A Study of Hypochlorous Acid Concentration in Disinfection

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Disinfection Background and Objectives

Hypochlorous acid (HOCl) has emerged as a powerful disinfectant with a rich history dating back to its discovery in the early 19th century. Initially recognized for its potent antimicrobial properties, HOCl has since become a subject of intense research and development in the field of disinfection. This naturally occurring molecule, produced by the human immune system to fight infections, has gained significant attention in recent years due to its effectiveness against a wide range of pathogens, including bacteria, viruses, and fungi.

The evolution of HOCl as a disinfectant has been marked by significant advancements in production methods, stability enhancement, and application techniques. Early challenges in maintaining HOCl stability have been largely overcome through innovative formulation strategies and improved manufacturing processes. These developments have paved the way for HOCl's increased adoption across various sectors, including healthcare, food processing, and water treatment.

In the context of global health challenges, such as the recent COVID-19 pandemic, the importance of effective and safe disinfection methods has been brought to the forefront. HOCl's unique properties, including its broad-spectrum efficacy and low toxicity profile, position it as a promising solution to meet these evolving disinfection needs. The growing emphasis on environmentally friendly and sustainable disinfection methods further underscores the relevance of HOCl in current and future disinfection strategies.

The primary objective of this technical research report is to conduct a comprehensive study on the role of hypochlorous acid concentration in disinfection efficacy. This investigation aims to elucidate the optimal concentration ranges for various applications, considering factors such as target pathogens, surface types, and environmental conditions. By examining the relationship between HOCl concentration and its disinfection performance, we seek to establish evidence-based guidelines for its effective use across different sectors.

Additionally, this study intends to explore the latest technological advancements in HOCl production, stabilization, and application methods. By analyzing current research trends and emerging technologies, we aim to identify potential areas for innovation and improvement in HOCl-based disinfection systems. This includes investigating novel delivery mechanisms, synergistic combinations with other disinfectants, and strategies to enhance HOCl's long-term stability without compromising its efficacy.

Furthermore, this research seeks to address the growing demand for sustainable and eco-friendly disinfection solutions. By evaluating HOCl's environmental impact and comparing it with traditional disinfectants, we aim to provide insights into its potential as a green alternative in various disinfection applications. This aspect of the study will contribute to the broader goal of developing disinfection strategies that balance efficacy, safety, and environmental responsibility.

The evolution of HOCl as a disinfectant has been marked by significant advancements in production methods, stability enhancement, and application techniques. Early challenges in maintaining HOCl stability have been largely overcome through innovative formulation strategies and improved manufacturing processes. These developments have paved the way for HOCl's increased adoption across various sectors, including healthcare, food processing, and water treatment.

In the context of global health challenges, such as the recent COVID-19 pandemic, the importance of effective and safe disinfection methods has been brought to the forefront. HOCl's unique properties, including its broad-spectrum efficacy and low toxicity profile, position it as a promising solution to meet these evolving disinfection needs. The growing emphasis on environmentally friendly and sustainable disinfection methods further underscores the relevance of HOCl in current and future disinfection strategies.

The primary objective of this technical research report is to conduct a comprehensive study on the role of hypochlorous acid concentration in disinfection efficacy. This investigation aims to elucidate the optimal concentration ranges for various applications, considering factors such as target pathogens, surface types, and environmental conditions. By examining the relationship between HOCl concentration and its disinfection performance, we seek to establish evidence-based guidelines for its effective use across different sectors.

Additionally, this study intends to explore the latest technological advancements in HOCl production, stabilization, and application methods. By analyzing current research trends and emerging technologies, we aim to identify potential areas for innovation and improvement in HOCl-based disinfection systems. This includes investigating novel delivery mechanisms, synergistic combinations with other disinfectants, and strategies to enhance HOCl's long-term stability without compromising its efficacy.

Furthermore, this research seeks to address the growing demand for sustainable and eco-friendly disinfection solutions. By evaluating HOCl's environmental impact and comparing it with traditional disinfectants, we aim to provide insights into its potential as a green alternative in various disinfection applications. This aspect of the study will contribute to the broader goal of developing disinfection strategies that balance efficacy, safety, and environmental responsibility.

Market Analysis for HOCl Disinfectants

The global market for hypochlorous acid (HOCl) disinfectants has experienced significant growth in recent years, driven by increasing awareness of hygiene and sanitation, especially in the wake of the COVID-19 pandemic. HOCl disinfectants have gained traction across various sectors due to their effectiveness, safety, and eco-friendly properties.

In the healthcare sector, HOCl disinfectants have seen a surge in demand for hospital-acquired infection control and general surface disinfection. The healthcare industry remains a key driver of market growth, with stringent regulations on infection prevention fueling adoption.

The food and beverage industry has also emerged as a major consumer of HOCl disinfectants. Increasing concerns about foodborne illnesses and the need for safe food processing environments have led to widespread use in food production facilities, restaurants, and packaging plants.

Water treatment applications represent another significant market segment for HOCl disinfectants. Municipal water treatment plants and industrial water systems are increasingly adopting HOCl solutions for their efficacy in eliminating pathogens without harmful byproducts.

The consumer market for HOCl disinfectants has expanded rapidly, with products ranging from household cleaners to personal care items. This growth is attributed to rising health consciousness among consumers and the preference for natural, non-toxic disinfection solutions.

Geographically, North America and Europe lead the HOCl disinfectant market, owing to advanced healthcare infrastructure and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, improving healthcare facilities, and increasing awareness of hygiene practices.

Market trends indicate a shift towards sustainable and environmentally friendly disinfection solutions, positioning HOCl products favorably against traditional chemical disinfectants. The ease of production and versatility of HOCl solutions have also contributed to their market expansion.

Challenges in the HOCl disinfectant market include educating consumers about its benefits compared to conventional disinfectants and addressing stability issues in some formulations. However, ongoing research and development efforts are focused on improving product stability and shelf life, which is expected to further boost market growth.

The HOCl disinfectant market is projected to continue its upward trajectory, with increasing applications across various industries and growing consumer acceptance. As the global focus on health and hygiene intensifies, HOCl disinfectants are poised to play a crucial role in meeting the rising demand for effective, safe, and sustainable disinfection solutions.

In the healthcare sector, HOCl disinfectants have seen a surge in demand for hospital-acquired infection control and general surface disinfection. The healthcare industry remains a key driver of market growth, with stringent regulations on infection prevention fueling adoption.

The food and beverage industry has also emerged as a major consumer of HOCl disinfectants. Increasing concerns about foodborne illnesses and the need for safe food processing environments have led to widespread use in food production facilities, restaurants, and packaging plants.

Water treatment applications represent another significant market segment for HOCl disinfectants. Municipal water treatment plants and industrial water systems are increasingly adopting HOCl solutions for their efficacy in eliminating pathogens without harmful byproducts.

The consumer market for HOCl disinfectants has expanded rapidly, with products ranging from household cleaners to personal care items. This growth is attributed to rising health consciousness among consumers and the preference for natural, non-toxic disinfection solutions.

Geographically, North America and Europe lead the HOCl disinfectant market, owing to advanced healthcare infrastructure and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, improving healthcare facilities, and increasing awareness of hygiene practices.

Market trends indicate a shift towards sustainable and environmentally friendly disinfection solutions, positioning HOCl products favorably against traditional chemical disinfectants. The ease of production and versatility of HOCl solutions have also contributed to their market expansion.

Challenges in the HOCl disinfectant market include educating consumers about its benefits compared to conventional disinfectants and addressing stability issues in some formulations. However, ongoing research and development efforts are focused on improving product stability and shelf life, which is expected to further boost market growth.

The HOCl disinfectant market is projected to continue its upward trajectory, with increasing applications across various industries and growing consumer acceptance. As the global focus on health and hygiene intensifies, HOCl disinfectants are poised to play a crucial role in meeting the rising demand for effective, safe, and sustainable disinfection solutions.

Current State and Challenges in HOCl Production

The production of hypochlorous acid (HOCl) has seen significant advancements in recent years, driven by its increasing demand as an effective and environmentally friendly disinfectant. Currently, the most common method for HOCl production is through electrolysis of salt water, which allows for on-site generation of the solution. This process has been refined to improve efficiency and consistency in HOCl concentration, typically ranging from 200 to 500 parts per million (ppm).

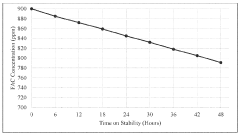

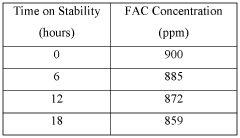

Despite these improvements, several challenges persist in HOCl production. One of the primary issues is maintaining stability of the HOCl solution over time. The compound tends to degrade rapidly, especially when exposed to light or heat, which limits its shelf life and effectiveness. This instability necessitates frequent production or the use of stabilizing agents, which can impact the purity and efficacy of the final product.

Another significant challenge is achieving precise control over HOCl concentration during production. Variations in water quality, salt concentration, and electrolysis parameters can lead to inconsistencies in the final product. This variability can affect the disinfection efficacy and safety of the solution, particularly in sensitive applications such as healthcare or food processing.

The scalability of HOCl production also presents challenges, especially for large-scale industrial applications. While small-scale on-site generation systems are relatively common, scaling up production while maintaining consistent quality and concentration remains a technical hurdle. This limitation has implications for widespread adoption in sectors requiring large volumes of disinfectant.

Environmental concerns also play a role in current HOCl production challenges. Although HOCl itself is considered environmentally friendly, the electrolysis process can be energy-intensive. Improving the energy efficiency of production systems is an ongoing area of research and development in the field.

Additionally, the raw materials used in HOCl production, particularly the quality and source of salt, can impact the final product. Impurities in the salt can lead to unwanted by-products or affect the stability of the HOCl solution. Ensuring a consistent and high-quality supply of raw materials is crucial for maintaining product standards.

Regulatory compliance and standardization present another set of challenges in HOCl production. Different regions and industries may have varying requirements for disinfectant concentrations and purity levels. Meeting these diverse standards while maintaining cost-effectiveness in production is an ongoing challenge for manufacturers.

Despite these improvements, several challenges persist in HOCl production. One of the primary issues is maintaining stability of the HOCl solution over time. The compound tends to degrade rapidly, especially when exposed to light or heat, which limits its shelf life and effectiveness. This instability necessitates frequent production or the use of stabilizing agents, which can impact the purity and efficacy of the final product.

Another significant challenge is achieving precise control over HOCl concentration during production. Variations in water quality, salt concentration, and electrolysis parameters can lead to inconsistencies in the final product. This variability can affect the disinfection efficacy and safety of the solution, particularly in sensitive applications such as healthcare or food processing.

The scalability of HOCl production also presents challenges, especially for large-scale industrial applications. While small-scale on-site generation systems are relatively common, scaling up production while maintaining consistent quality and concentration remains a technical hurdle. This limitation has implications for widespread adoption in sectors requiring large volumes of disinfectant.

Environmental concerns also play a role in current HOCl production challenges. Although HOCl itself is considered environmentally friendly, the electrolysis process can be energy-intensive. Improving the energy efficiency of production systems is an ongoing area of research and development in the field.

Additionally, the raw materials used in HOCl production, particularly the quality and source of salt, can impact the final product. Impurities in the salt can lead to unwanted by-products or affect the stability of the HOCl solution. Ensuring a consistent and high-quality supply of raw materials is crucial for maintaining product standards.

Regulatory compliance and standardization present another set of challenges in HOCl production. Different regions and industries may have varying requirements for disinfectant concentrations and purity levels. Meeting these diverse standards while maintaining cost-effectiveness in production is an ongoing challenge for manufacturers.

Existing HOCl Concentration Methods

01 Concentration ranges for hypochlorous acid solutions

Various concentrations of hypochlorous acid solutions are used for different applications. The concentration can range from very low (parts per million) to higher levels, depending on the intended use. Lower concentrations are often used for disinfection and sanitization purposes, while higher concentrations may be employed for industrial or specialized applications.- Concentration ranges for hypochlorous acid solutions: Various concentrations of hypochlorous acid solutions are used for different applications. The concentration can range from very low (parts per million) to higher levels, depending on the intended use. Lower concentrations are often used for disinfection and sanitization purposes, while higher concentrations may be employed for industrial or specialized applications.

- Methods for producing specific concentrations of hypochlorous acid: Different techniques are employed to produce hypochlorous acid solutions with specific concentrations. These may include electrolysis of salt solutions, chemical reactions, or dilution of more concentrated solutions. The methods often involve precise control of parameters such as pH, temperature, and reactant ratios to achieve the desired concentration.

- Stabilization of hypochlorous acid solutions: Stabilizing hypochlorous acid solutions is crucial to maintain their effectiveness over time. Various additives and methods are used to prevent degradation and maintain the desired concentration. These may include pH adjustments, addition of stabilizing agents, or special packaging and storage conditions.

- Applications of hypochlorous acid at different concentrations: The concentration of hypochlorous acid is tailored for specific applications. Lower concentrations are often used in healthcare settings for wound care and disinfection. Higher concentrations may be used in water treatment, industrial cleaning, or as a precursor in chemical synthesis. The choice of concentration depends on factors such as efficacy, safety, and regulatory requirements.

- Measurement and control of hypochlorous acid concentration: Accurate measurement and control of hypochlorous acid concentration are essential for many applications. Various analytical methods and instruments are used to determine and monitor the concentration. These may include spectrophotometric techniques, electrochemical sensors, or titration methods. Automated systems may be employed for continuous monitoring and adjustment of concentration in industrial processes.

02 Methods for producing specific concentrations of hypochlorous acid

Different techniques are employed to produce hypochlorous acid solutions with specific concentrations. These may include electrolysis of salt water, chemical reactions, or dilution of more concentrated solutions. The methods often involve precise control of parameters such as pH, temperature, and reactant ratios to achieve the desired concentration.Expand Specific Solutions03 Stabilization of hypochlorous acid solutions

Stabilizing hypochlorous acid solutions is crucial to maintain their effectiveness over time. Various additives and processes are used to prevent degradation and maintain the desired concentration. This may include pH adjustment, addition of stabilizing agents, or special packaging and storage conditions.Expand Specific Solutions04 Applications of different hypochlorous acid concentrations

The concentration of hypochlorous acid is tailored for specific applications. Lower concentrations are often used in healthcare settings for wound care and disinfection. Higher concentrations may be used in water treatment, food processing, or industrial cleaning. The choice of concentration depends on factors such as efficacy, safety, and regulatory requirements.Expand Specific Solutions05 Measurement and monitoring of hypochlorous acid concentration

Accurate measurement and monitoring of hypochlorous acid concentration is essential for quality control and efficacy. Various analytical methods are used, including spectrophotometry, electrochemical sensors, and titration techniques. Real-time monitoring systems may be employed in industrial settings to ensure consistent concentration levels.Expand Specific Solutions

Key Players in HOCl Disinfectant Industry

The study of hypochlorous acid concentration in disinfection is currently in a growth phase, with increasing market demand driven by heightened awareness of hygiene and sanitation. The global market size for hypochlorous acid-based disinfectants is expanding, particularly in healthcare, food processing, and water treatment sectors. Technologically, the field is advancing rapidly, with companies like Annihilare Medical Systems and aquagroup AG developing innovative on-site generation systems. Established players such as Kao Corp. and Fresenius Medical Care are also investing in R&D to improve product efficacy and safety. The technology's maturity varies, with some companies focusing on traditional applications while others explore novel uses in air purification and sustainable disinfection solutions.

ANNIHILARE MEDICAL SYSTEMS, INC.

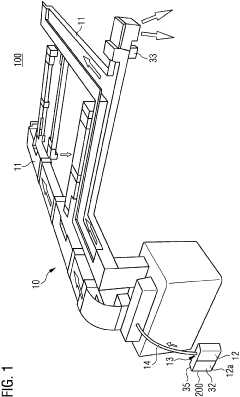

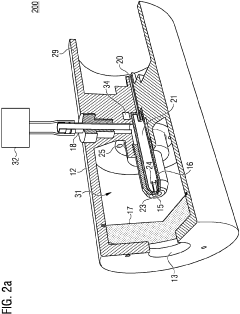

Technical Solution: ANNIHILARE MEDICAL SYSTEMS has developed an advanced hypochlorous acid (HOCl) generation system for disinfection purposes. Their technology utilizes electrochemical activation to produce a stable and highly effective HOCl solution with a concentration range of 200-500 ppm[1]. The system incorporates precise pH control mechanisms to maintain the optimal pH level of 5.5-6.5, ensuring maximum efficacy and stability of the HOCl solution[2]. Additionally, they have implemented a proprietary membrane technology that enhances the purity and consistency of the generated HOCl, reducing the formation of unwanted by-products[3]. The company's approach also includes real-time monitoring and adjustment of chlorine concentration, allowing for consistent and reliable disinfection performance across various applications.

Strengths: High-purity HOCl production, precise concentration control, and stable pH maintenance. Weaknesses: Potentially higher initial equipment costs and the need for specialized maintenance.

Kao Corp.

Technical Solution: Kao Corporation has made significant advancements in hypochlorous acid concentration studies for disinfection purposes. Their research has led to the development of a novel HOCl generation system that produces solutions with concentrations ranging from 20 to 300 ppm, suitable for various applications from household to industrial use[10]. Kao's technology incorporates a unique electrolysis process that optimizes the balance between chlorine species, resulting in a more stable and effective HOCl solution[11]. The company has also implemented an innovative pH buffering system that maintains the optimal acidity level for HOCl efficacy, even in challenging environmental conditions[12]. Furthermore, Kao has developed a proprietary formulation that enhances the penetration and surface coverage of their HOCl solutions, improving overall disinfection performance.

Strengths: Optimized chlorine species balance, enhanced solution stability, and improved surface coverage. Weaknesses: Potential limitations in achieving very high concentrations for specialized applications.

Core Innovations in HOCl Stability

Method for producing hypochlorous acid

PatentWO2023220374A1

Innovation

- A stable dry mix product kit containing premeasured calcium hypochlorite and cation exchange resins, allowing end-users to produce hypochlorous acid solutions on demand with adjustable concentration and pH, using a simple mixing process that does not require protective gear, and can be stored and diluted with tap water, reducing production and shipping costs.

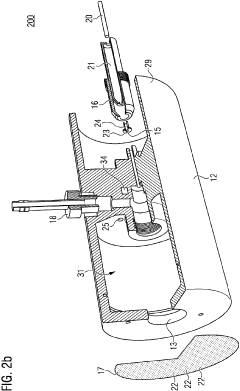

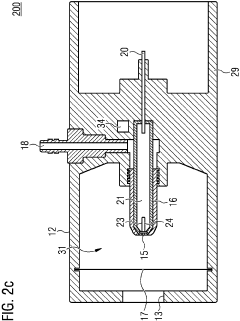

Method, apparatus and system for disinfecting air and/or surfaces

PatentActiveEP3954398A1

Innovation

- A method involving the dispersion of electrolyzed or sterilized water containing hypochlorous acid at a controlled rate to maintain a concentration between 0.05 mg/m³ and 10.0 mg/m³, allowing for continuous and homogeneous protection, adjustable based on environmental conditions, using a system with a micro sieve and air pump to produce a breathable aerosol, and optionally integrating with HVAC systems and filtration devices.

Regulatory Framework for Disinfectants

The regulatory framework for disinfectants plays a crucial role in ensuring the safety and efficacy of products containing hypochlorous acid (HOCl) for disinfection purposes. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing the registration and use of disinfectants under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

The EPA requires manufacturers to submit extensive data on the chemistry, toxicology, and efficacy of their disinfectant products before granting registration. For HOCl-based disinfectants, this includes demonstrating the stability of the active ingredient, its effectiveness against specific pathogens, and its safety profile for human and environmental exposure.

The Food and Drug Administration (FDA) also regulates certain applications of HOCl, particularly when used in medical devices or as an over-the-counter antiseptic. The FDA's regulatory framework focuses on ensuring the safety and effectiveness of these products for their intended use, often requiring clinical studies to support claims.

Internationally, regulatory approaches to HOCl disinfectants vary. The European Union, through the Biocidal Products Regulation (BPR), has established a harmonized system for the approval of active substances and authorization of biocidal products, including those containing HOCl. This regulation aims to ensure a high level of protection for human health and the environment while improving the functioning of the biocidal products market.

In Japan, the Ministry of Health, Labour and Welfare regulates disinfectants under the Pharmaceutical Affairs Law. HOCl products must meet specific criteria for efficacy and safety before being approved for use in healthcare settings or as consumer products.

The World Health Organization (WHO) provides guidelines on the use of disinfectants, including those containing HOCl, in various settings such as healthcare facilities and during public health emergencies. While not regulatory in nature, these guidelines often inform national policies and regulations.

Regulatory bodies typically require manufacturers to provide detailed information on the concentration of HOCl in their products, as well as stability data over the product's shelf life. This is particularly important given the potential for HOCl to degrade over time, which can affect its efficacy as a disinfectant.

Many regulatory frameworks also address the environmental impact of HOCl-based disinfectants. This includes assessing the potential for byproduct formation, effects on aquatic ecosystems, and the overall environmental fate of the compound when used at scale.

As research continues to elucidate the mechanisms of action and potential applications of HOCl, regulatory frameworks are likely to evolve. This may include updates to testing requirements, refinements in concentration guidelines, and potentially new categories of approved uses based on emerging scientific evidence.

The EPA requires manufacturers to submit extensive data on the chemistry, toxicology, and efficacy of their disinfectant products before granting registration. For HOCl-based disinfectants, this includes demonstrating the stability of the active ingredient, its effectiveness against specific pathogens, and its safety profile for human and environmental exposure.

The Food and Drug Administration (FDA) also regulates certain applications of HOCl, particularly when used in medical devices or as an over-the-counter antiseptic. The FDA's regulatory framework focuses on ensuring the safety and effectiveness of these products for their intended use, often requiring clinical studies to support claims.

Internationally, regulatory approaches to HOCl disinfectants vary. The European Union, through the Biocidal Products Regulation (BPR), has established a harmonized system for the approval of active substances and authorization of biocidal products, including those containing HOCl. This regulation aims to ensure a high level of protection for human health and the environment while improving the functioning of the biocidal products market.

In Japan, the Ministry of Health, Labour and Welfare regulates disinfectants under the Pharmaceutical Affairs Law. HOCl products must meet specific criteria for efficacy and safety before being approved for use in healthcare settings or as consumer products.

The World Health Organization (WHO) provides guidelines on the use of disinfectants, including those containing HOCl, in various settings such as healthcare facilities and during public health emergencies. While not regulatory in nature, these guidelines often inform national policies and regulations.

Regulatory bodies typically require manufacturers to provide detailed information on the concentration of HOCl in their products, as well as stability data over the product's shelf life. This is particularly important given the potential for HOCl to degrade over time, which can affect its efficacy as a disinfectant.

Many regulatory frameworks also address the environmental impact of HOCl-based disinfectants. This includes assessing the potential for byproduct formation, effects on aquatic ecosystems, and the overall environmental fate of the compound when used at scale.

As research continues to elucidate the mechanisms of action and potential applications of HOCl, regulatory frameworks are likely to evolve. This may include updates to testing requirements, refinements in concentration guidelines, and potentially new categories of approved uses based on emerging scientific evidence.

Environmental Impact of HOCl Production

The production of hypochlorous acid (HOCl) for disinfection purposes has significant environmental implications that warrant careful consideration. The primary method of HOCl production involves the electrolysis of salt water, which requires electricity and salt as key inputs. This process, while efficient, can contribute to energy consumption and associated carbon emissions, depending on the source of electricity used.

The environmental impact of HOCl production extends to water usage and potential salinization of water bodies. The electrolysis process requires a constant supply of water, which may strain local water resources in areas where water scarcity is a concern. Additionally, the discharge of salt-rich wastewater from production facilities can potentially affect aquatic ecosystems if not properly managed.

However, it is important to note that HOCl has several environmental advantages compared to traditional chemical disinfectants. HOCl breaks down into harmless components (water and salt) after use, leaving no toxic residues. This characteristic significantly reduces the environmental burden associated with persistent chemical pollutants often found in conventional disinfectants.

The production of HOCl also has implications for air quality. Unlike the manufacturing of many chemical disinfectants, HOCl production does not typically release volatile organic compounds (VOCs) or other air pollutants. This aspect contributes to its overall lower environmental footprint in terms of air quality impacts.

From a lifecycle perspective, the environmental impact of HOCl production should be weighed against its benefits in disinfection efficacy and safety. The ability to produce HOCl on-site reduces the need for transportation and packaging of disinfectants, potentially lowering the overall carbon footprint associated with disinfection practices.

Efforts to mitigate the environmental impact of HOCl production focus on improving energy efficiency in the electrolysis process and exploring renewable energy sources for production facilities. Research is also being conducted on optimizing salt and water usage to minimize resource consumption and waste generation.

In conclusion, while HOCl production does have environmental considerations, particularly in terms of energy and water use, its overall environmental profile is generally favorable when compared to many traditional disinfectants. The key to maximizing its environmental benefits lies in sustainable production practices and responsible use in disinfection applications.

The environmental impact of HOCl production extends to water usage and potential salinization of water bodies. The electrolysis process requires a constant supply of water, which may strain local water resources in areas where water scarcity is a concern. Additionally, the discharge of salt-rich wastewater from production facilities can potentially affect aquatic ecosystems if not properly managed.

However, it is important to note that HOCl has several environmental advantages compared to traditional chemical disinfectants. HOCl breaks down into harmless components (water and salt) after use, leaving no toxic residues. This characteristic significantly reduces the environmental burden associated with persistent chemical pollutants often found in conventional disinfectants.

The production of HOCl also has implications for air quality. Unlike the manufacturing of many chemical disinfectants, HOCl production does not typically release volatile organic compounds (VOCs) or other air pollutants. This aspect contributes to its overall lower environmental footprint in terms of air quality impacts.

From a lifecycle perspective, the environmental impact of HOCl production should be weighed against its benefits in disinfection efficacy and safety. The ability to produce HOCl on-site reduces the need for transportation and packaging of disinfectants, potentially lowering the overall carbon footprint associated with disinfection practices.

Efforts to mitigate the environmental impact of HOCl production focus on improving energy efficiency in the electrolysis process and exploring renewable energy sources for production facilities. Research is also being conducted on optimizing salt and water usage to minimize resource consumption and waste generation.

In conclusion, while HOCl production does have environmental considerations, particularly in terms of energy and water use, its overall environmental profile is generally favorable when compared to many traditional disinfectants. The key to maximizing its environmental benefits lies in sustainable production practices and responsible use in disinfection applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!