Exploring New Frontiers with Hypochlorous Acid in Bioproducts Development

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl in Bioproducts: Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising frontier in bioproducts development, offering a unique combination of effectiveness and safety. This naturally occurring molecule, produced by the human immune system, has garnered significant attention in recent years due to its potent antimicrobial properties and biocompatibility.

The evolution of HOCl technology can be traced back to its discovery in the early 19th century. However, it wasn't until the late 20th century that researchers began to fully appreciate its potential in various applications. The development of stable HOCl solutions marked a turning point, enabling its practical use in diverse fields such as healthcare, agriculture, and water treatment.

Recent technological advancements have further expanded the possibilities for HOCl in bioproducts. Improved production methods, including electrolysis of salt water and advanced stabilization techniques, have made it possible to create HOCl solutions with longer shelf lives and consistent efficacy. This has paved the way for its integration into a wide range of products, from wound care solutions to food safety applications.

The growing interest in HOCl is driven by several factors, including the increasing demand for safe, eco-friendly antimicrobial agents and the rising concerns over antibiotic resistance. As a result, the bioproducts industry is witnessing a shift towards HOCl-based solutions as alternatives to traditional chemical disinfectants and preservatives.

The primary objective of exploring HOCl in bioproducts development is to harness its unique properties to create innovative, effective, and environmentally friendly solutions. This includes developing new formulations that maximize HOCl's antimicrobial efficacy while ensuring stability and ease of use. Additionally, researchers aim to expand its applications across various sectors, including healthcare, agriculture, food processing, and personal care.

Another key goal is to overcome the challenges associated with HOCl production and storage. This involves improving manufacturing processes to increase yield and purity, as well as developing advanced packaging solutions to extend shelf life. Furthermore, there is a focus on understanding the mechanisms of HOCl's antimicrobial action at a molecular level, which could lead to optimized formulations and novel applications.

As we delve deeper into the potential of HOCl in bioproducts, the ultimate aim is to revolutionize the way we approach disinfection, sanitation, and microbial control. By leveraging this powerful yet gentle molecule, we seek to create a new generation of products that are not only highly effective but also safe for humans and the environment.

The evolution of HOCl technology can be traced back to its discovery in the early 19th century. However, it wasn't until the late 20th century that researchers began to fully appreciate its potential in various applications. The development of stable HOCl solutions marked a turning point, enabling its practical use in diverse fields such as healthcare, agriculture, and water treatment.

Recent technological advancements have further expanded the possibilities for HOCl in bioproducts. Improved production methods, including electrolysis of salt water and advanced stabilization techniques, have made it possible to create HOCl solutions with longer shelf lives and consistent efficacy. This has paved the way for its integration into a wide range of products, from wound care solutions to food safety applications.

The growing interest in HOCl is driven by several factors, including the increasing demand for safe, eco-friendly antimicrobial agents and the rising concerns over antibiotic resistance. As a result, the bioproducts industry is witnessing a shift towards HOCl-based solutions as alternatives to traditional chemical disinfectants and preservatives.

The primary objective of exploring HOCl in bioproducts development is to harness its unique properties to create innovative, effective, and environmentally friendly solutions. This includes developing new formulations that maximize HOCl's antimicrobial efficacy while ensuring stability and ease of use. Additionally, researchers aim to expand its applications across various sectors, including healthcare, agriculture, food processing, and personal care.

Another key goal is to overcome the challenges associated with HOCl production and storage. This involves improving manufacturing processes to increase yield and purity, as well as developing advanced packaging solutions to extend shelf life. Furthermore, there is a focus on understanding the mechanisms of HOCl's antimicrobial action at a molecular level, which could lead to optimized formulations and novel applications.

As we delve deeper into the potential of HOCl in bioproducts, the ultimate aim is to revolutionize the way we approach disinfection, sanitation, and microbial control. By leveraging this powerful yet gentle molecule, we seek to create a new generation of products that are not only highly effective but also safe for humans and the environment.

Market Analysis for HOCl-based Bioproducts

The market for hypochlorous acid (HOCl)-based bioproducts is experiencing significant growth, driven by increasing awareness of its effectiveness as a disinfectant and its potential applications in various industries. The global HOCl market is projected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026, with the bioproducts segment showing particularly strong potential.

Healthcare and medical applications currently dominate the HOCl-based bioproducts market, accounting for a substantial share of the overall demand. The use of HOCl in wound care, sterilization, and disinfection has gained traction due to its broad-spectrum antimicrobial properties and safety profile. Hospitals, clinics, and long-term care facilities are increasingly adopting HOCl-based solutions for infection control and prevention.

The agriculture sector represents another significant market opportunity for HOCl-based bioproducts. Farmers and growers are turning to HOCl as an eco-friendly alternative to traditional pesticides and disinfectants. Its application in crop protection, post-harvest treatment, and livestock management is driving demand in this sector.

Water treatment is emerging as a promising market for HOCl-based bioproducts. Municipal water suppliers and industrial water treatment facilities are exploring HOCl as a safer and more effective alternative to chlorine-based disinfectants. This trend is expected to accelerate as regulations on water quality and environmental impact become more stringent.

The food and beverage industry is also showing increased interest in HOCl-based bioproducts for sanitation and food safety applications. The ability of HOCl to effectively eliminate pathogens without leaving harmful residues makes it an attractive option for food processing and packaging facilities.

Consumer products represent a growing segment of the HOCl-based bioproducts market. Personal care items, household cleaners, and pet care products incorporating HOCl are gaining popularity among health-conscious consumers seeking safer and more natural alternatives to traditional chemical-based products.

Geographically, North America and Europe currently lead the HOCl-based bioproducts market, driven by stringent regulations on chemical use and a strong focus on sustainability. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by increasing industrialization, growing healthcare expenditure, and rising awareness of hygiene and sanitation.

Key market challenges include the need for education on HOCl's benefits and applications, as well as competition from established chemical disinfectants. However, ongoing research and development efforts are expected to expand the range of HOCl-based bioproducts and improve their stability and shelf life, further driving market growth.

Healthcare and medical applications currently dominate the HOCl-based bioproducts market, accounting for a substantial share of the overall demand. The use of HOCl in wound care, sterilization, and disinfection has gained traction due to its broad-spectrum antimicrobial properties and safety profile. Hospitals, clinics, and long-term care facilities are increasingly adopting HOCl-based solutions for infection control and prevention.

The agriculture sector represents another significant market opportunity for HOCl-based bioproducts. Farmers and growers are turning to HOCl as an eco-friendly alternative to traditional pesticides and disinfectants. Its application in crop protection, post-harvest treatment, and livestock management is driving demand in this sector.

Water treatment is emerging as a promising market for HOCl-based bioproducts. Municipal water suppliers and industrial water treatment facilities are exploring HOCl as a safer and more effective alternative to chlorine-based disinfectants. This trend is expected to accelerate as regulations on water quality and environmental impact become more stringent.

The food and beverage industry is also showing increased interest in HOCl-based bioproducts for sanitation and food safety applications. The ability of HOCl to effectively eliminate pathogens without leaving harmful residues makes it an attractive option for food processing and packaging facilities.

Consumer products represent a growing segment of the HOCl-based bioproducts market. Personal care items, household cleaners, and pet care products incorporating HOCl are gaining popularity among health-conscious consumers seeking safer and more natural alternatives to traditional chemical-based products.

Geographically, North America and Europe currently lead the HOCl-based bioproducts market, driven by stringent regulations on chemical use and a strong focus on sustainability. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by increasing industrialization, growing healthcare expenditure, and rising awareness of hygiene and sanitation.

Key market challenges include the need for education on HOCl's benefits and applications, as well as competition from established chemical disinfectants. However, ongoing research and development efforts are expected to expand the range of HOCl-based bioproducts and improve their stability and shelf life, further driving market growth.

Current HOCl Technology and Challenges

Hypochlorous acid (HOCl) has emerged as a promising compound in bioproducts development, offering unique properties that make it valuable across various industries. However, the current state of HOCl technology faces several challenges that need to be addressed to fully harness its potential.

One of the primary challenges in HOCl technology is stability. HOCl is inherently unstable and tends to degrade rapidly, especially when exposed to light or heat. This instability limits its shelf life and effectiveness in many applications. Researchers are actively working on developing stabilization techniques, such as encapsulation and the use of specific buffer systems, to prolong the active life of HOCl solutions.

Another significant challenge lies in the production and scalability of HOCl. While electrolysis of salt water is a common method for generating HOCl, achieving consistent concentration and purity at large scales remains difficult. The process is sensitive to various factors, including electrode materials, current density, and solution composition. Improving production efficiency and maintaining product quality during scale-up are crucial areas of focus for manufacturers.

The concentration control of HOCl solutions presents another technical hurdle. Different applications require specific concentrations of HOCl, and maintaining these precise levels over time is challenging due to the compound's reactivity. Advanced sensing and monitoring technologies are being developed to address this issue, allowing for real-time adjustment of HOCl concentrations in various systems.

Compatibility with other materials is an ongoing concern in HOCl technology. The strong oxidizing nature of HOCl can lead to corrosion or degradation of certain materials, limiting its use in some applications. Research is underway to develop HOCl-resistant materials and coatings that can withstand prolonged exposure without compromising the integrity of equipment or packaging.

Safety considerations also pose challenges in the widespread adoption of HOCl technology. While HOCl is generally considered safe at low concentrations, handling and storage of higher concentrations require careful management. Developing safer formulations and improved handling protocols is essential for expanding the use of HOCl across different industries.

The regulatory landscape surrounding HOCl presents another challenge. As a relatively new player in many fields, HOCl-based products often face regulatory hurdles. Establishing clear guidelines and standards for HOCl use in various applications, particularly in sensitive areas like food safety and healthcare, is crucial for industry growth.

Lastly, the cost-effectiveness of HOCl technology remains a challenge in some sectors. While HOCl offers numerous benefits, the production costs and specialized equipment required can be prohibitive for certain applications. Ongoing research aims to develop more cost-effective production methods and demonstrate the long-term economic benefits of HOCl use to encourage wider adoption.

One of the primary challenges in HOCl technology is stability. HOCl is inherently unstable and tends to degrade rapidly, especially when exposed to light or heat. This instability limits its shelf life and effectiveness in many applications. Researchers are actively working on developing stabilization techniques, such as encapsulation and the use of specific buffer systems, to prolong the active life of HOCl solutions.

Another significant challenge lies in the production and scalability of HOCl. While electrolysis of salt water is a common method for generating HOCl, achieving consistent concentration and purity at large scales remains difficult. The process is sensitive to various factors, including electrode materials, current density, and solution composition. Improving production efficiency and maintaining product quality during scale-up are crucial areas of focus for manufacturers.

The concentration control of HOCl solutions presents another technical hurdle. Different applications require specific concentrations of HOCl, and maintaining these precise levels over time is challenging due to the compound's reactivity. Advanced sensing and monitoring technologies are being developed to address this issue, allowing for real-time adjustment of HOCl concentrations in various systems.

Compatibility with other materials is an ongoing concern in HOCl technology. The strong oxidizing nature of HOCl can lead to corrosion or degradation of certain materials, limiting its use in some applications. Research is underway to develop HOCl-resistant materials and coatings that can withstand prolonged exposure without compromising the integrity of equipment or packaging.

Safety considerations also pose challenges in the widespread adoption of HOCl technology. While HOCl is generally considered safe at low concentrations, handling and storage of higher concentrations require careful management. Developing safer formulations and improved handling protocols is essential for expanding the use of HOCl across different industries.

The regulatory landscape surrounding HOCl presents another challenge. As a relatively new player in many fields, HOCl-based products often face regulatory hurdles. Establishing clear guidelines and standards for HOCl use in various applications, particularly in sensitive areas like food safety and healthcare, is crucial for industry growth.

Lastly, the cost-effectiveness of HOCl technology remains a challenge in some sectors. While HOCl offers numerous benefits, the production costs and specialized equipment required can be prohibitive for certain applications. Ongoing research aims to develop more cost-effective production methods and demonstrate the long-term economic benefits of HOCl use to encourage wider adoption.

Existing HOCl Bioproduct Solutions

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: To enhance the shelf life and maintain the efficacy of hypochlorous acid solutions, various stabilization techniques are employed. These may include pH adjustment, addition of stabilizing agents, and specialized packaging methods to prevent degradation and maintain the active chlorine content.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to promote healing while providing antimicrobial protection makes it valuable in various medical formulations and devices.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation, industrial cleaning, and agricultural applications. Its eco-friendly nature and effectiveness in removing contaminants make it suitable for use in water treatment systems, surface disinfection, and crop protection.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

Stabilization of hypochlorous acid solutions is crucial for maintaining their efficacy over time. Various techniques are employed, such as pH adjustment, addition of stabilizing agents, and specialized packaging methods, to extend the shelf life and preserve the antimicrobial properties of hypochlorous acid products.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid finds applications in medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in environmental and industrial settings for purposes such as water treatment, surface disinfection, and odor control. Its eco-friendly nature and broad-spectrum antimicrobial activity make it suitable for various large-scale applications.Expand Specific Solutions

Key Players in HOCl Bioproduct Industry

The development of hypochlorous acid in bioproducts is in its early stages, with a growing market driven by increasing demand for eco-friendly and safe disinfectants. The technology is rapidly maturing, with companies like WIAB WATER INNOVATION AB and Industrie De Nora SpA leading innovation. Academic institutions such as Hunan University of Science & Technology and Xiamen University are contributing to research advancements. The competitive landscape is diverse, including established players like Robert Bosch GmbH and emerging specialists like Suretol Ltd. and Symbiosis Technology Co., Ltd. As the technology evolves, we can expect increased collaboration between industry and academia to drive further innovation and market expansion.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrochemical technologies for the production of hypochlorous acid (HOCl) in bioproducts development. Their approach involves using dimensionally stable anodes (DSA) in electrolysis cells to generate HOCl from salt water. The company has optimized the electrolysis process to produce high-purity HOCl with minimal by-products, achieving concentrations up to 500 ppm [1]. They have also implemented innovative membrane technology to separate the anodic and cathodic compartments, enhancing the efficiency and stability of HOCl production [3]. De Nora's systems incorporate real-time monitoring and control mechanisms to maintain consistent HOCl quality and concentration, crucial for bioproduct applications [5].

Strengths: High-purity HOCl production, advanced electrode technology, and precise control systems. Weaknesses: High initial investment costs and energy-intensive process.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: The Dalian Institute of Chemical Physics has pioneered research in HOCl applications for bioproducts development. They have developed a novel catalytic system for the selective oxidation of biomass-derived compounds using HOCl as an environmentally friendly oxidant [2]. This approach enables the conversion of renewable resources into high-value chemicals and materials. The institute has also explored the use of HOCl in the pretreatment of lignocellulosic biomass, enhancing its digestibility for biofuel production [4]. Their research extends to the development of HOCl-based antimicrobial coatings for biomedical applications, utilizing the potent disinfectant properties of HOCl [6]. Additionally, they have investigated the potential of HOCl in green synthesis routes for pharmaceutical intermediates, reducing the environmental impact of drug manufacturing processes [8].

Strengths: Cutting-edge research in biomass conversion and green chemistry applications. Weaknesses: Potential challenges in scaling up laboratory findings to industrial processes.

Innovative HOCl Technologies in Bioproducts

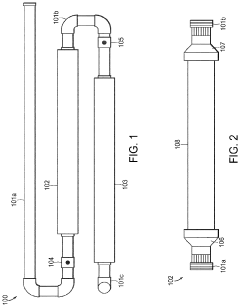

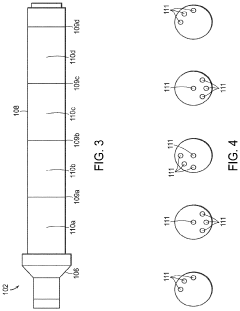

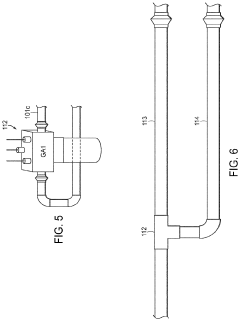

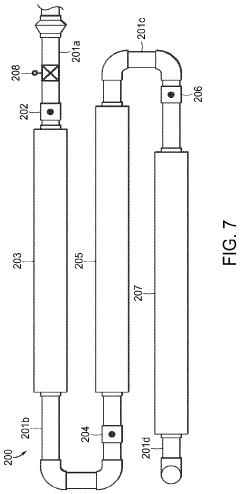

Mixing device

PatentActiveUS20210346854A1

Innovation

- A mixing device that produces a stable form of HOCl by creating fluidic vortices within a chamber with apertures, allowing controlled protonation and hypochlorite ion reaction in an air-free environment, using compounds like acetic acid and NaOCl, and maintaining pH stability through buffering, enabling longer storage and reduced need for onsite generation.

Environmental Impact of HOCl Bioproducts

The development of hypochlorous acid (HOCl) bioproducts represents a significant advancement in sustainable and eco-friendly solutions across various industries. However, it is crucial to thoroughly assess the environmental impact of these products to ensure their long-term viability and safety.

One of the primary environmental benefits of HOCl bioproducts is their biodegradability. Unlike many traditional chemical disinfectants and cleaning agents, HOCl naturally breaks down into harmless components: water and salt. This characteristic significantly reduces the risk of persistent environmental contamination and accumulation of harmful substances in ecosystems.

The production process of HOCl bioproducts also contributes to their positive environmental profile. Many HOCl solutions can be generated on-site using electrolysis of salt water, which minimizes transportation-related carbon emissions and reduces packaging waste. This localized production model aligns well with circular economy principles and supports sustainable manufacturing practices.

In terms of aquatic ecosystems, HOCl bioproducts demonstrate a favorable impact compared to traditional chlorine-based disinfectants. Studies have shown that HOCl is less toxic to aquatic life and degrades more rapidly in water bodies, reducing the risk of long-term ecological disruption. This makes HOCl-based solutions particularly attractive for applications in water treatment and aquaculture.

The use of HOCl bioproducts in agriculture presents both opportunities and challenges from an environmental perspective. While these products can reduce the need for harmful pesticides and increase crop yields, their widespread application may alter soil microbial communities. Ongoing research is necessary to fully understand the long-term effects on soil health and biodiversity.

Air quality is another area where HOCl bioproducts show promise. When used in air purification systems, HOCl can effectively neutralize airborne pathogens and pollutants without introducing harmful byproducts. This could lead to improved indoor air quality in various settings, from homes to hospitals, without the negative environmental impacts associated with some traditional air treatment methods.

However, it is important to note that the environmental impact of HOCl bioproducts is not uniformly positive. The energy consumption required for on-site generation systems and the potential for misuse or overuse of these products must be carefully considered. Additionally, while HOCl itself is environmentally friendly, the production of precursor materials and associated equipment may have environmental costs that need to be factored into overall sustainability assessments.

In conclusion, while HOCl bioproducts offer significant environmental advantages over many conventional alternatives, a comprehensive life cycle analysis is essential to fully understand and optimize their environmental impact. Continued research and development in this field should focus on enhancing the sustainability of production processes, improving energy efficiency, and exploring new applications that maximize the environmental benefits of these innovative bioproducts.

One of the primary environmental benefits of HOCl bioproducts is their biodegradability. Unlike many traditional chemical disinfectants and cleaning agents, HOCl naturally breaks down into harmless components: water and salt. This characteristic significantly reduces the risk of persistent environmental contamination and accumulation of harmful substances in ecosystems.

The production process of HOCl bioproducts also contributes to their positive environmental profile. Many HOCl solutions can be generated on-site using electrolysis of salt water, which minimizes transportation-related carbon emissions and reduces packaging waste. This localized production model aligns well with circular economy principles and supports sustainable manufacturing practices.

In terms of aquatic ecosystems, HOCl bioproducts demonstrate a favorable impact compared to traditional chlorine-based disinfectants. Studies have shown that HOCl is less toxic to aquatic life and degrades more rapidly in water bodies, reducing the risk of long-term ecological disruption. This makes HOCl-based solutions particularly attractive for applications in water treatment and aquaculture.

The use of HOCl bioproducts in agriculture presents both opportunities and challenges from an environmental perspective. While these products can reduce the need for harmful pesticides and increase crop yields, their widespread application may alter soil microbial communities. Ongoing research is necessary to fully understand the long-term effects on soil health and biodiversity.

Air quality is another area where HOCl bioproducts show promise. When used in air purification systems, HOCl can effectively neutralize airborne pathogens and pollutants without introducing harmful byproducts. This could lead to improved indoor air quality in various settings, from homes to hospitals, without the negative environmental impacts associated with some traditional air treatment methods.

However, it is important to note that the environmental impact of HOCl bioproducts is not uniformly positive. The energy consumption required for on-site generation systems and the potential for misuse or overuse of these products must be carefully considered. Additionally, while HOCl itself is environmentally friendly, the production of precursor materials and associated equipment may have environmental costs that need to be factored into overall sustainability assessments.

In conclusion, while HOCl bioproducts offer significant environmental advantages over many conventional alternatives, a comprehensive life cycle analysis is essential to fully understand and optimize their environmental impact. Continued research and development in this field should focus on enhancing the sustainability of production processes, improving energy efficiency, and exploring new applications that maximize the environmental benefits of these innovative bioproducts.

Regulatory Framework for HOCl in Bioproducts

The regulatory framework for hypochlorous acid (HOCl) in bioproducts development is a complex and evolving landscape. As HOCl gains traction in various applications, regulatory bodies worldwide are adapting their guidelines to ensure its safe and effective use.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl-based products. The EPA has approved HOCl as an active ingredient in disinfectants and sanitizers under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This approval has paved the way for the development of numerous HOCl-based bioproducts.

The Food and Drug Administration (FDA) also oversees HOCl applications in food safety and medical devices. The FDA has granted Generally Recognized as Safe (GRAS) status to electrolyzed water systems that produce HOCl, allowing its use in food processing and handling.

In the European Union, the regulatory framework for HOCl is governed by the Biocidal Products Regulation (BPR). HOCl is listed as an active substance for various product types, including disinfectants and preservatives. The European Chemicals Agency (ECHA) oversees the evaluation and authorization process for HOCl-based bioproducts.

Japan's Ministry of Health, Labour and Welfare has approved HOCl as a food additive, recognizing its potential in food safety applications. This regulatory stance has encouraged the development of HOCl-based solutions in the Japanese food industry.

As the use of HOCl expands into new areas, such as agriculture and personal care products, regulatory bodies are adapting their frameworks. For instance, the U.S. Department of Agriculture (USDA) is evaluating the use of HOCl in organic farming practices, potentially opening new avenues for sustainable agriculture.

Regulatory challenges persist, particularly in standardizing the production and quality control of HOCl solutions. The stability and concentration of HOCl can vary depending on production methods, necessitating the development of robust quality assurance protocols.

International harmonization of HOCl regulations remains an ongoing process. Organizations like the World Health Organization (WHO) and the Codex Alimentarius Commission are working towards establishing global standards for HOCl use in various applications, aiming to facilitate international trade and ensure consistent safety standards worldwide.

As research continues to uncover new potential applications for HOCl in bioproducts, regulatory frameworks will need to evolve accordingly. This dynamic regulatory landscape presents both challenges and opportunities for innovators in the field of HOCl-based bioproduct development.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl-based products. The EPA has approved HOCl as an active ingredient in disinfectants and sanitizers under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This approval has paved the way for the development of numerous HOCl-based bioproducts.

The Food and Drug Administration (FDA) also oversees HOCl applications in food safety and medical devices. The FDA has granted Generally Recognized as Safe (GRAS) status to electrolyzed water systems that produce HOCl, allowing its use in food processing and handling.

In the European Union, the regulatory framework for HOCl is governed by the Biocidal Products Regulation (BPR). HOCl is listed as an active substance for various product types, including disinfectants and preservatives. The European Chemicals Agency (ECHA) oversees the evaluation and authorization process for HOCl-based bioproducts.

Japan's Ministry of Health, Labour and Welfare has approved HOCl as a food additive, recognizing its potential in food safety applications. This regulatory stance has encouraged the development of HOCl-based solutions in the Japanese food industry.

As the use of HOCl expands into new areas, such as agriculture and personal care products, regulatory bodies are adapting their frameworks. For instance, the U.S. Department of Agriculture (USDA) is evaluating the use of HOCl in organic farming practices, potentially opening new avenues for sustainable agriculture.

Regulatory challenges persist, particularly in standardizing the production and quality control of HOCl solutions. The stability and concentration of HOCl can vary depending on production methods, necessitating the development of robust quality assurance protocols.

International harmonization of HOCl regulations remains an ongoing process. Organizations like the World Health Organization (WHO) and the Codex Alimentarius Commission are working towards establishing global standards for HOCl use in various applications, aiming to facilitate international trade and ensure consistent safety standards worldwide.

As research continues to uncover new potential applications for HOCl in bioproducts, regulatory frameworks will need to evolve accordingly. This dynamic regulatory landscape presents both challenges and opportunities for innovators in the field of HOCl-based bioproduct development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!