The Future of Hypochlorous Acid in Integrated Pest Management

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL in IPM: Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising solution in the field of Integrated Pest Management (IPM), offering a sustainable and eco-friendly approach to pest control. The evolution of HOCl in IPM can be traced back to the early 2000s when researchers began exploring alternatives to conventional pesticides. This natural compound, produced by the human immune system to fight infections, has gained attention for its potential to revolutionize agricultural practices and pest management strategies.

The primary objective of incorporating HOCl into IPM is to develop a more effective and environmentally responsible method of pest control. By harnessing the power of this naturally occurring substance, researchers aim to reduce reliance on synthetic pesticides, minimize environmental impact, and enhance crop yields. The integration of HOCl into IPM aligns with the growing global demand for sustainable agricultural practices and food safety.

Over the past two decades, the technology surrounding HOCl production and application has advanced significantly. Initial challenges included stability issues and limited shelf life, which hindered widespread adoption. However, recent breakthroughs in stabilization techniques and delivery systems have paved the way for more practical and efficient use of HOCl in agricultural settings.

The current landscape of HOCl in IPM is characterized by a surge in research and development activities. Scientists are exploring various aspects of HOCl application, including its efficacy against different pest species, optimal concentrations for various crops, and potential synergies with other IPM strategies. The goal is to create a comprehensive pest management approach that leverages HOCl's unique properties while minimizing any potential drawbacks.

As the agricultural sector faces increasing pressure to reduce chemical inputs and adopt more sustainable practices, HOCl presents a compelling alternative. Its non-toxic nature, broad-spectrum antimicrobial properties, and ability to break down into harmless byproducts make it an attractive option for both conventional and organic farming systems. The future of HOCl in IPM holds promise for addressing key challenges in global food production, including pest resistance, environmental degradation, and food safety concerns.

The technological trajectory of HOCl in IPM is expected to focus on enhancing its stability, improving application methods, and expanding its range of uses. Researchers are also investigating the potential of HOCl in post-harvest treatments, seed disinfection, and soil health management. As the body of knowledge grows, it is anticipated that HOCl will play an increasingly significant role in shaping the future of sustainable agriculture and pest management practices worldwide.

The primary objective of incorporating HOCl into IPM is to develop a more effective and environmentally responsible method of pest control. By harnessing the power of this naturally occurring substance, researchers aim to reduce reliance on synthetic pesticides, minimize environmental impact, and enhance crop yields. The integration of HOCl into IPM aligns with the growing global demand for sustainable agricultural practices and food safety.

Over the past two decades, the technology surrounding HOCl production and application has advanced significantly. Initial challenges included stability issues and limited shelf life, which hindered widespread adoption. However, recent breakthroughs in stabilization techniques and delivery systems have paved the way for more practical and efficient use of HOCl in agricultural settings.

The current landscape of HOCl in IPM is characterized by a surge in research and development activities. Scientists are exploring various aspects of HOCl application, including its efficacy against different pest species, optimal concentrations for various crops, and potential synergies with other IPM strategies. The goal is to create a comprehensive pest management approach that leverages HOCl's unique properties while minimizing any potential drawbacks.

As the agricultural sector faces increasing pressure to reduce chemical inputs and adopt more sustainable practices, HOCl presents a compelling alternative. Its non-toxic nature, broad-spectrum antimicrobial properties, and ability to break down into harmless byproducts make it an attractive option for both conventional and organic farming systems. The future of HOCl in IPM holds promise for addressing key challenges in global food production, including pest resistance, environmental degradation, and food safety concerns.

The technological trajectory of HOCl in IPM is expected to focus on enhancing its stability, improving application methods, and expanding its range of uses. Researchers are also investigating the potential of HOCl in post-harvest treatments, seed disinfection, and soil health management. As the body of knowledge grows, it is anticipated that HOCl will play an increasingly significant role in shaping the future of sustainable agriculture and pest management practices worldwide.

Market Analysis for HOCL-based Pest Control

The market for HOCL-based pest control solutions is experiencing significant growth, driven by increasing demand for sustainable and environmentally friendly agricultural practices. As consumers become more conscious of food safety and environmental impact, there is a growing preference for chemical-free or reduced-chemical pest management strategies. This shift in consumer behavior is creating new opportunities for HOCL-based products in the integrated pest management (IPM) sector.

The global IPM market is projected to expand at a compound annual growth rate (CAGR) of over 6% in the coming years, with HOCL-based solutions poised to capture a substantial share of this growth. Factors contributing to this trend include stricter regulations on conventional pesticides, rising organic farming practices, and the need for more effective and sustainable pest control methods in both agriculture and urban settings.

In the agricultural sector, HOCL-based pest control is gaining traction due to its broad-spectrum efficacy against various pests and pathogens, coupled with its low environmental impact. Large-scale farming operations are increasingly adopting HOCL solutions as part of their IPM strategies, particularly in high-value crops such as fruits, vegetables, and ornamentals. The horticulture industry is also showing strong interest in HOCL-based products for greenhouse and nursery applications.

Urban pest management represents another significant market opportunity for HOCL-based solutions. With growing concerns about the use of harsh chemicals in residential and commercial spaces, there is a rising demand for safer alternatives that can effectively control pests without compromising human health or environmental safety. This trend is particularly evident in sensitive environments such as schools, healthcare facilities, and food processing plants.

The market landscape for HOCL-based pest control is characterized by a mix of established agrochemical companies and innovative startups. Major players are investing in research and development to improve the stability, efficacy, and application methods of HOCL formulations. Collaborations between technology providers and pest control service companies are also emerging, aiming to develop integrated solutions that combine HOCL products with smart monitoring and application systems.

Geographically, North America and Europe are currently the leading markets for HOCL-based pest control, driven by stringent regulations and high adoption rates of sustainable agricultural practices. However, Asia-Pacific is expected to witness the fastest growth in the coming years, fueled by increasing awareness of food safety, rapid urbanization, and government initiatives promoting eco-friendly pest management solutions.

Despite the promising market outlook, challenges remain in scaling up HOCL-based pest control solutions. These include the need for improved storage and handling technologies to maintain product stability, as well as the development of more efficient application methods to enhance efficacy and reduce costs. Addressing these challenges will be crucial for realizing the full market potential of HOCL-based pest control in the evolving landscape of integrated pest management.

The global IPM market is projected to expand at a compound annual growth rate (CAGR) of over 6% in the coming years, with HOCL-based solutions poised to capture a substantial share of this growth. Factors contributing to this trend include stricter regulations on conventional pesticides, rising organic farming practices, and the need for more effective and sustainable pest control methods in both agriculture and urban settings.

In the agricultural sector, HOCL-based pest control is gaining traction due to its broad-spectrum efficacy against various pests and pathogens, coupled with its low environmental impact. Large-scale farming operations are increasingly adopting HOCL solutions as part of their IPM strategies, particularly in high-value crops such as fruits, vegetables, and ornamentals. The horticulture industry is also showing strong interest in HOCL-based products for greenhouse and nursery applications.

Urban pest management represents another significant market opportunity for HOCL-based solutions. With growing concerns about the use of harsh chemicals in residential and commercial spaces, there is a rising demand for safer alternatives that can effectively control pests without compromising human health or environmental safety. This trend is particularly evident in sensitive environments such as schools, healthcare facilities, and food processing plants.

The market landscape for HOCL-based pest control is characterized by a mix of established agrochemical companies and innovative startups. Major players are investing in research and development to improve the stability, efficacy, and application methods of HOCL formulations. Collaborations between technology providers and pest control service companies are also emerging, aiming to develop integrated solutions that combine HOCL products with smart monitoring and application systems.

Geographically, North America and Europe are currently the leading markets for HOCL-based pest control, driven by stringent regulations and high adoption rates of sustainable agricultural practices. However, Asia-Pacific is expected to witness the fastest growth in the coming years, fueled by increasing awareness of food safety, rapid urbanization, and government initiatives promoting eco-friendly pest management solutions.

Despite the promising market outlook, challenges remain in scaling up HOCL-based pest control solutions. These include the need for improved storage and handling technologies to maintain product stability, as well as the development of more efficient application methods to enhance efficacy and reduce costs. Addressing these challenges will be crucial for realizing the full market potential of HOCL-based pest control in the evolving landscape of integrated pest management.

Current Challenges in HOCL Application for IPM

The application of Hypochlorous Acid (HOCl) in Integrated Pest Management (IPM) faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the stability of HOCl solutions. Due to its reactive nature, HOCl tends to degrade rapidly, especially when exposed to light, heat, or organic matter. This instability limits its shelf life and effectiveness in field applications, requiring frequent preparation and application, which can be both time-consuming and costly for farmers and pest control professionals.

Another challenge lies in the concentration control of HOCl solutions. The efficacy of HOCl as a pesticide is highly dependent on its concentration, with too low concentrations being ineffective and too high concentrations potentially causing phytotoxicity or environmental concerns. Maintaining the optimal concentration throughout the application process is difficult due to factors such as dilution from irrigation water, evaporation, and interaction with soil components.

The pH sensitivity of HOCl presents an additional hurdle. The biocidal activity of HOCl is most potent at a slightly acidic pH range (around 5.5-6.5). However, maintaining this optimal pH in diverse agricultural environments with varying soil types and water qualities can be challenging. Fluctuations in pH can significantly reduce the effectiveness of HOCl treatments, leading to inconsistent pest control results.

Furthermore, the broad-spectrum nature of HOCl's antimicrobial activity, while beneficial in many scenarios, can also be a drawback in IPM. There are concerns about its potential impact on beneficial microorganisms in the soil and on plant surfaces, which play crucial roles in plant health and natural pest suppression. Striking a balance between effective pest control and preservation of beneficial microbial communities remains a significant challenge.

The application method and equipment for HOCl in IPM settings also present technical difficulties. Traditional spraying equipment may not be suitable for HOCl application due to its corrosive nature and specific concentration requirements. Developing specialized, cost-effective application systems that ensure uniform distribution and minimal degradation of HOCl during application is an ongoing challenge.

Lastly, regulatory hurdles and lack of standardized protocols for HOCl use in agriculture contribute to the challenges. The classification and registration of HOCl as a pesticide vary across different regions, leading to inconsistencies in its approved uses and application guidelines. This regulatory uncertainty can deter manufacturers and farmers from investing in HOCl-based IPM solutions, slowing down its integration into mainstream pest management practices.

Another challenge lies in the concentration control of HOCl solutions. The efficacy of HOCl as a pesticide is highly dependent on its concentration, with too low concentrations being ineffective and too high concentrations potentially causing phytotoxicity or environmental concerns. Maintaining the optimal concentration throughout the application process is difficult due to factors such as dilution from irrigation water, evaporation, and interaction with soil components.

The pH sensitivity of HOCl presents an additional hurdle. The biocidal activity of HOCl is most potent at a slightly acidic pH range (around 5.5-6.5). However, maintaining this optimal pH in diverse agricultural environments with varying soil types and water qualities can be challenging. Fluctuations in pH can significantly reduce the effectiveness of HOCl treatments, leading to inconsistent pest control results.

Furthermore, the broad-spectrum nature of HOCl's antimicrobial activity, while beneficial in many scenarios, can also be a drawback in IPM. There are concerns about its potential impact on beneficial microorganisms in the soil and on plant surfaces, which play crucial roles in plant health and natural pest suppression. Striking a balance between effective pest control and preservation of beneficial microbial communities remains a significant challenge.

The application method and equipment for HOCl in IPM settings also present technical difficulties. Traditional spraying equipment may not be suitable for HOCl application due to its corrosive nature and specific concentration requirements. Developing specialized, cost-effective application systems that ensure uniform distribution and minimal degradation of HOCl during application is an ongoing challenge.

Lastly, regulatory hurdles and lack of standardized protocols for HOCl use in agriculture contribute to the challenges. The classification and registration of HOCl as a pesticide vary across different regions, leading to inconsistencies in its approved uses and application guidelines. This regulatory uncertainty can deter manufacturers and farmers from investing in HOCl-based IPM solutions, slowing down its integration into mainstream pest management practices.

Existing HOCL Solutions for Pest Management

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization and formulation of hypochlorous acid solutions: Techniques for stabilizing hypochlorous acid solutions to extend their shelf life and maintain efficacy are crucial. This includes pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation and ensure consistent performance in various applications.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in wound care, dermatology, and respiratory treatments. Its ability to promote healing, reduce inflammation, and combat infections without harming healthy tissue makes it valuable in medical settings for treating various conditions.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation, wastewater treatment, and industrial cleaning processes. Its eco-friendly nature and effectiveness in breaking down contaminants make it suitable for large-scale applications in various industries.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

Researchers have developed various stabilization techniques to prolong the shelf life and maintain the efficacy of hypochlorous acid solutions. These methods may include pH adjustment, addition of stabilizing agents, or specialized packaging to prevent degradation and ensure consistent performance over time.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid has found applications in medical and therapeutic settings, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in environmental remediation and industrial processes due to its strong oxidizing properties. Applications include water treatment, air purification, and surface decontamination in various industries, offering an eco-friendly alternative to harsher chemicals.Expand Specific Solutions

Key Players in HOCL and IPM Industries

The future of hypochlorous acid in integrated pest management is entering a dynamic phase, with the market poised for significant growth. The technology is transitioning from early adoption to mainstream acceptance, driven by increasing demand for sustainable and eco-friendly pest control solutions. Key players like Industrie De Nora, Annihilare Medical Systems, and PI Industries are advancing the technology's applications in agriculture and public health. The market size is expanding rapidly, with projections indicating substantial growth over the next decade. While the technology is relatively mature, ongoing research by companies such as Shenyang Research Institute of Chemical Industry and Central China Normal University is focused on improving efficacy and expanding applications, suggesting that hypochlorous acid's full potential in pest management is yet to be realized.

Industrie De Nora SpA

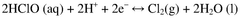

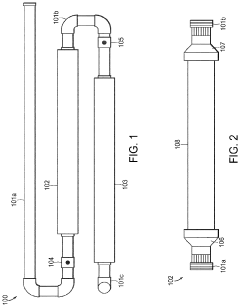

Technical Solution: Industrie De Nora has developed an advanced electrochemical cell technology for on-site generation of hypochlorous acid. Their system, designed for large-scale agricultural operations, produces HOCl through the electrolysis of salt water, ensuring a constant supply of fresh, highly effective HOCl solution[5]. The company's technology allows for precise control over the HOCl concentration, typically maintaining it between 200-500 ppm for optimal pest control efficacy[6]. De Nora's system also incorporates a proprietary membrane technology that enhances the purity of the generated HOCl, minimizing by-products and increasing its effectiveness against a wide range of agricultural pests. The on-site generation capability eliminates transportation and storage issues associated with pre-made HOCl solutions.

Strengths: Consistent supply of fresh HOCl, customizable concentration levels, and reduced reliance on chemical transport. Weaknesses: High initial setup costs and the need for technical expertise to operate and maintain the system.

Jiangsu Yangnong Chemical Co., Ltd.

Technical Solution: Jiangsu Yangnong Chemical has focused on developing HOCl-based formulations specifically tailored for integrated pest management in greenhouse environments. Their approach combines HOCl with natural plant extracts to create a synergistic effect that enhances pest control while promoting plant health. The company's research has shown that their HOCl formulations, when combined with specific botanical extracts, can increase pest mortality rates by up to 30% compared to HOCl alone[7]. Additionally, Jiangsu Yangnong has developed a novel misting system for HOCl application in greenhouses, which maintains a consistent low-level presence of HOCl in the air, providing continuous protection against airborne pathogens and pests[8]. This system has been shown to reduce the incidence of fungal diseases by up to 40% in controlled trials.

Strengths: Enhanced efficacy through synergistic formulations, specialized for greenhouse use, and continuous protection capabilities. Weaknesses: Limited applicability outside of controlled environments and potential phytotoxicity concerns with some plant species.

Innovative HOCL Formulations for IPM

The compounds to combat fungal and bacterial with plant disease

PatentWO2025037126A1

Innovation

- The use of hypochlorous acid-based compounds, combined with nonionic surfactants, as a controlled oxidizing agent to combat fungal and bacterial diseases, including Pseudomonas syringae, without leaving residues and with minimal environmental impact.

Mixing device

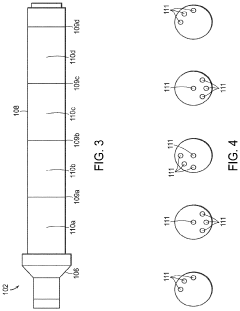

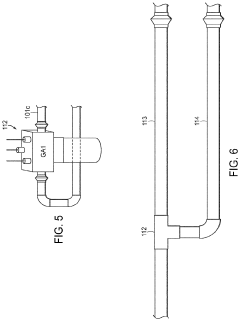

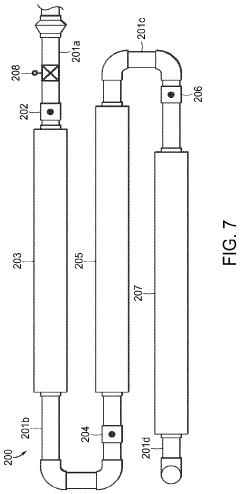

PatentActiveUS20210346854A1

Innovation

- A mixing device that produces a stable form of HOCl by creating fluidic vortices within a chamber with apertures, allowing controlled protonation and hypochlorite ion reaction in an air-free environment, using compounds like acetic acid and NaOCl, and maintaining pH stability through buffering, enabling longer storage and reduced need for onsite generation.

Environmental Impact of HOCL in Agriculture

The use of hypochlorous acid (HOCl) in integrated pest management (IPM) presents both opportunities and challenges for agricultural environmental impact. As a powerful oxidizing agent, HOCl has shown significant potential in controlling various pests and pathogens without leaving harmful residues, aligning with sustainable farming practices. However, its widespread adoption necessitates a thorough examination of its environmental implications.

HOCl's primary environmental advantage lies in its rapid decomposition into harmless byproducts - water, oxygen, and salt. This characteristic minimizes the risk of long-term soil and water contamination, a common concern with traditional pesticides. Furthermore, its efficacy at low concentrations reduces the overall chemical load applied to agricultural systems, potentially decreasing the environmental footprint of pest management practices.

The production of HOCl through electrolysis of saltwater solutions offers an environmentally friendly alternative to synthetic pesticide manufacturing. This process requires minimal raw materials and energy inputs, contributing to a reduced carbon footprint compared to conventional pest control methods. Additionally, on-site generation capabilities can minimize transportation-related emissions associated with pesticide distribution.

However, the environmental impact of HOCl in agriculture is not without considerations. While generally safe, high concentrations or improper application could temporarily alter soil pH or affect beneficial microorganisms. Careful management and precise application techniques are crucial to mitigate these potential risks and maintain ecological balance in agricultural ecosystems.

The use of HOCl in irrigation systems presents both opportunities and challenges. While it can effectively disinfect water and prevent the spread of waterborne pathogens, improper dosing could impact aquatic ecosystems if discharged into natural water bodies. Implementing closed-loop systems and monitoring protocols is essential to harness the benefits while minimizing environmental risks.

As HOCl gains traction in IPM strategies, its impact on biodiversity and non-target organisms requires ongoing assessment. Initial studies suggest minimal adverse effects on beneficial insects and soil fauna when used as directed, but long-term ecological studies are necessary to fully understand its role in agroecosystems.

The potential for HOCl to reduce reliance on conventional pesticides could lead to significant positive environmental outcomes. By minimizing the use of persistent and bioaccumulative chemicals, HOCl-based IPM strategies may contribute to improved soil health, reduced water pollution, and enhanced ecosystem resilience. However, realizing these benefits requires careful integration into holistic pest management approaches that prioritize ecological balance and sustainability.

HOCl's primary environmental advantage lies in its rapid decomposition into harmless byproducts - water, oxygen, and salt. This characteristic minimizes the risk of long-term soil and water contamination, a common concern with traditional pesticides. Furthermore, its efficacy at low concentrations reduces the overall chemical load applied to agricultural systems, potentially decreasing the environmental footprint of pest management practices.

The production of HOCl through electrolysis of saltwater solutions offers an environmentally friendly alternative to synthetic pesticide manufacturing. This process requires minimal raw materials and energy inputs, contributing to a reduced carbon footprint compared to conventional pest control methods. Additionally, on-site generation capabilities can minimize transportation-related emissions associated with pesticide distribution.

However, the environmental impact of HOCl in agriculture is not without considerations. While generally safe, high concentrations or improper application could temporarily alter soil pH or affect beneficial microorganisms. Careful management and precise application techniques are crucial to mitigate these potential risks and maintain ecological balance in agricultural ecosystems.

The use of HOCl in irrigation systems presents both opportunities and challenges. While it can effectively disinfect water and prevent the spread of waterborne pathogens, improper dosing could impact aquatic ecosystems if discharged into natural water bodies. Implementing closed-loop systems and monitoring protocols is essential to harness the benefits while minimizing environmental risks.

As HOCl gains traction in IPM strategies, its impact on biodiversity and non-target organisms requires ongoing assessment. Initial studies suggest minimal adverse effects on beneficial insects and soil fauna when used as directed, but long-term ecological studies are necessary to fully understand its role in agroecosystems.

The potential for HOCl to reduce reliance on conventional pesticides could lead to significant positive environmental outcomes. By minimizing the use of persistent and bioaccumulative chemicals, HOCl-based IPM strategies may contribute to improved soil health, reduced water pollution, and enhanced ecosystem resilience. However, realizing these benefits requires careful integration into holistic pest management approaches that prioritize ecological balance and sustainability.

Regulatory Framework for HOCL Use in IPM

The regulatory framework for hypochlorous acid (HOCL) use in Integrated Pest Management (IPM) is a complex and evolving landscape. As HOCL gains traction as a potential eco-friendly alternative in pest control, regulatory bodies are adapting to ensure its safe and effective implementation.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCL for pest management applications. The EPA has classified HOCL as a minimum risk pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), which exempts it from certain registration requirements. This classification facilitates its adoption in IPM strategies while maintaining oversight on its use and distribution.

The European Union, through the European Chemicals Agency (ECHA), has also recognized HOCL's potential in pest management. Under the Biocidal Products Regulation (BPR), HOCL is listed as an active substance for various product types, including disinfectants and pest control agents. This regulatory framework ensures that HOCL-based products meet stringent safety and efficacy standards before entering the market.

In Asia, countries like Japan and South Korea have established their own regulatory pathways for HOCL in pest management. The Japanese Ministry of Agriculture, Forestry and Fisheries (MAFF) has approved HOCL for use in certain agricultural applications, while South Korea's Rural Development Administration (RDA) has included it in their list of approved biopesticides.

Globally, the Food and Agriculture Organization (FAO) and World Health Organization (WHO) have been instrumental in developing international guidelines for the use of HOCL in food production and pest management. These guidelines serve as a reference for countries developing their own regulatory frameworks, promoting harmonization in global standards.

As research continues to demonstrate HOCL's efficacy and safety profile, regulatory bodies are likely to refine their approaches. This may include expanding approved applications, adjusting concentration limits, or implementing new monitoring protocols. The challenge for regulators is to balance the promotion of innovative, sustainable pest management solutions with the need to protect human health and the environment.

Stakeholders in the IPM industry, including manufacturers, farmers, and pest control professionals, must stay informed about these evolving regulations. Compliance with current and emerging regulatory requirements will be crucial for the successful integration of HOCL into IPM strategies. As the regulatory landscape continues to evolve, it is expected that clearer, more comprehensive frameworks will emerge, potentially accelerating the adoption of HOCL in IPM practices worldwide.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCL for pest management applications. The EPA has classified HOCL as a minimum risk pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), which exempts it from certain registration requirements. This classification facilitates its adoption in IPM strategies while maintaining oversight on its use and distribution.

The European Union, through the European Chemicals Agency (ECHA), has also recognized HOCL's potential in pest management. Under the Biocidal Products Regulation (BPR), HOCL is listed as an active substance for various product types, including disinfectants and pest control agents. This regulatory framework ensures that HOCL-based products meet stringent safety and efficacy standards before entering the market.

In Asia, countries like Japan and South Korea have established their own regulatory pathways for HOCL in pest management. The Japanese Ministry of Agriculture, Forestry and Fisheries (MAFF) has approved HOCL for use in certain agricultural applications, while South Korea's Rural Development Administration (RDA) has included it in their list of approved biopesticides.

Globally, the Food and Agriculture Organization (FAO) and World Health Organization (WHO) have been instrumental in developing international guidelines for the use of HOCL in food production and pest management. These guidelines serve as a reference for countries developing their own regulatory frameworks, promoting harmonization in global standards.

As research continues to demonstrate HOCL's efficacy and safety profile, regulatory bodies are likely to refine their approaches. This may include expanding approved applications, adjusting concentration limits, or implementing new monitoring protocols. The challenge for regulators is to balance the promotion of innovative, sustainable pest management solutions with the need to protect human health and the environment.

Stakeholders in the IPM industry, including manufacturers, farmers, and pest control professionals, must stay informed about these evolving regulations. Compliance with current and emerging regulatory requirements will be crucial for the successful integration of HOCL into IPM strategies. As the regulatory landscape continues to evolve, it is expected that clearer, more comprehensive frameworks will emerge, potentially accelerating the adoption of HOCL in IPM practices worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!