Expanding the Reach of Hypochlorous Acid with Digital Innovations

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Tech Evolution

The evolution of hypochlorous acid (HOCl) technology has been marked by significant advancements in production methods, application techniques, and digital integration. Initially discovered in the early 19th century, HOCl's potential as a powerful yet safe disinfectant remained largely untapped due to its instability and short shelf life. However, the late 20th and early 21st centuries saw a resurgence of interest in HOCl, driven by the need for effective, eco-friendly sanitization solutions.

The technological trajectory of HOCl can be traced through several key phases. In the 1970s and 1980s, researchers focused on stabilizing HOCl solutions, leading to the development of electrolyzed water systems. These systems allowed for on-site generation of HOCl, addressing the stability issues that had previously limited its widespread use. The 1990s and early 2000s saw improvements in electrochemical cell design and membrane technology, enhancing the efficiency and consistency of HOCl production.

A significant leap forward came in the mid-2000s with the advent of advanced electrochemical activation (ECA) technology. This innovation enabled the production of highly stable HOCl solutions with longer shelf lives, opening up new possibilities for commercial applications. Concurrently, nanotechnology began to play a role in HOCl development, with researchers exploring ways to enhance its antimicrobial properties through nanoparticle integration.

The digital revolution of the 2010s brought about a new era for HOCl technology. Internet of Things (IoT) sensors and cloud-based monitoring systems were integrated into HOCl production and application processes, allowing for real-time quality control and optimization. This digital transformation extended to the development of smart dispensing systems and automated sanitation devices, further expanding HOCl's reach across various industries.

Recent years have seen a convergence of HOCl technology with artificial intelligence and machine learning. These advanced algorithms are now being employed to predict optimal HOCl concentrations for specific applications, analyze efficacy data, and even forecast maintenance needs for HOCl generation equipment. Additionally, blockchain technology is being explored to enhance traceability and quality assurance in HOCl supply chains.

Looking ahead, the future of HOCl technology is likely to be shaped by further digital innovations. Emerging trends include the development of AI-powered HOCl formulation systems, augmented reality applications for training and maintenance, and the integration of HOCl technology with autonomous cleaning robots. As environmental concerns and health safety standards continue to evolve, HOCl's role as a sustainable disinfection solution is expected to grow, driving further technological advancements in its production, application, and digital ecosystem.

The technological trajectory of HOCl can be traced through several key phases. In the 1970s and 1980s, researchers focused on stabilizing HOCl solutions, leading to the development of electrolyzed water systems. These systems allowed for on-site generation of HOCl, addressing the stability issues that had previously limited its widespread use. The 1990s and early 2000s saw improvements in electrochemical cell design and membrane technology, enhancing the efficiency and consistency of HOCl production.

A significant leap forward came in the mid-2000s with the advent of advanced electrochemical activation (ECA) technology. This innovation enabled the production of highly stable HOCl solutions with longer shelf lives, opening up new possibilities for commercial applications. Concurrently, nanotechnology began to play a role in HOCl development, with researchers exploring ways to enhance its antimicrobial properties through nanoparticle integration.

The digital revolution of the 2010s brought about a new era for HOCl technology. Internet of Things (IoT) sensors and cloud-based monitoring systems were integrated into HOCl production and application processes, allowing for real-time quality control and optimization. This digital transformation extended to the development of smart dispensing systems and automated sanitation devices, further expanding HOCl's reach across various industries.

Recent years have seen a convergence of HOCl technology with artificial intelligence and machine learning. These advanced algorithms are now being employed to predict optimal HOCl concentrations for specific applications, analyze efficacy data, and even forecast maintenance needs for HOCl generation equipment. Additionally, blockchain technology is being explored to enhance traceability and quality assurance in HOCl supply chains.

Looking ahead, the future of HOCl technology is likely to be shaped by further digital innovations. Emerging trends include the development of AI-powered HOCl formulation systems, augmented reality applications for training and maintenance, and the integration of HOCl technology with autonomous cleaning robots. As environmental concerns and health safety standards continue to evolve, HOCl's role as a sustainable disinfection solution is expected to grow, driving further technological advancements in its production, application, and digital ecosystem.

Market Demand Analysis

The market demand for hypochlorous acid (HOCl) has been steadily increasing across various sectors, driven by its effectiveness as a disinfectant and sanitizer. The global HOCl market is experiencing significant growth, particularly in healthcare, food and beverage, and water treatment industries. This growth is further accelerated by the recent global health crises, which have heightened awareness of the importance of effective sanitization.

In the healthcare sector, HOCl is gaining traction due to its broad-spectrum antimicrobial properties and safety profile. Hospitals, clinics, and long-term care facilities are increasingly adopting HOCl-based solutions for surface disinfection, wound care, and infection control. The demand is also rising in dental practices and veterinary clinics, where HOCl is used for instrument sterilization and oral care.

The food and beverage industry represents another significant market for HOCl. With stringent food safety regulations and consumer demand for clean-label products, food processors are turning to HOCl as a natural, non-toxic alternative to traditional chemical sanitizers. Its application in produce washing, equipment sanitization, and food packaging is driving market growth in this sector.

Water treatment is an emerging area of application for HOCl. Municipal water treatment facilities and industries requiring process water purification are exploring HOCl as an eco-friendly alternative to chlorine. This trend is particularly strong in regions facing water scarcity and stricter environmental regulations.

The consumer market for HOCl-based products is also expanding rapidly. With increased focus on personal hygiene and home sanitation, there is growing demand for HOCl-based sprays, wipes, and solutions for household use. This trend is expected to continue as consumers seek safer, more effective cleaning products.

Digital innovations are playing a crucial role in expanding the reach of HOCl. Online platforms and e-commerce channels have made HOCl products more accessible to a wider consumer base. Additionally, digital marketing strategies are helping to educate consumers about the benefits of HOCl, further driving market demand.

The agriculture sector is another area showing increased interest in HOCl. Its use in crop protection, livestock care, and post-harvest treatment is gaining attention due to its effectiveness and environmental friendliness. As sustainable farming practices become more prevalent, the demand for HOCl in agriculture is expected to grow significantly.

Overall, the market demand for HOCl is robust and diversifying. The combination of its versatile applications, safety profile, and effectiveness, coupled with digital innovations in marketing and distribution, is expected to drive continued growth across multiple industries in the coming years.

In the healthcare sector, HOCl is gaining traction due to its broad-spectrum antimicrobial properties and safety profile. Hospitals, clinics, and long-term care facilities are increasingly adopting HOCl-based solutions for surface disinfection, wound care, and infection control. The demand is also rising in dental practices and veterinary clinics, where HOCl is used for instrument sterilization and oral care.

The food and beverage industry represents another significant market for HOCl. With stringent food safety regulations and consumer demand for clean-label products, food processors are turning to HOCl as a natural, non-toxic alternative to traditional chemical sanitizers. Its application in produce washing, equipment sanitization, and food packaging is driving market growth in this sector.

Water treatment is an emerging area of application for HOCl. Municipal water treatment facilities and industries requiring process water purification are exploring HOCl as an eco-friendly alternative to chlorine. This trend is particularly strong in regions facing water scarcity and stricter environmental regulations.

The consumer market for HOCl-based products is also expanding rapidly. With increased focus on personal hygiene and home sanitation, there is growing demand for HOCl-based sprays, wipes, and solutions for household use. This trend is expected to continue as consumers seek safer, more effective cleaning products.

Digital innovations are playing a crucial role in expanding the reach of HOCl. Online platforms and e-commerce channels have made HOCl products more accessible to a wider consumer base. Additionally, digital marketing strategies are helping to educate consumers about the benefits of HOCl, further driving market demand.

The agriculture sector is another area showing increased interest in HOCl. Its use in crop protection, livestock care, and post-harvest treatment is gaining attention due to its effectiveness and environmental friendliness. As sustainable farming practices become more prevalent, the demand for HOCl in agriculture is expected to grow significantly.

Overall, the market demand for HOCl is robust and diversifying. The combination of its versatile applications, safety profile, and effectiveness, coupled with digital innovations in marketing and distribution, is expected to drive continued growth across multiple industries in the coming years.

HOCL Challenges

Hypochlorous acid (HOCl) faces several significant challenges that hinder its widespread adoption and utilization across various industries. One of the primary obstacles is its inherent instability. HOCl is highly reactive and tends to degrade rapidly, especially when exposed to light, heat, or organic matter. This instability limits its shelf life and makes it difficult to store and transport over long distances or for extended periods.

Another major challenge is the lack of standardization in production methods and quality control. Different manufacturing processes can result in varying concentrations and pH levels, leading to inconsistent efficacy and potential safety concerns. This variability makes it challenging for end-users to rely on HOCl products consistently and complicates regulatory compliance efforts.

The perception and awareness of HOCl among potential users and decision-makers also present a significant hurdle. Despite its proven effectiveness as a disinfectant and sanitizer, many industries and consumers are unfamiliar with HOCl or have misconceptions about its safety and applications. This knowledge gap hampers its adoption in sectors where it could provide substantial benefits.

Production scalability and cost-effectiveness pose additional challenges. While HOCl can be generated on-site using electrolysis of salt water, scaling up this process for large-scale industrial applications can be complex and expensive. The need for specialized equipment and expertise in maintaining optimal production conditions further complicates widespread implementation.

Regulatory hurdles and approval processes also impede the expansion of HOCl usage. Different countries and regions have varying regulations regarding the use of HOCl in different applications, particularly in sensitive areas such as food processing, healthcare, and water treatment. Navigating these regulatory landscapes and obtaining necessary certifications can be time-consuming and costly for manufacturers and distributors.

The environmental impact of HOCl production and disposal is another area of concern. While HOCl itself is environmentally friendly and breaks down into harmless components, the production process may involve energy-intensive steps or generate by-products that require careful management. Addressing these environmental considerations is crucial for sustainable long-term adoption.

Lastly, the integration of HOCl into existing industrial processes and systems presents technical challenges. Many industries have established disinfection and sanitation protocols that may require significant modifications to incorporate HOCl effectively. This resistance to change and the associated costs of system upgrades can slow down the adoption of HOCl-based solutions.

Another major challenge is the lack of standardization in production methods and quality control. Different manufacturing processes can result in varying concentrations and pH levels, leading to inconsistent efficacy and potential safety concerns. This variability makes it challenging for end-users to rely on HOCl products consistently and complicates regulatory compliance efforts.

The perception and awareness of HOCl among potential users and decision-makers also present a significant hurdle. Despite its proven effectiveness as a disinfectant and sanitizer, many industries and consumers are unfamiliar with HOCl or have misconceptions about its safety and applications. This knowledge gap hampers its adoption in sectors where it could provide substantial benefits.

Production scalability and cost-effectiveness pose additional challenges. While HOCl can be generated on-site using electrolysis of salt water, scaling up this process for large-scale industrial applications can be complex and expensive. The need for specialized equipment and expertise in maintaining optimal production conditions further complicates widespread implementation.

Regulatory hurdles and approval processes also impede the expansion of HOCl usage. Different countries and regions have varying regulations regarding the use of HOCl in different applications, particularly in sensitive areas such as food processing, healthcare, and water treatment. Navigating these regulatory landscapes and obtaining necessary certifications can be time-consuming and costly for manufacturers and distributors.

The environmental impact of HOCl production and disposal is another area of concern. While HOCl itself is environmentally friendly and breaks down into harmless components, the production process may involve energy-intensive steps or generate by-products that require careful management. Addressing these environmental considerations is crucial for sustainable long-term adoption.

Lastly, the integration of HOCl into existing industrial processes and systems presents technical challenges. Many industries have established disinfection and sanitation protocols that may require significant modifications to incorporate HOCl effectively. This resistance to change and the associated costs of system upgrades can slow down the adoption of HOCl-based solutions.

Current HOCL Solutions

01 Production methods of hypochlorous acid

Various methods for producing hypochlorous acid are described, including electrolysis of salt solutions and chemical reactions involving chlorine-containing compounds. These methods aim to optimize the yield and purity of hypochlorous acid for different applications.- Production methods of hypochlorous acid: Various methods for producing hypochlorous acid are described, including electrolysis of salt solutions and chemical reactions involving chlorine compounds. These methods aim to optimize the yield and purity of hypochlorous acid for different applications.

- Stabilization and storage of hypochlorous acid solutions: Techniques for stabilizing hypochlorous acid solutions to extend their shelf life and maintain efficacy are discussed. This includes the use of specific additives, pH control, and packaging innovations to prevent degradation and ensure long-term stability.

- Applications of hypochlorous acid in disinfection and sanitization: The use of hypochlorous acid as a powerful disinfectant and sanitizing agent is explored. Various applications in healthcare, food processing, water treatment, and general surface disinfection are described, highlighting its effectiveness against a wide range of pathogens.

- Environmental and safety considerations of hypochlorous acid: The environmental impact and safety aspects of hypochlorous acid are addressed. This includes its biodegradability, low toxicity to humans and animals when used properly, and considerations for safe handling and disposal.

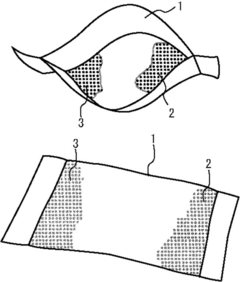

- Formulations and delivery systems for hypochlorous acid: Various formulations and delivery systems for hypochlorous acid are presented. This includes the development of gels, sprays, and other forms to enhance its application in different settings, as well as innovative packaging and dispensing methods to maintain its efficacy.

02 Stabilization and storage of hypochlorous acid

Techniques for stabilizing hypochlorous acid solutions and improving their shelf life are discussed. This includes the use of specific additives, pH control, and packaging methods to maintain the efficacy of the acid over extended periods.Expand Specific Solutions03 Applications in disinfection and sterilization

Hypochlorous acid is widely used as a disinfectant and sterilizing agent. Its effectiveness against various microorganisms and its applications in healthcare, food industry, and water treatment are explored.Expand Specific Solutions04 Environmental impact and safety considerations

The environmental impact of hypochlorous acid production and use is addressed, along with safety considerations for handling and application. This includes biodegradability, toxicity assessments, and safe disposal methods.Expand Specific Solutions05 Formulations and delivery systems

Various formulations and delivery systems for hypochlorous acid are described, including gels, sprays, and controlled release mechanisms. These formulations aim to enhance the effectiveness and ease of application of hypochlorous acid in different settings.Expand Specific Solutions

Key HOCL Players

The market for hypochlorous acid innovations is in a growth phase, with increasing applications across various industries. The global market size is expanding, driven by rising demand for eco-friendly disinfectants and water treatment solutions. Technologically, the field is advancing rapidly, with companies like Industrie De Nora SpA and Ecolab USA, Inc. leading in electrochemical and water treatment technologies. Universities such as Hunan University of Science & Technology and Zhejiang Sci-Tech University are contributing to research and development. Emerging players like Aquaox, Inc. and Adept Water Technologies A/S are introducing digital innovations to enhance product efficacy and expand market reach. The competitive landscape is diverse, with established chemical companies and innovative startups vying for market share in this growing sector.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrochemical cell technology for on-site generation of hypochlorous acid (HOCl). Their system utilizes a membrane-free electrolytic cell design that allows for efficient production of HOCl from salt, water, and electricity[1]. The company has integrated digital control systems and IoT connectivity to enable remote monitoring and optimization of HOCl generation[2]. This allows for precise control of HOCl concentration and production rates to meet varying demand. De Nora has also implemented predictive maintenance algorithms that analyze operational data to schedule servicing and reduce downtime[3].

Strengths: Efficient on-site HOCl generation, digital control for optimization, predictive maintenance. Weaknesses: Reliance on stable power supply, potential for electrode degradation over time.

Aquaox, Inc.

Technical Solution: Aquaox has pioneered a patented electrochemical activation (ECA) technology for producing hypochlorous acid. Their system employs a unique cell design with specialized electrodes and a semi-permeable membrane to generate HOCl at neutral pH[4]. Aquaox has developed smart production units with built-in sensors and microprocessors to continuously monitor and adjust key parameters like pH, ORP, and conductivity[5]. The company has also created a cloud-based platform that collects real-time production data, enabling remote diagnostics and performance optimization across multiple units[6]. Additionally, Aquaox offers a mobile app for customers to track HOCl inventory and schedule automated production cycles.

Strengths: Stable neutral pH HOCl production, smart monitoring systems, cloud-based fleet management. Weaknesses: Higher initial equipment cost, requires specialized maintenance.

HOCL Digital Patents

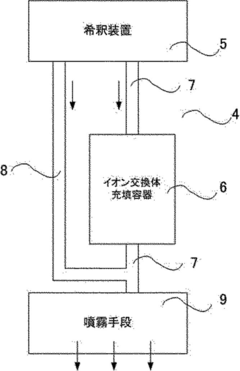

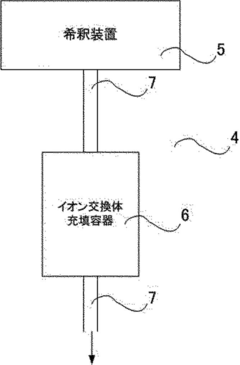

Weakly acidic hypochlorous acid, and production equipment and production method thereof

PatentActiveJPWO2011136091A1

Innovation

- A method and apparatus using a weakly acidic ion exchanger with a buffering action above the pH at which chlorine gas is generated to lower the pH of hypochlorite solutions, producing weakly acidic hypochlorous acid without acids, ensuring a pH range of 3.5 to 7.5 and preventing chlorine gas formation.

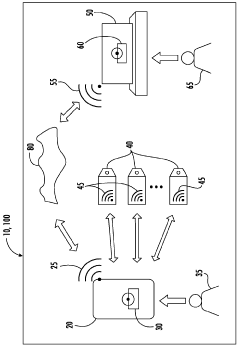

System and method for effective cleaning and disinfecting protocol

PatentInactiveGB2594696A

Innovation

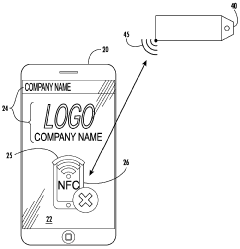

- A system and method utilizing a portable computing device with RFID/NFC technology to track and verify adherence to cleaning protocols, ensuring the use of effective disinfectants within their lifecycle, including Hypochlorous acid, through authentication, data management, and reporting functionalities.

Regulatory Framework

The regulatory framework surrounding hypochlorous acid (HOCl) and its digital innovations is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl as a disinfectant and sanitizer. The EPA's registration process ensures that HOCl products meet safety and efficacy standards before entering the market. Additionally, the Food and Drug Administration (FDA) oversees HOCl applications in food processing and medical devices, requiring manufacturers to adhere to strict guidelines for product formulation and labeling.

Internationally, the European Chemicals Agency (ECHA) regulates HOCl under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This framework mandates that companies register their HOCl products and provide comprehensive safety data. The World Health Organization (WHO) also recognizes HOCl as an effective disinfectant, influencing global health policies and recommendations.

As digital innovations expand the reach of HOCl, new regulatory challenges emerge. The integration of Internet of Things (IoT) devices in HOCl production and application systems raises concerns about data privacy and cybersecurity. Regulatory bodies are now tasked with developing guidelines that address these technological advancements while ensuring consumer safety and environmental protection.

The use of artificial intelligence and machine learning algorithms in optimizing HOCl production and application processes also falls under regulatory scrutiny. Agencies like the National Institute of Standards and Technology (NIST) in the US are working on frameworks to ensure the responsible development and deployment of AI in critical applications, including those involving HOCl.

Regulatory compliance in the digital age requires companies to navigate a complex landscape of data protection laws, such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States. These regulations impact how companies collect, process, and store data related to HOCl production, distribution, and usage.

As the technology evolves, regulatory bodies are adapting their approaches to keep pace. This includes the development of new testing methodologies to assess the efficacy of digitally-enhanced HOCl products and the creation of guidelines for the safe implementation of automated HOCl dispensing systems. The regulatory framework must balance innovation with safety, ensuring that the expanding reach of HOCl through digital technologies does not compromise public health or environmental standards.

Internationally, the European Chemicals Agency (ECHA) regulates HOCl under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This framework mandates that companies register their HOCl products and provide comprehensive safety data. The World Health Organization (WHO) also recognizes HOCl as an effective disinfectant, influencing global health policies and recommendations.

As digital innovations expand the reach of HOCl, new regulatory challenges emerge. The integration of Internet of Things (IoT) devices in HOCl production and application systems raises concerns about data privacy and cybersecurity. Regulatory bodies are now tasked with developing guidelines that address these technological advancements while ensuring consumer safety and environmental protection.

The use of artificial intelligence and machine learning algorithms in optimizing HOCl production and application processes also falls under regulatory scrutiny. Agencies like the National Institute of Standards and Technology (NIST) in the US are working on frameworks to ensure the responsible development and deployment of AI in critical applications, including those involving HOCl.

Regulatory compliance in the digital age requires companies to navigate a complex landscape of data protection laws, such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States. These regulations impact how companies collect, process, and store data related to HOCl production, distribution, and usage.

As the technology evolves, regulatory bodies are adapting their approaches to keep pace. This includes the development of new testing methodologies to assess the efficacy of digitally-enhanced HOCl products and the creation of guidelines for the safe implementation of automated HOCl dispensing systems. The regulatory framework must balance innovation with safety, ensuring that the expanding reach of HOCl through digital technologies does not compromise public health or environmental standards.

Environmental Impact

The integration of digital innovations with hypochlorous acid (HOCl) production and application presents a unique opportunity to enhance environmental sustainability. HOCl, known for its potent disinfecting properties, is inherently eco-friendly due to its natural occurrence in the human immune system and its ability to break down into harmless salt and water. By leveraging digital technologies, the environmental impact of HOCl can be further optimized across its lifecycle.

Smart production systems can significantly reduce the environmental footprint of HOCl manufacturing. IoT-enabled sensors and AI-driven process control can optimize resource utilization, minimizing energy consumption and raw material waste. These systems can adjust production parameters in real-time, ensuring optimal efficiency and reducing the overall carbon footprint of the manufacturing process.

Digital platforms can revolutionize HOCl distribution and application, leading to more targeted and efficient use. Mobile apps and cloud-based systems can provide users with precise dosing instructions and application guidelines, preventing overuse and reducing unnecessary environmental discharge. This precision approach not only conserves resources but also minimizes the potential for any unintended ecological impacts.

Remote monitoring and data analytics can play a crucial role in assessing the environmental impact of HOCl applications. Sensors deployed in treated areas can collect data on HOCl concentration levels, degradation rates, and interactions with various environmental factors. This information, when analyzed through advanced algorithms, can provide valuable insights into the long-term ecological effects and help in developing more sustainable application strategies.

The integration of blockchain technology can enhance transparency and traceability in the HOCl supply chain. This can ensure that environmentally responsible production methods are employed and that the product is used in compliance with ecological standards. Such transparency can also facilitate more accurate life cycle assessments, allowing for continuous improvement in environmental performance.

Digital innovations can also support the development of closed-loop systems for HOCl production and use. Smart recycling technologies can be employed to capture and reprocess HOCl after its application, reducing waste and minimizing environmental discharge. This circular approach, enabled by digital tracking and processing systems, can significantly enhance the overall sustainability of HOCl utilization.

By expanding the reach of HOCl through digital innovations, we can not only improve its efficacy and accessibility but also substantially reduce its environmental impact. These technological advancements pave the way for a more sustainable and responsible use of this powerful disinfectant, aligning its application with global environmental conservation efforts.

Smart production systems can significantly reduce the environmental footprint of HOCl manufacturing. IoT-enabled sensors and AI-driven process control can optimize resource utilization, minimizing energy consumption and raw material waste. These systems can adjust production parameters in real-time, ensuring optimal efficiency and reducing the overall carbon footprint of the manufacturing process.

Digital platforms can revolutionize HOCl distribution and application, leading to more targeted and efficient use. Mobile apps and cloud-based systems can provide users with precise dosing instructions and application guidelines, preventing overuse and reducing unnecessary environmental discharge. This precision approach not only conserves resources but also minimizes the potential for any unintended ecological impacts.

Remote monitoring and data analytics can play a crucial role in assessing the environmental impact of HOCl applications. Sensors deployed in treated areas can collect data on HOCl concentration levels, degradation rates, and interactions with various environmental factors. This information, when analyzed through advanced algorithms, can provide valuable insights into the long-term ecological effects and help in developing more sustainable application strategies.

The integration of blockchain technology can enhance transparency and traceability in the HOCl supply chain. This can ensure that environmentally responsible production methods are employed and that the product is used in compliance with ecological standards. Such transparency can also facilitate more accurate life cycle assessments, allowing for continuous improvement in environmental performance.

Digital innovations can also support the development of closed-loop systems for HOCl production and use. Smart recycling technologies can be employed to capture and reprocess HOCl after its application, reducing waste and minimizing environmental discharge. This circular approach, enabled by digital tracking and processing systems, can significantly enhance the overall sustainability of HOCl utilization.

By expanding the reach of HOCl through digital innovations, we can not only improve its efficacy and accessibility but also substantially reduce its environmental impact. These technological advancements pave the way for a more sustainable and responsible use of this powerful disinfectant, aligning its application with global environmental conservation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!