness of HOCl applications across diverse settings.

Current Challenges in HOCl Dosage Control

The effective control of hypochlorous acid (HOCl) dosage in various applications faces several significant challenges. One of the primary issues is the inherent instability of HOCl solutions. The compound tends to decompose over time, especially when exposed to light, heat, or certain contaminants. This instability makes it difficult to maintain a consistent concentration of HOCl in storage and during application, leading to potential under- or over-dosing.

Another challenge lies in the precise measurement and monitoring of HOCl concentrations in real-time. Traditional methods for measuring chlorine levels may not be sufficiently accurate or rapid enough for the dynamic nature of many HOCl applications. This limitation can result in delayed responses to concentration changes, potentially compromising the effectiveness of the treatment or leading to excessive use of the chemical.

The pH sensitivity of HOCl presents an additional hurdle in dosage control. The efficacy of HOCl is highly dependent on maintaining an optimal pH range, typically between 5 and 6.5. Fluctuations in pH can significantly alter the proportion of HOCl to other chlorine species, affecting its disinfection power. Controlling pH while simultaneously managing HOCl dosage adds complexity to the control systems required.

Environmental factors also play a crucial role in the challenges of HOCl dosage control. Temperature variations can affect the stability and activity of HOCl solutions, necessitating adjustments in dosage to maintain efficacy across different environmental conditions. Additionally, the presence of organic matter or other contaminants in the application environment can rapidly consume HOCl, requiring dynamic dosing strategies to compensate for these variations.

The diversity of applications for HOCl further complicates dosage control efforts. From water treatment and food processing to medical disinfection and agriculture, each application has unique requirements and constraints. Developing versatile control systems that can adapt to these varied scenarios while maintaining precision and reliability remains a significant challenge.

Lastly, the economic considerations of HOCl dosage control cannot be overlooked. Implementing sophisticated monitoring and control systems can be costly, particularly for smaller-scale operations. Balancing the need for accurate dosage control with economic feasibility is an ongoing challenge, often leading to compromises in control precision or the adoption of less optimal, manual control methods.

Another challenge lies in the precise measurement and monitoring of HOCl concentrations in real-time. Traditional methods for measuring chlorine levels may not be sufficiently accurate or rapid enough for the dynamic nature of many HOCl applications. This limitation can result in delayed responses to concentration changes, potentially compromising the effectiveness of the treatment or leading to excessive use of the chemical.

The pH sensitivity of HOCl presents an additional hurdle in dosage control. The efficacy of HOCl is highly dependent on maintaining an optimal pH range, typically between 5 and 6.5. Fluctuations in pH can significantly alter the proportion of HOCl to other chlorine species, affecting its disinfection power. Controlling pH while simultaneously managing HOCl dosage adds complexity to the control systems required.

Environmental factors also play a crucial role in the challenges of HOCl dosage control. Temperature variations can affect the stability and activity of HOCl solutions, necessitating adjustments in dosage to maintain efficacy across different environmental conditions. Additionally, the presence of organic matter or other contaminants in the application environment can rapidly consume HOCl, requiring dynamic dosing strategies to compensate for these variations.

The diversity of applications for HOCl further complicates dosage control efforts. From water treatment and food processing to medical disinfection and agriculture, each application has unique requirements and constraints. Developing versatile control systems that can adapt to these varied scenarios while maintaining precision and reliability remains a significant challenge.

Lastly, the economic considerations of HOCl dosage control cannot be overlooked. Implementing sophisticated monitoring and control systems can be costly, particularly for smaller-scale operations. Balancing the need for accurate dosage control with economic feasibility is an ongoing challenge, often leading to compromises in control precision or the adoption of less optimal, manual control methods.

Existing HOCl Dosage Control Solutions

01 Electrochemical generation and control of hypochlorous acid

Electrochemical systems are used to generate and control the dosage of hypochlorous acid. These systems typically involve electrolysis of salt solutions, with precise control of current, voltage, and electrolyte concentration to regulate the production of hypochlorous acid. Sensors and feedback mechanisms are often employed to maintain desired concentrations.- Electrochemical generation and control of hypochlorous acid: Electrochemical systems are used to generate and control the dosage of hypochlorous acid. These systems typically involve electrolysis of salt solutions, with precise control of electrical parameters to regulate the production rate and concentration of hypochlorous acid. Sensors and feedback mechanisms are often incorporated to maintain desired levels.

- Automated dosing systems for hypochlorous acid: Automated systems are developed to control the dosage of hypochlorous acid in various applications. These systems may include programmable controllers, flow meters, and dispensing mechanisms to deliver precise amounts of hypochlorous acid based on predetermined parameters or real-time measurements.

- Stabilization and preservation of hypochlorous acid solutions: Methods and compositions are developed to stabilize hypochlorous acid solutions, extending their shelf life and maintaining consistent dosage over time. This may involve the use of specific additives, pH control, or packaging technologies to prevent degradation and ensure accurate dosing.

- Dosage control in water treatment applications: Specialized systems are designed for controlling hypochlorous acid dosage in water treatment applications. These may include continuous monitoring of water quality parameters, adaptive dosing algorithms, and integration with existing water treatment infrastructure to maintain optimal disinfection levels.

- Hypochlorous acid dosage control in medical and healthcare settings: Precise dosage control methods are developed for medical and healthcare applications of hypochlorous acid. These may include specialized delivery devices, formulations tailored for specific medical uses, and protocols for safe and effective administration in clinical settings.

02 Automated dosing systems for hypochlorous acid

Automated systems are developed to control the dosage of hypochlorous acid in various applications. These systems may include pumps, flow meters, and programmable controllers to dispense precise amounts of the solution based on predetermined parameters or real-time measurements. Such systems ensure consistent and accurate dosing for water treatment, disinfection, or medical applications.Expand Specific Solutions03 pH-controlled production and stabilization of hypochlorous acid

The production and stability of hypochlorous acid are closely tied to pH control. Methods and systems are developed to maintain optimal pH levels during generation and storage, ensuring the desired concentration and efficacy of hypochlorous acid. This may involve the use of buffers, pH sensors, and automated adjustment mechanisms.Expand Specific Solutions04 Hypochlorous acid dosage control in medical and healthcare applications

Specific dosage control methods are developed for medical and healthcare applications of hypochlorous acid. These may include precise delivery systems for wound care, sterilization, or respiratory treatments. The focus is on maintaining effective antimicrobial action while ensuring patient safety through careful concentration management.Expand Specific Solutions05 Integration of hypochlorous acid dosage control in water treatment systems

Water treatment systems incorporate specialized dosage control mechanisms for hypochlorous acid. These systems may use real-time monitoring of water quality parameters, flow rates, and demand to adjust the dosage automatically. The goal is to maintain optimal disinfection levels while minimizing chemical usage and environmental impact.Expand Specific Solutions

Key Players in HOCl Dosing Systems

The competitive landscape for effective hypochlorous acid dosage control in applications is characterized by a growing market in the early stages of development. The industry is experiencing increased demand due to the rising awareness of hypochlorous acid's disinfection properties. Companies like Industrie De Nora SpA, ANNIHILARE MEDICAL SYSTEMS, INC., and Aquaox, Inc. are at the forefront of developing advanced dosage control technologies. The market size is expanding, driven by applications in water treatment, healthcare, and industrial sectors. While the technology is not yet fully mature, rapid advancements are being made by key players, including research institutions like Nanjing Forestry University and Dalian Institute of Chemical Physics, to improve efficiency and precision in hypochlorous acid dosage control systems.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed an advanced electrochemical cell technology for on-site generation of hypochlorous acid. Their system utilizes a membrane-based electrolytic cell to produce a stable and precise concentration of hypochlorous acid from salt, water, and electricity. The process involves careful control of pH, temperature, and electrolysis parameters to ensure consistent production. They have implemented real-time monitoring and feedback systems to maintain optimal dosage levels, with sensors measuring free available chlorine (FAC) concentrations and automatically adjusting production rates[1]. The company has also developed proprietary electrode coatings that enhance efficiency and longevity of the electrolytic cells[3].

Strengths: Precise control of hypochlorous acid concentration, on-site generation reducing transportation and storage risks, and long-lasting electrode technology. Weaknesses: Requires consistent supply of salt and electricity, initial setup costs may be higher than traditional chlorination methods.

Aquaox, Inc.

Technical Solution: Aquaox, Inc. has pioneered a patented Electrochemical Activation (ECA) technology for hypochlorous acid production and dosage control. Their system employs a unique cell design that allows for the generation of hypochlorous acid with a specific pH range of 6.5-7.5, ensuring maximum efficacy and stability[2]. The Aquaox system incorporates advanced microprocessor controls and proprietary software algorithms to continuously monitor and adjust the production parameters. This includes real-time analysis of water quality, salt concentration, and power input to maintain consistent hypochlorous acid output. Additionally, they have developed a smart dosing system that integrates with various applications, using flow sensors and programmable logic controllers (PLCs) to deliver precise amounts of hypochlorous acid based on demand[4].

Strengths: Highly stable and effective pH-controlled hypochlorous acid production, intelligent dosing capabilities, and versatile application integration. Weaknesses: May require specialized training for operation and maintenance, and system performance could be affected by variations in input water quality.

Innovative HOCl Sensing Technologies

Device for measuring hypochlorite concentration, and device for generating hypochlorite

PatentWO2023243535A1

Innovation

- A hypochlorous acid concentration measuring device that uses electrical conductivity of hypochlorous acid water, measured by a pair of electrodes with an AC voltage, to accurately determine concentration, and a hypochlorous acid water generating device that stabilizes the concentration using an electrolytic cell and conductivity-based control.

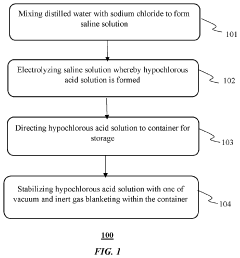

Method for stabilization of hypochlorous acid solution

PatentInactiveUS20200080208A1

Innovation

- A method involving the electrolysis of a saline solution using a uniflow membrane to produce hypochlorous acid, followed by storage in containers with vacuum or inert gas blanketing and specific gas and moisture transmission rates to maintain stability, and optionally coating with Titanium Dioxide.

Safety and Regulatory Considerations

Ensuring effective hypochlorous acid dosage control in applications requires careful consideration of safety and regulatory aspects. The use of hypochlorous acid is subject to various regulations and safety standards due to its potential health and environmental impacts. Regulatory bodies such as the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) in the United States, as well as similar organizations in other countries, have established guidelines for the safe use and handling of hypochlorous acid.

One of the primary safety considerations is the concentration of hypochlorous acid in the final application. While hypochlorous acid is generally considered safe at low concentrations, higher concentrations can pose risks to human health and the environment. Regulatory agencies typically specify maximum allowable concentrations for different applications, such as water treatment, food processing, and medical disinfection. Adhering to these concentration limits is crucial for ensuring both safety and compliance.

The method of hypochlorous acid generation and application also falls under regulatory scrutiny. On-site generation systems must meet specific safety standards to prevent accidental release or exposure. This includes proper ventilation, containment measures, and fail-safe mechanisms. Additionally, the storage and handling of precursor chemicals used in hypochlorous acid production, such as salt and water, must comply with relevant chemical storage regulations.

Worker safety is another critical aspect of regulatory compliance. Employers must provide appropriate personal protective equipment (PPE) and training for personnel handling hypochlorous acid or operating dosage control systems. This includes education on proper handling procedures, emergency response protocols, and the use of safety equipment such as eye wash stations and chemical showers.

Environmental considerations play a significant role in regulatory compliance for hypochlorous acid applications. Discharge limits and monitoring requirements are often in place to prevent harmful effects on aquatic ecosystems. Companies must implement proper disposal methods for any waste products and maintain detailed records of their hypochlorous acid usage and disposal practices.

Quality control and documentation are essential components of regulatory compliance. Regular testing and monitoring of hypochlorous acid concentrations, pH levels, and other relevant parameters are typically required. Maintaining accurate records of these tests, as well as equipment maintenance and calibration logs, is crucial for demonstrating compliance during regulatory inspections.

In medical and food processing applications, additional regulations may apply. For instance, the use of hypochlorous acid in these settings often requires certification of the generation equipment and validation of the dosage control processes. Compliance with Good Manufacturing Practices (GMP) and Hazard Analysis Critical Control Point (HACCP) principles may also be necessary, depending on the specific application.

As regulations evolve, staying informed about changes in safety standards and compliance requirements is vital. Companies must regularly review and update their dosage control protocols and safety procedures to ensure ongoing compliance with the latest regulatory standards. This proactive approach not only ensures legal compliance but also promotes a culture of safety and responsibility in the use of hypochlorous acid across various applications.

One of the primary safety considerations is the concentration of hypochlorous acid in the final application. While hypochlorous acid is generally considered safe at low concentrations, higher concentrations can pose risks to human health and the environment. Regulatory agencies typically specify maximum allowable concentrations for different applications, such as water treatment, food processing, and medical disinfection. Adhering to these concentration limits is crucial for ensuring both safety and compliance.

The method of hypochlorous acid generation and application also falls under regulatory scrutiny. On-site generation systems must meet specific safety standards to prevent accidental release or exposure. This includes proper ventilation, containment measures, and fail-safe mechanisms. Additionally, the storage and handling of precursor chemicals used in hypochlorous acid production, such as salt and water, must comply with relevant chemical storage regulations.

Worker safety is another critical aspect of regulatory compliance. Employers must provide appropriate personal protective equipment (PPE) and training for personnel handling hypochlorous acid or operating dosage control systems. This includes education on proper handling procedures, emergency response protocols, and the use of safety equipment such as eye wash stations and chemical showers.

Environmental considerations play a significant role in regulatory compliance for hypochlorous acid applications. Discharge limits and monitoring requirements are often in place to prevent harmful effects on aquatic ecosystems. Companies must implement proper disposal methods for any waste products and maintain detailed records of their hypochlorous acid usage and disposal practices.

Quality control and documentation are essential components of regulatory compliance. Regular testing and monitoring of hypochlorous acid concentrations, pH levels, and other relevant parameters are typically required. Maintaining accurate records of these tests, as well as equipment maintenance and calibration logs, is crucial for demonstrating compliance during regulatory inspections.

In medical and food processing applications, additional regulations may apply. For instance, the use of hypochlorous acid in these settings often requires certification of the generation equipment and validation of the dosage control processes. Compliance with Good Manufacturing Practices (GMP) and Hazard Analysis Critical Control Point (HACCP) principles may also be necessary, depending on the specific application.

As regulations evolve, staying informed about changes in safety standards and compliance requirements is vital. Companies must regularly review and update their dosage control protocols and safety procedures to ensure ongoing compliance with the latest regulatory standards. This proactive approach not only ensures legal compliance but also promotes a culture of safety and responsibility in the use of hypochlorous acid across various applications.

Environmental Impact of HOCl Usage

The environmental impact of hypochlorous acid (HOCl) usage is a critical consideration in its application across various sectors. HOCl, while effective as a disinfectant and sanitizer, presents both benefits and potential risks to the environment. Its decomposition into harmless byproducts, primarily water and salt, makes it an environmentally friendly alternative to many traditional chemical disinfectants. This characteristic significantly reduces the long-term ecological footprint associated with its use.

However, the production and application of HOCl require careful management to minimize negative environmental effects. The electrolysis process used to generate HOCl consumes electricity, which, depending on the energy source, may contribute to carbon emissions. Implementing renewable energy sources for HOCl production can mitigate this impact, aligning its use with sustainable practices.

In aquatic environments, the introduction of HOCl can have varying effects. At low concentrations, it rapidly dissipates without causing significant harm to aquatic life. However, excessive or improper dosage can lead to temporary pH changes and affect sensitive aquatic organisms. Proper dosage control and monitoring are essential to prevent these adverse effects, especially in applications near natural water bodies.

The use of HOCl in agriculture and food processing presents a unique environmental consideration. Its ability to effectively sanitize without leaving harmful residues on crops or food products reduces the need for more persistent and potentially harmful chemicals. This can lead to decreased chemical runoff into soil and water systems, contributing to overall environmental health.

In industrial settings, the adoption of HOCl can lead to a reduction in the use of more toxic and persistent disinfectants. This shift not only improves workplace safety but also reduces the environmental burden associated with the disposal of hazardous cleaning chemicals. The lower toxicity profile of HOCl means less risk of contamination in case of accidental spills or releases.

Despite its many environmental advantages, the widespread adoption of HOCl requires careful consideration of its production and distribution. The need for on-site generation or short-term storage due to its instability can lead to increased energy consumption and potential waste if not managed efficiently. Developing more stable formulations or improving storage technologies could enhance its environmental profile by reducing these logistical challenges.

However, the production and application of HOCl require careful management to minimize negative environmental effects. The electrolysis process used to generate HOCl consumes electricity, which, depending on the energy source, may contribute to carbon emissions. Implementing renewable energy sources for HOCl production can mitigate this impact, aligning its use with sustainable practices.

In aquatic environments, the introduction of HOCl can have varying effects. At low concentrations, it rapidly dissipates without causing significant harm to aquatic life. However, excessive or improper dosage can lead to temporary pH changes and affect sensitive aquatic organisms. Proper dosage control and monitoring are essential to prevent these adverse effects, especially in applications near natural water bodies.

The use of HOCl in agriculture and food processing presents a unique environmental consideration. Its ability to effectively sanitize without leaving harmful residues on crops or food products reduces the need for more persistent and potentially harmful chemicals. This can lead to decreased chemical runoff into soil and water systems, contributing to overall environmental health.

In industrial settings, the adoption of HOCl can lead to a reduction in the use of more toxic and persistent disinfectants. This shift not only improves workplace safety but also reduces the environmental burden associated with the disposal of hazardous cleaning chemicals. The lower toxicity profile of HOCl means less risk of contamination in case of accidental spills or releases.

Despite its many environmental advantages, the widespread adoption of HOCl requires careful consideration of its production and distribution. The need for on-site generation or short-term storage due to its instability can lead to increased energy consumption and potential waste if not managed efficiently. Developing more stable formulations or improving storage technologies could enhance its environmental profile by reducing these logistical challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!